- DL manuals

- Janome

- Sewing Machine

- Memory Craft 6700P

- Instruction Book

Janome Memory Craft 6700P Instruction Book - Danger

1

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the following:

This sewing machine is designed and manufactured for household use only.

Read all instructions before using this sewing machine.

DANGER

—

To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in. Always unplug this sewing

machine from the electric outlet immediately after using and before cleaning.

WARNING

—

To reduce the risk of burns, fire, electric shock, or injury to persons:

1. Do not allow to be used as a toy. Close attention is necessary when this sewing machine is used by or near

children.

2. Use this appliance only for its intended use as described in this owner’s manual.

Use only attachments recommended by the manufacturer as contained in this owner’s manual.

3. Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into water.

Return this sewing machine to the nearest authorized dealer or service center for examination, repair, electrical

or mechanical adjustment.

4. Never operate the appliance with any air opening blocked. Keep ventilation openings of this sewing machine and

foot controller free from accumulation of lint, dust and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

8. To disconnect, turn all controls to the off (“O”) position, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the sewing machine needle and/or

cutting blade.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

14. Switch this sewing machine off (“O”) when making any adjustment in the needle area, such as threading the

needle, changing the needle, threading the bobbin or changing the presser foot, and the like.

15. Always unplug this sewing machine from the electrical outlet when removing covers, lubricating, or when making

any other adjustments mentioned in this owner’s manual.

SAVE THESE INSTRUCTIONS

Please note that on disposal, this product must be safely recycled in accordance with relevant National

legislation relating to electrical/electronic products. If in doubt please contact your retailer for guidance. (European

Union only)

For Europe only:

This appliance can be used by children aged from 8 years and above and persons with reduced physical, sensory or

mental capabilities or lack of experience and knowledge if they have been given supervision or instruction concerning

use of the appliance in a safe way and understand the hazards involved. Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by children without supervision.

For outside Europe (except U.S.A and Canada):

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

Summary of Memory Craft 6700P

Page 1

Instruction book memory craft 6700p.

Page 3: Danger

1 important safety instructions when using an electrical appliance, basic safety precautions should always be followed, including the following: this sewing machine is designed and manufactured for household use only. Read all instructions before using this sewing machine. Danger — to reduce the ris...

Page 4

2 table of contents essential parts names of parts ............................................................... 4 standard accessories .................................................... 5 extension table .............................................................. 6 stitch reference chart ......

Page 5

3 deleting a pattern ......................................................... 83 inserting a pattern ........................................................ 84 duplicating a pattern .................................................... 84 programming auto-lock stitch ..................................

Page 6

4 essential parts names of parts q w e r t y u i o !0 !1 !2 !3 !4 !5 !6 !7 !8 !9 @0 @1 @2 @3 @4 @5 @6 @7 @8 @9 #0 #1 #2 #3 #4 #5 #6 #7 #8 #9 $0 $1 $2 $3 $4 $5 $6 $7 $8 $9 %0 %1 %2 %3 %4 foot pressure dial thread take-up lever left thread guide upper thread guide stitch reference chart lcd screen ret...

Page 7

5 standard accessories no. Part name part no. 1 zigzag foot a (set on the machine) 859802006 2 overedge foot m 859810007 3 satin stitch foot f 859806011 4 blind hemming foot g 859807001 5 zipper foot e 859805009 6 automatic buttonhole foot r 862822013 7 stabilizer plate 859832016 8 rolled hem foot d...

Page 8

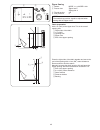

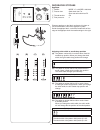

6 *the power supply cable included may differ from the illustration. #6 #7 #8 $4 $1 $2 $3 $0 no. Part name part no. 36 extension table 846401001 37 stitch reference chart 866629009 38 stitch chart bracket 846285007 39 setscrew x 2 000163600 40 dust cover 767805001 41 accessory box 866801007 42 instr...

Page 9

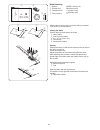

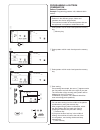

7 stitch reference chart attaching the stitch chart bracket align the screws with the holes on the backside of the machine. Firmly tighten screws with screwdriver. Stitch chart position the stitch chart can be placed in two positions on the chart bracket, store or view. Q back slots w front slots th...

