- DL manuals

- Janome

- Sewing Machine

- Elna Lotus

- Owner's Manual

Janome Elna Lotus Owner's Manual

Summary of Elna Lotus

Page 1

Janomeflyer.Com elna lotus instruction manual elna lotus sewing machine instruction manual www.Janomeflyer.Com lotus owners manual/ user guide.

Page 2: Danger

Janomeflyer.Com important safety instructions this appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a...

Page 3

Janomeflyer.Com table of contents section i. Names of parts names of parts ........................................................... 2-3 standard accessories ................................................... 3 accessory storages ...................................................... 4 protection...

Page 4

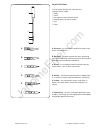

Janomeflyer.Com 2 section i. Names of parts names of parts q lcd screen w stitch width adjusting buttons e stitch length adjusting buttons r start/stop button t reverse stitch button y auto-lock button u needle up/down button i thread cutter button o speed control slider !0 touch panel !1 thread ten...

Page 5

Janomeflyer.Com 3 note: sewing machine design and specifications are subject to change without prior notice. $1 $2 $3 $4 $5 $6 $7 $8 $9 %0 %1 $1 feed adjusting screw $2 drop feed lever $3 carrying handle $4 handwheel $5 power switch $6 foot control jack $7 machine inlet $8 presser foot lifter $9 thr...

Page 6

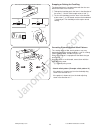

Janomeflyer.Com 4 accessory storages accessories can be stored in the accessory storage and the accessory drawer. Open the top cover to access the accessory storage. Open the protection flap (front) and pull the tab on the right side of the flap to open the accessory drawer. Elna lotus sewing machin...

Page 7

Janomeflyer.Com 5 protection flaps •openingandclosingprotectionflaps to open the protection flaps, slide the protection flap release lever q to the right. To close the protection flaps, fold the rear and front flaps w e, then fold the left flap r until it snaps to the both flaps. Q protection flaps ...

Page 8

Janomeflyer.Com 6 warning: while in operation, always keep your eyes on the sewing area and do not touch any moving parts such as the thread take-up lever, handwheel or needle. Always turn off the power switch and unplug from the power supply: - when leaving the machine unattended. - when attaching ...

Page 9

Janomeflyer.Com 7 changingthepresserfoot caution: turn off the power switch before changing the foot. Always use the proper foot for the selected pattern. The wrong foot can cause the needle to break. •removingthepresserfoot raise the needle to its highest position by turning the handwheel countercl...

Page 10

Janomeflyer.Com 8 changingtheneedle z turn off the power switch. Raise the needle to its highest position by turning the handwheel counterclockwise, and lower the presser foot. Loosen the needle clamp screw q by turning it counterclockwise. Remove the needle from the needle clamp w. X insert a new n...

Page 11

Janomeflyer.Com 9 q w e r t y a b c d e f needle definitions the illustration identifies the main parts of a sewing machine needle. Q body w shaft e long groove (round side of needle) r short groove (flat side of needle) t eye y point a:universal – an all-purpose needle that handles most woven and k...

Page 12

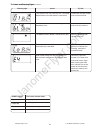

Janomeflyer.Com 10 w reversestitchbutton when stitches (01, 05, 06) are selected, the machine will sew in reverse while the reverse stitch button is pressed. If you press the reverse stitch button when stitch pattern 01, 05 or 06 is selected and the foot control is not connected, the machine will se...

Page 13

Janomeflyer.Com 11 i stitchwidthadjustingbutton press “ ” or “ ” to change the stitch width or needle drop position (see pages 23 and 25). The indicator !0 will show the stitch width or needle drop position. O stitchlengthadjustingbutton press “ ” or “ ” to change the stitch length (see pages 23 and...

Page 14

Janomeflyer.Com 12 •settingthespool z turn the spool thread guide e as illustrated, and the spool pin r will lift up. Warning do not lean over the top of spool pin when turning the spool guide. The spool pin pops up and it may strike your face. E spool thread guide r spool pin bobbin winding •removi...

Page 15

Janomeflyer.Com 13 •bobbinwinding notes: •setthespeedcontrolslideratitsfastestposition for bobbin winding. •closetheretractablethreadguideafterthebobbin winding. Z turn the spool guide as illustrated. Draw the thread from the spool and pass it through the spool guide. X pass the thread through the t...

Page 16

Janomeflyer.Com 14 •insertingthebobbin z place a bobbin in the bobbin holder w with the thread running off counterclockwise. Q end of thread w bobbin holder x guide the thread into the first notch e on the front side of the bobbin holder. E notch c draw the thread to the left, sliding it between the...

Page 17

Janomeflyer.Com 15 threadingthemachine raise the presser foot. Press the needle up/down button q to raise the thread take-up lever to its highest position. Q needle up/down button caution: turn off the power switch before threading the machine. •threadingthemachine z turn the spool thread guide w in...

