- DL manuals

- Janome

- Sewing Machine

- AQS2009

- Instruction Manual

Janome AQS2009 Instruction Manual

Summary of AQS2009

Page 1

Aaasewing.Com janome jem platinum 720 instruction manual model jp720 janome jem 720 instruction manual janome sewing machine www.Aaasewing.Com jem platinum 720 owners manual/ user guide.

Page 2: Danger

Aaasewing.Com important safety instructions when using an electrical appliance, basic safety precautions should always be followed, including the followings: read all instructions before using this appliance. Danger — to reduce the risk of electric shock: 1. An appliance should never be left unatten...

Page 3

Aaasewing.Com 1 know your machine name of parts ........................................................... 2 setting the spool pin ................................................. 2 standard accessories ............................................... 3 extension table ................................

Page 4

Aaasewing.Com 2 know your machine name of parts q direct pattern selection buttons w indicator window e bobbin winder stopper r bobbin winder spindle t spool pin (included in accessory bag) y bobbin winding thread guide u thread guide i thread take-up lever o tension regulating dial !0 face plate !1...

Page 5

Aaasewing.Com 3 extension table the extension table provides an extended sewing area and can be easily removed for free arm sewing. The accessories can be stored in the table. Detaching the table: pull the table away from the machine, as illustrated. Attaching the table: push the extension table, in...

Page 6

Aaasewing.Com 4 warning: while in operation, always keep your eyes on the sewing area, and do not touch any moving parts such as the thread take-up lever, handwheel or needle. Always turn off the power switch and unplug from the power supply: - when leaving the machine unattended. - when attaching o...

Page 7

Aaasewing.Com 5 controlling sewing speed speed control slider you can limit the maximum sewing speed with the speed control slider according to your sewing needs. To increase sewing speed, slide it to the right. To decrease sewing speed, slide it to the left. Foot control pressing on the foot contro...

Page 8

Aaasewing.Com 6 e auto-lock button when stitch pattern #01, #05 or #09 has been selected, the machine will immediately sew locking stitches and automatically stop when the auto-lock button is pressed. When sewing any other stitches, the machine will sew locking stitch at the end of the pattern being...

Page 9

Aaasewing.Com 7 t stitch width adjusting button when pressing this button,the stitch width of the selected pattern will be indicated and the green light on the top left will light up. To alter the stitch width, press on the "+" or "–" sign. The stitch width can be altered while stitching . Y stitch ...

Page 10

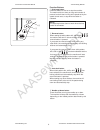

Aaasewing.Com 8 changing the presser foot caution: turn off the power switch before changing the foot. Always use the proper foot for the selected pattern. The wrong foot can cause the needle to break. Do not push the lever down to prevent it from being broken. To snap off: raise the needle and pres...

Page 11

Aaasewing.Com 9 balancing thread tension the thread tension should be adjusted depending on the sewing materials, layers of fabric and sewing method. To adjust the thread tension, turn the tension dial. Q tension regulating dial w setting mark balanced tension: the ideal straight stitch has threads ...

Page 12

Aaasewing.Com 10 changing needles warning: always make sure to turn the power switch off and disconnect the machine from power supply before changing the needle. Raise the needle by turning the handwheel and lower the presser foot. Turn off the power switch. Z loosen the needle clamp screw by turnin...

Page 13

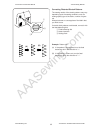

Aaasewing.Com 11 winding the bobbin removing the bobbin push the hook cover plate release button to the right and remove the cover plate. Q hook cover plate release button w hook cover plate lift out the bobbin. E bobbin setting the spool place a spool of thread on the spool pin with the thread comi...

Page 14

Aaasewing.Com 12 threading for bobbin winding set the speed control lever at . Z hold the thread with both hands and pass the thread under the thread guide. Q thread guide x draw the thread toward you and guide the thread around the bobbin winding thread guide. W bobbin winding thread guide c pass t...