Page 10

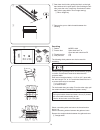

8 warning: while in operation, always keep your eyes on the sewing area, and do not touch any moving parts such as the thread take-up lever, handwheel or needle. Always turn off the power switch and unplug the machine from the power supply: - when leaving the machine unattended. - when cleaning the ...

Page 11

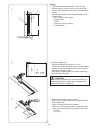

9 controlling sewing speed speed control slider you can limit the maximum sewing speed with the speed control slider according to your sewing needs. To increase the sewing speed, move the slider to the right. To decrease the sewing speed, move the slider to the left. Q w e foot control pressing on t...

Page 12

10 mode 1 mode 2 press the auto-lock key to sew a locking stitch immediately. The machine will automatically stop. When the machine is stopped, and press the auto- lock key to turn on the auto-lock function. The machine will immediately sew locking stitches and automatically stop when the machine is...

Page 13

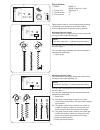

11 q mode key (refer to page 29) when the power is turned on, the pattern selection mode 1 is set automatically. Each time you press the mode key, the mode will change from 1 to 3. The selected mode is indicated on the upper left corner of the lcd screen. U i q w e r t y function keys and jog dials ...

Page 14

12 !4 !5 !6 o folder/fs key this key has two functions. 1: to stock or to recall the programmed pattern combinations (refer to page 96-97). 2: to register or to delete the favorite stitch settings (refer to page 40). !0 arrow keys (refer to pages 33, 83, 87) press “ ” or “ ” to select the stitch pat...

Page 15

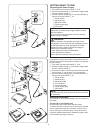

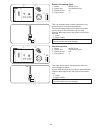

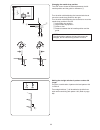

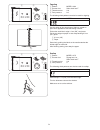

13 e w raising and lowering the presser foot r e t note: if you start the machine with the presser foot up, the lcd screen will advise you to lower the presser foot. Lower the presser foot and start sewing. The presser foot lifter or the knee lifter raises and lowers the presser foot. You can raise ...

Page 16

14 caution: to avoid damaging the lever, do not push it down. Replacing the presser foot caution: always make sure to press the lockout key to before replacing the presser foot. Use the proper foot for the selected pattern. The wrong foot can cause the needle to break. Z raise the needle by pressing...

Page 17

15 removing and attaching the foot holder remove the foot holder before using professional grade foot hp, darning foot pd-h, convertible free motion quilting foot qb-s, or dual feed foot ad. Caution: always make sure to press the lockout key to lockout the machine before replacing the foot holder. R...

Page 18

16 attaching the dual feed foot ad z attach the dual feed holder to the presser bar. Q dual feed holder x tighten the setscrew with your fingers. Push the dual feed link to engage it with upper feed drive. W dual feed link e upper feed drive c lower the presser foot lifter. Lower the needle to the l...

Page 19

17 replacing needles caution: always make sure to press the lockout key to lockout the machine before replacing the needle. Raise the needle by pressing the needle up/down key. Press the lockout key. Q needle up/down key w lockout key loosen the needle clamp screw by turning it counterclockwise. Rem...

Page 20

18 use the large spool holder for ordinary spools, while the small spool holder for small spools. R small spool t small spool holder note: avoid using a paper cored spool when it begins to empty since it will not unwind smoothly. It may cause the thread to bunch or slip when using the auto thread cu...

Page 21

19 bobbin winding while working on a sewing project there are 2 spool pins on the spool stand. You can use both spool pins when you need to wind a bobbin without unthreading the machine while working on a sewing project. Place a spool of thread on the spool pin and fix the spool with the spool holde...

Page 22

20 c winding the bobbin note: you can adjust the bobbin winding speed (refer to page 35). Z raise the retractable thread guide bar. Pass the thread through the guide on the thread guide bar from behind. Q thread guide bar x pass the thread under the bobbin winding tension disk. W bobbin winding tens...

