- DL manuals

- Janome

- Sewing Machine

- Memory Craft 6300P

- Instruction Manual

Janome Memory Craft 6300P Instruction Manual - Operating Instruction:

www.toews.com

OPERATING INSTRUCTION:

For appliances with a polarized plug (one blade wider than the other):

To reduce the risk of electric shock, this plug is intended to fit in a polarized outlet only

one way.

If the plug does not fit fully in the outlet, reverse the plug.

If it still does not fit, contact a qualified electrician to install the proper outlet.

Do not modify the plug in any way.

Foot Controller 21371 for use with this sewing machine.

Do’s and Don’ts

1. Always be aware of the up-and-down movement of the needle and do not turn your attention

away from the machine while it is running.

2. When leaving the sewing machine unattended, the main switch of the machine must be

switched off or the plug must be removed from the socket-outlet.

3. When servicing the sewing machine, or when removing covers or changing lamps, the machine

must be disconnected from the power supply by removing the plug from the socket-outlet.

4. Do not place anything on the foot control, otherwise the machine will start inadvertently, or the

control or motor may burn out.

5. The maximum permissible power for the sewing lamp bulb is 5 watts.

6. When using your sewing machine for the first time, place a piece of waste fabric under the

presser foot and run the machine without thread for a few minutes. Wipe away any oil which

may have appeared.

Janome MC6300 Instruction Manual

Janome Professional Sewing Machine

www.toews.com

MC6300 Owners Manual/ User Guide

Summary of Memory Craft 6300P

Page 1

Www.Toews.Com janome memory craft 6300p instruction manual janome mc6300 instruction manual janome professional sewing machine www.Toews.Com mc6300 owners manual/ user guide.

Page 2: Danger

Www.Toews.Com important safety instructions this appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concern- ing use of the appliance by a...

Page 3: Operating Instruction:

Www.Toews.Com operating instruction: for appliances with a polarized plug (one blade wider than the other): to reduce the risk of electric shock, this plug is intended to fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit,...

Page 4

Www.Toews.Com 1 know your machine names of parts ................................................................. 2 attaching the quick referencce board ................................ 2 standard accessories ....................................................... 3 getting ready to sew connecting ...

Page 5: Know Your Machine

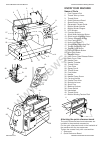

Www.Toews.Com 2 know your machine name of parts 1. Foot pressure dial 2. Thread take-up lever 3. Thread guide 4. Quick reference board 5. Speed control lever 6. Retractable thread guide 7. Bobbin winder spindle 8. Bobbin winder stopper 9. Led window 10. Function buttons 11. Stitch width adjusting bu...

Page 6

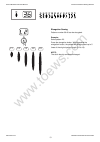

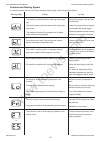

Www.Toews.Com 3 1 2 3 4 5 6 7 8 9 12 11 10 13 14 15 16 17 18 20 19 21 22 23 24 26 25 27 28 30 29 standard accessories 1. Zigzag foot a (comes attached to the machine) 2. Overedge foot c 3. Rolled hem foot d 4. Zipper foot e 5. Satin stitch foot f 6. Blind hem foot g 7. Cording foot h 8. Overcasting ...

Page 7: Getting Ready To Sew

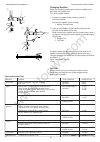

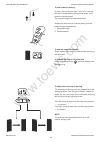

Www.Toews.Com 4 getting ready to sew connecting the power supply turn off the power switch. Insert the foot control plug into the machine socket. Insert the machine plug into the machine socket. Insert the power supply plug into the wall outlet. Turn on the power switch. 1 power switch 2 foot contro...

Page 8

Www.Toews.Com 5 function buttons 1 thread cutter button press this button after finishing sewing and the machine will trim the threads. The led signal blinks while cutting the threads. 5 thread cutter signal notes: the auto thread cutter does not work if the presser foot is raised. The auto thread c...

Page 9

Www.Toews.Com 6 1 bobbin winding button: press this button to wind the bobbin. 2 twin needle button: press this button when sewing with a twin needle. 3 clear button press this btton to delete the last pattern programmed. Holding this button being pressed will delete the entire program. 4 memory but...

Page 10

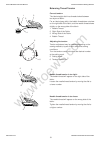

Www.Toews.Com 7 raising and lowering the presser foot the presser foot lifter raises and lowers the presser foot. You can raise the presser foot about 6 mm (1/4") higher than the normal up position by exerting more pressure when lifting the presser foot lifter. This allows for easy removal of the pr...

