Summary of DC5100

Page 1

Service manual parts list dc5100

Page 2: Contents

Contents locate and identify the parts...............................................................................................................1 winding the bobbin .....................................................................................................................................

Page 3

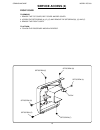

Sewing machine 1 model dc5100 extension table (accessory box) needle plate needle threader thread cutter face cover thread tension dial thread take-up lever thread guide spool pin spool holder flip top stitch chart screen brightness adjusting dial function touchpad speed control lever up/down needle...

Page 4: Winding The Bobbin

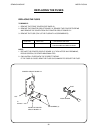

Sewing machine 2 model dc5100 (1) (2) (3) (4) (2) (a) (3) (b) 10 1/8 3/8 5/8 (4) (1) winding the bobbin (1) pass the thread around thread guide. (2) then through the hole in the bobbin. (3) put the bobbin on the bobbin winder spindle, and push the bobbin to the right. (4) when the bobbin is fully wo...

Page 5: Threading The Machine

Sewing machine 3 model dc5100 1 3 (1) (3) (4) (5) (6) threading the machine raise the presser foot lifter, and pass the thread through points (1) to (6). (1) hold the upper thread and pass the thread under the thread guide. Pull the thread down along the right channel. (2) draw the thread around the...

Page 6: Connector Diagram

4 sewing machine model dc5100 connector diagram refer to the diagram for locating the connector post on the circuit board a b c d e f g h b c d e f g h a : buttonhole sensor b : sewing light c : upper shaft sensor d : feed motor e : zigzag width motor f : dc motor g: power transformer (primary circu...

Page 7

5 sewing machine model dc5100 general trouble shooting procedure (machine doesn’t work well) is needle set ok? Is power supply ok? Is threading ok? N.G. O.K. O.K. N.G. Electric quick check end correct it start basic check mechanical electrical can’t judge electric quick check adjustment sewing check...

Page 8: What to Do When

6 sewing machine model dc5100 condition cause how to fix reference 1. Skipping stitches 1. Needle is not inserted properly. 2. Needle is bent or worn. 3. Incorrectly threaded. 4. Needle or thread are inappropriate for fabric being sewn. 5. Sewing on stretch fabric. 6. Inappropriate needle bar height...

Page 9

7 sewing machine model dc5100 condition cause how to fix reference 3. Breaking upper thread 1. Initial sewing speed is too fast. 2. Thread path is incorrect. 3. Needle is bent or dull. 4. Upper thread tension is too strong. 5. Needle size is inappropriate for fabric. 6. Needle eye is worn. 7. Needle...

Page 10

8 sewing machine model dc5100 condition cause how to fix reference 6. Noisy operation 1. Backlash between hook gear and lower shaft gear is too great. 2. Lower shaft gear is loose. 3. Inappropriate belt tension. 4. Not enough oil. See mechanical adjustment “backlash (between lower shaft gear and hoo...

Page 11: Self Diagnostic Tests

9 sewing machine model dc5100 step1 lcd&led next : clr 00 09 08 07 06 05 04 03 02 01 self diagnostic tests self-diagnostic test: preparation: • turn off the power switch. • shift the bobbin winder spindle to the left. • raise the feed dog. • shift the slide volume to the left. • remove the presser f...

Page 12: Self Diagnostic Tests

10 sewing machine model dc5100 correct results • the display shows “self check start”. Lcd and led blinks. • beeps when enter the lcd & led check mode. Press clr button to proceed to the next step. • the display shows “key” and the machine beeps. • beeps when enter the key check mode. • beeps when b...

Page 13: Self Diagnostic Tests

11 sewing machine model dc5100 * press the clr button to return to ”step 1”. End the self diagnostic tests. Step5 velosen 000 step6 volume 255 step7 footcont 210 step8 stm bm phase mem step8 stm fm phase mem step9 sewmotor correct results • the display shows “velosen”. • beep sound. • the value shou...

Page 14: Service Access (1)

12 sewing machine model dc5100 service access (1) face cover to remove: 1. Open the face cover. Remove the 2 screws (a) and remove the face cover (b). To attach: 2. Follow the procedure above in reverse. Top cover to remove: 1. Remove the 3 screws (c) and remove the top cover (d). To attach: 2. Foll...

Page 15: Service Access (2)

13 sewing machine model dc5100 service access (2) belt cover to remove: 1. Remove the 2 screws (a), then unhook the rib (c) and remove the belt cover (b). To attach: 2. Follow the procedure above in reverse screw (a) belt cover (b) screw (a) rib (c).

