- DL manuals

- Janome

- Sewing Machine

- Memory Craft 8900QCP

- Instruction Manual

Janome Memory Craft 8900QCP Instruction Manual

Summary of Memory Craft 8900QCP

Page 1

Aaasewing.Com janome memory craft 8900qcp instruction manual janome mc8900 instruction manual janome quilting & sewing machine www.Aaasewing.Com mc8900 owners manual/ user guide.

Page 2: Danger

Aaasewing.Com 1 important safety instructions this appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a...

Page 3

Aaasewing.Com 2 names of parts names of parts ............................................................... 3 standard accessories .................................................... 4 accessories storage ...................................................... 5 extension table ......................

Page 4

Aaasewing.Com 3 names of parts names of parts q w e r t y u i o !0 !1 !2 !3 !4 !5 !6 @6 @5 !7 !8 !9 @0 @1 @4 @3 @2 @9 #0 #1 #7 #6 #5 #2 #3 #4 #8 #9 $0 $1 $2 $4 $5 $6 $7 $3 q w e r t y u i o !0 !1 !2 !3 !4 !5 !6 !7 !8 !9 @0 @1 @2 @3 @4 @5 @6 @7 @8 @9 #0 #1 #2 #3 #4 #5 #6 #7 #8 #9 $0 $1 $2 $3 $4 $5 $6...

Page 5

Aaasewing.Com 4 zigzag foot a (set on the machine) rolled hem foot d zipper foot e satin stitch foot f open-toe satin stitch foot f2 blind hemming foot g overcast foot m 1/4 seam foot o darning foot pd-h convertible free motion quilting foot qb-s close-toe foot open-toe foot clear view foot automati...

Page 6

Aaasewing.Com 5 extension table the extension table provides an extended sewing area and can be removed for free-arm sewing. Q extension table w free-arm to detach: draw the table out to the left. To attach: slide the table on the base and push the table to the right. Free-arm sewing free-arm sewing...

Page 7

Aaasewing.Com 6 connecting the power supply z first make sure the power switch q is off. X insert the machine plug w of the power supply cord into the machine socket e . C insert the power supply plug r into the wall outlet t , and turn the power switch q on. Q power switch w machine plug e machine ...

Page 8

Aaasewing.Com 7 machine operating buttons q start/stop button press this button to start or stop the machine. The machine starts running slowly for the rst few stitches, it then runs at the speed set by the speed control slider. The machine runs slowly as long as this button is pressed. The button w...

Page 9

Aaasewing.Com 8 controlling sewing speed speed control slider youcanlimitthemaximumsewingspeedwiththespeed control slider according to your sewing needs. To increase the sewing speed, move the slider to the right. To decrease the sewing speed, move the slider to the left. Foot control pressing on th...

Page 10

Aaasewing.Com 9 function keys q stitch width adjusting key (refer to pages 34, 46, 58) press this key to alter the stitch width or needle drop position. W stitch length adjusting key (refer to pages 34, 46, 58) press this key to alter the stitch length. E edit key (refer to pages 24, 58, 94) press t...

Page 11

Aaasewing.Com 10 raising and lowering the presser foot the presser foot lifter raises and lowers the presser foot. Q presser foot lifter youcanraisethepresserfoothigherthanthenormalup position. This allows for changing the needle plate, and also helps you to place thick layers of fabrics under the f...

Page 12

Aaasewing.Com 11 adjusting the foot pressure the foot pressure can be adjusted with the foot pressure dial located under the top cover. The dial has 7 setting positions from 1 to 7. For ordinary sewing, set 5 at the setting mark. Q foot pressure dial w setting mark reduce the pressure when sewing ne...

Page 13

Aaasewing.Com 12 for general sewing, set the thread tension dial at auto, which covers a wide range of sewing conditions. Recommended tension setting for the selected pattern is indicated on the lcd screen. Q thread tension dial w recommended tension setting balancing thread tension auto-thread tens...