Page 23

21 q inserting the bobbin z press the lockout key. Place a bobbin in the bobbin holder with the thread running off counterclockwise as shown on the hook cover plate. Q lockout key w end of thread e bobbin holder r hook cover plate x hold the bobbin with your fingertip so it does not rotate. Guide th...

Page 24

22 threading the machine caution: always make sure to press the lockout key to lockout the machine before threading the machine. Z press the needle up/down key to raise the take-up lever to the highest position. Press the lockout key to lockout the machine. Q needle up/down key w thread take-up leve...

Page 25

23 , m . ⁄0 m while holding the thread at the spool, firmly draw the thread up and to the back of the take-up lever. Draw the thread forward to draw it into the eye of the take- up lever. !2 eye of the take-up lever m , then pull the thread down along the left channel and through the lower thread gu...

Page 26

24 n pull the thread loop to take the thread end out through the needle eye to the rear. Note: if the thread is caught in the hook and the thread loop is not formed, remove the thread from the hook and pull it to take the thread end out through the needle eye. B raise the threader slowly so a loop o...

Page 27

25 drawing up the bobbin thread after using auto thread cutting or threading the bobbin holder, you can start sewing without drawing up the bobbin thread. However, you need to draw up the bobbin thread when sewing gathering stitches etc. Z remove the bobbin. Insert the bobbin into the bobbin holder ...

Page 28

26 v push down on the mark of the needle plate until it locks in place. Make sure the warning message disappears and the straight stitch is automatically selected. Turn the handwheel slowly and make sure that the needle does not hit the needle plate. Press the lockout key to unlock. Y mark caution: ...

Page 29

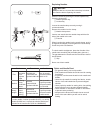

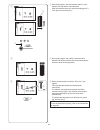

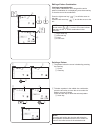

27 balancing thread tension correct tension the ideal straight stitch has threads locked between two layers of fabric. Q needle thread w right side of the fabric e wrong side of the fabric r bobbin thread t y q w e r for an ideal zigzag stitch, the bobbin thread does not show on the right side of th...

Page 30

28 dropping the feed dog the feed dog can be lowered for sewing on buttons, free motion quilting etc. Shift the drop feed lever toward you to lower the feed dog. Q drop feed lever w feed dog shift the drop feed lever away from you to raise the feed dog, it will return to the up position when you sta...

Page 31

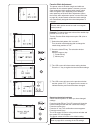

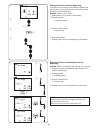

29 lcd screen when the power switch is turned on, the direct pattern selection (mode 1) is set automatically. On the lcd screen, the mode number and the following information are displayed: q selected mode or type of attached needle plate w recommended foot e recommended thread tension r recommended...

Page 32

30 selecting the pattern mode 1: direct pattern selection mode you can select the stitch patterns on the direct pattern reference window by pressing the corresponding numeral keys. Q direct pattern reference window w numeral keys w q direct pattern reference window press the stitch display key to hi...

Page 33

31 customizing direct pattern selection you can assign your favorite stitch pattern to the direct pattern selection. Note: • you cannot customize the direct pattern selection if the direct pattern reference chart is hidden. Press the stitch display key to show the reference window q. • you can assig...

Page 34

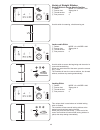

32 pattern selection in mode 2 and mode 3 • using numeral keys enter the 3-digit pattern number by pressing the numeral keys to select the desired stitch pattern. Example: selecting pattern 098 in mode 2 z press the mode key to select mode 2. Q mode key x press “0”, “9”, and “8” keys in order. X c t...

Page 35

33 v press the right arrow key to enter the desired setting. Turn the either of the jog dials to move the cursor and select the desired setting. Press the memory key to set the change. U right arrow key i memory key • using arrow keys you can use arrow keys to select your desired patterns in mode 2 ...

Page 36

34 screen brightness (page 1/3) the screen brightness can be adjusted from level 0 to 20. The preset level is 10. Turn the jog dial or press the arrow keys to adjust the screen brightness. Press the memory key to set the change. Q memory key buzzer sound (page 1/3) the level of the buzzer sound can ...

