- DL manuals

- Janome

- Sewing Machine

- MC8200QC

- Instruction Book

Janome MC8200QC Instruction Book

Summary of MC8200QC

Page 1

Instruction book.

Page 3: Danger

1 important safety instructions when using an electrical appliance, basic safety precautions should always be followed, including the following: this sewing machine is designed and manufactured for household use only. Read all instructions before using this sewing machine. Danger — to reduce the ris...

Page 4

2 table of contents names of parts names of parts ............................................................... 3 standard accessories .................................................... 4 accessories storage ...................................................... 5 extension table ..................

Page 5

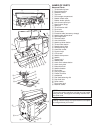

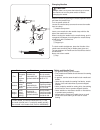

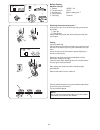

3 names of parts names of parts q w e r t y u i o !0 !1 !2 !3 !4 !5 !6 !7 !8 !9 @0 @3 @2 @1 @6 @7 @8 #4 #3 #2 @9 #0 #1 #5 #6 #7 #8 #9 $0 $1 $2 q w e r t y u i o !0 !1 !2 !3 !4 !5 !6 !7 !8 !9 @0 @1 @2 @3 @4 @5 @6 @7 @8 @9 #0 #1 #2 #3 #4 #5 #6 #7 #8 #9 $0 $1 $2 @4 @5 thread take-up lever foot pressure...

Page 6

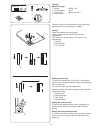

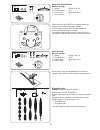

4 zigzag foot a (set on the machine) rolled hem foot d zipper foot e satin stitch foot f open-toe satin stitch foot f2 blind hemming foot g overcast foot m 1/4˝ seam foot o darning foot pd-h convertible free motion quilting foot qb-s close-toe foot open-toe foot clear view foot automatic buttonhole ...

Page 7

5 extension table the extension table provides an extended sewing area and can be removed for free-arm sewing. Q extension table w free-arm to detach: draw the table out to the left. To attach: slide the table on the base and push the table to the right. Free-arm sewing free-arm sewing is used for s...

Page 8

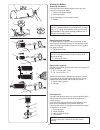

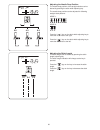

6 connecting the power supply z first make sure the power switch q is off. X insert the machine plug w of the power supply cord into the machine socket e . C insert the power supply plug r into the wall outlet t , and turn the power switch q on. Q power switch w machine plug e machine socket r power...

Page 9

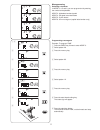

7 machine operating buttons q start/stop button press this button to start or stop the machine. The machine starts running slowly for the first few stitches, it then runs at the speed set by the speed control slider. The machine runs slowly as long as this button is pressed. The button will turn red...

Page 10

8 controlling sewing speed speed control slider youcanlimitthemaximumsewingspeedwiththespeed control slider according to your sewing needs. To increase the sewing speed, move the slider to the right. To decrease the sewing speed, move the slider to the left. Foot control pressing on the foot control...

Page 11

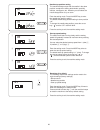

9 i o !0 !1 !2 !3 !4 !5 @2 !9 @0 @1 !8 !7 !6 function keys q lcd screen the lcd screen shows the following information when the machine is turned on: w stitch pattern e mode r stitch pattern number t recommended type of presser foot y stitch width u stitch length i mode key (refer to page 25) press ...

Page 12

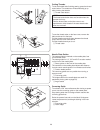

10 raising and lowering the presser foot the presser foot lifter raises and lowers the presser foot. Q presser foot lifter youcanraisethepresserfoothigherthanthenormalup position. This allows for changing the needle plate, and also helps you to place thick layers of fabrics under the foot. W extra l...

Page 13

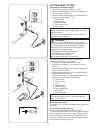

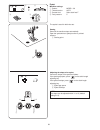

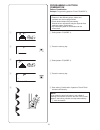

11 adjusting the foot pressure the foot pressure can be adjusted with the foot pressure dial located under the top cover. The dial has 7 setting positions from 1 to 7. For ordinary sewing, set 5 at the setting mark. Q foot pressure dial w setting mark reduce the pressure when sewing fine synthetics ...

Page 14

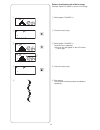

12 for general sewing, set the thread tension dial at auto, which covers a wide range of sewing conditions. Q thread tension dial balancing thread tension auto-thread tension manual thread tension adjustment youmayalsoneedtoadjusttensionmanuallydepending on the sewing conditions such as the type of ...