Page 14

Aaasewing.Com 13 changing the presser foot caution: always make sure to press the lockout key to lockout the machine or turn the power switch off before replacing the presser foot. Raise the needle to its highest position and raise the presser foot lifter. Press the black lever on the back of the fo...

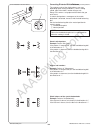

Page 15

Aaasewing.Com 14 removing and attaching the foot holder caution: always make sure to press the lockout key to lockout the machine or turn the power switch off before replacing the presser foot. Removing the foot holder raise the presser foot and loosen the setscrew. Remove the foot holder. Q w w e q...

Page 16

Aaasewing.Com 15 t y u i c attach the dual feed foot holder to the presser bar. Tighten the setscrew lightly with your nger. T dual feed link y dual feed foot holder u upper feed drive i dual feed foot v push the dual feed link to engage it with upper feed drive. B lower the presser foot lifter. Low...

Page 17

Aaasewing.Com 16 replacing the needle plate use the straight stitch needle plate when sewing ne fabrics or sewing with the dual feed foot. Caution: always make sure to press the lockout key to lockout the machine or turn the power switch off before replacing the needle plate. Z turn the handwheel an...

Page 18

Aaasewing.Com 17 changing needles caution: always make sure to press the lockout key to lockout the machine or turn the power switch off before changing the needle. Raise the needle by pressing the needle up/down button and lower the presser foot. Turn the power switch off. Loosen the needle clamp s...

Page 19

Aaasewing.Com 18 setting the spool of thread lift up the spool pin. Place the spool of thread on the spool pin with the thread coming off the spool as shown. Attach the large spool holder, and press it rmly against the spool of thread. Q large spool holder note: use the small spool holder to hold na...

Page 20

Aaasewing.Com 19 c pass the thread through the hole in the bobbin from the inside to the outside. Put the bobbin on the bobbin winder spindle. Push the bobbin to the right. The bobbin winding window appears. R hole v hold the free end of the thread in your hand and start the machine. Stop the machin...

Page 21

Aaasewing.Com 20 inserting the bobbin q w e r z place the bobbin in the bobbin holder with the thread running off counterclockwise. X guide the thread into the front notch on the bobbin holder. Q front notch c draw the thread to the left, sliding it between the tension spring blades. W tension sprin...

Page 22

Aaasewing.Com 21 c z x v b n m x q threading the machine raise the presser foot lifter to raise the presser foot. Turn the power switch on. Press the needle up/down button to raise the take-up lever to the highest position. Press the lockout key or turn the power switch off. Pass the thread in the o...

Page 23

Aaasewing.Com 22 z q w built-in needle threader notes: •theneedlethreadercanbeusedwitha#11to#16 needle. Threadsize50to90isrecommended. •theneedlethreadercannotbeusedwiththetwin needle. Z turnthepowerswitchon. Presstheneedleup/downbuttontoraisetheneedle. Pressthelockoutkeytolockthemachine. Pulldownth...

Page 24

Aaasewing.Com 23 drawing up the bobbin thread z raise the presser foot lifter. Hold the needle thread with your nger. Q needle thread x press the needle up/down button twice to draw up the bobbin thread. W needle up/down button c pull the needle thread to bring up the loop of bobbin thread. E loop o...

Page 25

Aaasewing.Com 24 the stitch patterns are classied into 11 groups and monogramming. To select the desired stitch pattern, refer to the reference chart inside the top cover to identify the stitch group and pattern number. Q the stitch patterns that start with “d” (for example, d1, d2 or d94) can be se...

Page 26

Aaasewing.Com 25 v the pattern selection window will open. Turn the jog dial and press the conrm button, or press the stitch icon to select the desired stitch pattern. B the lcd screen will display the pattern number and stitch image, along with information such as stitch width and length, recommend...

Page 27

Aaasewing.Com 26 example: stitch pattern d1 is selected. When you press the help key, the following will be displayed on the lcd screen as you turn the jog dial. Z the r st page shows the zigzag foot a and quilting guide bar for quilting. X the second page shows the rolled hem foot d for rolled hemm...

