- DL manuals

- Janome

- Sewing Machine

- MY LOCK 204D

- Instruction Manual

Janome MY LOCK 204D Instruction Manual

Summary of MY LOCK 204D

Page 1

Aaasewing.Com janome 204d instruction manual model 204d janome 204d instruction manual janome 204d serger www.Aaasewing.Com 204d owners manual/ user guide.

Page 2

Aaasewing.Com 1 important safety instructions your sewing machine is designed and constructed only for household use. Read all instructions before using (this appliance). Danger - to reduce the risk of electric shock: 1. An appliance should never be left unattended when plugged in. Always unplug thi...

Page 3

Aaasewing.Com operating instruction: for appliances with a polarized plug (one blade wider than the other): to reduce the risk of electric shock, this plug is intended to fit in a polar- ized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fi...

Page 4

Aaasewing.Com 2 do’s and don’ts 1. Always be aware of the up-and-down movement of the needle and do not turn your attention away from the machine while it is running. 2. When leaving the sewing machine unattended, the main switch of the machine must be switched off or the plug must be removed from t...

Page 5

Aaasewing.Com 3 preparation names of parts .................................................. 4 standard accessories ........................................ 4 connecting the machine to the power supply ....... 5 controlling sewing speed ................................. 5 for your safety .............

Page 6

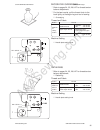

Aaasewing.Com 4 names of parts 1 left needle thread tension dial 2 right needle thread tension dial 3 upper looper thread tension dial 4 lower looper thread tension dial 5 side cover 6 looper cover 7 handwheel 8 power switch 9 machine socket 10 differential feed dial 11 stitch length dial 12 spool s...

Page 7

Aaasewing.Com 5 connecting the machine to the power supply [1] turn off the power switch, and connect the machine plug to the machine socket. [2] connect the power supply plug to your power supply. [3] turn on the power switch. Controlling sewing speed sewing speed can be varied by the speed control...

Page 8

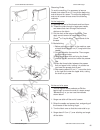

Aaasewing.Com 6 how to turn the handwheel always turn the handwheel toward you (counter- clockwise). 1 handwheel opening and closing the side cover to open: push the side cover to the left. To close: push the side cover to the right and slightly toward the machine body. 1 side cover opening and clos...

Page 9

Aaasewing.Com 7 [1] pull the thread guide bar up as far as it will go. [2] turn the thread guide bar so that the thread guides are right above the spool pins. The position of thread guide bar 1 thread guide bar 2 thread guide 3 stoppers 4 spool pin attaching the spool holder cap and net [1] when you...

Page 10

Aaasewing.Com 8 raising or lowering the presser foot by raising or lowering the presser foot lifter, the presser foot goes up and down. * while in operation, keep the presser foot lowered except when threading the machine or test- running without threads. Thread tension will not be released unless t...

Page 11

Aaasewing.Com 9 adjustment of foot pressure it is not necessary to adjust the presser foot pressure for normal sewing. When you sew heavy or lightweight fabrics, turn the adjusting screw: - clockwise for heavyweight fabric. - counterclockwise for iightweight fabric. * for normal sewing, set the adju...

Page 12

Aaasewing.Com 10 adjustment of stitch length to select stitch length, turn the dial. The larger the number, the longer the stitch. The stitch length can be adjusted from 1 to 5 mm. Position “r” is for rolled and narrow hemmings. 1 stitch length dial 2 setting mark adjustment of differential feed rat...

Page 13

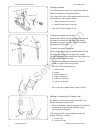

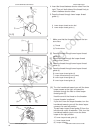

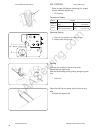

Aaasewing.Com 11 to deactivate the upper knife [1] turn off the power switch and unplug the machine. [2] open both the looper cover and side cover. [3] turn the upper knife release knob toward you while pushing it to the right, then guide the hole on the upper knife to the pin to lock the upper knif...

Page 14

Aaasewing.Com 12 adjustment of cutting width when cutting width is too narrow or too wide against seam width, adjust it as follows. [1] turn off the power switch and unplug the machine. [2] open the looper cover and side cover. [3] set the upper knife to down position [4] turn the cutting width adju...

Page 15

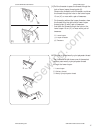

Aaasewing.Com 13 adjustment of needle plate setting knob (changing to standard serging or rolled hemming) [1] turn off the power switch and unplug the machine. [2] open the looper cover and side cover. [3] deactivate the upper knife. [4] push the cutting width adjusting dial to the right as far as i...