Page 15

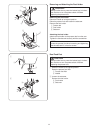

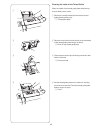

13 changing the presser foot caution: always make sure to press the lockout key to lockout the machine or turn the power switch off before replacing the presser foot. Raise the needle to its highest position and raise the presser foot lifter. Press the black lever on the back of the foot holder. The...

Page 16

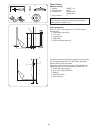

14 removing and attaching the foot holder caution: always make sure to press the lockout key to lockout the machine or turn the power switch off before replacing the presser foot. Removing the foot holder raise the needle to its highest position. Raise the presser foot and loosen the setscrew. Remov...

Page 17

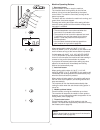

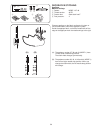

15 t y u i c attach the dual feed foot holder to the presser bar. Tighten the setscrew lightly with your finger. T dual feed link y dual feed foot holder u upper feed drive i dual feed foot v push the dual feed link to engage it with upper feed drive. B lower the presser foot lifter. Lower the needl...

Page 18

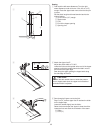

16 replacing the needle plate use the straight stitch needle plate when sewing fine fabrics or sewing with the dual feed foot. Caution: always make sure to press the lockout key to lockout the machine or turn the power switch off before replacing the needle plate. Z raise the needle to the highest p...

Page 19

17 changing needles caution: always make sure to press the lockout key to lockout the machine or turn the power switch off before changing the needle. Raise the needle by pressing the needle up/down button and lower the presser foot. Turn the power switch off. Loosen the needle clamp screw and remov...

Page 20

18 setting the spool of thread lift up the spool pin. Place the spool of thread on the spool pin with the thread coming off the spool as shown. Attach the large spool holder, and press it firmly against the spool of thread. Q large spool holder note: use the small spool holder to hold narrow or smal...

Page 21

19 z i e x w r t u y o c put the bobbin on the bobbin winder spindle. R bobbin t bobbin winder spindle v pass the thread to the bobbin. Hold the thread with both hands and wind it around the bobbin clockwise several times. B insert the thread into one of the slits u of the flange plate y and pull th...

Page 22

20 inserting the bobbin z press the lockout key. Place a bobbin in the bobbin holder with the thread running off counterclockwise as shown on the hook cover plate. Q lockout key w end of thread e bobbin holder r hook cover plate x hold the bobbin with your fingertip so it does not rotate. Guide the ...

Page 23

21 c z x v b n m x q threading the machine raise the presser foot lifter to raise the presser foot. Turn the power switch on. Press the needle up/down button to raise the take-up lever to the highest position. Press the lockout key or turn the power switch off. Pass the thread in the order from z to...

Page 24

22 z q built-in needle threader note: •theneedlethreadercanbeusedwitha#11to#16 needle. Thread size 50 to 90 is recommended. •theneedlethreadercannotbeusedwiththetwin needle. Z turn the power switch on. Press the needle up/down button to raise the needle. Press the lockout key to lock the machine. Pu...

Page 25

23 r q z x c v drawing up the bobbin thread after using auto thread cutting or threading the bobbin holder, you can start sewing without drawing up the bobbin thread. However, you need to draw up the bobbin thread when sewing gathering stitches etc. Z remove the bobbin. Insert the bobbin into the bo...

Page 26

24 selecting the patterns direct pattern selection youcanselectthestitchpatterns01,04,11and06 directly by pressing the corresponding direct pattern selection keys e . Stitch pattern 01s , 04s or 06s can be also selected when the straight stitch needle plate is attached to the machine (refer to page ...

Page 27

25 buzzer sound setting the buzzer sound can be turned on or off using the buzzer sound setting. The default buzzer sound setting is “on”. Enter the setting mode. To turn off the buzzer sound, press the cursor key “ ” and the “of” mark will blink. To turn on the buzzer sound, press the cursor key “ ...

Page 28

26 needle stop position setting the machine always stops with the needle in the down position except when sewing buttonholes, specialty stitches, monograms, etc. However you can select the needle stop position to up or down. Enter the setting mode. Press the mode key to enter the needle stop positio...

Page 29

27 q z x m “t5” will be shown on the lcd screen. Press u on the touch panel. Key position calibration if the function keys seem out of alignment, calibrate the key position as follows. Z enter the machine setting mode. Press the mode key 4 times to enter the key position calibration. X press the sta...

