Summary of 6019QC

Page 1

Instruction book.

Page 2: Danger—

Important safety instructions when using an electrical appliance, basic safety precautions should always be followed, including the followings: read all instructions before using this appliance. Danger— to reduce the risk of electric shock: 1. An appliance should never be left unattended when plugge...

Page 3

1 table of contents name of parts ................................................................ 2 standard accessories and storage ................................ 3 extension table and free arm sewing .......................... 4 getting ready to sew connecting to the power supply .................

Page 4

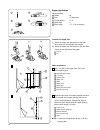

2 - 1 - 2 name of parts pattern indicating window stitch length lever stitch width lever bobbin winder stopper bobbin winder spindle accessory storage compartment spool pin spool holder reference chart top cover hole for the additional spool pin bobbin winder thread guide thread guide (a) thread gui...

Page 5

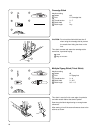

3 standard accessories and storage g d c f a 1 2 3 4 5 6 7 8 9 10 11 14 13 15 16 12 17 19 18 a: zigzag foot (set on the machine) f: satin stitch foot c: overedge foot d: rolled hem foot g: blind hem foot r: automatic buttonhole foot 1 2 3 4 5 6 accessory storage box accessories are conveniently stor...

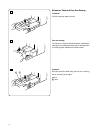

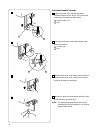

Page 6

4 1 2 3 extension table and free arm sewing to detach: pull the extension table to the left. Free arm sewing: the free arm is useful for stitching sleeves, waistbands, pant legs or any tubular garment, also for darning socks or mending knees, elbows and children’s wear. To attach: slide the extensio...

Page 7

5 connecting to the power supply 1. Turn the power switch off. 2. Insert the machine plug into the machine socket. 3. Insert the power supply plug into the outlet. 4. Turn the power switch on. Power switch machine plug power supply plug outlet the symbol “ ” of a switch indicates the “ off ” positio...

Page 8

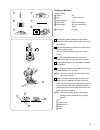

6 dropping the feed dog the feed dog can be lowered by the drop feed lever for sewing on buttons, manual embroidery etc. Push the drop feed lever to the direction a to lower the feed dog. Push the lever to the direction b to raise the feed dog, it will return to the up position when starting the mac...

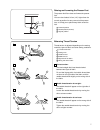

Page 9

7 4 3 2 6 5 4 raising and lowering the presser foot the presser foot lifter raises and lowers the presser foot. You can raise it about 0.6 cm (1/4”) higher than the normal up position for easy removal of the presser foot, or to help you to place heavy fabric under the foot. Lowered position raised p...

Page 10

8 selecting threads and needles light medium lawn georgette tricot wool, synthetic cotton, synthetic fine jersey wool denim jersey coating quilting thread silk #80-100 cotton #80-100 synthetic #80-100 silk #50 cotton #60-80 synthetic #50-80 cotton #50 silk #50 cotton #40-50 synthetic #40-50 silk #30...

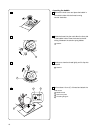

Page 11

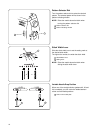

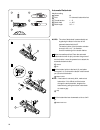

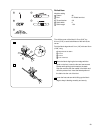

9 winding the bobbin • removing the bobbin slide the hook cover release button to the right, and remove the hook cover. Lift the bobbin out. Hook cover release button hook cover setting the spool of thread lift up the spool pin. Place the spool of thread on the spool pin with the thread coming off t...

Page 12

10 1 2 3 4 1 2 3 5 4 • inserting the bobbin remove the hook cover and place the bobbin in the bobbin holder with the thread running counter-clockwise. Guide the thread into the notch a on the front side of the bobbin holder. Draw the thread to the left sliding it between the tension spring blades. N...

Page 13

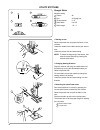

11 1 2 3 4 threading the machine • threading the needle thread * raise the presser foot. * turn the handwheel to bring the take-up lever to its highest position. * turn off the power switch. Draw the end of the thread with your left hand and pass it under the thread guide (a) then hook around the th...

Page 14

12 1 2 3 4 automatic needle threader lower the presser foot. Depress the needle threader knob as far as it will go. The hook comes out through the needle eye from behind. Needle threader knob hook draw the thread down around the threader guide and under the hook. Threader guide hook release the thre...

Page 15

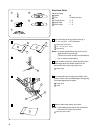

13 1 2 3 1 2 1 drawing up bobbin thread raise the presser foot and hold the needle thread with your fingers. Needle thread turn the handwheel one complete rotation toward you and raise the needle to its highest position. Pull the needle thread to pick up a loop of the bobbin thread. Bobbin thread dr...

