Summary of 525S -

Page 1

Instruction book model 525s.

Page 2: Danger

Important safety instructions when using an electrical appliance, basic safety precautions should always be followed, including the followings: read all instructions before using this appliance. Danger — to reduce the risk of electric shock: 1. An appliance should never be left unattended when plugg...

Page 3

1 section 1. Know your machine names of parts .............................................................. 2 standard accessories .................................................... 3 accessory storage .......................................................... 3 extension table .....................

Page 4

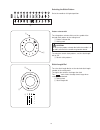

2 q w e r t y u i o !0 !1 !2 !3 !4 !5 !6 !7 !8 !9 @0 @1 @2 @3 @4 @5 @6 @7 @8 @9 #0 #1 #2 #3 names of parts q bobbin winder stopper w bobbin winder spindle e hole for additional spool pin r spool holder t spool pin y bobbin winder thread guide u thread take-up lever i foot pressure dial o face plate ...

Page 5

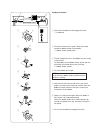

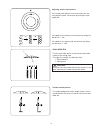

3 q w e r t y u i o !0 !1 !2 !3 !4 !5 standard accessories q overedge foot c w zipper foot e e blind hemming foot g r buttonhole foot b t automatic buttonhole foot r y needles u bobbins i screwdriver o lint brush !0 seam ripper (buttonhole opener) !1 quilting guide !2 spool holder (large) !3 spool h...

Page 6

4 extension table to detach: pull the extension table to the left. To attach: insert the pin into the hole and push the extension table to snap it in place. Q pin w hole free-arm sewing free-arm sewing is used for stitching sleeves, waistbands, pant legs or any other tubular garments. It is also use...

Page 7

5 connecting the power supply z turn the power switch off. X insert the machine plug into the machine socket. C insert the power supply plug into the wall outlet. V turn the power switch on. Q power switch w machine plug e machine socket r power supply plug t wall outlet note: before connecting to t...

Page 8

6 reverse stitch lever push the reverse stitch lever down to sew in reverse. The machine will sew in reverse while the lever is pushed. Foot pressure dial turn the foot pressure dial to adjust the foot pressure. The foot pressure dial should be set at “3” for regular sewing. Reduce the pressure to “...

Page 9

7 raising and lowering the presser foot the presser foot lifter raises and lowers the presser foot. You can raise the foot about 1/4" (0.6 cm) higher than the normal up position for easy removal of the presser foot, or to help you place heavy fabric under the foot. Q lowered position w normal up pos...

Page 10

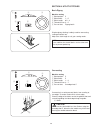

8 changing needles caution: always make sure to turn the power switch off and disconnect the machine from power supply before changing the needle. Raise the needle by turning the handwheel and lower the presser foot. Turn off the power switch. Z loosen the needle clamp screw by turning it counterclo...

Page 11

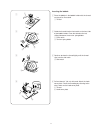

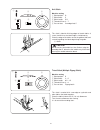

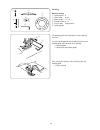

9 winding the bobbin setting the spool place a spool of thread on the spool pin with the thread coming off the spool as illustrated. A: press the large spool holder firmly against the spool of thread. Q large spool holder b: for a small spool, use the small spool holder. W small spool holder additio...

Page 12

10 winding the bobbin z pull out the handwheel to disengage the clutch. Q handwheel x draw the thread from the spool. Guide the thread around the bobbin winder thread guide. W bobbin winder thread guide c thread through the hole in the bobbin from the inside to the outside. Put the bobbin on the bob...

Page 13

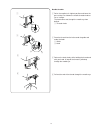

11 inserting the bobbin z place the bobbin in the bobbin holder with the thread running off as illustrated. Q thread x guide the thread into the front notch on the front side of the bobbin holder. Draw the thread to the left, sliding it between the tension spring blades. W front notch e tension spri...

Page 14

12 threading the machine to set the needle thread: raise the thread take-up lever to the highest position by turning the handwheel. Raise the presser foot. Z draw the thread from the spool and pass it under the thread guide. Then draw it down along the right channel. Q thread guide w right channel x...

Page 15

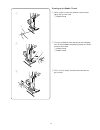

13 needle threader z raise the needle to its highest position and lower the presser foot. Push down the needle threader knob as far as it will go. The hook comes out through the needle eye from behind. Q threader knob x draw the thread from the left around the guide and under the hook. W guide e hoo...

