- DL manuals

- Janome

- Sewing Machine

- dc2015

- Instruction Book

Janome dc2015 Instruction Book

Summary of dc2015

Page 1

Instruction book.

Page 3: Danger

Important safety instructions when using an electrical appliance, basic safety precautions should always be followed, including the following: this sewing machine is designed and manufactured for household use only. Read all instructions before using this sewing machine. Danger — to reduce the risk ...

Page 4

Table of instruction section i. Names of parts names of parts ................................................................. 1 standard accessories ...................................................... 2 extension table ................................................................ 3 section i...

Page 5

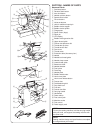

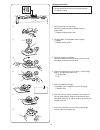

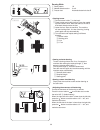

1 #1 #2 #3 #4 #8 $6 q w e r t u y o !0 !2 !3 !1 !6 !5 !7 !8 !9 @1 @0 @2 !4 @3 @5 @6 @4 @7 @8 @9 #0 i section i. Names of parts names of parts start/stop button reverse stitch button auto-lock button needle up/down button speed control slider cursor buttons value set buttons hole for additional spool...

Page 6

2 q w e r t y u i o !0 !1 !2 !3 !4 !5 !6 !7 !8 standard accessories q zigzag foot: a (set on the machine) w overedge foot: c e zipper foot: e r satin stitch foot: f t blind hem foot: g y open toe satin foot: f2 u automatic buttonhole foot: r i spool holder ( x 2) (special) o needle set !0 spool hold...

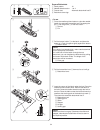

Page 7

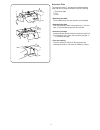

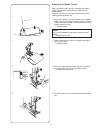

3 q r w e q extension table the extension table q provides an extended sewing area and can be easily removed for free-arm sewing. Q extension table w pin e hole • detaching the table pull the table away from the machine, as illustrated. • attaching the table push the extension table, inserting the p...

Page 8

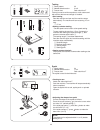

4 q t e r u y w i e t r w q for the u.S.A. And canada only polarized plug (one blade wider than the other): to reduce the risk of electric shock, this plug is intended to fit in a polarized outlet only one way. If it does not fit fully in the outlet, reverse the plug. If it still does not fit, conta...

Page 9

5 speed control slider sewing speed can be varied by the speed control slider according to your sewing needs. To increase sewing speed, slide the slider to the right. To decrease sewing speed, slide the slider to the left. Controlling sewing speed foot control pressing on the foot control can vary s...

Page 10

6 w q w reverse stitch button press and hold the reverse stitch button w to sew in reverse. Release the button w to sew forward. Press and hold the button w when the machine is stopped and foot control is disconnected to sew in reverse slowly. Release the button w to stop the machine. Any other stit...

Page 11

7 r e r up/down needle position button press the up/down needle position button r to bring the needle up or down. The machine will stop with the needle up or down depending on the needle position determined by this button. Note: the needle will always stop in the up position after sewing buttonholes...

Page 12

8 y cursor buttons use these buttons to move the cursor i. Press button to move the cursor to left. Press button to move the cursor to right. U value set buttons use these buttons to change the set value. Move the cursor under the digit you would like to change. Press button to increase the value. P...

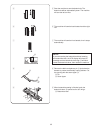

Page 13

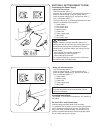

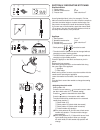

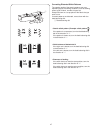

9 q w e e w q q w q w e w e q removing and attaching the foot holder changing the presser foot • removing the foot holder raise the needle to its highest position by turning the handwheel counterclockwise. Raise the presser foot, and remove the thumbscrew q by turning it counterclockwise with a scre...

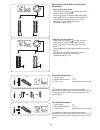

Page 14

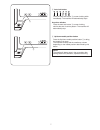

10 q w q w e dropping or raising the feed dog the drop feed lever is located underneath the free arm bed on the back of the machine. Q to drop the feed dog, push the lever in the direction of the arrow q. W to raise the feed dog, push the lever in the direction of the arrow w, as illustrated, and tu...