Page 16

14 pattern selector dial turn the pattern selector dial to select the desired pattern. The selected pattern will be shown in the pattern indicating window. Note: raise the needle above the fabric when turning the pattern selector dial. Pattern selector dial pattern indicating window stitch width lev...

Page 17

15 stitch length lever slide the stitch length lever to set the setting mark at the desired stitch length. The higher the number, the longer the stitch length. Notes: mark indicates the adjustable allowance for buttonhole stitch density. Raise the presser foot when sliding the stitch length lever. S...

Page 18

16 utility stitches 5 4 3 0 1 2 3 4 1 2 1 2 3 4 5 straight stitch machine setting pattern #2 foot a: zigzag foot thread tension 2 ~ 6 stitch width 0 or 6.5 stitch length 1.5 ~ 4 • starting to sew raise the presser foot and place the fabric on the machine. Lower the needle into the fabric where you w...

Page 19

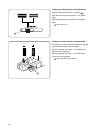

17 • using the seam guide lines the seam guides on the needle plate and hook cover help you to measure seam allowance. Note: the number indicates the distance from the center needle position. Number 10 20 30 40 1/2 3/4 1 1 1/2 distance 1.0 2.0 3.0 4.0 1.3 1.9 2.5 3.8 (cm) center needle position edge...

Page 20

18 5 4 3 5 4 3 1 2 3 4 5 1 2 3 4 5 straight stretch stitch machine setting pattern #18 foot a: zigzag foot thread tension 2 ~ 6 stitch width 0 or 6.5 stitch length any (not necessary to adjust) this strong, durable stitch is recommended where both elasticity and strength are required. Use this stitc...

Page 21

19 1 2 3 4 5 1 2 3 4 5 5 4 3 0 1 2 3 4 0 1 2 3 4 5 4 3 2 1 basic zigzag stitch machine setting pattern #3 foot a: zigzag foot thread tension 3 ~ 5 stitch width 1 ~ 6.5 stitch length 0.5 ~ 3 zigzag stitch is one of the most useful and versatile stitches. It is used for overcastting, mending, appliqué...

Page 22

20 1 2 3 4 5 1 2 3 4 5 6 5 4 5 4 3 0 1 2 3 4 overedge stitch machine setting pattern #13 foot c: overedge foot thread tension 3 ~ 7 stitch width 5 stitch length any caution: do not set the stitch width less than 5 when using the overedge foot to prevent the needle from hitting the wires on the foot....

Page 23

21 sewing on buttons machine setting pattern #3 foot f: satin stitch foot thread tension 3 ~ 7 stitch width adjust as necessary stitch length any (not necessary to adjust) feed dog dropped unthread the needle. Adjust the stitch width to match the needle swing with the span of the holes on the button...

Page 24

22 (a) (b) 1 2 3 4 5 4 3 2 0 1 2 3 4 1 2 3 1 2 4 3 5 automatic buttonhole machine setting pattern #1 foot r: automatic buttonhole foot thread tension 1 ~ 5 stitch width 4 ~ 6.5 stitch length 0.5 ~ 1 notes: the size of buttonhole is automatically set by placing the button in the rear of the automatic...

Page 25

23 4 5 6 7 8 9 8 9 6 7 10 12 13 11 14 15 16 17 draw the needle thread to the left through the hole on the foot. Place the fabric under the foot and lower the needle at the starting point of the buttonhole mark. Then lower the foot. Needle thread bobbin thread buttonhole mark starting point note: mak...

Page 26

24 0 1 2 3 4 to adjust the stitch sdensity of the buttonhole: adjust the stitch density within a range of . Slide the stitch length lever toward “1” for coarser stitch. Slide the stitch length lever toward “0” for denser stitch. Stitch length lever to adjust the stitch balance of the buttonhole: if ...

Page 27

25 corded buttonholes machine setting pattern 1 foot r: automatic buttonhole foot thread tension 1 ~ 5 stitch width 4 ~ 6.5 stitch length 0.5 ~ 1 with the buttonhole foot raised, hook the filler cord on the cord spur on the back of the buttonhole foot. Bring the ends toward you under the foot, and h...

Page 28

26 zipper application machine setting pattern #2 foot e: zipper foot thread tension 3 ~ 6 stitch width 0 stitch length 1.5 ~ 2 (4 for basting) to attach the zipper foot: (1) attach the zipper foot with the pin on the right, when sewing on the left side of the zipper. (2) attach the zipper foot with ...

