- DL manuals

- Janome

- Sewing Machine

- MEMORY CRAFT 9000

- Service Manual

Janome MEMORY CRAFT 9000 Service Manual

Summary of MEMORY CRAFT 9000

Page 1

1 servicing manual.

Page 2

2 table of contents to change the face plate and top cover .................................................................................. 3 to change the belt cover unit ................................................................................................... 4 to change the bed cover ...

Page 3

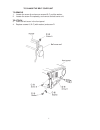

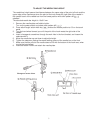

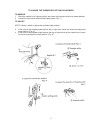

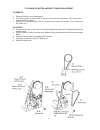

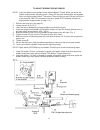

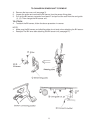

3 to change the face plate unit and top cover unit face plate unit to remove 1. Remove the two screws, and remove the face plate. To attach 2. Tighten the two screws slightly, and attach the face plate. 3. Close the face plate, and check the unevenness between the face plate and arm. Tighten the scr...

Page 4

4 to change the belt cover unit to remove 1. Loosen the screw a and remove screws b, c and the washer. 2. Loosen the screw d completely, and remove the belt cover unit. To attach 3. Insert the belt cover in the front panel. 4. Replace screws a, b. C (with washer) and screw d..

Page 5

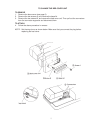

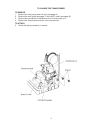

5 to change the bed cover unit to remove 1. Remove the base cover (see page 6). 2. Remove the two screws a, and remove the base lid. 3. Remove the two screws b, and remove the bed cover unit. Then pull out the connectors from the connector supporter and disconnect them. To attach 4. Follow the above...

Page 6

6 to change the base unit to remove 1. Remove the base cover. 2. Pull the connectors for the x-axis and y-axis motors from “a” board. 3. Remove the 4 screws and the base unit. To attach 4. Follow the above procedure in reverse. Check the position of feed dog “up and down”. Note: 1) set the base unit...

Page 7

7 to adjust the needle position when straight stitch #2 is selected, the needle should be at the center hole of the needle plate. When the zigzag stitch is selected with the zigzag width set to the maximum (7.0), the clearance between the side of the needle and the outer edges of the left and right ...

Page 8

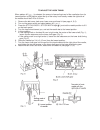

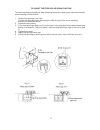

8 to adjust the needle bar height the needle bar height means the distance between the upper edge of the point of hook and the upper edge of the needle eye when the point of the hook meets the right side of the needle in the upward travel of the needle bar from the lowest position with stitch patter...

Page 9

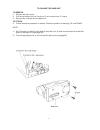

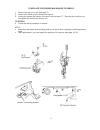

9 to adjust the hook timing when pattern #2 ( ) is selected, the amount of ascending travel of the needle bar from its lowest position to the position where the tip of the rotary hook exactly meets the right side of the needle should be 3.25 to 3.55 mm. 1. Remove the belt cover, bed cover, base cove...

Page 10

10 to adjust the upper shaft shield plate position note: when the machine is set for zigzag stitching, the needle should start to swing 7.0 to 8.2 mm above the surface of the needle plate. 1. Remove the top cover unit. 2. Turn on the power switch. Then select zigzag pattern #8 (see page 8). 3. Turn ...

Page 11

11 to adjust the needle thread tension 1. Turn on the power switch, select the pattern #9 ( ) and press the s/s key to turn the hand wheel 2 to 3 rotations. 2. Open the face plate and adjust the thread tension with a screwdriver in the direction of: a to looser the tension. B to tighter the tension....

Page 12

12 to adjust the tension release mechanism for knee lifter when the presser foot lifter is raised, the tension disc supporter should move by approx. 0.8 mm before adjusting the tension release mechanism for the knee lifter. 1. Remove the top cover unit (see page 3). 2. Lower the presser foot lifter,...

Page 13

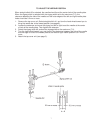

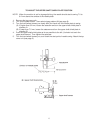

13 to change the threader plate and adjustment to remove 1. Raise the needle to its highest position and lower the threader knob to its lowest position. 2. Loosen the screw and remove the threader plate. (fig. 1) to adjust note: use #11 needle to adjust the threader plate position. 3. If the hook of...

Page 14

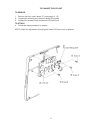

14 to change front panel (“a” board unit) 1 to remove 1. Remove top cover, belt cover and bed cover (see page 3, 4, 5), 2. Disconnect the lcd connector from inverter and remove it from cord guide. 3. Remove screw a and loosen screws b, c, d. 4. Pull out 17 connectors form the printed circuit board (...

Page 15

15 to change printed circuit board (“a” board unit) 2 to remove 1. Remove front panel (see page 14). 2. Disconnect the lcd and the touch panel flat cable and “f” board connector from “a” board unit. 3. Remove 6 screws to disconnect the printed circuit board “a” and card guide. To attach 4. Insert th...