Page 28

Aaasewing.Com 27 customizing machine settings youcancustomizethemachinesettingstoyour preference. Press the set key and the lcd screen will show the machine setting window. Q set key w machine setting window to close the machine setting window, press the cross mark. E cross mark turn the jog dial to...

Page 29

Aaasewing.Com 28 sub window display time a sub window will appear when selecting certain patterns such as buttonholes. The duration of the sub window display can be altered. Q sub window q turn the jog dial to select x0.5 (1 second), x1.0 (2 seconds) or x1.5 (3 seconds). The preset time is x1.0 (2 s...

Page 30

Aaasewing.Com 29 needle stop position setting the machine always stops with the needle in the down position except when sewing buttonholes, specialty stitch- es, monograms, etc. However you can select the needle stop position to up or down. Turn the jog dial to select down or up position. Press the ...

Page 31

Aaasewing.Com 30 deleting stored pattern combinations all the pattern combinations stored in the memory bank can be deleted at one time. Press and hold the clear key or clear icon to delete all the stored pattern combinations. Q clear icon q resetting all to default the following customized settings...

Page 32

Aaasewing.Com 31 touch panel calibration if the touch panel keys seem out of alignment, calibrate the key position as follows. Z press the center of the stitch width adjusting key with the touch panel stylus. Z x press the center of the stitch length adjusting key with the touch panel stylus. X c pr...

Page 33

Aaasewing.Com 32 traditional sewing straight stitch machine settings q pattern: d1 or d1s w thread tension: auto e presser foot: zigzag foot a or dual feed foot ad r foot pressure: 5 starting to sew raise the presser foot and position the fabric next to a seam guide on the needle plate. Lower the ne...

Page 34

Aaasewing.Com 33 needle plate guides the seam guides are marked on the needle plate, free arm and hook cover. The seam guides for 1/4, 3/8 and 5/8 are also marked on the front of the needle plate. Q seam guides on the front of the needle plate the numbers on the needle plate indicate the distance fr...

Page 35

Aaasewing.Com 34 adjusting the stitch length the stitch length can be altered by pressing the stitch length adjusting key. The stitch length indication will change as the key is pressed. Note: the value in the brackets q indicates the preset setting. Press the “ ” sign on the key to move the needle ...

Page 36

Aaasewing.Com 35 using the cloth guide remove the extension table and attach the extra wide table. Attach the cloth guide to the free arm by pushing the cloth guide down to snap it in place. Slide the cloth guide to the desired position. Place the fabric with its edge against the cloth guide and sew...

Page 37

Aaasewing.Com 36 example:to change the preset value of the stitch length “2.40” to “3.00”. Select the stitch pattern you wish to change the preset value. The indication of stitch width and length are in the brackets. Q custom setting value press the stitch length adjusting key to adjust the stitch l...

Page 38

Aaasewing.Com 37 sewing with the dual feed device patterns number d1, d2, d3, d4, d94, d95, d96, d97, d98, d1s, d2s, d3s and d4s can be sewn with the dual feed device. The dual feed device is extremely effective for sewing with hard to feed material such as vinyl or leather. It also eliminates layer...

Page 39

Aaasewing.Com 38 lock-a-matic stitch machine settings q pattern: d2 or d2s w thread tension: auto e presser foot: zigzag foot a or dual feed foot ad r foot pressure: 5 q e w r use this stitch to secure the beginning and the end of a seam with backstitching. When you reach the end of the seam, press ...

Page 40

Aaasewing.Com 39 use this stitch to seam the edge of fabrics. Straight stitch with left needle position machine settings q pattern: d4 or d4s w thread tension: auto e presser foot: zigzag foot a or dual feed foot ad r foot pressure: 5 q e w r triple stretch stitch machine settings q pattern: 5 w thr...

Page 41

Aaasewing.Com 40 fabric preparation add 1 cm (3/8“) to the zipper size. This is the overall opening size. Q right sides of the fabric w 1 cm (3/8“) e opening size r zipper size t end of the zipper opening zipper sewing machine settings q pattern: d1 w thread tension: auto e presser foot: zipper foot...