Page 37

35 favorite stitch adjustment (fs) (page 2/3) if you want to save the changes to manual stitch settings, turn on this option by turning the jog dials or pressing the arrow keys. If this option is turned off, the manual stitch setting will be cleared when the power switch is turned off. Press the num...

Page 38

36 auto-off timer (page 3/3) the machine will be automatically turned off if you do not use the machine within the time period set by this timer. The auto-off timer can be set from 1 to 12 hours. If you want to turn off the timer, turn the jog dials or press and hold the arrow key until “off” shows ...

Page 39

37 starting to sew raise the presser foot and position the fabric edge next to a seam guide on the needle plate. Lower the needle at the point where you want to start. Pull the needle thread toward the rear. Lower the presser foot. Note: pull the needle thread to the left when using satin stitch foo...

Page 40

38 cutting threads to cut the threads after finishing sewing, press the thread cutter key. The needle bar automatically rises after trimming the threads. W thread cutter key note: if you press the thread cutter key with the presser foot up, the lcd screen will advise you to lower the presser foot. L...

Page 41

39 mode 1 turn the stitch width adjusting dial clockwise to move the needle drop position to the right. Turn the stitch width adjusting dial counterclockwise to move the needle drop position to the left. Adjusting the needle drop position the needle drop position of the straight stitches can be alte...

Page 42

40 example: to change the preset value of the needle drop position from “4.5” to “5.0”. Turn the favorite stitch adjustment option on (refer to page 35). Z select the stitch pattern 001 in mode 2. Turn the stitch width adjusting dial to change the needle drop position at “5.0”. X press the folder/fs...

Page 43

41 place the fabric under the foot and lower the needle at the point where you want to start. Start sewing at medium speed. When seaming plaid fabrics, match the plaids of the upper and lower layers and pin them together. Remove the pins as you sew. Q w e sewing with the dual feed device dual feed b...

Page 44

42 sewing with the professional grade foot hp use the professional grade foot for the straight stitch with a professional result. The following stitch patterns can be sewn with the professional grade foot. See page 16 for how to attach the professional grade foot. Replace the needle plate with the p...

Page 45

43 lock-a-matic stitch q pattern: mode 1: 2 or mode 2: 002 w presser foot: zigzag foot a e thread tension: 2-6 r foot pressure: 3 use this stitch to secure the beginning and the end of a seam with backstitching. When you reach the end of the seam, press the reverse key q once. The machine will sew f...

Page 46

44 straight stitch in left needle position q pattern: mode 2: 004 w presser foot: zigzag foot a e thread tension: 2-6 r foot pressure: 3 stretch stitches q pattern: mode 2: 009 or 010 w presser foot: zigzag foot a e thread tension: 3-6 r foot pressure: 3 use this stitch to seam fabrics close to the ...

Page 47

45 fabric preparation add 1 cm (3/8“) to the zipper size. This is the overall opening size. Q right sides of the fabric w 1 cm (3/8“) e opening size r zipper size t end of the zipper opening q w e r t u i t o y place the right sides of the fabric together and sew to the end of the opening with a 2 c...

Page 48

46 x attach the zipper foot. Adjust the needle drop position to 7.5–8.5. Lower the foot onto the topside at the end of the zipper opening so that the needle pierces the fabric next to the fold and the zipper tape. Sew along the zipper guiding the zipper teeth along the side edge of the foot. Sewing ...

Page 49

47 v close the zipper and spread the fabric open flat with the right side facing up. Attach the zigzag foot a. Adjust the stitch length to 5.00, needle drop position to 4.5 (default value) and thread tension dial to 1. Baste the opened fabric and zipper tape together. I basting o zipper tape b attac...

Page 50

48 sewing z fold the edge of the fabric twice, 6 cm (2 - 3/8˝) in length and 0.3 cm (1/8˝) in width. Q 6 cm (2 - 3/8˝) w 0.3 cm (1/8˝) x place the fabric aligning the edge of the hem with the guide on the foot. Lower the foot and sew 1-2 cm (1/2˝-1˝) while pulling both thread to the back. E threads ...