Page 16

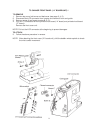

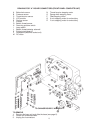

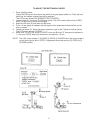

16 drawing for “a” board connectors (front panel complete unit) a buttonhole sensor n thread tension stepping motor b pressure sensor o zigzag width stepping motor c thread tension sensor p feed stepping motor d lcd module q x axis stepping motor for embroidery e position sensor r y axis stepping mo...

Page 17

17 to attach 4. Follow the above procedure in reverse. 5. Attach the base unit. (check the feed dog up/down position with “adj” key after attaching the base unit.) to change the fuse 6. After remove the board “c” case unit, remove two setscrews to pull out the printed circuit board “c”. 7. Replace t...

Page 18

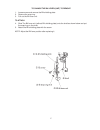

18 to change dc motor and belt tension adjustment to remove 1. Remove the belt cover (see page 4). 2. Pull out the plug connector from “a” board unit and remove 2 screws. Then remove the lamp switch fixing plate. 3. Pull out the motor connector from “a” board unit and remove 2 screws. Then remove th...

Page 19

19 to change the transformer to remove 1. Remove the front panel (board a unit) (see page 14). 2. Remove the cord guide (see page 7) and the dc motor (see page 18). 3. Remove two connectors of transformer from c board case unit. 4. Remove the three screws and pull out the transformer. To attach 5. F...

Page 20

20 to change the receptacle (machine socket unit) to remove 1. Remove the belt cover (see page 4). 2. Cut the cord binder. 3. Pull out the connectors from board a unit and board “c” case unit. 4. Remove two set screws and change the receptacle (machine socket unit). To attach 5. Follow the above pro...

Page 21

21 to change the lcd unit to remove 1. Remove the front cover (board “a”) (see page 14, 15). 2. Loosen two screws a and remove a board fixing plate. 3. Loosen four screws b and remove the lcd frame unit. To attach 4. Follow the above procedure in reverse. Note: check the adjustment of touch panel wh...

Page 22

22 to adjust presser foot sensor (1) 1. Enter adjustment mode: (turn the power switch on while pressing the s/s key and the reverse key. Next, press needle stop key within two seconds, then press the needle stop key again.) 2. Attach presser foot “a” and set the pressure dial at “3” lower the presse...

Page 23

23 to adjust presser foot sensor (2) 7. Set the presser dial at “2.” 8. Aft ach embroidery foot “p” and lower the presser foot slowly. 9. Turn the hand wheel toward you to bring the needle bar to its highest position. 10. Watch the lcd screen while moving the shielding plate along the free play. Lcd...

Page 24

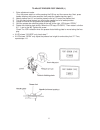

24 to adjust bobbin thread sensor note: insert the bobbin to the bobbin holder without bobbin thread. When you check the bobbin thread sensor adjusting mode. (press s/s key and reverse stitch key together while turning the power switch, then press the auto-look key and s/s key next with in a few sec...

Page 25

25 to replace the presser bar sensor to remove 1. Remove the top cover unit (see page 3). 2. Remove the screw and the presser bar sensor. 3. Unplug the presser bar sensor connector from the board “f”. Remove the cord from the cord guide and remove the sensor unit. To attach 4. Follow the above proce...

Page 26

26 to adjust the buttonhole lever 1. Enter adjusting mode. (press the s/s key and the reverse key while turning the power switch on. Press the lock stitch key and needle up/down key within seconds.) the lcd screen shows “bh sensor start closed.” 2. Loosen screw “a” and move the bh lever guide. The l...

Page 27

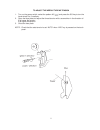

27 to change the bh lever (unit) to remove 1. Loosen screw and remove the bh shielding plate. 2. Remove the snap ring. 3. Pull out the bh lever unit. To attach 4. Slide the bh lever unit (without bh shielding plate) onto the shaft as shown below and put the snap ring on the shaft. 5. Attach the bh s...

Page 28

28 to change bh sensor unit to remove 1. Remove the top cover unit (see page 3). 2. Loosen the screw and remove the bh sensor from the sensor fixing plate. 3. Pull out the bh sensor connector from board f and pull out the cord from the cord guide (1), (2). Then change the bh sensor unit. To attach 4...

Page 29

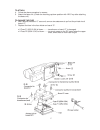

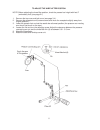

29 to adjust the feed dog up/down function the feed dog drops automatically when selecting embroidery sewing and rises auto-matically when selecting normal stitches. 1. Remove the carriage cover cap. (pull the carriage away from the machine a little and pry off the cover cap with a screwdriver, as s...

Page 30

30 to adjust the knee lifter position note: before adjusting the knee lifter position, check the presser bar height with foot p (embroidery foot) (see page 21). 1. Remove the top cover and belt cover (see page 3, 4). 2. Remove the receptacle unit (loosen screws and move the receptacle slightly away ...

Page 31

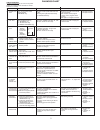

31 diagnosis chart check operation if nothing happens when you turn on the power switch, turn off the power and wait 4-5 minute. Then turn on switch. Steps 01) buzzer, led test 02) key test 03) touch panel test 04) bobbin winder switch test 05) feed dog up/ down switch key test 06) speed setting sli...