- DL manuals

- Janome

- Sewing Machine

- NH15

- Service Manual & Parts List

Janome NH15 Service Manual & Parts List - Parts List

Summary of NH15

Page 1

1 service manual & model: nh15 parts list.

Page 2: Contents

2 contents what to do when ...................................................................................... 3-5 service access face cover ............................................................................................... 6 top cover ...................................................

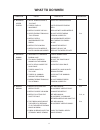

Page 3: What To Do When

3 condition cause how to fix reference 1. Skipping 1. Needle is not inserted insert the needle properly. Stitches properly. 2. Needle is bent or worn. Change the needle. 3. Incorrectly threaded rethread. 4. Needle or thread are use the recommended inappropriate for the sewing needle and thread. Fabr...

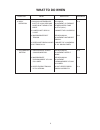

Page 4: What To Do When

4 condition cause how to fix reference 3. Breaking 1. Initial sewing speed is start with medium speed. Upper too fast. Thread 2. Thread path is use the proper thread incorrect. Path. 3. Needle is bent or dull. Replace with a new needle. 4. Upper thread tension is adjust upper thread p.10 too strong....

Page 5: What To Do When

5 condition cause how to fix reference 6. Noisy 1. Backlash between see mechanical p.16 operation shuttle hook gear and adjustment “clearance lower shaft gear is too between needle and great. Shuttle (no.2)”. 2. Lower shaft gear is eliminate the looseness. Loose. 3. Inappropriate belt see mechanical...

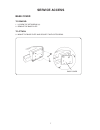

Page 6: Service Access

6 face cover setscrew(b) cap(a) setscrew(c) thread guide service access face cover to remove: 1. Remove the face cover by removing the cap (a) and setscrew (b). To attach: 2. Follow the above procedure in reverse. Top cover to remove: 1. Remove the setscrews (c). 2. Slide the corner of the top cover...

Page 7: Service Access

7 (a) base cover service access base cover to remove: 1. Loosen the setscrews (a). 2. Remove the base plate. To attach: 3. Mount the base plate and secure it with setscrews..

Page 8: Service Access

8 (b) (a) (c) (d) (e) (f) (g) (h) (i) (j) (c) service access rear cover to remove: 1. Remove the face cover and setscrew (a) (see page 4). 2. Open the shuttle cover and remove the setscrews (b), (c) and (d). 3. Remove the caps and setscrews (e), (f), (g), 4. Remove the setscrews (h) and (i). 5. Open...

Page 9: Service Access

9 (a) (b) (c) (d) (e) (f) (g) (h) service access front cover to remove: 1. Remove the face cover and top cover (see page 4 and 5). 2. Loosen the setscrew (a). 3. Remove the setscrew (b), remove the rear cover (see page 6). Loosen the setscrew (c), (e) and (h). Remove the setscrew (d). 4. Open the sh...

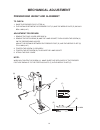

Page 10: Mechanical Adjustment

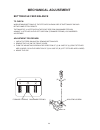

10 mechanical adjustment top tension the top tension should be between 65 and 95g when pulling the thread up in the direction of c. * use polyester sewing thread #50 (white). * if it is not within the above limit, adjust as follows. 1. Set the tension dial “3”. 2. Remove the cover. 3. Lower the pres...

Page 11: Mechanical Adjustment

11 (b) (e) (d) (c) cotton thread #50 mechanical adjustment bobbin tension to check: set the bobbin in the bobbin case and pass the thread (cotton #50) through the tension spring. The bobbin thread tension should be 45–55g when pulling the thread in the direction of (b). If the tension is out of the ...

Page 12: Mechanical Adjustment

12 (c) (a) (d) (e) (f) 6.0 mm (b) mechanical adjustment presser bar height and alignment to check: 1. Raise the presser foot lifter (a). 2. The distance between the presser foot (d) and the needle plate (e) should be 6.0 mm (0.24˝). Adjustment procedure: 1. Remove the face cover (see page 6). 2. Rem...