Page 11

Www.Toews.Com 8 1 2 3 4 5 6 8 7 9 10 11 12 13 variety of presser feet and their uses 1 zigzag foot a: this is the most versatile foot. It can be used for various stitches including straight stitches and zigzag stitches. It is designed to achieve firm and neat seam results. 2 overedge foot c: this fo...

Page 12

Www.Toews.Com 9 changing the presser foot caution: turn off the power switch before changing the foot. Always use the proper foot for the selected pattern. Wrong foot can cause the needle to break. To snap off: raise the needle and presser foot. Press the red button on the back of the foot holder an...

Page 13

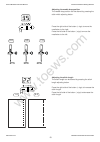

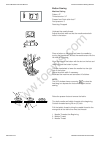

Www.Toews.Com 10 attaching the even feed foot remove the foot holder. Attach the even feed foot to the presser bar with the lever over the needle clamp screw and secure it with the thumb screw. 1 thumb screw 2 lever 3 presser bar 1 3 2 attaching the darning foot p loosen the thumbscrew and remove th...

Page 14

Www.Toews.Com 11 winding the bobbin removing the bobbin slide the hook cover plate release button to the right, and remove the hook cover plate. Lift out the bobbin from the bobbin holder. 1 hook cover plate release button 2 hook cover plate 3 bobbin notes: avoid using a bobbin when it begins to emp...

Page 15

Www.Toews.Com 12 winding the bobbin z pass the thread through the guide on the thread guide post from behind. 1 thread guide post x pass the thread under the bobbin winding tension disk. 2 bobbin winding tension disk c thread through the hole in the bobbin from the inside to the outside. Put the bob...

Page 16

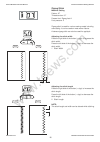

Www.Toews.Com 13 inserting the bobbin z place the bobbin in the bobbin holder with the thread running off counterclockwise. 1 thread 2 bobbin holder x guide the thread into notch (a) on the front of the bobbin holder. C draw the thread to the left, sliding it between the tension spring blades. V con...

Page 17

Www.Toews.Com 14 threading the machine raise the presser foot lifter. Press the up/down needle button twice to raise the needle to its highest position. Z pass the thread through the guide on the thread guide bar from behind. 1 thread guide bar x pass the thread through the right thread guide. 2 rig...

Page 18

Www.Toews.Com 15 threading the machine (continued) b draw the thread down and around the tension dial from the right to the left. While holdin the thread beside the left thread guide, pull the thread up to insert it between the tension disks and under the loop of the check spring. Be sure that the t...

Page 19

Www.Toews.Com 16 automatic needle threader raise the needle to its highest position by pressing the up/down needle button twice. Turn the power switch off. Lower the presser foot. Z depress the needle threader knob as far as it will go. The hook comes out through the needle eye from behind. 1 needle...

Page 20

Www.Toews.Com 17 1 3 drawing up the bobbin thread z raise the presser foot lifter. Hold the needle thread with your finger and press the up/down needle button twice to pick up the bobbin thread. 1 needle thread 2 needle up/down button x draw up the needle thread to bring up a loop of the bobbin thre...

Page 21

Www.Toews.Com 18 changing needles raise the needle by pressing the up/down needle button and lower the presser foot. Turn off the power switch. Z loosen the needle clamp screw by turning it counterclockwise. Remove the needle from the clamp. 1 needle clamp screw x insert a new needle into the needle...

Page 22

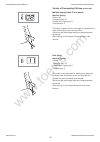

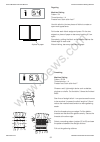

Www.Toews.Com 19 0 1 2 3 4 5 6 7 8 9 balancing thread tension correct tension: the ideal straight stitch has threads locked between two layers of fabric. For an ideal zigzag stitch, the bobbin thread does not show on the right side of the fabric, and the needle thread shows slightly on the wrong sid...

Page 23

Www.Toews.Com 20 adjusting the foot pressure the foot pressure dial should be set at “3” for regular sewing. Reduce the pressure for appliqué, sewing on fine synthetics and elastic fabrics. Set the dial at “1” when sewing extra fine fabrics. 1 foot pressure dial 2 setting mark note: do not reduce th...

Page 24: Basic Stitches

Www.Toews.Com 21 basic stitches straight stitch machine setting pattern: 01 or 02 thread tension:2-6 presser foot: zigzag foot a foot pressure: 3 to sew raise the presser foot and position the fabric next to a seam guide line on the needle plate. Lower the needle to the point where you wish to start...