Page 18

Janomeflyer.Com 16 note: the needle threader can be used with a #11 to #16 needle or a blue tipped needle. Thread sizes 50 to 90 are recommended. •needlethreader caution: turn off the power switch when using the needle threader. Z lower the presser foot. Raise the needle to its highest position. Pul...

Page 19

Janomeflyer.Com 17 •drawingupthebobbinthread z raise the presser foot. Hold the needle thread lightly with your left hand. X press the needle up/down button q twice to lower and raise the needle to pick up the bobbin thread. Q needle up/down button c pull both threads 4˝ to 6˝ (10 to 15 cm) under an...

Page 20

Janomeflyer.Com 18 •tensionistooloose q needle thread (top thread) w bobbin thread (bottom thread) e to tighten tension r right side (top side) of fabric t wrong side (bottom side) of fabric the needle thread shows through on the wrong side of the fabric, and the stitch feels bumpy. Turn the dial to...

Page 21

Janomeflyer.Com 19 droppingorraisingthefeeddog the drop feed lever is located underneath the free arm bed on the back of the machine. Q to drop the feed dog, push the lever in the direction of the arrow q. Set the stitch length value at “0.0” e. W to raise the feed dog, push the lever in the directi...

Page 22

Janomeflyer.Com 20 •buzzersoundsetting the buzzer sound can be turned on or off using the buzzer sound setting. Enter the setting mode. The default buzzer sound setting is “on”. To turn the buzzer sound off, press the stitch length adjusting button “ ”, and the “of” mark will blink. To turn the buzz...

Page 23

Janomeflyer.Com 21 •keypositionadjustment you can adjust the key position when you think the key sensor is off from the actual key position. Z enter the setting mode. Press the thread cutter button twice to enter the key position adjustment. X the key position adjustment screen appears and “p1” is s...

Page 24

Janomeflyer.Com 22 straightstitchsewing q stitch pattern: 01 w needle thread tension: 2 to 6 e presser foot: zigzag foot a •startingtosew raise the presser foot and position the fabric next to a seam guide line on the needle plate (5/8˝ (1.6 cm) is most common). Lower the needle to the point where y...

Page 25

Janomeflyer.Com 23 press the stitch width adjustment button to change the needle drop position. Press “ ” to move the needle to the right r. Press “ ” to move the needle to the left w. W left (0.0) e middle (3.5) r right (7.0) •adjustingthestitchlength press the stitch length adjustment button q to ...

Page 26

Janomeflyer.Com 24 lock-a-maticstitch q stitch pattern: 02 w needle thread tension: 2 to 6 e presser foot: zigzag foot a r reverse stitch button use this stitch to secure the beginning and the end of a seam with backstitching. When you reach the end of the seam, press the reverse stitch button r onc...

Page 27

Janomeflyer.Com 25 •adjustingthestitchlength press the stitch length adjustment button q to change the stitch length w. Press “ ” to decrease stitch length e. Press “ ” to increase stitch length r. The stitch length can be varied from 0.2 to 5.0. The zigzag stitch is one of the most useful and versa...

Page 28

Janomeflyer.Com 26 superstretchstitch q stitch pattern: 07 w needle thread tension: 3 to 6 e presser foot: zigzag foot a this stitch is recommended for sewing fabrics such as swimwear and stretch velour as it provides great stretchability and strength. Seams lie flat and do not lose their shape. Pla...

Page 29

Janomeflyer.Com 27 zippersewing q stitch pattern: 01 w needle thread tension: 1 to 4 e presser foot: zigzag foot a zipper foot e q w e •attachingthezipperfoot fit the pin w on the zipper foot into the groove q in the foot holder. To sew the left side of the zipper, attach the zipper foot with the ri...

Page 30

Janomeflyer.Com 28 x c i o v !0 !1 bn !2 m x attach the zipper foot with the pin on the right. Sew through all the layers from the end of the zipper opening, guiding the zipper teeth along the edge of the foot. C stop the machine 2˝ (5 cm) before the foot reaches the slider on the zipper tape. Raise...

Page 31

Janomeflyer.Com 29 rolled hem q stitch pattern: 01 w needle thread tension: 1 to 4 e presser foot: rolled hem foot d q w e z attach the rolled hem foot d. Fold the fabric edge twice to form a hem, 0.3 cm (1/8˝) wide and 5 cm (2˝) long then press. X place the fabric aligning the hem edge with the gui...

Page 32

Janomeflyer.Com 30 pintuckis q stitch pattern: 01 w needle thread tension: 1 to 4 e presser foot: blind hem foot g a beautiful accent to any project. Pintucks should be added to your fabric before cutting out the pattern piece. Use a washable marker to draw parallel lines for pintucks on fabric righ...