Page 30

28 q starting to sew raise the presser foot and position the fabric edge next to a seam guide on the needle plate. Lower the needle at the point where you wish to start. Pull the needle thread toward the rear. Lower the presser foot. Note: pull the needle thread to the left when using satin stitch f...

Page 31

29 q needle plate guides the seam guides are marked on the needle plate, free arm and hook cover. The seam guides for 1/4˝, 3/8˝ and 5/8˝ are also marked on the front of the needle plate. Q seam guides on the front of the needle plate the numbers on the needle plate indicate the distance from the ce...

Page 32

30 press the “ ” sign on the stitch width adjusting key to move the needle bar to the right. Press the “ ” sign on the stitch width adjusting key to move the needle bar to the left. Adjusting the stitch length the stitch length can be altered by pressing the stitch length adjusting key. The stitch l...

Page 33

31 dual feed balancing dial the dual feed balancing dial should be set at “0”. However, you may need to adjust the dual feed balance with this dial since the effect of the dual feed varies depending on the type of fabric. Test sew on scrap piece of the fabric you intended to sew to check the feed ba...

Page 34

32 replace the needle plate with the straight stitch needle plate (refer to page 16). “s” mark will appear at the end of the pattern number when the straight stitch needle plate is attached. Q straight stitch needle plate w s mark straight stitch needle plate the stitch patterns 01-08 (mode 1) can b...

Page 35

33 use this stitch to seam the edge of fabrics. Straight stitch with left needle position machine settings q pattern: mode 1: 04, 04s w thread tension: auto e presser foot: zigzag foot a or dual feed foot ad r foot pressure: 5 q e w r triple stretch stitch machine settings q pattern: mode 1: 09 w th...

Page 36

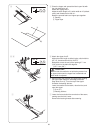

34 fabric preparation add 1 cm (3/8˝) to the zipper size. This is the overall opening size. Q right sides of the fabric w 1 cm (3/8˝) e opening size r zipper size t end of the zipper opening zipper sewing machine settings q pattern: mode 1: 01 w thread tension: auto e presser foot: zipper foot e zig...

Page 37

35 x attach the zipper foot e. Adjust the stitch width to 7.5–8.5. Lower the foot onto the topside at the end of the zipper opening so that the needle pierces the fabric next to the fold and the zipper tape. Sew along the zipper guiding the zipper teeth along the side edge of the foot. Sewing z fold...

Page 38

36 v close the zipper and spread the fabric open flat with the right side facing up. Attach the zigzag foot a. Adjust the stitch length to 5.0, stitch width to 4.5 (default value) and thread tension dial to 1. Baste the opened fabric and zipper tape together. I basting o zipper tape b attach the zip...

Page 39

37 rolled hem machine settings q pattern: mode 1: 01 w thread tension: auto e presser foot: rolled hem foot d r foot pressure: 5 sewing z fold the edge of the fabric twice, 6 cm (2 - 3/8˝) in length and 0.3 cm (1/8˝) in width. Q 6 cm (2 - 3/8˝) w 0.3 cm (1/8˝) x place the fabric aligning the edge of...

Page 40

38 gathering machine settings q pattern: mode 1: 01 w thread tension: 1 e presser foot: zigzag foot a r foot pressure: 5 q e w r pintucking machine settings q pattern: mode 1: 04 w thread tension: auto e presser foot: blind hem foot g r foot pressure: 5 q e w r fold the fabric with the wrong sides t...

Page 41

39 zigzag stitch is used for various sewing needs including overcasting. It can be used on most woven fabrics. A dense zigzag stitch can also be used for applique. Adjusting the stitch length the stitch length of the zigzag stitches can be altered by pressing the stitch length adjusting key. Press t...

Page 42

40 multiple zigzag stitch (tricot stitch) machine settings q pattern: mode 1: 13 w thread tension: auto e presser foot: zigzag foot a r foot pressure: 5 q e w r this stitch is used to finish a raw edge of synthetics and other stretch fabrics that tend to pucker. Sew along the fabric edge leaving an ...

Page 43

41 knit stitch machine settings q pattern: mode 1: 15 w thread tension: auto e presser foot: overcast foot m r foot pressure: 4 q e w r w q this stitch is recommended for sewing such fabrics as synthetic knits and stretch velour as it provides the greatest amount of elasticity and strength. Place th...

