Summary of JF1018S

Page 1

Servicing manual model jf1018s.

Page 2

Contents what to do when ............................................................................................... 1-2 service access face plate ............................................................................................................. 3 belt cover .............................

Page 3

What to do when condition 1. Skipping stitches 2. Fabric not moving 3. Breaking upper thread 4. Breaking bobbin thread cause 1. Needle is not inserted properly. 2. Needle is bent or worn. 3. Incorrectly threaded. 4. Needle or thread is inappropriate for fabric being sewn. 5. Sewing on stretch fabric...

Page 4

2 cause 1.Needle is hitting the needle plate. 2.Needle is bent or worn. 3.Needle is hitting the hook race. 4.The fabric moves while the needle is piercing it, or the needle swings while in fabric. 5.Fabric is being pulled too strongly while sewing. 1.Backlash between shuttle hook gear and lower shaf...

Page 5

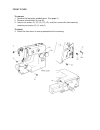

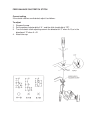

3 face plate to remove 1. Remove the face plate by removing the cap and set screw. To attach 2. Attach the face plate by the set screw. Then, attach the cap. Belt cover to remove 1. Loosen the set screw, and remove the belt cover by removing the belt cover rib from the front cover. To attach 2. Atta...

Page 6

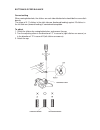

4 front cover to remove 1. Remove the face plate and belt cover. (see page 4.) 2. Remove selector dials (a) and (b). 3. Loosen set screws (c), (d), (e), (ff), (g), and then, remove the front cover by removing set screws (h), (i), and (j), to attach 4. Attach the front cover in reverse procedure of t...

Page 7

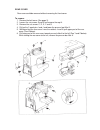

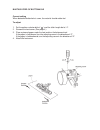

5 rear cover rear cover could be removed without removing first front cover. To remove 1. Remove the belt cover (see page 3). 2. Loosen the set screws a and b and remove the cap h. 3. Remove the set screws c, d, e, f and g. 4. Pull up the 2 spool pins i and j and lower the presser foot lifter k. 5. ...

Page 8

6 upper thread tension dial correct setting the upper thread tension should be 65 - 95g when pulling the thread (cotton thread size 50) in the direction of b with setting the tension dial at “3”. (make sure the foot is lowered.) if the tension is out of the standard range, adjust it as follows: to a...

Page 9

7 bobbin thread tension correct setting set the bobbin in the bobbin case and pass the thread (cotton size 50) through the tension spring. The bobbin thread tension should be 45 - 55g when pulling the thread in the direction of b. If the tension is out of the range, adjust it as follows: to adjust 1...

Page 10

8 presser bar height and alignment correct setting when presser foot lifter is up position, the distance between the bottom surface of the foot and needle plate should be 6.0mm. To adjust 1. Remove the face plate. (see page 3.) 2. Remove set screw a and remove lamp holder set plate. 3. Raise the pre...

Page 11

9 needle swing correct setting if the timing of needle swing is not correctly adjusted, the needle will move sidewise while it is in the fabric. Ideally the needle should start swing from a position 2- 3 mm above the needle plate in its right outflow with maximum zigzag width. To adjust 1. Set the p...

Page 12

10 needle drop correct setting when the needle swings in maximum zigzag width, the distance between the both ends of needle hole on the needle plate and the needle drop positions should be equal. If not. Make adjustment as follows: to adjust 1. Remove the face plate. (see page 3.) 2. Set the pattern...

Page 13

11 height of feed dog correct setting lower the presser foot and turn the balance wheel toward you until the needle bar comes to the highest point of its travel. In this condition, the height of the feed dog above the needle plate should be 0.75 - 0.90mm. If it is not in the range, make adjustment a...

Page 14

12 clearance between needle and hook (no.1) correct setting the clearance between needle and shut1le race should be 0-0.15mm. If not, make adjustment as follows: to adjust 1. Remove the face plate. (see page 3.) 2. Set the pattern selector dial at “b”. (stitch length dial at any position.) 3. Loosen...

Page 15

13 clearance between needle and hook (no.2) use this adjustment no.2 when adjustment no.1 can not be used. Correct setting the clearance between needle and shuttle race should be 0 - 0.15mm. To adjust 1. Set the pattern selector dial at “b”. (stitch length dial at any position.) 2. Loosen the screw ...

Page 16

14 needle bar height correct setting the distance between the upper edge of needle eye and the tip of shuttle hook should be in the range of 2.9 - 3.5mm when the tip of shuttle hook meets the left side of the needle in ascending travel of needle from its left and lowest position. To adjust 1. Remove...

Page 17

15 hook timing correct setting the standard height of needle point from its lowest point of travel should be in the range of 1.45 -1.95mm when the tip of shuttle hook meets exactly the left side of needle at left needle position. To adjust 1. Set the pattern selector dial at “b”. 2. Remove the front...

Page 18

16 feed balance on stretch stitch correct setting if the stretch stitches are distorted, adjust it as follows: to adjust 1. Remove the cap. 2. Set the pattern selector dial at” a “, and the stitch length dial at “ss”. 3. Turn the stretch stitch adjusting screw in the direction of “c” when a> b, or i...

Page 19

17 buttonhole feed balance correct setting when sewing buttonhole, the stitches on each side of buttonhole should be the same stitch density. The range of 9 -11 stitches in the right side row (backward feeding) against 10 stitches in the left side row (forward feeding) is considered acceptable. To a...

Page 20

18 bartack feed of buttonhole correct setting when bartack of buttonhole is sewn, the material should not be fed. To adjust 1. Set the pattern selector dial at “ “ and the stitch length dial at “4”. 2. Remove the front cover. (see page 4.) 3. Place a piece of paper under the foot and turn the balanc...

Page 21

19 disengagement of cam follower correct setting too narrow clearance between the cam follower and the top convex of zigzag cam may often cause difficulty in turning of thepattern selector dial, selecting a correct pattern or zigzaging in straight stitch setting. To adjust 1. Remove the front cover....

Page 22

20 buttonhole function correct setting in buttonhole stitching, the buttonhole should be about 3mm longer than the length set by the foot “r”. To adjust 1. Remove the face plate. (see page 3.) 2. Turn the adjusting screw in the direction of (a) if the buttonhole stitch length is longer than the stan...

Page 23

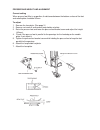

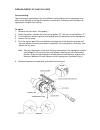

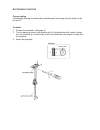

21 motor belt tension too tight or too loose motor belt tension may create belt noise and also too tight motor belt tension can cause the machine to run slow and will overload the motor. Too loose motor belt tension may cause jumping of the belt teeth on the motor pulley. The correct motor belt tens...

Page 24

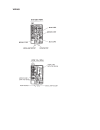

22 wiring.