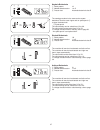

Page 15

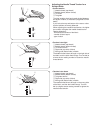

11 z x c w q changing the needle z turn off the power switch. Raise the needle to its highest position by turning the handwheel counterclockwise, and lower the presser foot. Loosen the needle clamp screw q by turning it counterclockwise. Remove the needle from the needle clamp w. X insert a new need...

Page 16

12 • spool holder (special) use the spool holder (special) when using a long spool of thread as shown. E 9.5 - 10.5mm (3/8 - 7/16 inch) r 70 - 75mm (2-3/4 - 3 inch) attach the spool holder (special) by inserting it into the hole of the spool of thread. Make sure there is no gap between the spool hol...

Page 17

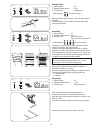

13 q z x w e r t y c v n • winding the bobbin note: •setthespeedcontrolslideratitsfastestposition for bobbin winding. Z draw the thread from the spool. Guide the thread around the bobbin winding tension disk. Q bobbin winding tension disk x put the bobbin on the bobbin winder spindle. W bobbin e bob...

Page 18

14 z x c v inserting the bobbin z place a bobbin in the bobbin holder with the thread running off counterclockwise as shown on the hook cover plate. Q end of thread w bobbin holder e hook cover plate x hold the bobbin with your fingertip so it does not rotate. Guide the thread into the front notch o...

Page 19

15 q z z x c v b n w v b n q c x threading the machine raise the presser foot. Press the needle up/down button to raise the thread take-up lever to its highest position. Caution: turn off the power switch before threading the machine. • threading the machine z xdraw the end of the thread around the ...

Page 20

16 q w t r w e z x c v note: the needle threader can be used with a #11 to #16 needle or a blue tipped needle. Thread sizes 50 to 90 are recommended. Needle threader caution: turn off the power switch when using the needle threader. Z lower the presser foot. Raise the needle to its highest position....

Page 21

17 drawing up the bobbin thread after using auto thread cutting or threading the bobbin holder, you can start sewing without drawing up the bobbin thread. However, you need to draw up the bobbin thread when sewing gathering stitches etc. Z remove the bobbin. Insert the bobbin into the bobbin holder ...

Page 22

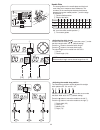

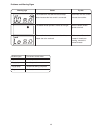

18 lcd display the lcd display shows the following information when the machine is turned on. Q identification letter for recommended foot w stitch pattern number e cursors r stitch width t stitch length q w e r t z x c selecting stitch patterns z press the cursor buttons to move the cursor under th...

Page 23

19 adjusting the needle thread tension for a straight stitch • correct tension q needle thread (top thread) w bobbin thread (bottom thread) e to loosen r to tighten the ideal straight stitch has threads locked between two layers of fabric, as illustrated (magnified to show detail). If you look at th...

Page 24

20 q w q w q w adjusting the needle thread tension for a zigzag stitch for an ideal zigzag stitch, the bobbin thread does not show on the right side (top side) of the fabric, and the needle thread shows slightly on the wrong side (bottom side) of the fabric. See the illustrations for the correct app...

Page 25

21 q e w straight stitch sewing q stitch pattern: 00 w needle thread tension: 2 to 6 e presser foot: zigzag foot a • starting to sew raise the presser foot and position the fabric next to a seam guide line on the needle plate (1.6 cm is most common). Lower the needle to the point where you want to s...

Page 26

22 [1.0] [2.2] [5.0] • adjusting the stitch length press the cursor buttons to move the cursor q under the stitch length value “2.4” w (default setting). Press the button to decrease stitch length. Press the button to increase stitch length. The stitch length can be varied from 0.0 to 5.0. Q cursor ...

Page 27

23 q e w q e w q e w q e w lock-a-matic stitch q stitch pattern: 01 w needle thread tension: 2 to 6 e presser foot: zigzag foot a use this stitch to secure the beginning and the end of a seam with backstitching. When you reach the end of the seam, press the reverse stitch button r once. The machine ...

