Summary of Magnolia 7312

Page 1

Service manual model 7312.

Page 2

Table of contents 0. Dismantling the rear cover 1. Upper shaft end play 2. Cam stack gear mesh 3. Needle bar height 4. Shuttle timing 5. Needle position 6. Zeroing the needle 7. Feed dog height 8. Feed lifting cam 9. Stretch stitch selector cam 10. V belt adjusting 11. Bobbin winder 12. Take-up spri...

Page 3

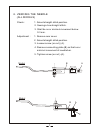

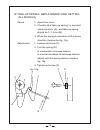

0. Dismantling the rear cover 1. Unscrew the screws: a. B. C. D. E. F. 2. Open face cover and shuttle cover and pull out the spool p i n s . 3. Remove the rear cover in direction of arrow. A b e f c d spool pins face cover shuttle cover 1.

Page 4

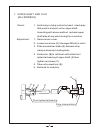

1. Upper shaft end play check : 1. Hold clamp of stop motion by hand , check play that push in and pull out on upper shaft. According with above method, recheck upper shaft play at any point during the revolution. Adjustment : 1. Remove rear cover . 2. Loosen set screw (c) (hexagen m5x5) in collor. ...

Page 5

2. Cam stack gear mesh check : 1. Remove rear cover. 2. Place machine in straight stitch. 3. Check at three different points in a full revolution, zero or very slight play is acceptable. Adjustment : 1. Loosen set screw (e). 2. Hold gear (f) slightly forward, but can not turn. 3. If machine marked b...

Page 6

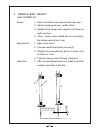

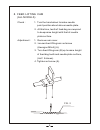

3. Needle bar height check : 1. Take out bobbin case and shuttle race cap. 2. Select zigzag and max , width stitch. 3. Rotate hand wheel until needle is full down in right position. 4. Then , slowly raise needle bar to (a) position , the distance shall be 1 mm. Adjustment : 1. Open face cover. 2. Lo...

Page 7

4. Shuttle timing check : 1. Take out bobbin case and shuttle race cap. 2. Select zigzag and max, width stitch. 3. Rotate hand wheel until needle is full down in the left needle position. 4. The point of shuttle shall be 3.2 mm to the left o f n e e d l e . Adjustment : 1. Remove rear cover. 2. Loos...

Page 8

5. Needle position check : 1. Set machine for zigzag max, width. 2. Turn machine by hand and observe needle as it enters the needle plate , left and right entry should be equal distance from the edge of the needle plate hole (a). Adjustment : 1. Open face cover. 2. Loosen set screw (d) and (b). 3. T...

Page 9

6. Zeroing the needle check : 1. Select straight stitch position. 2. Sewing a line straight stitch. 3. Shall be no or minimul movement below 0.3 mm. Adjustment : 1. Remove rear cover. 2. Select straight stitch position. 3. Loosen screw (or nut ) (a). 4. Remove connecting plate (b) so that no or mini...

Page 10

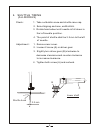

7. Feed dog height check : 1. Bring feed dog to it's highest point. 2. The top or the feed dog should be 0.8-1.0 mm above the surface of the needle plate. Adjustment : 1. Remove rear cover. 2. Bring feed dog to it's highest point. 3. Loosen nut (a). 4. Turn set screw (b) as required. 5. Tighten nut ...

Page 11

8. Feed lifting cam check : 1. Turn the hand wheel to make needle point position about above needle plate. 2. At this time, teeth of feed dog are required to keep same height with that of needle plate surface. Adjustment : 1. Remove rear cover. 2. Loosen feed lifting cam set screw (hexagon m5x5) (a)...

Page 12

9. Stretch stitch selector cam check : 1. Set pattern selector dial at (a) and (d). 2. Sewing (a) and (d) pattern. 3. Sewn-out look (a) and (d), stitch length must be same. Adjustment : 1. Remove rear cover. 2. Set pattern select dial at (a) position. 3. Loosen two set screw (hexagon m4x4) (e) and (...

Page 13

10. V belt adjusting check : 1. Remove rear cover and front cover. 2. Belt about parallel of two side during pressure 300g use spring gauge measured. Adjustment : 1. Remove rear cover and front cover . 2. Loosen two screw of motor (b). 3. Movement motor up and down, adjusting belt tension until as r...

Page 14

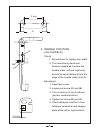

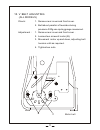

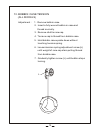

12 11. Bobbin winder clamp stop motion washer check: 1. Loosen clamp stop motion large screw (a) and run machine. 2. Hand wheel (c) should rotate freely without needle bar moving up or down. 3. Tighten clamp stop motion large screw (a) and sew over heavy seam (6 ply denim or equivalent). 4. Clamp st...

Page 15

K i a d c l j 0.8~1.5mm f g h 11. B e 13.

Page 16

12.Take-up spring replacement and setting check : 1. Open face cover. 2. Check to this "take-up spring", in normal it should touch to (a) , and take-up spring should be 1~1.5 mm (b). 3. When this spring in operation (lift in arrow direction) tension be 6g~12g. Adjustment : 1. Loosen set screw (c). 2...

Page 17

13. Bobbin case tension adjustment : 1. Remove bobbin case. 2. Insert a fully wound bobbin in case and thread normally. 3. Remove shuttle race cap. 4. Tie race cap to thread from bobbin case. 5. Hold bobbin case upside down without touching tension spring. 6. Loosen tension spring adjustment screw (...

Page 18

14. Stretch stitch sewing check : 1. Set the pattern selector at ( ). 2. Sewn-out patterns look not like (a) patterns are too far and (c) patterns are overlap. Adjustment : 1. Remove rear cover . 2. Loosen nut (f). 3. If sewn-out patterns look like (a), the nut (g) must be clockwise turn until nice ...

Page 19

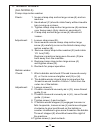

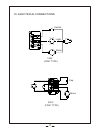

16. Electrical connections 17 switch light motor 120v (fdm type) 230v (fdm type) cap motor.