Aaasewing.Com instruction book janome decor excel 5024 instruction manual janome 5024 instruction manual www.Aaasewing.Com 5024 owners manual/ user guide.

Aaasewing.Com important safety instructions when using an electrical appliance, basic safety precautions should always be followed, including the followings: read all instructions before using this appliance. DangerÑ to reduce the risk of electric shock: 1. An appliance should never be left unattend...

Aaasewing.Com 1 table of contents names of parts .................................................... 2 detachable extension table ................................. 3 accessory storage compartment ........................ 4 connecting machine to power supply ................. 5 foot control ...........

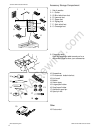

Aaasewing.Com 2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 names of parts 1. Stitch length control 2. Zigzag width control 3. Foot storage compartment 4. Flip-top sewing instruction panel 5. Top cover 6. Thread tension dial 7. Pressure dial 8. Face plate 9. Thread cutter 10...

Aaasewing.Com 3 detachable extension table for free arm sewing to remove, lift out the extension table toward you as illustrated. Advantages of free arm sewing: * avoid fabric bunching around the needle when bar tacking to reinforce pockets, plackets and waistlines. * for stitching sleeves, waistban...

Aaasewing.Com 4 l g d c f a e 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 accessory storage compartment 1. Set of needles 2. L: quilter 3. G: blind stitch hem foot 4. D: hemmer foot 5. E: zipper foot 6. A: zigzag foot 7. F: satin stitch foot 8. C: overedge foot 9. Extension table open the extens...

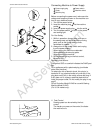

Aaasewing.Com 5 ¥ foot control sewing speed can be varied by the foot control. The harder you press on the control, the faster the machine runs. Connecting machine to power supply power supply plug power switch outlet machine socket machine plug before connecting the power cord, make sure the voltag...

Aaasewing.Com 6 pressure dial the pressure dial should be set at Ò3Ó for regular sewing. Reduce the pressure to Ò2Ó for appliquŽ, cutwork, drawn work, basting and embroidery. Set the pressure to Ò1Ó when sewing chiffon, lace, organdy and other fine fabrics. Velours and knits with a lot of stretch ma...

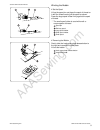

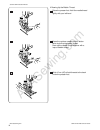

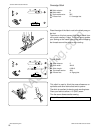

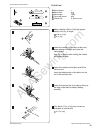

Aaasewing.Com 7 to remove and attach presser foot press the red button on the back of the foot holder. The presser foot will drop off. Place the selected presser foot so the pin on the foot lies just under the groove of the foot holder. Lower the presser bar to lock the foot in place. Red button gro...

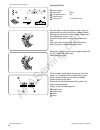

Aaasewing.Com 8 changing needle raise the needle by pressing the up/down needle position button and lower the presser foot. Turn off the power switch. Loosen the needle clamp screw by turning it counterclockwise. Remove the needle from the clamp. Insert the new needle into the needle clamp with the ...

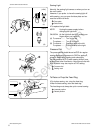

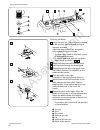

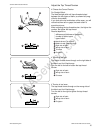

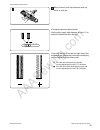

Aaasewing.Com 9 winding the bobbin ¥ set the spool lift up the spool pin and place the spool of thread on it with the thread coming off the spool as shown. Press the large spool holder firmly against the spool of thread. * the small spool holder is used with small or narrow spools of thread. Spool p...

Aaasewing.Com 10 ¥ winding the bobbin lift up the spool pin. Place the spool of thread on the spool pin with the thread coming off the spool as shown. Attach the large spool holder, and press it firmly against the spool of thread. * the small spool holder is used with narrow or small spools of threa...

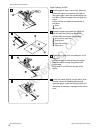

Aaasewing.Com 11 ¥ inserting the bobbin place the bobbin in the holder with the thread running off counterclockwise. End of thread guide the thread into the notch on the front side of the bobbin holder. Draw the thread to the left, sliding it between the tension spring blades. Notch continue to draw...

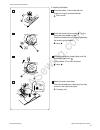

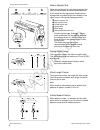

Aaasewing.Com 12 threading the machine * raise the presser foot lifter. * press the up/down needle position button twice to raise the needle. Presser foot lifter lead the thread from the spool and pass it through the thread guide. Then draw it down along the right slot. Thread guide then, down aroun...