Page 44

42 select pattern 19 for woven fabrics or pattern 20 for elastic fabrics. Folding the fabric fold the fabric to make a hem as shown. Q heavy fabric w fine to medium fabric e 0.4 – 0.7 cm (3/16˝–1/4˝) r overcasting t wrong side of fabric sewing position the fabric so that the fold comes to the left s...

Page 45: →

43 press the “ ” sign to move the needle to the right. Press the “ ” sign to move the needle to the left. Q left needle drop position w right needle drop position e guide on foot r distance between the left needle position and the guide note: the stitch width of patterns 19 (mode 1) and 20 (mode 1) ...

Page 46

44 use a light weight fabric (tricot, for example). Fold the fabric as shown and stitch on the fold. Allow the needle to just clear the folded edge to create ashellededge.Youmayneedtoincreasetheneedle thread tension. Q folded edge w right needle drop position if you sew rows of shell stitches, space...

Page 47

45 the size of a buttonhole is automatically set by placing a button in the rear of automatic buttonhole foot r. The button holder of the foot takes a button size of 1 cm (3/8˝) to 2.5 cm (1˝) in diameter. When selecting the buttonholes, the lcd screen advise you to lower the buttonhole lever. Note:...

Page 48

46 v lower the presser foot and pull the buttonhole lever down as far as it will go. U buttonhole lever note: make sure there is no gap between the slider and front stopper, otherwise the buttonhole will be out of position or there will be a sewing gap. I no gap o starting point !0 sewing gap o o o ...

Page 49

47 n the buttonhole is sewn automatically in the sequence shown. When the buttonhole is finished, the machine will stop automatically with the needle in the up position. Press the thread cutter button and remove the fabric. Note: if you start sewing without pulling down the buttonhole lever, the lcd...

Page 50

48 adjusting the buttonhole stitch density the buttonhole stitch density can be adjusted by pressing the stitch length adjusting key. Press the “ ” sign on the stitch length adjusting key to make the buttonhole stitch less dense. Press the “ ” sign on the stitch length adjusting key to make the butt...

Page 51

49 using the stabilizer plate the stabilizer plate holds and supports the fabric so it is helpful when sewing buttonholes over the hem of thick fabrics. Z insert the tab of the stabilizer plate q into the slot w of the buttonhole foot. Q stabilizer plate w slot w x place the button on the button hol...

Page 52

50 q e w r round end and fine fabric buttonholes machine settings q pattern: mode 1: 24, 25 w thread tension: auto e presser foot: automatic buttonhole foot r r foot pressure: 5 the sewing procedure is the same as the square buttonhole (refer to pages 45-47). The machine will sew a buttonhole in the...

Page 53

51 q e w r corded buttonhole machine settings q pattern: mode 1: 29 w thread tension: auto e presser foot: automatic buttonhole foot r r foot pressure: 5 place the button on the button holder on the buttonhole foot. Hook a filler cord on the spur on the front of the foot. Bring the ends of cord towa...

Page 54

52 q w w q e e r q e r e w z x c v b n q e w r welted buttonhole machine settings q pattern: mode 1: 32 w thread tension: auto e presser foot: automatic buttonhole foot r r foot pressure: 5 a welted buttonhole is made by stitching a strip or patch of fabric to the buttonhole. Welted buttonholes are ...

Page 55

53 m fold over the length of the garment fabric, sew back and forth beside the original seam to secure flaps of the patch. R wrong side of garment fabric t sew back and forth r t q r w e r u y u y u y u m , . ⁄0 ⁄1 ⁄2 ⁄3 , fold over the end of fabric and sew back and forth three times over the trian...

Page 56

54 button sewing machine settings q pattern: mode 1: 33 w thread tension: auto e presser foot: button sewing foot t r foot pressure: 5 t feed dog: lowered q w q e w r attaching the button sewing foot t insert the rear pin on the foot into the rear groove of the foot holder. Q rear pin w rear groove ...

Page 57

55 z attach the automatic buttonhole foot r and pull the button holder all the way out. Place the fabric under the foot, and lower the needle at the starting point. Then lower the foot. Q button holder w starting point x start the machine and sew to the required length, then press the reverse button...

Page 58

56 to adjust the evenness of darning stitches youcancorrectunevennessofdarningstitchesby pressing the “ ” or “ ” key of the stitch length adjusting key. If the left corner is lower than the right side, press the “ ” key to correct it, and vice versa. Note: the evenness can be adjusted within d1 to d...

Page 59: →

57 → → tacking is used to reinforce pockets, crotch seams and belt carriers where extra strength is needed. Sewing lower the needle at the starting point. Lower the foot and sew until the machine stops automatically. The machine will sew a tacking 1.5 cm (9/16˝) long automatically. Q tacking w start...

