- DL manuals

- Janome

- Sewing Machine

- Memory Craft 3000

- Service Manual

Janome Memory Craft 3000 Service Manual

Summary of Memory Craft 3000

Page 1

********* service manual **********.

Page 2

Contents top cover & face plate attaching and removing .................................................................................... 1 base & bed cover attaching and removing ............................................................................................ 2 belt cover attaching an...

Page 3

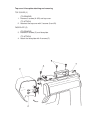

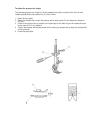

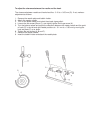

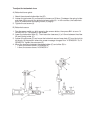

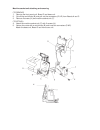

Top cover & face plate attaching and removing top cover (y) (to remove) 1. Remove 3 screws (a & b) and top cover. (to attach) 2. Attached the top cover with 3 screws (a and b). Faceplate (z) (to remove) 3. Remove 2 screws (c) and face plate. (to attach) 4. Attach the face plate with 2 screws (c). 1.

Page 4

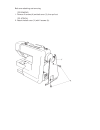

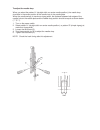

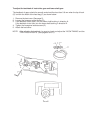

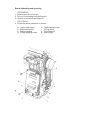

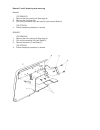

Base & bed cover attaching and removing base (y) (to remove) 1. Remove 6 screws (a) and base. (to attach) 2. Attach the base with 6 screws (a). Bed cover (z) (to remove) 3. Move the drop lever to the left, then remove 2 screws (b). 4. Remove the bed cover. (to attach) 5. Move the drop lever (c) to t...

Page 5

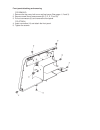

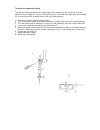

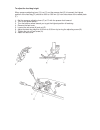

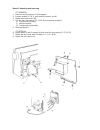

Belt cover attaching and removing (to remove) 1. Remove 2 screws (a) and belt cover (y), then pull out. (to attach) 2. Attach the belt cover (y) with 2 screws (a). 3.

Page 6

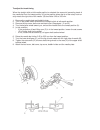

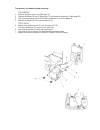

Front panel attaching and removing (to remove) 1. Remove the top cover, belt cover and bed cover (see pages 1, 2 and 3). 2. Remove screw a and loose screws (b, c, d, e, f and g). 3. Pull out connectors (h) and remove the front panel. (to attach) 4. Insert connectors (h) and attach the front panel. 5...

Page 7

To adjust the presser bar height the standard presser bar height is 6.0 mm between the bottom surface of the foot (a) and needle plate(b) when the presser bar (c) lifter is lifted. 1. Open the face plate. 2. Raise the presser foot, loosen the presser bar bracket screw (d) and adjust the height to 6....

Page 8

To adjust the needle drop when you select the pattern 01 (straight stitch on center needle position), the needle drop should be in the center position of the needle hole in the needle plate. When the needle swings in maximum zigzag width, the distance between both edges of the needle hole on the nee...

Page 9

To adjust the needle bar height the standard distance between the upper edge of the needle eye (a) and the tip of shook should be in the range of 1.6 to 2.0 mm when the tip of hook meets the right side of the needle (b) in ascending travel of needle from its left and lowest position. 1. Remove the n...

Page 10

To adjust the hook timing when the straight stitch at left needle position is selected, the amount of ascending travel of the needle bar from its lowest position (a) to the position where the tip of the rotary hook ex- actly meets the right side of the needle (b) should be 3.25 to 3.55 mm. 1. Remove...

Page 11

To adjust the clearance between the needle and the hook the clearance between needle and hook should be - 0.10 to + 0.05 mm (g). If not, make an adjustment as follows: 1. Remove the needle plate and bobbin holder. 2. Attach the master needle. 3. Turn on the power switch and select the simple zigzag ...

Page 12

To adjust the backlash of hook drive gear and lower shaft gear the backlash of gears should be smooth and should be less than 0.8 mm when the tip of hook (e) is within the width of the feed dog (c) as shown below. 1. Remove the bed cover (see page 2). 2. Loosen the hexagon socket screw (d). 3. If th...

Page 13

To adjust the feed dog height when pressure adjusting lever (c) is at “3” and the presser foot (d) is lowered, the highest position of the feed dog (e) should be 0.80 to 0.90 mm (h) from the surface of the needle plate (f). 1. Set the pressure adjusting lever (c) at “3” with the presser foot lowered...

Page 14

To adjust the upper shaft shield plate position when the machine is set for zigzag stitching, the needle should start to swing 6.3 mm to 7.5 mm (g) above the surface of the needle plate (c). 1. Remove top cover. 2. Turn on the power switch and select the simple zigzag stitch. 3. Turn the balance whe...

Page 15

To adjust the upper thread tension the upper thread tension should be 65 g - 95 g when pulling the thread (cotton thread size 50) in direction c with setting the tension dial at” 3 (make sure the foot is lowered.) 1. Set the thread tension dial to “3”. 2. Open the face plate and adjust the thread te...