Page 15

Aaasewing.Com 13 inserting the bobbin z place the bobbin in the bobbin holder with the thread running off counterclockwise. Q thread w bobbin holder x guide the thread into the notch on the front of the bobbin holder. E notch on the front c draw the thread to the left, sliding it between the tension...

Page 16

Aaasewing.Com 14 raise the presser foot. Press the needle up/down button to raise the thread take-up lever to its highest position. Z draw the thread from the spool and pass it under the thread guide. Q thread guide x draw the thread down along the right channel and pull it up around the bottom of t...

Page 17

Aaasewing.Com 15 needle threader z raise the needle to its highest position. Pull down the needle threader knob as far as it will go. Q threader knob x turn the knob in the direction of the arrow in the illustration, then insert hook into the needle eye. Lead the thread around guide and under hook. ...

Page 18

Aaasewing.Com 16 drawing up the bobbin thread z raise the presser foot lifter. Turn the power switch on. Hold the needle thread with your finger q presser foot lifter w needle thread x press the needle up/down button twice to pick up the bobbin thread. Draw up the needle thread to bring up a loop of...

Page 19

Aaasewing.Com 17 basic stitches straight stitch to sew raise the presser foot and position the fabric next to a seam guide line on the needle plate. Lower the needle into the fabric where you wish to start. Pull the needle and bobbin threads to the back. Lower the presser foot. Depress the foot cont...

Page 20

Aaasewing.Com 18 altering the needle drop position the needle drop position of the following stitches can be altered: press the stitch width adjusting button to change the needle drop position. The top green light will light up and the preset value "2.5" (center needle position) will be indicated. P...

Page 21

Aaasewing.Com 19 sewing from the edge of thick fabric the black button on the zigzag foot locks the foot in the horizontal position. This is helpful when starting sewing from the extreme edge of thick fabrics or sewing across a hem. Lower the needle into the fabric at the point where you wish to sta...

Page 22

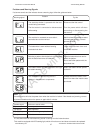

Aaasewing.Com 20 #01 straight stitch presser foot: zigzag foot a thread tension: 2 – 6 use this stitch for seaming and for zipper sewing. #02 lock-a-matic stitch presser foot: zigzag foot a thread tension: 2 – 6 use this stitch to secure the beginning and the end of a seam with backstitching. When y...

Page 23

Aaasewing.Com 21 altering the stitch length the stitch length can be altered between 0.0 and 4.0. Press the stitch length adjusting button to alter the stitch length. The bottom green light will light up and the preset value "2.0" will be indicated. Press the "+" sign to increase the stitch length. ...

Page 24

Aaasewing.Com 22 multiple zigzag stitch (tricot stitch) this stitch is used to finish a raw edge of synthetics and other stretch fabrics that tend to pucker. Sew along the fabric edge leaving an adequate seam allowance. After sewing, trim the seam allowance close to the stitches. Overcasting with zi...

Page 25

Aaasewing.Com 23 buttonholes #14 square buttonhole (sensor buttonhole) this buttonhole is widely used on medium to heavy weight fabrics. The buttonhole size is automatically determined by placing a button in the rear of the foot. Square buttonhole machine settings q stitch pattern: #14 w foot: autom...

Page 26

Aaasewing.Com 24 to sew z press the needle up/down button to raise the needle. Attach the automatic buttonhole foot r snapping the pin into the groove of the foot holder. Q groove w pin x pull the button holder to the back, and place the button in it. Push it together tightly to the button. Note: if...

Page 27

Aaasewing.Com 25 b start the machine to sew the buttonhole. The buttonhole will be automatically sewn. Step 1: the machine will sew the front bartack and the left row first. Then it goes back to the starting point with straight stitch. Step 2: the machine will sew the right row. Step 3: the machine ...

Page 28

Aaasewing.Com 26 altering the buttonhole width press the stitch width adjusting button to change the buttonhole width. Press the "+" sign to increase the buttonhole width. Press the "–" sign to decrease the buttonhole width. Q narrower buttonhole w wider buttonhole * the width can be altered between...