Page 16: Service Access (3)

14 sewing machine model dc5100 service access (3) base plate bed cover to remove: 1. Remove the 2 screws (a) and 4 screws (b). 2. Remove the base (c). To attach: 3. Reverse this procedure. To remove: 1. Remove the 2 screws (d). 2. Remove the bed cover (e). To attach: 3. Move the drop lever to the le...

Page 17: Service Access (4)

15 sewing machine model dc5100 front cover to remove: 1. Remove the top cover, belt cover and bed cover. 2. Loosen the setscrews (a), (d), (e) and remove the setcrews (b), (c) and (f). 3. Remove the front cover. To attach: 4. Follow the procedure above in reverse. Setscrew (a) setscrew (b) setscrew ...

Page 18: Service Access (5)

16 sewing machine model dc5100 rear cover to remove: 1. Remove the belt cover. 2. Remove the setscrews (a), (b), (c), (d) and (e). 3. To remove the cover, detach the presser foot lifter section first, with the presser foot lifter in the down position. To attach: 4. Follow the procedure above in reve...

Page 19: Service Access (6)

17 sewing machine model dc5100 free arm cover to remove: 1. Remove setscrew (a) and the needle plate. 2. Remove the bed cover (see page 14). 3. Remove setscrew (b) and the free-arm cover. To attach: 4. Follow the procedure above in reverse. Needle plate setscrew (a) setscrew (b) free arm cover servi...

Page 20: Mechanical Adjustment (1)

18 sewing machine model dc5100 setscrew eccentric pin mechanical adjustment (1) needle drop position set the stitch pattern at " "; the standard needle drop position should be at the center of the needle plate hole. When the needle swings in maximum zigzag width " ", the distance between both ends o...

Page 21: Mechanical Adjustment (2)

19 sewing machine model dc5100 mechanical adjustment (2) setscrew (a) needle setting groove tip of hook meets right side of needle needle #14 hook race 1.6-2.0 mm upper edge of needle eye hook race unit needle bar height the distance between the upper edge of needle eye and the tip of the hook shoul...

Page 22: Mechanical Adjustment (3)

20 sewing machine model dc5100 mechanical adjustment (3) lower shaft gear when the machine is set the straight stitch pattern no.2 ( left needle position), the amount of ascending travel of the needle bar from its lowest position to the position where the tip of the hook meets the right side of the ...

Page 23: Mechanical Adjustment (4)

21 sewing machine model dc5100 mechanical adjustment (4) clearance between needle and hook the clearance between the test pin and the tip of the hook should be between –0.10 and +0.05 mm. Preparation: 1. Turn on the power switch and set the stitch pattern to maximum zigzag width " ". 2. Remove the n...

Page 24: Mechanical Adjustment (5)

22 sewing machine model dc5100 backlash (between lower shaft gear and hook gear) backlash allowance point of hook race check the backlash groove groove of lower shaft bushing lower shaft gear a mechanical adjustment (5) b hook gear jog the hook race back and forth to check rotary play. The standard ...

Page 25: Mechanical Adjustment (6)

23 sewing machine model dc5100 mechanical adjustment (6) feed dog height the highest position of the feed dog should be between 0.8 to 0.9 mm from the surface of the needle plate when the the presser foot is raised. 1. Lower the presser foot. 2. Turn on the power switch. 3. Remove the bed cover. 4. ...

Page 26: Mechanical Adjustment (7)

24 sewing machine model dc5100 zigzag synchronization 1. Pattern: (zigzag stitch) mechanical adjustment (7) 1. Remove the front cover (refer to page 15). 2. Turn on the power switch, select the pattern no. 2 and set the machine at the maximum zigzag width. 3. Turn the handwheel toward you slowly wit...

Page 27: Mechanical Adjustment (8)

25 sewing machine model dc5100 tension release mechanism correct setting: when the presser foot lifter is raised, the tension disk supporter should move approximately 1 mm. To adjust: 1. Remove the top cover, belt cover and front cover (see pages 12, 13 and 15). 2. Lower the presser foot lifter, and...

Page 28: Mechanical Adjustment (9)

26 sewing machine model dc5100 stretch stitch feed balance adjustment g f adjusting screw ( e ) base cup (d) feed balancing dial ( c ) indication line standard setting mark 1. When a strech pattern is sewn with the feed balancing dial (c) set at the standard setting mark '' '' , the pattern should b...

Page 29: Mechanical Adjustment (10)

27 sewing machine model dc5100 adjusting plate spring (d) lead screw (e) c b thread tension dial at ''4'' needle thread polyester sewing thread #50 (white) fig.1 needle thread tension to check: 1. The standard tension should be 75 to 90 grams when the tension dial is set at "4", mesured by a #50 whi...