Page 16

To adjust the stretch feed balance when the triple straight stitch is sewn with the feed balancing dial (c) at the standard setting mark (g, the forward feed (a) and reverse feed (b) should be same length. 1. Set the triple straight stitch and the feed balancing dial at standard setting mark (g). 2....

Page 17

To replace and adjust the threader plate if the needle threader plate is broken or bent, replace it as follows: (to replace) 1. Turn the balance wheel toward you until the needle bar reaches its highest position and lower the needle threader knob (d) as far as it will go. 2. Loosen screw (e) and rep...

Page 18

To adjust the buttonhole lever a) buttonhole lever guide 1. Attach the automatic buttonhole foot (r). 2. Loosen the set screw (a) and leave the clearance of 2.9mm (i) between the spring holder and slider (b) by moving the buttonhole lever guide (k). In this condition, the buttonhole lever (e) should...

Page 19

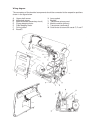

Board a attaching and removing (to remove) 1. Remove the front cover unit. 2. Pull out 8 connectors from the board a. 3. Remove 4 screws (b) and board a. (to attach) 3. Follow the above procedure in reverse. D: upper shaft sensor h: feed stepping motor e: buttonhole sensor i: driving motor f: machin...

Page 20

Board c attaching and removing (to remove) 1. Remove the front panel unit (see page 4). 2. Loosen screws (h, i & j), and remove screws l and m. 3. Remove the rear cover (w). 4. Pull out the 4 connectors (o, p, q & r) and remove screws n. O: transformer (primary) p: machine socket q: transformer (sec...

Page 21

Board c and fuse attaching and removing (to remove) 1. Remove the rear cover. 2. Remove 3 screws (a) and board c (see page 18). 3. Remove 3 screws (b) and remove case cover (g). 4. Replace fuse or board c. (to attach) 5. Attach the case cover with 3 screws (b). 6. Attach the board c with 3 screws (a...

Page 22

Driving motor unit attaching and removing (to remove) 1. Remove the front panel unit (see page 4). 2. Remove the machine socket unit (see page 22). (no need to pull out the connectors) 3. Cut the cord binder (h) and pull out the motor connector (c) from board a. 4. Remove the screw (a) and the cord ...

Page 23

Transformer unit attaching and removing (to remove) 1. Remove the front panel unit (see page 4). 2. Remove the board a and c (see page 17) and machine socket unit (see page 20). 3. Pull out the connectors (a & b) for the transformer (f) from the board c. 4. Remove 3 screws (d & e) and transformer (f...

Page 24

Machine socket unit attaching and removing (to remove) 1. Remove the front panel unit, board c and base unit. 2. Cut off the cord binder (b) and pull out the connectors (d & e) from boards a and c. 3. Remove 2 screws (h) and machine socket unit (f). (to attach) 4. Attach the machine socket unit (f) ...

Page 25

Buttonhole lever attaching and removing (to remove) 1. Remove set screw (a) and bh shield plate (b). 2. Remove the snap ring (c). 3. Pull the buttonhole lever (d) toward you, and remove it. (to attach) 4. Insert the shaft into the holes of the buttonhole lever (d) , and attached the buttonhole lever...

Page 26

Boards f and k attaching and removing board k (to remove) 1. Remove the front panel unit (see page 4). 2. Remove the 9 screws (a). 3. Pull out the connector (b) from board k and remove board k. (to attach) 4. Follow the above procedure in reverse. Board f (to remove) 1. Remove the front panel unit (...

Page 27

Buttonhole sensor attaching and removing (to remove) 1. Remove the front panel (see page 4). 2. Remove screw (a) and remove the buttonhole sensor unit (b) from the sensor set plate (c). 3. Pull out the connector (d) of buttonhole sensor unit from the board k. 4. Pull out the cord (f) of buttonhole s...

Page 28

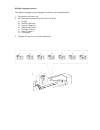

Wiring diagram the connectors of the electrical components should be connected to the respective positions shown in the figure below. A upper shaft sensor h lamp socket b. Buttonhole sensor i board k c machine socket (secondary circuit) j transformer primary cord d zigzag stepping motor k machine so...

Page 29

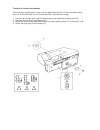

Multiple language function the display language can be changed if necessary, as illustrated bellow. 1. Remove the top cover unit. 2. Move the dip switches with the tail of the lint brush a: english b: deutsch (german) c: espanol (spanish) d: nederlands (dutch) e: francais (french) f: italiano (itali...

Page 30

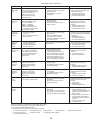

Memory craft 3000 diagnosis chart [check operation] if nothing happens on the machine when turned on the power switch is, turn off the power switch and do following: 1. Check all wire connections and recheck. 2. Replace the machine socket and recheck. 3. Replace board a and recheck. 4. Replace board...

Page 31

29 diagnosis chart for mc3000 test operation turn on the power switch while pressing reverse stitch key, then press auto-lock key within 2. 5 seconds.The machine runs at normal speed if auto-lock key is pressed too late. Press the keys shown below in order.Reverse, auto- lock, u/d, width -, width +,...