Page 29

Aaasewing.Com 27 b remove the fabric from the machine and cut the sewing threads. N pull the left end of the filler cord to tighten it. Thread the end of the cord through a darning needle and draw it to the wrong side of the fabric and cut. Corded buttonhole to sew a corded buttonhole, follow the sa...

Page 30

Aaasewing.Com 28 z pull the button holder all the way out. Insert the fabric under the foot. Press the up/ down needle button twice. Remove the fabric to the left to draw the needle thread through the hole of the foot. X insert the garment under the foot, and lower the needle at the starting point. ...

Page 31

Aaasewing.Com 29 button sewing unthread the needle thread. Place a button on the fabric and lower the needle by turning the handwheel, so that the needle enters into the left hole in the button. Align the holes in the button with the slot on the foot and lower it to hold the button in place. Turn th...

Page 32

Aaasewing.Com 30 zipper sewing attaching the zipper foot (optional item) (a) attach zipper foot e with the pin on the right- hand side to the groove to sew the left side of the zipper. (b) attach zipper foot e with the pin on the left- hand side to the groove to sew the right side of the zipper. Q p...

Page 33

Aaasewing.Com 31 x c v b n !0 i o x place zipper teeth next to margin edge and baste the zipper tape to the lower fabric layer. Align zipper foot with margin edge. Return thread tension and stitch length to original settings. Sew a seam the entire length of zipper tape. Note: to secure the beginning...

Page 34

Aaasewing.Com 32 blind hemming machine setting q stitch pattern: #13 or #12 w presser foot: zigzag foot a e thread tension: 3 – 6 z on heavy weight fabrics that ravel, the raw edge should be overcast first. Fold the hem under the fabric as illustrated for fine or medium fabrics. Fold a hem with the ...

Page 35

Aaasewing.Com 33 patchwork machine setting q stitch pattern: #09 w presser foot: satin stitch foot f e thread tension: 1 – 4 applique machine setting q stitch pattern: #16, #17, #18 w presser foot: satin stitch foot f e thread tension: 1 – 4 place the applique on the fabric and baste it in place. Se...

Page 36

Aaasewing.Com 34 20 smocking machine setting q stitch pattern: #20 w presser foot: satin stitch foot f e thread tension: 3 – 6 smocking is a delicate, decorative treatment on children’s clothes or women’s blouses. Choose a soft, lightweight fabric such as batiste, gingham or challis. Cut the fabric ...

Page 37

Aaasewing.Com 35 correcting distorted stretch patterns the sewing results of the stretch patterns may vary depending upon the sewing conditions, such as sewing speed, type of the fabric, number of layers etc. Always test sew on a scrap piece of the fabric that you wish to use. If stretch stitch patt...

Page 38

Aaasewing.Com 36 care and maintenance warning: turn the power switch off and unplug the machine before cleaning. Note: do not dismantle the machine in any way other than what is explained in this section. Clean the outside of the machine with a soft cloth and mild soap. Cleaning the hook race and fe...

Page 39

Aaasewing.Com 37 audible signal the buzzer sounds when: pip normal operation pip-pip-pip invalid operation pip-pip-peep buttonhole sewing completed peep malfunciton the start/stop button is pressed with the foot control being connected. The foot control is connected or disconnected while sewing. Dis...

Page 40

Aaasewing.Com 38 condition cause reference the needle breaks. Skipped stitches seam puckering the cloth is not fed smoothly. The needle thread breaks. The bobbin thread breaks. 1. The needle thread is not threaded properly. 2. The needle thread tension is too tight. 3. The needle is bent or blunt. 4...

Page 41

Aaasewing.Com 806-800-011 (e) printed in taiwan janome jem 720 instruction manual janome sewing machine www.Aaasewing.Com jem platinum 720 owners manual/ user guide.