Page 16

14 drawing up the bobbin thread z raise the presser foot and hold the needle thread lightly with your left hand. Q needle thread x turn the handwheel slowly toward you one complete turn. Bring the bobbin thread up by pulling the needle thread as illustrated. Q needle thread w bobbin thread c pull 4”...

Page 17

15 selecting the stitch pattern raise the needle to its highest position. Pattern selector dial turn the pattern selector dial to set the symbol of the desired stitch pattern at the setting mark. Q pattern selector dial w setting mark caution: do not turn the pattern selector dial while the needle i...

Page 18: “+”

16 adjusting stretch stitch balance if the stretch stitch patterns are uneven when you sew on a particular fabric, correct them by turning the stitch length dial. If the patterns are drawn out, correct them by setting the dial to the “–” side. If the patterns are compressed, correct them by setting ...

Page 19

17 balancing needle thread tension the thread tension should be adjusted depending on the sewing materials, layers of fabric and sewing method. To adjust the thread tension, turn the tension dial. Q tension dial balanced tension: the ideal straight stitch has threads locked between two layers of fab...

Page 20

18 section 3. Basic sewing straight stitch sewing machine setting: q stitch pattern: a w stitch width: 0 or 5 e stitch length: 1.5 – 4 r thread tension: 2 – 6 t presser foot: zigzag foot a starting to sew raise the presser foot and place the fabric under the foot. Lower the needle into the fabric. L...

Page 21

19 seam guides on the needle plate the seam guides on the needle plate help you to measure seam allowance. The numbers indicate the distance between the center needle position and the seam guide. Q seam guides turning a square corner the cornering guide helps you maintain a 5/8” (1.6 cm) seam allowa...

Page 22

20 section 4. Utility stitches basic zigzag machine setting q stitch pattern: c w stitch width: 1 – 5 e stitch length: 0.5 – 3 r thread tension: 2 – 5 t presser foot: zigzag foot a simple zigzag stitching is widely used for overcasting, sewing on buttons etc. Adjust the stitch length to suit your se...

Page 23

21 knit stitch machine setting q stitch pattern: g w stitch width: 5 e stitch length: s.S. R thread tension: 3 – 7 t presser foot: overedge foot c this stitch is ideal for finishing edges of stretch fabrics. It seams and finishes the fabric edges simultaneously. Place the edge of the fabric next to ...

Page 24

22 straight stretch stitch machine setting q stitch pattern: a w stitch width: 0 or 5 e stitch length: s.S. R thread tension: 2 – 5 t presser foot: zigzag foot a the pattern is sewn with two stitches forward and one stitch backward, forming a seam that does not rip easily. Use it to reinforce areas ...

Page 25

23 button sewing machine setting q stitch pattern: c w stitch width: adjust as necessary e stitch length: any r thread tension: 3 – 7 t presser foot: buttonhole foot b y feed dog: lowered unthread the needle. Adjust the stitch width to match it with the span of the holes in the button. Turn the hand...

Page 26

24 automatic buttonhole machine setting q stitch pattern: bh w stitch width: 4 – 5 e stitch length: 0.5 – 1 r thread tension: 1 – 5 t presser foot: automatic buttonhole foot r notes: the size of buttonhole is automatically determined by placing the button in the automatic buttonhole foot. The button...

Page 27

25 c pull the buttonhole lever down as far as it will go. R buttonhole lever v raise the foot and pass the needle thread through the opening in the foot. Draw both needle and bobbin threads to the left. Insert the fabric under the foot and lower the needle into the fabric at the starting point. Lowe...

Page 28

26 m when buttonhole sewing is finished, push the buttonhole lever up as far as it will go. Adjusting the buttonhole stitch density turn the stitch length dial within the range of “ ” to adjust the buttonhole stitch density. Q stitch length dial to sew another buttonhole, turn the stitch selector to...

Page 29

27 corded buttonhole machine setting q stitch pattern: bh w stitch width: 4 – 5 e stitch length: 0.5 – 1 r thread tension: 1 – 5 t presser foot: automatic buttonhole foot r z with the buttonhole foot raised, hook the filler cord on the spur at the back of the foot. Bring the ends toward you under th...

Page 30

28 manual buttonhole machine setting q stitch pattern: bh w stitch width: 4 – 5 e stitch length: 0.5 – 1 r thread tension: 1 – 5 t presser foot: buttonhole foot b if the diameter of the button is more than 1" (2.5 cm), a buttonhole must be made manually as follows: z replace the foot with the button...