Page 25

Www.Toews.Com 22 changing sewing direction: stop the machine a few stitches before the end of a seam. Press the up/down needle button a few times until the needle falls on the end of the seam. Raise the presser foot. Pivot the fabric around the needle to change the sewing direction as desired. Lower...

Page 26

Www.Toews.Com 23 1.0 5.0 7.0 3.5 0.0 adjusting the needle drop position the needle drop position can be altered by pressing the stitch width adjusting button. Press the right side of the button (+ sign) to move the needle bar to the right. Press the left side of the button (- sign) to move the needl...

Page 27

Www.Toews.Com 24 variety of the straight stitches 02 straight stitch with left needle position use this stitch to seam the edge of fabrics. 03 lock-a-matic stitch use this stitch to secure the beginning and the end of a seam with backstitching. When you reach the end of the seam, press the reverse b...

Page 28

Www.Toews.Com 25 basting machine setting pattern: 06 thread tension:1-3 presser foot: darning foot p foot pressure: 1 feed dog: dropped the basting stitch is used to hold fabric layers together during fitting. Lower the feed dog and set the foot pressure dial at “1”. Draw the both needle and bobbin ...

Page 29

Www.Toews.Com 26 1.0 5.0 2.0 7.0 zigzag stitch machine setting pattern: 07 thread tension: 3-7 presser foot: zigzag foot a foot pressure: 3 zigzag stitch is used for various sewing needs including overcasting. It can be used on most woven fabrics. A dense zigzag stitch can also be used for appliqué....

Page 30

Www.Toews.Com 27 variety of overcasting stitches overcasting with zigzag stitch machine setting pattern: 07 thread tension: 3-7 presser foot: overedge foot c foot pressure: 3 place the fabric edge next to the guide of the foot and then sew. 1 edge of fabrics 2 guide 3 wires on foot caution: when you...

Page 31

Www.Toews.Com 28 variety of overcasting stitches (continued) multiple zigzag stitch (tricot stitch) machine setting pattern: 08 thread tension: 3-7 presser foot: zigzag foot a foot pressure: 3 this stitch is used to finish a raw edge of synthetics and other stretch fabrics that tend to pucker. Sew a...

Page 32

Www.Toews.Com 29 zipper sewing machine setting pattern: 01 thread tension: 2-6 presser foot: zipper foot e foot pressure: 3 to attach the zipper foot e fit the pin on zipper foot e to the groove on the foot holder. 1 groove 2 pin 4 to sew the left side of the zipper, attach zipper foot e with the pi...

Page 33

Www.Toews.Com 30 to sew c fold back the left seam allowance. Turn the right seam allowance under to form a 0.2 to 0.3 cm (1/8“) fold. Place the zipper teeth next to the fold and pin it in place. Set the stitch length and thread tension back to the original setting. 1 lower fabric 2 end of the openin...

Page 34

Www.Toews.Com 31 n close the zipper and spread the fabric open flat with the right side facing up. Baste the opened fabric and zipper tape together. 11 basting 12 zipper tap m re-attach the zipper foot e with the left pin. Backstitch across the end of opening to 0.7 – 1 cm (3/8“). Stitch through the...

Page 35

Www.Toews.Com 32 rolled hem machine setting pattern: 01 thread tension: 2-6 presser foot: rolled hem foot d foot pressure: 3 to sew: fold the edge of the fabric twice, 6 cm (2 3/8”) in length and 0.3 cm (1/8”) in width. Trim the corner 0.5 cm (3/16”) by 0.8 cm (1/4”) for easier insertion of the hem ...

Page 36

Www.Toews.Com 33 blind hem machine setting pattern: 13 or 14 thread tension: 1-4 presser foot: blind hem foot g foot pressure: 3 select the pattern 13 for woven fabrics or pattern 14 fo elastic fabrics. Note: the stitch width of the patterns 13 and 14 cannot be changed, but the needle drop position ...

Page 37: Utility Stitches

Www.Toews.Com 34 utility stitches buttonholes variety of buttonholes 16 sensor (square) bh this square buttonhole is widely used on medium to heavy weight fabrics. The buttonhole size is automatically determined by placing a button in the foot. 17 automatic (square) bh this is also a square buttonho...

Page 38

Www.Toews.Com 35 c pull the buttonhole lever down as far as it will go. 1 buttonhole lever note: if you start sewing without pulling down the buttonhole lever, the led window will show a warning and the machine will stop after a few stitches. Pull the buttonhole lever down and restart the machine. A...