Page 51

49 fold the fabric with the wrong sides together. Place the folded fabric under the blind hem foot. Align the edge of the fold with the guide on the foot, and lower the foot. You may adjust the needle drop position to 0.5-1.5 if necessary. Sew while guiding the edge of the fold along the guide. Open...

Page 52

50 note: refer to page 16 for how to attach the darning foot pd-h. To sew hold the fabric taut and depress the foot control. The machine will make one stitch and stop automatically. Slide the fabric to the rear for the next stitch. Note: use foot control for your convenience when basting. W e r q ba...

Page 53

51 zigzag stitch is used for various sewing needs including overcasting. It can be used on most woven fabrics. A dense zigzag stitch can also be used for applique. Adjusting the stitch length the stitch length of the zigzag stitches can be altered by turning the stitch length adjusting dial. Note: t...

Page 54

52 overcasting stitch q pattern: mode 2: 013 w presser foot: overcasting foot m e thread tension: 3-7 r foot pressure: 3 this stitch can be used to simultaneously seam and overcast edges of fabrics. Use this stitch when you do not need to open seams flat. Place the fabric edge next to the guide of t...

Page 55

53 overlocking stitch q pattern: mode 2: 016 w presser foot: overcasting foot m e thread tension: 6-8 r foot pressure: 3 this stitch can be used to simultaneously seam and overcast edges of fabrics. Use this stitch when you do not need to open seams flat. Place the fabric edge next to the guide of t...

Page 56

54 select pattern 018 in mode 2 for woven fabrics or pattern 19 in mode 2 for elastic fabrics. Folding the fabric fold the fabric to make a hem as shown. Q heavy fabric w fine to medium fabric e 0.4 – 0.7 cm (3/16˝–1/4˝) r overcasting t wrong side of fabric sewing position the fabric so that the fol...

Page 57: →

55 changing the needle drop position the lcd screen shows the distance between the left needle position and the guide in millimeters r. → ← e r q r w turn the stitch width adjusting dial counterclockwise to move the needle drop position to the right. Turn the stitch width adjusting dial clockwise to...

Page 58

56 use a light weight fabric (tricot, for example). Fold the fabric on the bias as shown and stitch on the fold. Allow the needle to just clear the folded edge to create a shelled edge. You may need to increase the needle thread tension. Q bias w folded edge e right needle drop position if you sew r...

Page 59

57 variety of buttonholes 023 sensor (square) buttonhole this square buttonhole is widely used on medium to heavy weight fabrics. The buttonhole size is automatically determined by placing a button in the foot. 024 automatic (square) buttonhole this is also a square buttonhole similar to the sensor ...

Page 60

58 sewing z pull the button holder to the back, and place the button in it. Push it together tightly on the button. Q button holder note: check the length of the test buttonhole, and adjust the buttonhole length if necessary by turning the adjusting screw on the buttonhole foot. To increase the butt...

Page 61

59 c draw the needle thread to the left through the hole of the foot. Mark the buttonhole position on the fabric and place it under the buttonhole foot. Lower the needle at the starting point by turning the handwheel. Y starting point c y v b i v lower the presser foot and pull the buttonhole lever ...

Page 62

60 n m , m after you finish buttonhole sewing, push the buttonhole lever up as far as it will go. , place a pin just below the bartack at each end to prevent accidentally cutting the threads. Cut the opening with the seam ripper. Use an eyelet puncher* to open a keyhole buttonhole. N the buttonhole ...

Page 63

61 adjusting the buttonhole stitch density the buttonhole stitch density can be adjusted by turning the stitch length adjusting dial. Turn the stitch length adjusting dial clockwise to make the buttonhole stitch less dense. Turn the stitch length adjusting dial counterclockwise to make the buttonhol...

Page 64

62 c place the fabric between the buttonhole foot and stabilizer plate. Lower the needle into the starting point by turning the handwheel. Lower the foot and buttonhole lever. Start the machine while pulling the needle thread lightly to the left. After sewing a few stitches, free the thread and cont...