Page 42

Aaasewing.Com 41 x attach the zipper foot. Adjust the stitch width to 7.5–8.5. Lower the foot onto the topside at the end of the zipper opening so that the needle pierces the fabric next to the fold and the zipper tape. Sew along the zipper guiding the zipper teeth along the side edge of the foot. S...

Page 43

Aaasewing.Com 42 v close the zipper and spread the fabric open at with the right side facing up. Attach the zigzag foot a. Adjust the stitch length to 5.0, stitch width to 4.5 (default value) and thread tension dial to 1. Baste the opened fabric and zipper tape together. I basting o zipper tape b at...

Page 44

Aaasewing.Com 43 rolled hem machine settings q pattern: d1 w thread tension: auto e presser foot: rolled hem foot d r foot pressure: 5 sewing z fold the edge of the fabric twice, 6 cm (2 - 3/8) in length and 0.3 cm (1/8) in width. Q 6 cm (2 - 3/8) w 0.3 cm (1/8) x place the fabric aligning the edge ...

Page 45

Aaasewing.Com 44 gathering machine settings q pattern: d1 w thread tension: 1 e presser foot: zigzag foot a r foot pressure: 5 q e w r pintucking machine settings q pattern: d4 w thread tension: auto e presser foot: blind hem foot g r foot pressure: 5 q e w r fold the fabric with the wrong sides tog...

Page 46

Aaasewing.Com 45 basting machine settings q pattern: 8 w thread tension: 13 e presser foot: darning foot pd-h r foot pressure: 5 t feed dog: lowered q w attaching the darning foot pd-h attach the darning foot pd-h to the presser bar by putting the pin on the needle clamp screw. Q pin w needle clamp ...

Page 47

Aaasewing.Com 46 zigzag stitch is used for various sewing needs including overcasting. It can be used on most woven fabrics. A dense zigzag stitch can also be used for applique. Adjusting the stitch length the stitch length of the zigzag stitches can be altered by pressing the stitch length adjustin...

Page 48

Aaasewing.Com 47 multiple zigzag stitch (tricot stitch) machine settings q pattern: 11 w thread tension: auto e presser foot: zigzag foot a r foot pressure: 5 q e w r this stitch is used to nish a raw edge of synthetics and other stretch fabrics that tend to pucker. Sew along the fabric edge leaving...

Page 49

Aaasewing.Com 48 knit stitch machine settings q pattern: 13 w thread tension: auto e presser foot: overcast foot m r foot pressure: 4 q e w r w q this stitch is recommended for sewing such fabrics as synthetic knits and stretch velour as it provides the greatest amount of elasticity and strength. Pl...

Page 50

Aaasewing.Com 49 w q overlocking stitch machine settings q pattern: 15 w thread tension: 6–8 e presser foot: overcast foot m r foot pressure: 5 q e w r this stitch nishes the edges of fabric similar to a commercial overlocking machine for a professional look. Place the fabric edge next to the guide ...

Page 51

Aaasewing.Com 50 select pattern 16 for woven fabrics or pattern 17 for elastic fabrics. Folding the fabric fold the fabric to make a hem as shown. Q heavy fabric w fine to medium fabric e 0.4 – 0.7 cm (3/16–1/4) r overcasting t wrong side of fabric sewing position the fabric so that the fold comes t...

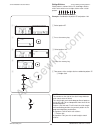

Page 52: →

Aaasewing.Com 51 changing the needle drop position press the stitch width adjusting key. The lcd screen shows the distance between the left needle position and the guide in millimeters r . → ← e r q r w press the “ ” sign to move the needle to the right. Press the “ ” sign to move the needle to the ...

Page 53

Aaasewing.Com 52 use a light weight fabric (tricot, for example). Fold the fabric as shown and stitch on the fold. Allow the needle to just clear the folded edge to create ashellededge.Youmayneedtoincreasetheneedle thread tension. Q folded edge w right needle drop position if you sew rows of shell s...