Page 13: Mechanical Adjustment

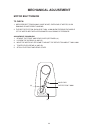

13 upper shaft worm gear setscrew (2pcs.) 2–3 mm mechanical adjustment needle swing to check: adjust the needle swing according to the following procedure, if the needle bar starts moving sideways while the needle is in the fabric at sewing the zigzag pattern (with maximum zigzag width). Adjustment ...

Page 14: Mechanical Adjustment

14 eccentric pin screw both clearances should be equal mechanical adjustment needle drop position to check: when the needle swings in maximum zigzag width, the distance between both ends of the needle hole on the needle plate and the needle drop positions should be equal. If not, adjust as follows: ...

Page 15: Mechanical Adjustment

15 mechanical adjustment clearance between needle and shuttle (adjustment method no. 1) to check: the clearance between the needle and shuttle race should be –0.05 to +0.10 mm. If not, adjust as follows: adjustment procedure: 1. Remove the face cover (see page 6). 2. Set the pattern selector dial at...

Page 16: Mechanical Adjustment

16 mechanical adjustment clearance between needle and shuttle (adjustment method no.2) to check: use this adjustment method no. 2 if the clearance cannot be adjusted by method no.1. The clearance between the needle and shuttle race should be –0.05 to +0.10 mm. Adjustment procedure: 1. Set the patter...

Page 17: Mechanical Adjustment

17 screw (a) feed lifting pin 0.75–0.90 mm needle plate mechanical adjustment feed dog height to check: 1. Lower the presser foot. 2. Turn the handwheel toward you until the needle bar comes to the feed dog above the needle plate should be 0.75–0.90 mm. If it is not in the range, adjust as follows. ...

Page 18: Mechanical Adjustment

18 mechanical adjustment needle bar height to check: when the tip of shuttle hook meets the left side of the needle in ascending travel of the needle from its left and lowest position, the distance between the top of the needle eye and the tip of the shuttle hook should be in the range of 2.9-3.5 mm...

Page 19: Mechanical Adjustment

19 mechanical adjustment needle timing to shuttle to check: the height of the needle point from its lowest point of travel should be in the range of 1.45-1.95 mm when the tip of the shuttle hook just meets the left side of the needle at the left needle position. Adjustment procedure: 1. Set the patt...

Page 20: Mechanical Adjustment

20 a b forward feeding backward feeding adjusting screw (d) (c) mechanical adjustment buttonhole feed balance to check: when sewing buttonhole, the stitches on each side of buttonhole should be the same stitch density. The range of 9-12 stitches in the right side row (backward feeding) against 10 st...

Page 21: Mechanical Adjustment

21 0.3 mm cam follower cam follower releasing arm setscrew convex part zigzag cam pattern select cam position (a) position (b) (c) mechanical adjustment disengagement of cam follower to check: too narrow clearance between the cam follower and the top convex of zigzag cam may often cause difficulty i...

Page 22: Mechanical Adjustment

22 300g load deflection 7-9mm (b) (a) mechanical adjustment motor belt tension to check: 1. Improper belt tension may cause noise, overload of motor, slow running or motor belt jumping. 2. The belt deflection should be 7 mm - 9 mm when pressing the middle of the motor belt with approximately 300 gra...

Page 23: Wiring

23 wiring 1. Wiring for machine socket unit. L m m: motor l: lamp m l 120v 240v.

Page 24: Parts List

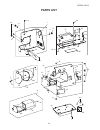

24 model: nh15 parts list 1 2 33 35 3 6 25 44 7 45 46 47 48 49 13 14 29 31 32 26 4 24 19 4 37 38 7 12 40 41 40 42 43 20 18 34 27 30 16 15 12 12 28 10 7 8 5 11 22 21 6 6 6 28 36 23 9 39 17.

Page 25: Parts List

Key parts no. No. Description 25 parts list model: nh15 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 310613909 310048701 310049001 000120203 810220003 000115205 000081005 000198305 000080901 000114709 000115...

Page 26: Parts List

26 model: nh15 parts list 1 2 3 4 5 6 7 8 9 10 19 18 17 20 11 12 13 14 16 16 21 23 22 24 25 26 28 29 30 27 15.