Page 29

27 1 2 3 4 1 2 3 4 5 6 7 8 5 9 9 10 12 11 1 2 3 4 to sew: fold up the upper seam allowance. Fold back the bottom seam allowance to form a 0.3 cm (1/8˝) fold. Place the zipper teeth next to the fold and pin it in place. Bottom fabric end of the zipper opening zipper teeth 0.3 cm (1/8˝) wrong side of ...

Page 30

28 5 6 14 13 detach the foot and re-attach it with the pin on the left. Backstitch across the end of opening to 0.7 – 1 cm (3/8˝). Turn the fabric 90 degrees and stitch through the garment and zipper tape. Stop the machine 5 cm (2˝) before the foot reaches the slider on the zipper tape. Lower the ne...

Page 31

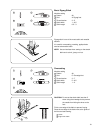

29 1 2 3 4 5 5 4 3 0 1 2 3 4 1 2 1 4 1 2 3 rolled hem machine setting pattern #2 foot d: rolled hem foot thread tension 3-6 stitch width 0 stitch length 1.5-4 trim off the corner of the fabric 0.5 cm (3/16˝) by 0.8 cm (5/16˝) to avoid a bulkiness of the hem at the corner. Fold the fabric edge twice ...

Page 32

30 blind hem stitch machine setting pattern #4 foot g: blind hem foot thread tension 2 ~ 6 stitch width 2 ~ 3 stitch length 1 ~ 3 fold a hem with the wrong side up forming a 0.4 ~ 0.7 cm (3/16 ~ 5/16˝) allowance. Wrong side of the fabric 0.4 ~ 0.7 cm (3/16 ~ 5/16”) overcasting notes: on heavy weight...

Page 33

31 sewing application and decorative stitches appliqué machine setting pattern #16 foot f: satin stitch foot thread tension 1 ~ 4 stitch width 3 ~ 6.5 stitch length any (not necessary to adjust) foot pressure dial 2 baste or glue applique pieces on the fabric. Stitch around the applique making sure ...

Page 34

32 1 2 3 4 5 1 2 3 4 5 5 4 3 0 1 2 3 4 0 1 2 3 4 5 4 3 4 2 3 1 1 1 2 1 2 3 4 5 pin tucking machine setting pattern #2 foot g: blind hem foot thread tension 2 ~ 6 stitch width 0 o r 6.5 stitch length 1.5 ~ 3 pin tucking is used to decorate chest of blouses, dress shirts etc. Fold the fabric with wron...

Page 35

33 1 2 3 4 5 1 2 3 4 5 shell tucking machine setting pattern #6 foot f: satin stitch foot thread tension 6 ~ 8 stitch width 5 ~ 6.5 stitch length 2 ~ 3 fold the fabric in bias. Sew along the folded edge so that the needle on the right swing just clear the folded edge to form tucks. Open the fabric w...

Page 36

34 1 2 3 4 5 1 2 3 4 5 4 3 2 1 2 1 2 4 3 2 0 1 2 3 4 2 3 1 4 1 3 2 1 smocking machine setting pattern #14 foot a: zigzag foot thread tension 1 ~ 4 stitch width 3 ~ 6.5 stitch length any (not necessary to adjust) set the thread tension dial at 1 ~ 3, and stitch length dial at 3 ~ 4, sew straight line...

Page 37

35 4 3 2 0 1 2 3 4 1 2 3 4 5 1 2 3 4 5 decorative satin stitches machine setting pattern #8, #9 foot f: satin stitch foot thread tension 1 ~ 4 stitch width 3 ~ 6.5 stitch length 0.5 ~ 1 test the stitch on the actual fabric for the desired patterns and adjust the stitch density for the best sewing re...

Page 38

36 (a) (b) adjusting stretch stitch balance the sewing results of the stretch stitch patterns may vary depending upon the sewing conditions, such as sewing speed, type of the fabric, number of layers etc. Always make test sewing on a scrap piece of the fabric that you wish to use. (a) if the pattern...

Page 39

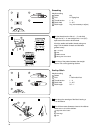

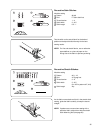

37 1 2 3 4 5 1 2 3 2 1 3 4 5 6 8 7 2 3 cleaning hook race and feed dog warning: raise the presser foot and needle, and then unplug the machine. Do not dismantle the machine other than as explained in this section. Remove the needle and presser foot. Remove the two setscrews and unhook the hook to re...

Page 40

38 troubleshooting condition the needle thread breaks. The bobbin thread breaks. The needle breaks. Skipped stitches seam puckering the cloth is not feeding smoothly. Loops on the seams fabric layers shift the machine doesn’t work. Buttonhole is not sewn properly. The machine is noisy. Cause the nee...