Page 65

63 pull the button holder all the way out. Mark the buttonhole position on the fabric. Place the fabric under the foot, and lower the needle at the starting point. Lower the foot and start sewing while pulling the needle thread lightly to the left. After sewing a few stitches, free the thread and co...

Page 66

64 b when the buttonhole is finished, “m” mark e will appear. This indicates the buttonhole size has been memorized. To make the next buttonhole, position the fabric and start sewing again. The machine sews another buttonhole identical to the first one then stops automatically. To sew another button...

Page 67

65 the sewing procedure is the same as that of 023 square (sensor) buttonhole (refer to pages 58-60). Note: the buttonhole width can be adjusted from 2.6 to 9.0. The stitch density can be adjusted from 0.20 to 1.00. W e r q round end and fine fabric buttonholes q pattern: mode 2: 025 mode 2: 026 w p...

Page 68

66 c cut the filler cord at both ends as close to the buttonhole as possible. Note: set the stitch width in accordance with the thickness of the cord used. To cut the buttonhole opening, refer to the instructions on page 60. To sew a corded buttonhole, follow the same procedure as for 023 square (se...

Page 69

67 q w attaching the button sewing foot t make sure to press the lockout key to lock the machine. Insert the rear pin on the foot into the rear groove of the foot holder. Q rear pin w rear groove gently lower the presser bar while holding the foot with your fingers. Press the lockout key to unlock t...

Page 70

68 darning q pattern: mode 2: 033 w presser foot: automatic buttonhole foot r e thread tension: 3-6 r foot pressure: 3 z attach the automatic buttonhole foot r and pull the button holder all the way out. Place the fabric under the foot, and lower the needle at the starting point. Then lower the foot...

Page 71: →

69 → → → tacking is used to reinforce pockets, crotch seams and belt carriers where extra strength is needed. Sewing lower the needle at the starting point. Lower the foot and sew until the machine stops automatically. The machine will sew a tacking 1.5 cm (9/16˝) long automatically. Q tacking w sta...

Page 72

70 the eyelet is used for belt holes, etc. Attach the satin stitch foot f. To sew: place the garment under the foot and lower the needle to the starting point. Sew until the machine stops automatically. Q starting point open the eyelet with an awl, puncher or pointed scissors. To correct the shape o...

Page 73

71 (c) right fixed patterns (b) center fixed patterns (a) left fixed pattern place an applique on the fabric and baste it in place or use a fusible web to secure the applique in place. Guide the applique fabric, so that the needle falls off the edge of the applique when the needle swings to the righ...

Page 74

72 fringing adds a special touch on table linens and shawls. Choose a firm, woven fabric like linen where threads can be removed easily. Z carefully cut the fabric on the grain. Remove a single strand of yarn or thread where the fringing is to begin. X sew down the left side so the right hand stitch...

Page 75

73 choose a soft, lightweight fabric such as batiste, gingham or challis. Cut the fabric three times wider than the projected width. Sew rows of straight stitches, 1.2-1.5 cm (1/2˝) apart with the stitch length “3.0” to “5.0” and thread tension dial at “1” to across the area to be smocked. Q 1.2-1.5...

Page 76

74 use this stitch to join two pieces of fabric to create an open work appearance and add design interest. Fold under each fabric edge 1.5 cm (5/8˝) and press. Pin the two edges to paper or tear away backing 0.3 cm (1/8˝) apart. Q 0.3 cm (1/8˝) w paper sew slowly, guiding the fabric so the needle ca...

Page 77

75 angle scales on the needle plate you can easily seam patchwork pieces at the desired angle without marking, by using the angle scales on the needle plate. The angle scales are marked at 45, 60, 90 and 120 degrees. Use the broken lines when piecing the patchwork pieces with the 1/4˝ seam foot o as...

Page 78

76 q w attaching the quilting guide bar the quilting guide bar is helpful when sewing parallel, evenly spaced rows of stitching. Insert the quilting guide bar into the opening and slide the quilting guide bar to the position according to the desired space between seams. Q opening on the foot holder ...