Aaasewing.Com 13 ¥ needle threader raise the needle to its highest position. Pull down the needle threader knob as far as it will go. Turn the knob in the direction of the arrow in the illustration, then insert hook into the needle eye. Lead the thread around guide and under hook . Turn the knob in ...

Aaasewing.Com 14 ¥ drawing up the bobbin thread raise the presser foot. Hold the needle thread lightly with your left hand. Press the up/down needle position button twice to pick up the bobbin thread. Draw up the needle thread together with a loop of bobbin thread. Slide 10 cm (4Ó) of both threads t...

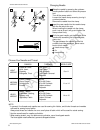

Aaasewing.Com 15 4 3 5 4 3 5 4 3 5 adjust the top thread tension ¥ choose the correct tension for straight stitch: the ideal straight stitch will have threads locked between the two layers of fablic, as shown left (mag- nified to show detail). If you look at the top and bottom of the seam, you will ...

Aaasewing.Com 16 pattern selector dial raise the needle and turn the pattern selector dial until the red indication is below the desired stitch. At the same time the appropriate thread tension, zigzag width and stitch length are indicated in the upper portion of the guide message window. Pattern sel...

Aaasewing.Com 17 0 1 3 2 4 5 6 1 2 3 4 0 4 3 5 straight stitching stitch selector: 1 stitch width: stitch length: 1.5Ð4 top thread tension: 2Ð6 presser foot: a: zigzag foot ¥ starting to sew raise the presser foot and position the fabric next to a seam guide line on the needle plate (see page 18). L...

Aaasewing.Com 18 seam allowance lines the seam guides on the needle plate and hook cover plate help you measure seam width. * the number indicates the distance between the middle needle position and the seam allowance line. Sewing on heavy fabrics pressing the black button on foot a (before lowering...

Aaasewing.Com 19 0 1 3 2 4 5 6 1 2 3 4 0 5 4 6 1 2 3 4 0 0 1 3 2 4 5 6 zigzag stitching stitch selector: 3 stitch width: 1Ð6.5 stitch length: 0.5Ð3 top thread tension: 3Ð5 presser foot: a: zigzag foot simple zigzag stitching is widely used for overcasting, appliquŽing, sewing on buttons, etc. Overca...

Aaasewing.Com 20 tricot stitch stitch selector: 5 stitch width: 3Ð6.5 stitch length: 0.5Ð1.5 top thread tension: 3Ð6 presser foot: a: zigzag foot this stitch is used to finish the seam allowance on synthetics and other fabrics that tend to pucker. The stitch is excellent for darning and mending tear...

Aaasewing.Com 21 0 1 3 2 4 5 6 4 3 5 0 1 3 2 4 5 6 4 3 5 triple strength stitch stitch selector: 24 stitch width: top thread tension: 2Ð6 presser foot: a: zigzag foot this strong, durable stitch is recommended where both elasticity and strength are needed to insure comfort and durability. Use it to ...

Aaasewing.Com 22 0 1 3 2 4 5 6 3 2 4 sewing buttons stitch selector: 3 stitch width: 3Ð3.5 top thread tension: 3Ð7 drop feed dog presser foot: f: satin stitch foot tape the button over the placement mark. A pin can be placed on top of the foot to form a shank. Before lowering the foot, test the need...

Aaasewing.Com 23 0 1 3 2 4 5 6 1 2 3 4 0 3 2 4 automatic buttonhole stitch selector: bh stitch width: 4Ð6.5 stitch length: top thread tension: 1Ð5 presser foot: r: automatic button hole foot * the size of buttonhole is automatically set by placing the button in the automatic buttonhole foot (r). * t...

Aaasewing.Com 24 draw both threads to the left under the foot. Insert the garment under the foot, and lower the needle at the starting point. Then lower the automatic buttonhole foot. * make sure there is no gap between the slider and the spring holder . If there is a gap , the length of the rows wi...

Aaasewing.Com 25 1 2 3 4 0 when finished, push the buttonhole lever up as far as it will go. ¥to adjust buttonhole stitch density. Set the stitch length slider between 0.5 and 1.0 to adjust the buttonhole stitch density. If the stitch density on the left and right side of the buttonhole are unbalanc...

Aaasewing.Com 26 0 1 3 2 4 5 6 1 2 3 4 0 3 2 4 corded buttonholes stitch selector: bh stitch width: 4Ð6.5 stitch length: top thread tension: 1Ð5 presser foot: r: automatic buttonhole foot use the same procedure as automatic buttonhole. * set the stitch width to match the thickness of the cord used. ...