Page 28

24 q e w stretch stitch q stitch pattern: 05 w needle thread tension: 3 to 6 e presser foot: zigzag foot a this stitch is a narrow stretch stitch designed to eliminate puckering on knit fabrics and bias seams, while permitting the seam to be pressed completely open flat..

Page 29

25 the zigzag stitch is one of the most useful and versatile stitches. It is used for overcasting, mending, applique, and also used as a decorative stitch. Note: use an interfacing when sewing on stretch fabrics such as knit, jersey or tricot. Q e w r u zigzag stitch q stitch pattern: 06 or 07 w nee...

Page 30

26 q e w overcasting with zigzag stitch q stitch pattern: 07 w needle thread tension: 3 to 7 e presser foot: overedge foot c this zigzag variation is very useful in garment construction and in finishing raw edges of any sewing project. The black ridge and the guide wires on the overedge foot keep th...

Page 31

27 this stitch can be used for sewing fabrics that tend to fray extensively such as linens and gabardines. Two rows of zigzag stitches are simultaneously sewn over the edge to ensure that your seams will not ravel. Adjust the thread tension so both the needle and bobbin threads meet at the edge of t...

Page 32

28 q e w zipper sewing q stitch pattern: 00 w needle thread tension: 1 to 4 e presser foot: zigzag foot a zipper foot e q w e r • attaching the zipper foot fit the pin w on the zipper foot into the groove q in the foot holder. To sew the left side of the zipper, attach the zipper foot with the right...

Page 33

29 x c i o v !0 !1 bn !2 m x attach the zipper foot with the pin on the right. Sew through all the layers from the end of the zipper opening, guiding the zipper teeth along the edge of the foot. C stop the machine 5 cm before the foot reaches the slider on the zipper tape. Lower the needle into the ...

Page 34

30 q e w blind hemming q stitch pattern: 12 w needle thread tension: 1 to 4 e presser foot: blind hem foot g z fold a hem with the wrong side of the fabric up to form a 0.4 – 0.7 cm allowance. Q wrong side of fabric w 0.4 – 0.7 cm (1) on heavyweight fabrics that tend to ravel, the raw edge should be...

Page 35

31 q e w r button sewing q stitch pattern: 06 w needle thread tension: 3 to 7 e presser foot: satin stitch foot f r feed dog: dropped z lower the feed dog. X match the holes of button to the horizontal slot on the presser foot. C lower the foot to hold the button in place. V adjust the stitch width ...

Page 36

32 q e w attaching elastic q stitch pattern: 14 w needle thread tension: 3 to 7 e presser foot: satin stitch foot f * stitch pattern can also be used. Mark the elastic into quarters. Match those to the center front, center back and side seams, and pin the elastic to the fabric. Place the elastic und...

Page 37

33 note: •tosewthebuttonholes16to21,followthesame procedure as square bh (see page 34 to 35). •thesizeofabuttonholeisautomaticallyset by placing a button in the rear of the automatic buttonhole foot r. •thebuttonholderofthefoottakesabuttonsizeof up to 2.5 cm in diameter. •itissometimesnecessarytocha...

Page 38

34 q e w square buttonhole q stitch pattern: 16 w needle thread tension: 1 to 4 e presser foot: automatic buttonhole foot r r buttonhole lever sign q w t y u i !0 o !1 z x e r c v • to sew z press the needle up/down button to raise the needle. Attach the automatic buttonhole foot r snapping the pin ...

Page 39

35 b b start the machine to sew the buttonhole. The buttonhole will be automatically sewn. The machine will sew the left row first. N m n the machine will sew the back bartack and the right row. M the machine will sew the front bartack, then it stops automatically. Note: if you start sewing the butt...

Page 40

36 7.0 2.5 • adjusting the stitch density press the cursor buttons to move the cursor under the stitch density (stitch length) valume. Press the button to make the buttonhole stitch denser q. Press the button to make the buttonhole stitch less dense w. The stitch density can be varied from 0.2 to 0....