Page 79

77 you can close quilt layers and using the clasp stitch. Select stitch 098 in mode 2. Press the memory key. Select stitch 202 in mode 2 (l.S ). Press the memory key. Start sewing. The machine sews clasp stitch and locking stitch then stops automatically. W e r q clasp stitch q pattern: mode 2: 098 ...

Page 80

78 free-quilting with darning foot pd-h stitch patterns 001, 004, 007, 008 and 011 in mode 2 can also be used for the free motion quilting. Use the darning foot pd-h when sewing those patterns. Note: a message appears when starting the machine with the feed dog lowered. Start sewing again to proceed...

Page 81

79 elongation ratio example: pattern number 127 select pattern number 127 in mode 2. Press the elongation key to select the desired elongation ratio. Elongation ratio is indicated in multiples of the original pattern length; x1 (original length) to x5. Q elongation key w elongation ratio the stitch ...

Page 82

80 twin needle sewing preparation replace the needle with the twin needle supplied with the standard accessories. Caution: turn the power switch off or press the lockout key before changing the needle. Do not use twin needles other than one included in the standard accessories, otherwise the needle ...

Page 83

81 when the twin needle mark is displayed, the pattern not suitable for the twin needle sewing will not be shown or cannot be selected (shown as the twin needle with the cross mark). T patterns not suitable for twin needle sewing note: • when you sew patterns with the twin needle, test the stitches ...

Page 84

82 v start sewing. Once sewing has started, the cursor w appears under the first pattern and will shift to the right as you sew. The information of the currently sewn pattern will be displayed on the lcd screen e. Combination of patterns 190, 188 and 184 will be sewn accordingly and repeatedly. Note...

Page 85

83 editing a pattern combination viewing a long combination if the pattern combination is too long and the entire pattern combination is not displayed, press the arrow key to view the rest of the combination. Press the right arrow key “ ” q to shift the cursor to the right. Press the left arrow key ...

Page 86

84 duplicating a pattern z press the arrow key to move the cursor under the pattern you want to duplicate. Q cursor w arrow key z x inserting a pattern q q w e z press the arrow keys to move the cursor where you want to insert a pattern. Q cursor w arrow keys x enter the desired pattern to insert. P...

Page 87

85 programming auto-lock stitch example: programming patterns 127 in mode 2 and auto-lock stitch. The machine will sew the pattern, auto-lock stitch, and stop automatically. Z select pattern 127 in mode 2. Press the memory key. Q memory key x select pattern “l.S” (202 in mode 2). Press the memory ke...

Page 88

86 mirror image example: pattern 184 in mode 2 and its mirror image z select pattern 184 in mode 2. X press the mirror image key to flip the pattern on a vertical line. The vertical mirror sign is displayed. Q mirror image key w vertical mirror sign c press the mirror image key again to flip the pat...

Page 89

87 pattern combination with a mirror image example: pattern 128 in mode 2 and its mirror image z select pattern 128 in mode 2. Press the memory key. Q memory key x select pattern 128 again. Press the memory key. C press the left arrow key “ ” to move the cursor w under the pattern you want to turn o...

Page 90

88 sewing the pattern from the beginning if you have to stop sewing in the middle of a pattern and want to sew it over again, press the startover key to sew the pattern from the beginning. Example: pattern 127 in mode 2 z select pattern 127 in mode 2. Start sewing. X sewing stopped. Q stopped positi...

Page 91

89 bridge stitches the following stitch patterns are bridge stitches, which are used to insert straight stitches after a stitch pattern. Example: combination of pattern 053 and pattern 139 in mode 2 z select pattern 053 in mode 2. Press the memory key. Q memory key x select pattern 139 in mode 2. Pr...

Page 92

90 use a blank space if you want to insert a space between stitch patterns (mode 2: pattern 201). T blank space t uniform stitch adjustment the stitch width and length of the programmed patterns can be uniformly adjusted. Example 1: adjusting the stitch width of the programmed pattern 151 in mode 2 ...

Page 93

91 individual stitch adjustment the stitch width and length can be individually adjusted for each pattern in a programmed combination. Example: changing the stitch width of the one pattern in the combination z press the arrow key to shift the cursor under the pattern you want to adjust. Q left arrow...