Aaasewing.Com 27 zipper sewing stitch selector: 1 stitch width: stitch length: 1.5Ð4 top thread tension: 3Ð6 presser foot: e: zipper foot ¥to snap on the zipper foot fit the pin on the zipper foot into the groove on the foot holder. * to sew the left side of the zipper, attach the zipper foot on the...

Aaasewing.Com 28 zipper sewing, contÕd sew through all layers next to fold. Stop just before the zipper foot reaches the slider on the zipper tape. Lower the needle slightly into the fabric. Raise the zipper foot and open the zipper. Lower the foot and stitch the remainder of the seam. Slider 5 cm (...

Aaasewing.Com 29 rolled hem stitch selector: 1 stitch width: stitch length: 1.5Ð4 top thread tension: 3Ð6 presser foot: d: hemmer foot make a double 0.25cm (1/8ý) fold approxi- mately 8 cm (3ý) in length. 0.25 cm (1/8ý) 8 cm (3ý) lower the needle into the fabric at the point where sewing is to begin...

Aaasewing.Com 30 blind stitch hemming stitch selector: 4 stitch width: 2Ð3 stitch length: 1Ð3 top thread tension: 2Ð6 presser foot: g: blind stitch hem foot how to fold the fabric. Wrong side of fabric 0.4Ð0.7 cm (5/32ýÐ1/4ý) sewing technique and guide setting. * when the needle comes to the left ha...

Aaasewing.Com 31 decorative satin stitch patterns stitch selector: 10Ð15 stitch width: 3Ð6.5 stitch length: 0.5Ð1 top thread tension: 1Ð4 presser foot: f: satin stitch foot for a delicate appearance on fabric such as chiffon, use a single iayer with a tear-away backing if neces- sary. Stretch stitch...

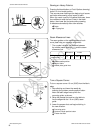

Aaasewing.Com 32 adjusting stretch stitch balance if stretch stitch patterns are uneven when sewn on a particular fabric, adjust them with the feed balance dial. Feed balance dial standard mark setting mark example: pattern # 21 to ajust distorted patterns if patterns are compressed, correct by turn...

Aaasewing.Com 33 quilting stitch selector: 1 stitch width: stitch length: 1.5Ð4 top thread tension: 3Ð6 presser foot: a: zigzag foot quilter the quilting guide will help to keep the stitching lines straight. Loosen the quilter holding screw. Slide the quilter in the opening to the desired width and ...

Aaasewing.Com 34 shell tuck stitch selector: 6 stitch width: 5Ð6.5 stitch length: 2Ð3 top thread tension: 6Ð8 presser foot: f: satin stitch foot * use a lightweight fabric such as tricot. Fold and stitch on the bias. Set the stitch width and length as you desire. You may need to tighten the top thre...

Aaasewing.Com 35 appliquŽ stitch selector: 3 stitch width: 3Ð5 stitch length: 0.5Ð1 top thread tension: 1Ð4 presser foot: f: satin stitch foot presser dial: 2 baste (or fuse with iron-on fabric joiner) appliquŽ pieces on the fabric. Stitch around the appliquŽ making sure the needle falls along the o...

Aaasewing.Com 36 scallop hems stitch selector: 11 stitch width: 3Ð6.5 stitch length: 0.5Ð1 top thread tension: 1Ð4 presser foot: f: satin stitch foot some of the craft patterns can be used to attractively finish the edges of collars, pockets and placements. To edge a collar, place interfacing betwee...

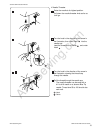

Aaasewing.Com 37 care of your machine caution: before performing any of the following, make sure that the sewing machine is unplugged from the power source. * press the up/down needle position button to raise the needle and unplug the machine before cleaning. * do not dismantle the machine other tha...

Aaasewing.Com 38 condition the needle thread breaks. The bobbin thread breaks. The needle breaks. Skipped stitches. Seam puckering. The cloth is not feeding smoothly. Cause 1. The needle thread is not threaded properly. 2. The needle thread tension is too tight. 3. The needle is bent or blunt. 4. Th...

Aaasewing.Com 39 condition gathering the machine doesnÕt work. Patterns are distorted. The automatic buttonhole stitches are not working. Noisy operation. Cause 1. The needle thread tension is too loose. 2. The needle is too heavy or light for the fabrics being sewn. 1. The machine is not plugged in...