Page 39

Www.Toews.Com 36 b start the machine to sew the buttonhole. The buttonhole will be automatically sewn. Step 1: the machine will sew the front bartack and the left row first. Then it goes back to the starting point with straight stitch. Step 2: the machine will sew the right row. Step 3: the machine ...

Page 40

Www.Toews.Com 37 double layer buttonhole to make a solid and sturdy buttonhole, sew another layer of buttonhole over the previous stitches. After the buttonhole is finished, simply start the machine again. Do not raise the foot or buttonhole lever. The machine will sew another buttonhole in the foll...

Page 41

Www.Toews.Com 38 changing buttonhole width press the stitch width adjusting button to alter the buttonhole width. The width of the buttonhole will be imdicated in the led window. Press on “+“ to increase the buttonhole width. Press on “—“ to decrease the buttonhole width. 1 narrower buttonhole 2 wid...

Page 42

Www.Toews.Com 39 automatic buttonhole machine setting pattern: 17 thread tension: 1-5 presser foot: automatic buttonhole foot r foot pressure: 3 z pull the button holder of the buttonhole foot all the way out. Insert the fabric under the foot. Press the up/down needle button twice. Remove the fabric...

Page 43

Www.Toews.Com 40 c start the machine again. The machine will automatically tack and sew down the right side of the buttonhole. Stop the machine when you are directly opposite the starting point. Press the reverse button. 6 starting point v keep the foot control depressed. The machine will sew a bart...

Page 44

Www.Toews.Com 41 button sewing machine setting pattern: 07 thread tension: 3-7 presser foot: satin stitch foot f foot pressure: 3 feed dog: dropped unthread the needle thread. Adjust the stitch width so that the needle enters both holes in the button. Place a button on the fabric and lower the needl...

Page 45

Www.Toews.Com 42 darning machine setting pattern: 20 thread tension: 3-6 presser foot: automatic buttonhole foot r foot pressure: 3 pull the button holder to the rear. Place the garment under the foot. Press the up/down needle button twice. Remove the fabric to the left to draw both threads under th...

Page 46

Www.Toews.Com 43 to sew a shorter darning to sew a darning shorter than 2 cm (3/4”), first stop the machine after sewing the required length, then press the reverse button. The required length has been determined. Restart the machine and continue sewing until the machine stops automatically. 1 requi...

Page 47

Www.Toews.Com 44 tacking machine setting pattern: 21 thread tension: 3-6 presser foot: satin stitch foot f foot pressure: 3 tacking is used to reinforce pockets, crotches and belt carriers where extra strength is needed. To sew depress the foot control until the machine stops automatically. The mach...

Page 48

Www.Toews.Com 45 eyelet machine setting pattern: 22 thread tension: 1-4 presser foot: satin stitch foot f foot pressure: 3 the eyelet is used for belt holes, etc. To sew depress the foot control to sew. The machine will sew an eyelet and stop automatically when completed. Open the eyelet with an awl...

Page 49: Patchwork And Quilting

Www.Toews.Com 46 patchwork and quilting patchwork seaming patchwork pieces machine setting pattern: 01 thread tension: 2-6 presser foot: 1/4” seam foot o foot pressure: 3 place the patchwork pieces right sides together. Sew while guiding the edge of the fabric along the guide on the foot to keep a p...

Page 50

Www.Toews.Com 47 quilting bar for the zigzag foot machine setting pattern: 01 thread tension: 2-6 presser foot: zigzag foot a foot pressure: 2 reduce the foot pressure to “2” for better handling of bulky material. To attach loosen the screw on the back of the foot holder. Insert the quilting bar int...

Page 51

Www.Toews.Com 48 clasp stitch machine setting pattern: 29 thread tension: 3-6 presser foot: satin stitch foot f foot pressure: 2-3 you can bind the thick quilt layers together with the clasp stitch. Select pattern 29. Press the memory button. Select pattern 47 (locking stitch). Press the memory butt...

Page 52

Www.Toews.Com 49 pattern programming and decorative stitches programming a pattern combination example: programming patterns 36 and 38. Select pattern 36. Press memory button. Select pattern 38. Press memory button. Note: set the thread tension at 1-4, foot pressure at 3 and use the satin stitch foo...

Page 53

Www.Toews.Com 50 pattern combination with auto thread cutting example: programming the patterns 36 and 53 with auto thread cutting (pattern 48). Select the pattern 36. Press memory button. Select pattern 53. Press memory button. Select pattern 48 (auto thread cutting). Press the memory button. The l...