Page 31

29 b restart the machine to sew the back bartack and right row, and then stop the machine at the starting point. N when buttonhole sewing is finished, push the buttonhole lever up as far as it will go. B n.

Page 32

30 zipper application machine setting q stitch pattern: a w stitch width: 5 e stitch length: 1.5 – 4 r thread tension: 3 – 6 t presser foot: zipper foot e attaching the zipper foot a: to sew the left side of the zipper, attach zipper foot with the right side pin. B: to sew the right side of zipper, ...

Page 33

31 to sew z attach zipper foot with the right side pin. Fold back the upper layer seam allowance. Fold back the lower layer seam allowance to leave a 1/8" (0.4 cm) margin of fabric. Q lower layer w end of the opening e zipper teeth r 1/8” (0.4 cm) margin t upper layer y opening size u folded edge i ...

Page 34

32 b raise and release the foot, and re-attach it with the left side pin. Starting just below zipper bottom stop, sew across fabric to about 3/8" (1 cm) distance from the basting line. Turn fabric 90 degrees and sew a seam the entire length of the zipper tape. Before reaching the slider, stop the ma...

Page 35

33 blind hemming machine setting q stitch pattern: e or f w stitch width: 2 – 3 e stitch length: 2 – 3 r thread tension:1 – 4 t presser foot: blind hemming foot g z on heavy weight fabrics that ravel, the raw edge should be overcast first. Fold the hem under the fabric as illustrated for fine or med...

Page 36

34 decorative satin stitches machine setting q stitch pattern: i – l w stitch width: 3 – 5 e stitch length: 0.5 – 1 r thread tension:1 – 4 t presser foot: zigzag foot a or buttonhole foot b determine the appropriate stitch density by test sewing. For a delicate appearance on fabric such as chiffon, ...

Page 37

35 smocking machine setting q stitch pattern: d w stitch width: 3 – 5 e stitch length: s.S. R thread tension:1 – 4 t presser foot: zigzag foot a step 1: choose a soft and lightweight fabric such as batiste, gingham or challis. Cut the fabric three times wider than the project width. Increase the sti...

Page 38

36 quilting machine setting q stitch pattern: a w stitch width: 0 or 5 e stitch length: 1.5 – 4 r thread tension:3 – 6 t presser foot: zigzag foot a y quilting guide the quilting guide will help keep the seam spacing constant. Insert the quilting guide into the opening and set the quilting guide at ...

Page 39

37 pin tucking machine setting q stitch pattern: a w stitch width: 0 or 5 e stitch length: 1.5 – 3 r thread tension:2 – 6 t presser foot: blind hemming foot g fold a fabric wrong side together and lower the needle into the fabric 0.1 – 0.2 cm inside the folded edge. Lower the foot and turn the screw...

Page 40

38 fagoting machine setting q stitch pattern: h w stitch width: 3 – 5 e stitch length: 1 – 3 r thread tension:1 – 4 t presser foot: zigzag foot a use this stitch to join two pieces of fabric to create an open work appearance, and add design interest. Fold under each fabric edge 1/2" (1.3 cm) and pre...

Page 41

39 appliqué machine setting q stitch pattern: c w stitch width: 3 – 5 e stitch length: 0.5 – 1 r thread tension:1 – 4 t presser foot: buttonhole foot b y foot pressure: “2” baste appliqué pieces on the fabric, or fuse the appliqué pieces with an iron-on fabric joiner. Stitch around the appliqué, mak...

Page 42

40 section 6. Care and maintenance warning: turn the power switch off and unplug the machine before cleaning. Note: do not dismantle the machine in any way other than what is explained in this section. Clean the outside of the machine with a soft cloth and mild soap. Cleaning the hook race and feed ...

Page 43

41 replacing the bobbin holder z insert the bobbin holder into the hook race. X make sure the knob of the bobbin holder fits next to the stopper on the race. Q knob w stopper c replace the bobbin. Attach the needle plate, inserting the two guide pins into the holes in the needle plate. Tighten the s...

Page 44

42 condition cause reference the needle breaks. Skipped stitches seam puckering the cloth is not fed smoothly. The needle thread breaks. The bobbin thread breaks. 1. The needle thread is not threaded properly. 2. The needle thread tension is too tight. 3. The needle is bent or blunt. 4. The needle i...

Page 45

507-800-037 (e) printed in taiwan.