Page 54

Aaasewing.Com 53 buttonholes variety of buttonholes 23 square (sensor) buttonhole this square buttonhole is widely used on medium to heavy weight fabrics. The buttonhole size is automatically determined by placing a button in the foot. 24 square (memory) buttonhole this is also a square buttonhole s...

Page 55

Aaasewing.Com 54 q e w r square (sensor) buttonholes machine settings q pattern: 23 w thread tension: auto e presser foot: automatic buttonhole foot r r foot pressure: 5 sensor buttonhole patterns number 23 and 25 to 33 are sensor buttonholes. The size of a buttonhole is automatically set by placing...

Page 56

Aaasewing.Com 55 v mark the buttonhole position on the fabric and place it under the buttonhole foot. Lower the needle at the starting point by turning the hand wheel. U starting point u note: make sure there is no gap between the slider and front stopper, otherwise the buttonhole will be out of pos...

Page 57

Aaasewing.Com 56 n the buttonhole is sewn automatically in the sequence shown. When the buttonhole is nished, the machine will stop automatically with the needle in the up position. Press the thread cutter button and remove the fabric. Note: if you start sewing without pulling down the buttonhole le...

Page 58

Aaasewing.Com 57 using the stabilizer plate the stabilizer plate holds and supports the fabric so it is helpful when sewing buttonholes over the hem of thick fabrics. Z insert the tab of the stabilizer plate q into the slot w of the buttonhole foot. Q stabilizer plate w slot q w x place the button o...

Page 59

Aaasewing.Com 58 adjusting the buttonhole stitch density the buttonhole stitch density can be adjusted by pressing the stitch length adjusting key. Press the “ ” sign on the stitch length adjusting key to make the buttonhole stitch less dense. Press the “ ” sign on the stitch length adjusting key to...

Page 60

Aaasewing.Com 59 q e w r memory buttonholes machine settings q pattern: 24 w thread tension: auto e presser foot: automatic buttonhole foot r or satin stitch foot f r foot pressure: 5 z pull the button holder all the way out. X mark the buttonhole position on the fabric. Place the fabric under the f...

Page 61

Aaasewing.Com 60 v start sewing again, and the machine sews back with a straight stitch. Stop the machine when you reach the starting point. Then press the reverse button. B start sewing again, and the machine sews the front bartack and right side of the buttonhole. Stop the machine when you reach t...

Page 62

Aaasewing.Com 61 q e w r round end and ne fabric buttonholes machine settings q pattern: 25 or 26 w thread tension: auto e presser foot: automatic buttonhole foot r r foot pressure: 5 the sewing procedure is the same as the square (sensor) buttonhole (refer to pages 54-56). The machine will sew a bu...

Page 63

Aaasewing.Com 62 q e w r stretch buttonhole machine settings q pattern: 30 or 32 w thread tension: auto e presser foot: automatic buttonhole foot r r foot pressure: 5 the sewing procedure is the same as the square (sensor) buttonhole (refer to pages 54-56). The machine will sew a buttonhole in the o...

Page 64

Aaasewing.Com 63 q e w r corded buttonhole machine settings q pattern: 30 or 31 w thread tension: auto e presser foot: automatic buttonhole foot r r foot pressure: 5 with the automatic buttonhole foot r raised, hook the ller cord on the spur at the front of the buttonhole foot. Q spur bring the ends...

Page 65

Aaasewing.Com 64 a welted buttonhole is made by stitching a strip or patch of fabric to the buttonhole. Welted buttonholes are particularly suitable for tailored garments, but are not recommended for sheer or delicate fabrics where the patch might show through or add bulk. Z baste a patch to the gar...

Page 66

Aaasewing.Com 65 m fold over the length of the garment fabric, sew back and forth beside the original seam to secure aps of the patch. R wrong side of garment fabric t sew back and forth r t q r w e r u y u y u y u m , . ⁄0 ⁄1 ⁄2 ⁄3 , fold over the end of fabric and sew back and forth three times ov...