Page 30: Mechanical Adjustment (11)

28 sewing machine model dc5100 left right (lcd screen) (1) (2) (3) bh lever guide (b) setscrew (a) bh lever (c) sensor plate (e) setscrew (d) bh sensor right left bh foot "r" mechanical adjustment (11) step4 sensor bh:l bs:l fs:l step4 sensor bh:h bs:l fs:l step4 sensor bh:h bs:l fs:l (1.6 mm) butto...

Page 31: Mechanical Adjustment (12)

29 sewing machine model dc5100 mechanical adjustment (12) presser bar lifter setscrew 4x8 [presser foot alignment] should be parallel [height of presser foot] presser foot needle plate feed dog presser foot height and alignment when the presser foot is raised, the clearance between the presser foot ...

Page 32

30 sewing machine model dc5100 needle thread tension unit to remove: 1. Remove the front cover (see page 15). 2. Remove screws (a) and (b) and the needle thread tension unit (c). To attach: 1. Reverse this procedure. Note: after changing the needle thread tension unit, check the mechanical adjustmen...

Page 33

31 sewing machine model dc5100 threader plate when the hook of the threader plate is damaged, change or adjust the part as follows. To change the threader plate: 1. Raise the needle to its highest position and lower the threader knob to its lowest position. 2. Loosen the screw and remove the threade...

Page 34

32 sewing machine model dc5100 printed circuit board f" setscrew setscrews printed circuit board "a" to remove: 1. Remove the front cover (see page 15). 2. Unplug the connectors from the board "a". 3. Remove the 6 screws and remove board "a". Note: to disconnect the connectors: 1. Grasp the connecto...

Page 35

33 sewing machine model dc5100 printed circuit "f" board connector printed circuit board f setscrews (2) to remove: 1. Remove the front cover unit 2. Unplug the connector of the printed circuit board "f". 3. Remove the 2 setscrews and printed circuit board "f". To attach: 4. Follow the procedure abo...

Page 36: Replacing Slide Volume

34 sewing machine model dc5100 to remove: 1 remove the front cover. 2 disconnect the slide volume connector. 3 remove the printed circuit board "a". 4 remove the cs rings (2). 5 remove the slide volume. To attach: 6 follow the procedure above in reverse. Replacing slide volume slide volume connector...

Page 37: Motor Belt Tension

35 sewing machine model dc5100 replacing dc motor and adjusting motor belt tension pressure 300g belt deflection: 7~9 mm setscrews (2) setscrews (2) dc motor belt to remove: 1. Remove the front and rear covers (see page 8). 2. Disconnect the motor connector. Remove the two setscrews, then remove the...

Page 38: Replacing The Fuses

36 sewing machine model dc5100 replacing the fuses to remove: 1. Remove the front covers (see page 15). 2. Remove the printed circuit board "a". Remove the four setscrews and remove the cover from the printed circuit board "a". 3. Remove the fuse (pry up the fuse with a screwdriver). Note: 1. Replac...

Page 39

37 sewing machine model dc5100 to remove: 1. Remove the front and rear cover (see page 16). 2. Remove the two setscrews and remove the machine socket. To install: 3. To install the machine socket, follow the above procedure in reverse. Note: pull out the cord in front of the arm to prevent it from c...

Page 40: Replacing Transformer

38 sewing machine model dc5100 to remove: 1. Remove the front cover 2. Remove the two setscrews and remove the transformer. To install: 3. To install the transformer, follow the above procedure in reverse note: place the rear end of the transformer on the transformer support. Slide the two transform...

Page 41

39 sewing machine model dc5100 to remove: 1. Remove the front and rear cover. 2. Remove the two setscrews (a) and remove the zigzag width motor protector plate. Cut the binder. 3. Remove the two zigzag rod setscrews (b). 4. Remove the two setscrews (c) and remove the zigzag width motor. To install: ...

Page 42

40 sewing machine model dc5100 to remove: 1. Remove the front cover and rear covers (see page 15 and 16) 2. Remove the snap ring (e-3) 3. Remove the two setscrews and remove the feed motor. Cut off the cord binder. To install: to install the feed motor, follow the above procedure in reverse. Note: a...

Page 43

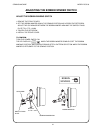

41 sewing machine model dc5100 adjust the bobbin winding switch 1. Remove the front cover. 2. Set the bobbin winder arm in the sewing position and loosen the setscrew. Adjust the clearance between the bobbin winder arm and the switch fixing plate to 0.7 to 1.3 mm. 3. Tighten the setscrew. 4. Install...

Page 44: Oiling

42 sewing machine model dc5100 factory lubricated parts will provide years of household sewing without routine oiling, but you should still check for possible lubrication needs whenever servicing machines. Oil: use good quality sewing machine oil at the points (a, b, c, d, e, f,g,h,i,j & k) indicate...