Page 60

58 adjusting the shape of an eyelet correct the shape of the eyelet as follows: if the eyelet gap opens, press “ ” on the stitch length adjusting key. If the eyelet overlaps, press “ ” on the stitch length adjusting key. Q eyelet gap opens w eyelet overlaps note: the shape can be adjusted within l1 ...

Page 61

59 q e w r – place an applique on the fabric and baste it in place or use a fusible web to secure the applique in place. Guide the applique fabric, so that the needle falls off the edge of the applique when the needle swings to the right. (a): the patterns number 37, 38 and 42 (mode 1) have a fixed ...

Page 62

60 q e w r fringing adds a special touch on table linens and shawls. Choose a firm, woven fabric like linen where threads can be removed easily. Carefully cut the fabric on the grain. Remove a single strand of yarn or thread where the fringing is to begin. Sew down the left side so the right hand st...

Page 63

61 choose a soft, lightweight fabric such as batiste, gingham or challis. Cut the fabric three times wider than the projected width. Sew rows of straight stitches, 1 cm (3/8˝) apart with the stitch length “5.0” and thread tension dial at “1” to across the area to be smocked. Q 1 cm (3/8˝) tie the th...

Page 64

62 q e w r use this stitch to join two pieces of fabric to create an open work appearance and add design interest. Fold under each fabric edge 1.5 cm (5/8˝) and press. Pin the two edges to paper or tear away backing 0.5 cm (3/16˝) apart. Q 0.5 cm (3/16˝) sew slowly, guiding the fabric so the needle ...

Page 65

63 note: use 1/4˝ seam foot o for the stitch pattern 06, 07, 06s and 07s in mode 1. Use zigzag foot or dual feed foot ad for stitch pattern 05 and 05s. Patchwork machine settings q pattern: mode 2: 08 w thread tension: auto e presser foot: satin stitch foot f r foot pressure: 5 * stitch patterns (mo...

Page 66

64 attaching the quilting guide bar the quilting guide bar is helpful when sewing parallel, evenly spaced rows of stitching. Insert the quilting guide bar into the opening and slide the quilting guide bar to the position according to the desired space between seams. Q opening on the foot holder w qu...

Page 67

65 stippling machine settings q pattern: mode 2: 03 w thread tension: auto e presser foot: satin stitch foot f or open-toe satin stitch foot f2 r foot pressure: 5 * stitch patterns (mode 2) can also be used. Q e w r a pre-programmed stippling stitch is a fast and easy method to quilt small areas. Pl...

Page 68

66 changing the foot this foot is comes with the closed-toe foot attached, however, it is convertible to the open-toe foot and clear view foot. To change the foot, raise the foot and turn the round nut to bring the foot to the lowest position. Remove the setscrew and remove the closed-toe foot. Atta...

Page 69

67 satin stitches machine settings q pattern: mode 1: 68–79 w thread tension: auto e presser foot: satin stitch foot f r foot pressure: 5 q e w r − patterns 68–79 can be elongated up to 5 times their original length while the stitch density remains the same. Elongation ratio example: pattern number ...

Page 70

68 twin needle sewing the utility stitches and decorative stitches shown on the left can be sewn with a twin needle. Replace the needle with the twin needle supplied with the standard accessories. Caution: turn the power switch off or press the lockout key before changing the needle. Do not use twin...

Page 71

69 •stitchpatternscannotbememorizedinthetwin needle mode. •usethethreadcutteronthefacecoverwhen trimming threads. •usefinethreads#60orlargernumberforthetwin needle sewing. Note: •whenyousewpatternswiththetwinneedle,test the stitches first before you sew on the garment. •usethezigzagfootaorsatinstitc...

Page 72

70 programming a pattern combination pattern combination example: programming patterns 73 and 75 (mode 1). Note: •patternsinthedifferentgroups,lettersand numbers can also be programmed. • check tension balance by test sewing. Manual tension adjustment may be required when sewing a pattern combinatio...

Page 73

71 programming auto-lock stitch example: programming patterns 70 (mode 1) and auto- lock stitch. The machine will sew the pattern, auto-lock stitch, and stop automatically. Z select pattern 70 (mode 1). X press the memory key. C select pattern 93 (mode 1). Press the memory key. V start sewing. Patte...