Page 67

Aaasewing.Com 66 button sewing machine settings q pattern: 34 w thread tension: auto e presser foot: button sewing foot t r foot pressure: 5 t feed dog: lowered q w q e w r attaching the button sewing foot t insert the rear pin on the foot into the rear groove of the foot holder. Q rear pin w rear g...

Page 68

Aaasewing.Com 67 q e w r darning machine settings q pattern: 35 w thread tension: auto e presser foot: automatic buttonhole foot r r foot pressure: 5 z attach the automatic buttonhole foot r and pull the button holder all the way out. Place the fabric under the foot, and lower the needle at the star...

Page 69

Aaasewing.Com 68 to adjust the evenness of darning stitches youcancorrectunevennessofdarningstitchesby pressing the “ ” or “ ” key of the stitch length adjusting key. If the left corner is lower than the right side, press the “–” key to correct it, and vice versa. Note: the evenness can be adjusted ...

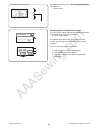

Page 70: →

Aaasewing.Com 69 → → → tacking is used to reinforce pockets, crotch seams and belt carriers where extra strength is needed. Sewing lower the needle at the starting point. Lower the foot and sew until the machine stops automatically. The machine will sew a tacking 1.5 cm (9/16) long automatically. Q ...

Page 71

Aaasewing.Com 70 q e w r fly stitches machine settings q pattern: 37 w thread tension: auto e presser foot: satin stitch foot f r foot pressure: 5 the y stitch is a triangle tacking stitch f or use on a zipper y bottom and on the side pockets of men’s pants. Attach the satin stitch foot f. To sew: p...

Page 72

Aaasewing.Com 71 adjusting the shape of an eyelet correct the shape of the eyelet as follows: if the eyelet gap opens, press “ ” on the stitch length adjusting key. If the eyelet overlaps, press “ ” on the stitch length adjusting key. Q eyelet gap opens w eyelet overlaps note: the shape can be adjus...

Page 73

Aaasewing.Com 72 q e w r applique machine settings q pattern: 41–56 w thread tension: auto e presser foot: satin stitch foot f or open-toe satin stitch foot f2 r foot pressure: 4 – place an applique on the fabric and baste it in place or use a fusible web to secure the applique in place. Guide the a...

Page 74

Aaasewing.Com 73 q e w r fringing machine settings q pattern: 41 w thread tension: auto e presser foot: satin stitch foot f r foot pressure: 4 fringing adds a special touch on table linens and shawls. Choose a rm, woven fabric like linen where threads can be removed easily. Carefully cut the fabric ...

Page 75

Aaasewing.Com 74 choose a soft, lightweight fabric such as batiste, gingham or challis. Cut the fabric three times wider than the projected width. Sew rows of straight stitches, 1 cm (3/8) apart with the stitch length “3.0” to “5.0” and thread tension dial at “1” to across the area to be smocked. Q ...

Page 76

Aaasewing.Com 75 q e w r fagoting machine settings q pattern: 68 w thread tension: auto e presser foot: satin stitch foot f r foot pressure: 5 * stitch patterns can also be used. Use this stitch to join two pieces of fabric to create an open work appearance and add design interest. Fold under each f...

Page 77

Aaasewing.Com 76 patchwork machine settings q pattern: 108 w thread tension: auto e presser foot: satin stitch foot f r foot pressure: 5 * stitch patterns can also be used. Patchwork piecing machine settings q pattern: d94-d96 w thread tension: auto e presser foot: 1/4 seam foot o or zigzag foot a o...

Page 78

Aaasewing.Com 77 attaching the quilting guide bar the quilting guide bar is helpful when sewing parallel, evenly spaced rows of stitching. Insert the quilting guide bar into the opening and slide the quilting guide bar to the position according to the desired space between seams. Q opening on the fo...