Page 54

Www.Toews.Com 51 l1 l2 l3 l4 l5 elongation sewing patterns number 36-48 can be elongated. Example: select pattern 23. Press the elongation button. When pressing the elongatioin button, the pattern will be elongated up to 5 times of the original pattern length (l2 to l5). Note: the stitch density rem...

Page 55

Www.Toews.Com 52 fagoting machine setting pattern: 54 thread tension: 1-4 presser foot: satin stitch foot f use this stitch to join two pieces of fabric to create an open work appearance. Fold under each fabric eadge and press. Pin the two edges to a piece of paper or tear away backing 0.3 cm apart....

Page 56

Www.Toews.Com 53 applique machine setting pattern: 60 or 61 thread tension:1-4 presser foot: satin stitch foot f foot pressure: 2 the open toe satin stitch foot f-2 can also be used. Place an applique on the fabric and baste it in place or use a fusible web to secure the applique in place. Guide the...

Page 57

Www.Toews.Com 54 twin needle sewing notes: when you sew patterns with the twin needle, press the twin needle button and test the stitches first before you begin to sew. Use the zigzag foot a or satin stitch foot f for twin needle sewing. Turn off the machine before changing the needle. Use #60 or fi...

Page 58

Www.Toews.Com 55 to sew example: select pattern 36. Press the twin needle button . The led above the twin needle button will turn on and the maximum stitch width is restricted to 3.0 mm. Note: the maximum stitch width is based on a 2 mm wide twin needle. Sew at a medium speed. When changing the sewi...

Page 59

Www.Toews.Com 56 correcting distorted stitch patterns the sewing results of the stretch stitch patterns may vary depending upon the sewing conditions, such as sewing speed, type of the fabric, number of layers, etc. Always test sew on a scrap piece of the fabric that you wish to use. If stretch stit...

Page 60

Www.Toews.Com 57 reviewing the programmed pattern combination example: to review the combination of patterns 36, 26 and 40. Press the twin needle button and pattern number 36 will be indicated in the led window. Press the twin needle button again and pattern numeber 26 will be indicated. Press the t...

Page 61

Www.Toews.Com 58 inserting a pattern in the programmed combination example: to insert pattern 53 before pattern 40 in the combination of patterns 36, 26 and 40. Press the twin needle button until pattern number 40 is indicated. Select pattern 53. Press the memory button to memorize pattern 53. The l...

Page 62

Www.Toews.Com 59 uniform stitch adjustment of the programmed patterns the stitch length and width of the programmed patterens can be adjusted uniformly. Example: to adjust stitch lengh and width of programmed patterns 36 and 38. Program the patterns 36 and 38. The led window will indicate "– –". Pre...

Page 63

Www.Toews.Com 60 individual stitch adjustment of the programmed patterns the stitch length and width of the programmed patterens can be adjusted individually. Example: to adjust stitch width of pattern 38 in the combination of patterns 36 and 38. Program the patterns 36 and 38. The led window will i...

Page 64

Www.Toews.Com 61 care of the machine cleaning the hook race and feed dog warning: turn the power switch off and unplug the machine before cleaning. Caution: do not dismantle the machine in any way other than what is explained on this page. Z remove the needle and presser foot. Remove the setscrews a...

Page 65

Www.Toews.Com 62 replacing the light bulb warning: turn the power off before replacing the light bulb. The bulb could be hot, wait until it has cooled down before touching it. To remove: remove the setscrew. Remove the faceplate. Swing the lamp socket to the left and pull out the bulb. To replace: i...

Page 66

Www.Toews.Com 63 the machine is started when it halts due to the overload. The feed dog is lowered while sewing. The bobbin winder spindle is locked while winding a bobbin. Wait for at least 15 seconds to start. Do not lower or raise the feed dog while the machine is running. Turn off the power and ...

Page 67

Www.Toews.Com 64 the power is turned on again after auto thread cutting has been interrupted. The presser foot is raised before auto thread cutting is completed. Press the thread cutter button to finish auto thread cutting. Pip normal operation pip-pip-pip invalid operation or malfunction pip-pip-pe...

Page 68

Www.Toews.Com 65 cause 1. The needle thread is not threaded properly. 2. The needle thread tension is too tight. 3. The needle is bent or blunt. 4. The needle is incorrectly inserted. 5. The needle thread and the bobbin thread are not set under the presser foot when start sewing. 6. The threads were...

Page 69

Www.Toews.Com printed in taiwan 846-800-738 (e) janome mc6300 instruction manual janome professional sewing machine www.Toews.Com mc6300 owners manual/ user guide.