Page 74

72 programming automatic thread cutting to cut the threads automatically after sewing the pattern combination, press automatic thread cutting key. The cutter sign will be indicated on the lcd screen. Press the automatic thread cutting key again to cancel it. Q cutter sign q z select pattern 73 (mode...

Page 75

73 pattern combination with a mirror image example: pattern 73 (mode 1) and its mirror image z select pattern 73 (mode 1). X press the memory key. C select pattern 73 (mode 1). Press the mirror image key. The mirror sign will appear on the lcd screen. Q mirror sign v press the memory key. B start se...

Page 76

74 resuming a pattern from the beginning if you have to stop sewing in the middle of a pattern and wish to sew it over again, press the startover key to sew the pattern from the beginning. Example: pattern 70 (mode 1) z select pattern 70 (mode 1). Start sewing. X sewing stopped. Q stopped position r...

Page 77

75 bridge stitches stitch patterns number 37 to 41 (mode 2) are bridge stitches, which are used to insert straight stitches after a stitch pattern. Example: combination of pattern 47 (mode 1) and pattern 39 (mode 2). Z select pattern 47 (mode 1). X press the memory key. C select pattern 39 (mode 2)....

Page 78

76 w use the stitch pattern 92 (blank space) in mode 1 or 2 if you wish to insert a space between stitch patterns. W blank space.

Page 79

77 monogramming selecting a character in mode 3, 4, 5 and 6, you can program text by entering the number and alphabets. Mode 3: alphabets/number/symbol mode 4: european accented letters mode 5: cyrillic letters mode 6: 9 mm monogram (capital letter/number only) programming a monogram example: to pro...

Page 80: A A J Y

78 reducing the size of letters to reduce the height of character to approximately 2/3 of its original size, select the character with the cursor key and press “ ” of the stitch width adjusting key. Note: the size of 9 mm monogram (mode 6) cannot be reduced. A 2/3 a spacing to enter the space in mon...

Page 81

79 editing a pattern combination viewing a long combination the lcd screen only shows one pattern at a time. If the entire combination is not displayed, press the cursor key to view the rest of the combination. Press the right arrow “ ” q on the cursor key to shift the cursor to the right. Press the...

Page 82

80 deleting and inserting a pattern example: deleting pattern “b” and inserting “w” from “abc”. C enter “w”. Pattern “w” will be inserted between “a” and “c”. Duplicating a pattern example: duplicating a “w”. Z press the cursor key to shift the cursor under pattern “b”. X press the clear key. Patter...

Page 83

81 unified needle drop position the needle drop position of the programmed patterns will vary depending on the pattern combination: (a) unified to the left when combining the patterns with the left needle position and the center needle position. (b) unified to the right when combining the patterns w...

Page 84

82 individual stitch adjustment the stitch width and length can be individually adjusted for each pattern in a programmed combination. Example: changing the stitch width of the one pattern in the combination note: to view the stitch settings of each pattern, shift the cursor under the desired patter...

Page 85

83 correcting distorted stitch patterns the sewing results of the stitch patterns may vary depending upon sewing conditions, such as sewing speed, type of the fabric, number of layers etc. Always test sew on a scrap piece of the fabric that you wish to use. If stretch stitch patterns, monogram or th...

Page 86

84 care and maintenance cleaning the hook area clean the hook area at least once a month. Turn the power switch off and unplug the machine. Remove the needle plate (refer to page 16). Remove the needle and presser foot. Note: do not dismantle the machine in any way other than as explained in this se...

Page 87

85 cleaning the inside of the thread guide clean the inside of the thread guide plate under the top cover at least once a month. Z remove the needle thread and remove the thread guide plate by pulling it up. Q thread guide plate q e x remove lint and dust from the brush on the underside of the threa...

Page 88

86 problems and warning signals if a buzzer sounds and the lcd screen shows a warning sign, follow the guidance below. The machine will stop if the buttonhole is sewn without lowering the buttonhole lever. The machine is started without lowering the presser foot. The machine will stop if the presser...

Page 89

87 the machine does not work properly due to a problem in the control circuit. Contact the service center or the store from whom the machine was purchased. Warning sign cause try this audible signal the buzzer sounds when: pip normal operation. Pip-pip-pip invalid operation or malfunction. Peep e1-e...

Page 90

88 cause 1. The needle thread is not threaded properly. 2. The needle thread tension is too tight. 3. The needle is bent or blunt. 4. The needle is incorrectly inserted. 5. The needle thread is not set under the presser foot when start sewing. 6. The fabric is moved too fast when stitching free moti...

Page 92

858-850-073 (en).