Page 79

Aaasewing.Com 78 stippling machine settings q pattern: 103 w thread tension: auto e presser foot: satin stitch foot f or open-toe satin stitch foot f2 r foot pressure: 5 * stitch patterns can also be used. Q e w r a pre-programmed stippling stitch is a fast and easy method to quilt small areas. Plac...

Page 80

Aaasewing.Com 79 changing the foot this foot is comes with the closed-toe foot attached, however, it is convertible to the open-toe foot and clear view foot. To change the foot, raise the foot and turn the round nut to bring the foot to the lowest position. Remove the setscrew and remove the closed-...

Page 81

Aaasewing.Com 80 satin stitches machine settings q pattern: 144 – 163 w thread tension: auto e presser foot: satin stitch foot f r foot pressure: 5 q e w r the stitches in this group can be elongated up to 5 times their original length while the stitch density remains the same. Elongation ratio exam...

Page 82

Aaasewing.Com 81 twin needle sewing the utility stitches and decorative stitches shown on the left can be sewn with a twin needle. Replace the needle with the twin needle supplied with the standard accessories. Caution: turn the power switch off or press the lockout key before changing the needle. D...

Page 83

Aaasewing.Com 82 press the twin needle key and select the desired pattern. Patterns not suitable for twin needle sewing cannot be selected. Buttonholes and specialty stitches such as darning or eyelet, and monogram cannot be selected. E patterns not suitable for twin needle sewing r twin needle key ...

Page 84

Aaasewing.Com 83 b start sewing. Combination of patterns 147 and 151 will be sewn continuously. Note: if you press the auto-lock button in the middle of sewing, the machine will sew to the end of the current pattern, sew locking stitches and stop automatically. Q auto-lock button programming a patte...

Page 85

Aaasewing.Com 84 programming auto-lock stitch example: programming patterns 147 and auto-lock stitch. The machine will sew the pattern, auto-lock stitch, and stop automatically. Z select pattern 147. Z x c v x press the memory key. Q c select pattern “l.S”. Q auto-lock sign w w v start sewing. Patte...

Page 86

Aaasewing.Com 85 programming automatic thread cutting to cut the threads automatically after sewing the pattern combination, press the auto thread cutter key after programming the pattern combination. The cutter sign will be indicated on the lcd screen and the led signal on the thread cutter button ...

Page 87

Aaasewing.Com 86 mirror image example: pattern 247 and its mirror image z select pattern 247. X press the mirror image key to turn over the pattern horizontally. The vertical mirror sign is displayed. Q vertical mirror sign c press the mirror image key again to turn over the pattern vertically. The ...

Page 88

Aaasewing.Com 87 pattern combination with a mirror image example: pattern 150 and its mirror image z select pattern 150. X press the memory key. C select pattern 150 again. V press the mirror image key to turn over the pattern. Q vertical mirror sign b press the memory key. N start sewing. The machi...

Page 89

Aaasewing.Com 88 sewing the pattern from the beginning if you have to stop sewing in the middle of a pattern and wish to sew it over again, press the startover key to sew the pattern from the beginning. Example: pattern 147 z select pattern 147. Start sewing. X sewing stopped. Q stopped position sew...

Page 90

Aaasewing.Com 89 bridge stitches stitch patterns number 164 to 171 are bridge stitches, which are used to insert straight stitches after a stitch pattern. Example: combination of pattern 57 and pattern 168 z select pattern 57. X press the memory key. C select pattern 168. V press the memory key. Q n...

Page 91

Aaasewing.Com 90 use a blank space if you wish to insert a space between stitch patterns. W blank space w w checking pattern combination length youcancheckthetotallengthofthepatterncombination by pressing on the stitch image window. Q stitch image window the readout of the total length is a theoreti...

Page 92

Aaasewing.Com 91 monogramming selecting a letter style press the monogram key. Q monogram key the monogram selection window will open. Press the monogram key to select the letter style. The following 5 styles are available. W block e script r broadway t russian y 9 mm monogram o w e r t y selecting ...