Page 41

37 q e w keyhole buttonhole q stitch pattern: 19 w needle thread tension: 1 to 5 e presser foot: automatic buttonhole foot r the sewing procedure is the same as the square buttonhole. Use the seam ripper and an eyelet punch r to open the buttonhole. R eyelet punch the stitch density can be varied fr...

Page 42

38 q e w corded buttonhole q stitch pattern: 16 w needle thread tension: 1 to 5 e presser foot: automatic buttonhole foot r z use the same procedure as the square buttonhole procedure. Set the stitch width to match the thickness of the cord used. With the buttonhole foot raised, hook the filler cord...

Page 43

39 • adjusting the evenness of the darning correct the evenness of the darning as follows: press the cursor buttons to move the cursor under the value “d5” i (default setting). When the right side of the darn is lower than the left side, press the button to set the value to “d6” – “d9”, and make the...

Page 44

40 q e e w q r t w r e tacking q stitch pattern: 23 w needle thread tension: 3 to 6 e presser foot: satin stitch foot f tacking is used to reinforce pockets, crotch seams and belt carriers where extra strength is needed. • start sewing start the machine and sew until the machine stops automatically....

Page 45

41 q e w shelltuck stitch q stitch pattern: 13 w needle thread tension: 6 to 8 e presser foot: satin stitch foot f use a lightweight fabric (tricot, for example). Fold the fabric as shown and stitch on the fold. Allow the needle to just clear the folded edge to create a shelled edge. You may need to...

Page 46

42 q e w pintucking q stitch pattern: 03 w needle thread tension: 1 to 4 e presser foot: blind hem foot g fold the fabric with the wrong sides together. Place the folded fabric under the blind hem foot. Align the edge of the fold with the guide on the foot, and lower the foot. Sew while guiding the ...

Page 47

43 q e w stippling stitch q stitch pattern: 31 w needle thread tension: 3 to 6 e presser foot: satin stitch foot f open toe satin stitch foot f2 a pre-programmed stippling stitch is a fast and easy method to quilt small areas. Place a batting (wadding) between quilt top and backing fabric. Q e w pat...

Page 48

44 fagoting q stitch pattern: 43 w needle thread tension: 3 to 6 e presser foot: satin stitch foot f * stitch patterns can also be used. Use this stitch to join two pieces of fabric to create an open work appearance and add design interest. Fold under each fabric edge 1.5 cm and press. Pin the two e...

Page 49

45 q e w fringing q stitch pattern: 26 w needle thread tension: 3 to 6 e presser foot: satin stitch foot f fringing adds a special touch on table linens and shawls. Choose a firm, woven fabric like linen where threads can be removed easily. Z carefully cut the fabric on the grain. Remove a single st...

Page 50

46 cross stitch q stitch pattern: 45 w needle thread tension: 3 to 6 e presser foot: satin stitch foot f open toe satin stitch foot f2 q e w you can make cross stitch designs with these patterns in half the time it would take if embroidered by hand. * if you press the auto-lock button before sewing,...

Page 51

47 correcting distorted stitch patterns the sewing results of the stretch patterns may vary depending upon the sewing conditions, such as sewing speed, type of fabric, number of layers etc. Always test sew on a scrap piece of the fabric that you wish to use. If stretch patterns are distorted, correc...

Page 52

48 section v. Care of your machine cleaning the hook race and feed dog warning: •turnthepowerswitchoffandunplugthemachine before cleaning. •donotdismantlethemachineotherthanasexplained in this section. Caution: do not store the machine in a high-humidity area, near a heat radiator, or in direct sunl...

Page 53

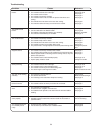

49 audible signal pip pip-pip-pip pip-pip-peep peep the buzzer sounds when: normal operation invalid operation buttonhole sewing completed malfunction problems and warning signs cause try this the machine will not sew with the start/stop button because the foot control is connected. Disconnect the f...

Page 54

50 troubleshooting condition the needle thread breaks. 1. The needle thread is not threaded properly. 2. The needle thread tension is too tight. 3. The needle is bent or blunt. 4. The needle is incorrectly inserted. 5. The needle thread is not set under the presser foot when start sewing. 6. The thr...

Page 56

809-850-015 (en).