Page 16

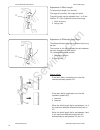

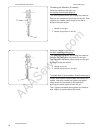

Aaasewing.Com 14 threading the machine the machine is pre-threaded to make threading easier. Tie the end of a new thread to one of the pre-set threads, and pull it to draw the new thread through the machine, following the steps below. [1] turn off the power switch before threading the machine. [2] p...

Page 17

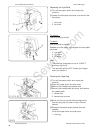

Aaasewing.Com 15 1 ● threading the lower looper open the looper cover and side cover. Place the spool of thread on the right side spool pin. * the points to thread for lower looper are marked in green. * a convenient threading chart is placed on the machine body inside the looper cover. [1] draw the...

Page 18

Aaasewing.Com 16 4. Insert the thread between tension discs from the right. Then pull both sides of the thread firmly to insert it between tension discs. 5. Pass the thread through lower looper thread guide (1). 4 lower looper thread tension dial 5 lower looper thread guide (1) * make sure that the ...

Page 19

Aaasewing.Com 17 [11]pull the threader to pass the thread through the hole of lower looper thread guide (5). Remove the thread from the threader, and draw the thread through the hole on the lower looper 10 cm (4”) or more with a pair of tweezers. * for threading without the looper threader, draw the...

Page 20

Aaasewing.Com 18 (a) (b) ● threading the upper looper place a spool of thread on the spool pin second from the right. * the points to thread for upper looper are marked in red. * a convenient threading chart is placed on the machine body inside the looper cover. [1] draw the thread through the threa...

Page 21

Aaasewing.Com 19 ● how to thread only the upper looper turn the handwheel toward you until the upper looper comes to the middle point of its travel, and unhook the thread of the lower looper from the upper looper. Thread the upper looper. When you thread the upper looper only, to avoid tangled threa...

Page 22

Aaasewing.Com 20 ● threading the needle on the right place the spool of thread on the spool pin second from the left. * the points to thread for needle on the right are marked in blue. * a convenient threading chart is placed on the machine body inside the looper cover. [1] draw the thread through t...

Page 23

Aaasewing.Com 21 [3] insert the thread between tension discs from the right. Then pull both sides of thread. 3 right needle thread tension dial [4] turn the handwheel toward you to bring the needle bar to its highest position, then pass the thread through the right needle thread guide and the thread...

Page 24

Aaasewing.Com 22 ● threading the needle on the left place the spool of thread on the left side spool pin. * the points to thread for needle on the left are marked in orange. * a convenient threading chart is placed on the machine body inside the looper cover. [1] draw the thread through the thread g...

Page 25

Aaasewing.Com 23 [3] insert the thread between tension discs from the right. Then pull both sides of thread. [4] turn the handwheel toward you to bring the needle bar to its highest position, then pass the thread through the thread take-up lever cover. 3 left needie thread tension dial 4 thread take...

Page 26

Aaasewing.Com 24 starting sewing 1. Insert the fabric under the toe of the foot. (it is not necessary to raise the foot.) 2. Turn the handwheel gently toward you a couple of turns and check the thread chain. Then start sewing slowly. The fabric will be automatically fed. Guide the fabric in the desi...

Page 27

Aaasewing.Com 25 securing ends to avoid unravelling, it is necessary to leave a thread chain about 5 cm (2”) long at the beginning and at the end of a seam. To secure the beginning and end of a seam choose one of the following methods. At the beginning a. Separate the end of the threads and knot the...

Page 28

Aaasewing.Com 26 thread tension (4 threads) correct tension the illustration at left shows sewing results with correct tension settings. However, adjusting the thread tension may be required depending upon the type of fabric and thread being used. 1 wrong side of fabric 2 right side of fabric 3 righ...

Page 29

Aaasewing.Com 27 looper thread tension is out of balance (1) the illustration shows sewing results when the lower looper thread tension is too tight and/or upper looper thread tension is too loose. Remedy: loosen lower looper thread tension and/or tighten upper looper thread tension. 1 wrong side of...

Page 30

Aaasewing.Com 28 threading the machine (3 threads) using the needle on the right only (for regular three-thread serging) turn off the power switch and unplug the machine. Remove the needle and the thread on the left. Then retighten the needle clamp screw on the left to prevent losing the screw. 1 ne...

Page 31

Aaasewing.Com 29 thread tension (3 threads) correct tension the illustration at left shows sewing results with correct tension settings. However, adjusting the thread tension may be required depending on the type of fabric and thread being used. 1 wrong side of fabric 2 right side of fabric 3 right ...