Page 94

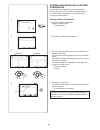

92 monogramming in mode 3, you can program text by entering the number and alphabets. Press the mode key to enter mode 3 w (monogramming mode). Q mode key • selecting a character style turn the stitch width adjusting dial clockwise or counterclockwise with the monogram selection window displayed. Th...

Page 95

93 • selecting a font style turn the stitch width adjusting dial and move the cursor out of the character style selection to change the font style. The tab of selected font style will be inverted as shown in !6. The following 3 styles are available. !5 block !6 script !7 9 mm monogram !8 font style ...

Page 96

94 programming a monogram example: to program “r&b” z press the mode key to enter mode 3. Press the stitch display key. Q mode key w stitch display key x turn the stitch length adjusting dial to select the letter “ r”. Press the memory key. E memory key c press the memory key again. The letter “ r” ...

Page 97: A A J Y Ё 1 2

95 reducing the size of letters to reduce the height of character to approximately 2/3 of its original size, select the character with the arrow key and turn the stitch width adjusting dial counterclockwise. The stitch width (the height of character) is set at “6.0” w. Q arrow key note: the size of ...

Page 98

96 storing and recalling a pattern combination up to 20 pattern combinations can be stored in the memory for future use even after turning the power off. The stored pattern combination can be recalled by pressing the folder/fs key. Storing a pattern combination z program a pattern combination. Press...

Page 99

97 recalling a stored combination z press the folder/fs key. The selection window appears when a single pattern is displayed on the lcd screen. Press the numeral key “0” to display the memory recall window. Q folder/fs key w selection window x turn the jog dials to select the memory address where th...

Page 100

98 correcting distorted stitch patterns the sewing results of the stitch patterns may vary depending upon sewing conditions, such as sewing speed, type of the fabric, number of layers etc. Always test sew on a scrap piece of the fabric that you wish to use. If stretch stitch patterns, monogram or th...

Page 101

99 cleaning the hook area clean the hook area at least once a month. Z turn the power switch off and unplug the machine. Remove the needle plate (refer to page 26). Remove the needle and presser foot. Take out the bobbin and bobbin holder. Q bobbin holder x clean the bobbin holder with a lint brush....

Page 102

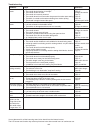

100 problems and warning signals if a buzzer sounds and the lcd screen shows a warning sign, follow the guidance below. Warning sign cause try this the foot control is out of order. Contact the service center or the store from whom the machine was purchased. The start/stop key is pressed with the fo...

Page 103

101 warning sign cause try this the twin needle key is pressed when a pattern unsuitable for twin needle sewing has been selected. Select the pattern suitable for twin needle sewing. The twin needle has to be replaced with a single needle. Replace the twin needle with a single needle, then press the...

Page 104

102 troubleshooting condition cause reference the needle thread breaks 1. The needle thread is not threaded properly. 2. The needle thread tension is too tight. 3. The needle is bent or blunt. 4. The needle is incorrectly inserted. 5. The needle thread is not set under the presser foot when start se...

Page 105

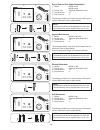

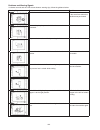

103 stitch chart * stitch patterns marked with grey can be flipped vertically. (horizontal mirror image) mode 1 mode 2 straight stitch needle plate professional grade needle plate.

Page 106

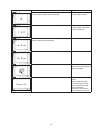

104 block (9 mm) block script stitch chart (monogram) mode 3.

Page 107

105 ec declaration of conformity manufacturer: janome sewing machine co., ltd. Address: 1463 hazama-cho, hachioji-shi, tokyo 193-0941, japan this machine complies with the following regulations: en 60335-2-28: 2003; a1 en 60335-1: 2012; a11 en 62233: 2008 en 55014-1: 2006; a1; a2 en 55014-2: 2015 en...

Page 108

106 this page is left intentionally blank.

Page 109

107 this page is left intentionally blank.

Page 110

108 this page is left intentionally blank version 1.01 11/05/2017.

Page 112

866-800-006(en).