Page 33

Janomeflyer.Com 31 buttonsewing q stitch pattern: 05 w needle thread tension: 3 to 7 e presser foot: satin stitch foot f r feed dog: dropped z lower the feed dog r. X slide the speed control slider to the left to decrease the sewing speed. C select stitch pattern 05. Press the stitch length adjustin...

Page 34

Janomeflyer.Com 32 blind hem q stitch pattern: 10 w needle thread tension: 1 to 4 e presser foot: blind hem foot g q w e 0.4 – 0.7 cm 0.4 – 0.7 cm q w z use the same color thread as the fabric. On heavy weight fabrics that ravel, the raw edge should be overcast first. Fold the hem, as illustrated. Q...

Page 35

Janomeflyer.Com 33 place an applique on the fabric and baste or pin it in place. Reduce the foot pressure. Sew while guiding the fabric so the needle falls along the outer edge of the applique. Q applique w outer edge when turning around a corner, stop the machine with the needle at the outer edge o...

Page 36

Janomeflyer.Com 34 sculpturestitch q stitch pattern: 12 w needle thread tension: 3 to 6 e presser foot: satin stitch foot f for top stitching and outlining designs. Sew slowly at the corners. Q w e q w e patchwork q stitch pattern: 13 w needle thread tension: 3 to 6 e presser foot: satin stitch foot...

Page 37

Janomeflyer.Com 35 attachingelastic q stitch pattern: 14 w needle thread tension: 3 to 7 e presser foot: satin stitch foot f * stitch pattern 06 can also be used. Mark the elastic into quarters. Match those to the center front, center back and side seams, and pin the elastic to the fabric. Place the...

Page 38

Janomeflyer.Com 36 classicsquarebuttonhole q stitch pattern: 16 w needle thread tension: 1 to 5 e presser foot: automatic buttonhole foot r r buttonhole lever sign •tosew z press the needle up/down button to raise the needle. Attach the automatic buttonhole foot r snapping the pin w into the groove ...

Page 39

Janomeflyer.Com 37 x pull the button holder e to the back, and place the button in it. Push it together tightly against the button. Note: if the button is extremely thick, make a test buttonhole on an extra piece of the fabric. If it is difficult to fit the button through the test buttonhole, you ca...

Page 40

Janomeflyer.Com 38 b start the machine to sew the buttonhole. The buttonhole will be automatically sewn. The machine will sew the left row first. N the machine will sew the back bartack and the right row. M the machine will sew the front bartack, then it stops automatically with the needle in the up...

Page 41

Janomeflyer.Com 39 •adjustingthestitchdensity press the stitch length adjustment button q to change the stitch density. Press the “ ” button to make the buttonhole stitch denser w. Press the “ ” button to make the buttonhole stitch less dense e. The stitch density can be varied from 0.3 to 0.8 depen...

Page 42

Janomeflyer.Com 40 cordedbuttonhole q stitch pattern: 16 w needle thread tension: 1 to 5 e presser foot: automatic buttonhole foot r z use the same procedure as the square buttonhole procedure. Set the stitch width to match the thickness of the cord used. With the buttonhole foot raised, hook the fi...

Page 43

Janomeflyer.Com 41 •adjustingtheevennessofthedarning correct the evenness of the darning as follows: press the stitch length adjustment button i to adjust the evenness. When the right side of the darn is lower than the left side, press “ ” to make the darn even. When the left side of the darn is low...

Page 44

Janomeflyer.Com 42 section iv. Care of your machine cleaningthehookrace,feeddogandthe threadcuttermechanism warning: •turnthepowerswitchoffandunplugthemachine before cleaning. •donotdismantlethemachineotherthanasexplained in this section. Caution: do not store the machine in a high-humidity area, ne...

Page 45

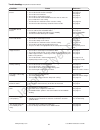

Janomeflyer.Com 43 audiblesignal pip pip-pip-pip pip-pip-peep peep thebuzzersoundswhen: normal operation invalid operation buttonhole sewing completed malfunction problems and warning signs cause trythis the machine will not sew with the start/stop button because the foot control is connected. Disco...

Page 46

Janomeflyer.Com 44 troubleshooting condition the needle thread breaks. 1. The needle thread is not threaded properly. 2. The needle thread tension is too tight. 3. The needle is bent or blunt. 4. The needle is incorrectly inserted. 5. The needle thread and the bobbin thread are not set under the pre...

Page 47

Janomeflyer.Com elna lotus sewing machine instruction manual www.Janomeflyer.Com lotus owners manual/ user guide.

Page 48

Janomeflyer.Com 809-800-342 elna lotus sewing machine instruction manual www.Janomeflyer.Com lotus owners manual/ user guide.