Page 32

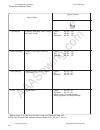

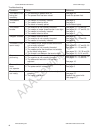

Aaasewing.Com 30 lightweight mediumweight heavyweight knits cotton, linen, satin, ordinary fabric. Tweed, coating, denim, doeskin, thick fabric. Knitted fabric. Cotton: no. 80 - 100 silk: no. 80 - 100 synthetic: no. 80 - 100 cotton: no. 60 - 100 silk: no. 50 - 100 synthetic: no. 60 - 100 cotton: no....

Page 33

Aaasewing.Com 31 needle stitch length differential feed ratio ha-1 sp no. 11 ha-1 sp no. 11 Ð 14 ha-1 sp no. 14 ha-1 sp no. 11 - 14 2.0 - 3.0 2.5 - 3.5 3.0 - 5.0 2.5 - 4.0 0.5 - 1.0 1.0 1.0 1.0 - 2.2 janome 204d instruction manual janome 204d serger www.Aaasewing.Com 204d owners manual/ user guide.

Page 34

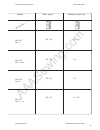

Aaasewing.Com 32 stitch length differential feed ratio needle plate setting knob needle needle thread upper and lower looper threads fabric standard setting of tension dials correct thread tension (r) (1.0) (r) (3 ~ 4) (1.0) (r) (r) (1.0) (r) needle thread tension (l) 8 3 4 5 6 7 9 0 1 2 8 3 4 5 6 7...

Page 35

Aaasewing.Com 33 thread tension for rolled hemming and picot edging correct tension the illustration at left shows sewing results with correct tension settings. Adjusting the thread tension may be required de- pending on the type of fabric and thread being used. 1 wrong side of fabric 2 right side o...

Page 36

Aaasewing.Com 34 for better results rolled hemming pull the end of thread chain to the back lightly in the beginning and end of sewing. 1 fabric 2 thread chain picot edging pull the fabric lightly to the back while sewing. 1 fabric for narrow hemming correct tension the illustration at left shows se...

Page 37

Aaasewing.Com 35 * refer to pages 24, 25, 26 & 27 for thread tension balance adjustment. * for the best results, pull the thread chain to the back lightly at the beginning and end of sewing. 1 overedging thread and fabric decorative overedging fabric medium t o heavy fabric needle threads upper loop...

Page 38

Aaasewing.Com 36 pin tucking * refer to page 29 (narrow hemming) for thread tension balance adjustment. 1 pin tucking thread and fabric fabric light to medium fabric needle thread on the right upper looper thread lower looper thread synthetic : no. 60~80 silk : no. 50~80 synthetic : no. 60~100 silk ...

Page 39

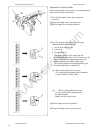

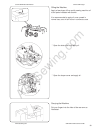

Aaasewing.Com 37 replacing the upper knife to remove: [1] turn off the power switch and unplug the machine. [2] open the looper cover and side cover. [3] deactivate the upper knife. [4] remove the hexagonal bolt, and remove the upper knife. 1 upper knife 2 hexagonal bolt 3 stopper pin 4 lower knife ...

Page 40

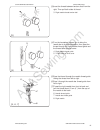

Aaasewing.Com 38 replacing the light bulb [1] turn off the power switch and unplug the machine. [2] loosen the face plate set screw, and remove the face plate. 1 face plate 2 set screw to remove: push and twist to the left. To attach: push and twist to the right. Reattach the face plate, and retight...

Page 41

Aaasewing.Com 39 oiling the machine apply a few drops of fine quality sewing machine oil to the parts indicated with arrows. It is recommended to apply oil once a week in normal use, once in ten hours in continuous use. * open the side cover and apply oil. * open the looper cover and apply oil. Carr...

Page 42

Aaasewing.Com 40 troubleshooting condition the fabric is not being fed smoothly. The needle breaks. The thread breaks. Skipped stitches the seam is not sewn neatly. Seam puckering. The machine does not operate. The fabric is not cut neatly. Cause 1. The feed dog is packed with lint. 2. The presser f...

Page 43

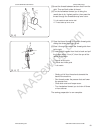

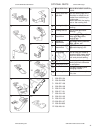

Aaasewing.Com 41 1 6 2 7 8 3 9 4 11 5 12 1 optional parts blind stitch foot taping foot with tape reel cording foot (1) cording foot (2) beading attachment gathering attachment elastic gathering attachment cloth guide piping foot (1/8”) piping foot (3/16”) needle threader gathering foot use to blind...