Page 93

Aaasewing.Com 92 programming a monogram example: to program “r&b” z press the monogram key. X select letter “r”. C press the memory key. V press the monogram key. B press the numbers and symbols icon q . Q n select letter “&”. W m press the upper case alphabet icon w . , select letter “b”. . Press t...

Page 94: A A J Y

Aaasewing.Com 93 reducing the size of letters to reduce the height of character to approximately 2/3 of its original size, select the character with the edit key and press “ ” of the stitch width adjusting key. Note: the size of 9 mm monogram cannot be reduced. A 2/3 a spacing to enter the space in ...

Page 95

Aaasewing.Com 94 editing a pattern combination viewing a long combination the lcd screen only shows up to 5 patterns or 9 charac- ters at a time. If the entire combination is not displayed, press the edit key to view the rest of the combination. Press the right arrow “ ” on the edit key to shift the...

Page 96

Aaasewing.Com 95 deleting and inserting the patterns example: deleting pattern “b” and inserting “w” from “abc”. C enter “w”. Pattern “w” will be inserted between “a” and “c”. Duplicating a pattern example: duplicating a “w”. Z press the edit key to shift the cursor under pattern “b”. X press the cl...

Page 97

Aaasewing.Com 96 uniform stitch adjustment the stitch width and length of the programmed patterns can be uniformly adjusted. Example 1: adjusting the stitch width of the programmed pattern 184 and its mirror image shift the cursor to the right of the last programmed pattern. Press the stitch width a...

Page 98

Aaasewing.Com 97 individual stitch adjustment the stitch width and length can be individually adjusted for each pattern in a programmed combination. Example: changing the stitch width of the one pattern in the combination z press the edit key to shift the cursor under the pattern you wish to adjust....

Page 99

Aaasewing.Com 98 storing and recalling a pattern combination up to 20 pattern combinations can be stored in the memory for future use even after turning the power off. The stored pattern combination can be recalled by pressing the memory recall key. Storing a pattern combination z program a pattern ...

Page 100

Aaasewing.Com 99 recalling a stored combination z press the memory recall key. Q memory recall key q x press the memory recall key or turn the jog dial to select the memory address where the desired pattern combination is stored. Press the conrm button or conrm button icon on the lcd screen to recal...

Page 101

Aaasewing.Com 100 correcting distorted stitch patterns the sewing results of the stitch patterns may vary depending upon sewing conditions, such as sewing speed, type of the fabric, number of layers etc. Always test sew on a scrap piece of the fabric that you wish to use. If stretch stitch patterns,...

Page 102

Aaasewing.Com 101 care and maintenance q q w t e r w cleaning the hook area clean the hook area at least once a month. Remove the needle plate (refer to page 16). Turn the power switch off and unplug the machine. Remove the needle and presser foot. Note: do not dismantle the machine in any way other...

Page 103

Aaasewing.Com 102 cleaning the inside of the thread guide clean the inside of the thread guide plate under the top cover at least once a month. Z remove the needle thread and remove the thread guide plate by pulling it up. Q thread guide plate q w e x remove lint and dust from the brush on the under...

Page 104

Aaasewing.Com 103 problems and warning signals if a buzzer sounds and the lcd screen shows a warning sign, follow the guidance below. The machine will stop if the buttonhole is sewn without lowering the buttonhole lever. The foot control is disconnected while sewing. The machine is started without l...

Page 105

Aaasewing.Com 104 the machine is started after halting due to overload. The feed dog is lowered while the machine is running. The presser foot is raised while the machine is running. The bobbin winder spindle is shifted to the left while winding a bobbin. The machine does not work properly due to a ...

Page 106

Aaasewing.Com 105 cause 1. The needle thread is not threaded properly. 2. The needle thread tension is too tight. 3. The needle is bent or blunt. 4. The needle is incorrectly inserted. 5. The needle thread and the bobbin thread are not set under the presser foot when start sewing. 6. The threads wer...

Page 107

Aaasewing.Com 858-800-481 q (en) janome mc8900 instruction manual janome quilting & sewing machine www.Aaasewing.Com mc8900 owners manual/ user guide.