Page 27: Parts List

Key parts no. No. Description 27 parts list model: nh15 305604200 735221008 735222009 000101404 000070506 000138307 303017101 735027002 735028003 000111500 735029004 000001609 735030008 000013903 735025000 000081005 310621003 310801009 301505002 660106001 739605002 739017001 739018002 739019003 0000...

Page 28: Parts List

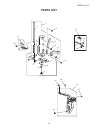

28 model: nh15 parts list 1 2 3 4 4 5 6 7 8 9 10 11 12 13 13 14 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 34.

Page 29: Parts List

Key parts no. No. Description 29 parts list model: nh15 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 face plate set plate setscrew 4x8 needle bar supportaer spring setscrew 4x6 lamp socket (unit) lamp 120v, 15w cord tie band needle bar support...

Page 30: Parts List

30 model: nh15 parts list 1 2 9 3 4 5 6 7 6 10 11 12 13 14 15 16 17 22 19 25 22 27 28 29 30 24 23 8 18 26 20 21.

Page 31: Parts List

Key parts no. No. Description 31 parts list model: nh15 310602008 102073003 000036717 732025001 639095000 000111304 749011109 000111201 761052007 731312005 304609006 304042005 743011008 304044007 304043006 000161309 000110107 732003003 000172602 743029009 310069007 000024206 502064003 502065004 3030...

Page 32: Parts List

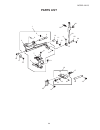

32 model: nh15 parts list 9 10 11 12 6 6 13 8 8 28 23 24 25 26 20 20 19 21 18 17 16 27 23 22 4 5 1 3 2 7 6 8 14 23 15.

Page 33: Parts List

Key parts no. No. Description 33 parts list model: nh15 310601007 310001001 310501006 310003003 000120203 000001609 505071002 000081005 310610009 737011009 000103808 310043175 310043245 310620002 000002507 735077007 735073003 000013800 648010009 000160102 739020007 310058003 000002105 735074004 7350...

Page 34: Parts List

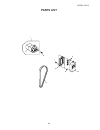

34 model: nh15 parts list 1 2 3 4 4 5 6 7 8 9 10 11 12 13 14 8 4 15 16 17 8 8 18 19.

Page 35: Parts List

Key parts no. No. Description 35 parts list model: nh15 744004001 681009101 735950003 000110107 000036201 735233003 735061008 000111304 735236006 822070003 735234004 639036003 639037004 000001609 000172602 735610101 532096007 647515006 102261000 needle plate setscrew lower shaft gear (unit) hexagona...

Page 36: Parts List

36 model: nh15 parts list 1 2 3 4 5 6 7 8 6 9 10 10 11 11 12 12 22 23 24 25 26 27 6 13 14 15 16 6 17 18 19 20 21.

Page 37: Parts List

Key parts no. No. Description 37 parts list model: nh15 735612000 735078008 735079009 735080003 000002507 000111201 735081004 735082005 735083006 735084007 735085008 000101404 301608006 301027005 735087000 735088001 735089002 735090006 000101703 739022009 000081119 743012009 743013000 102141003 7350...

Page 38: Parts List

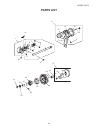

38 model: nh15 parts list 1 2 3 9 5 8 6 7 4.

Page 39: Parts List

Key parts no. No. Description 39 parts list model: nh15 743612005 014170108 000115504 739505403 000060802 739037007 000107802 000103509 650166008 motor (unit) motor setscrew tp5x10 machine socket (unit) nut machine socket cover setscrew 3x10 (b) setscrew 4x10 timing belt 1 2 3 4 5 6 7 8 9.

Page 40: Parts List

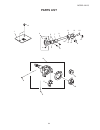

40 model: nh15 parts list 2 8 1 4 5 7 6 3 9 10 11.

Page 41: Parts List

Key parts no. No. Description 41 parts list model: nh15 1 2 3 4 5 6 7 8 9 10 11 310870009 647803004 102261000 647808009 639804000 735801008 611413002 611406002 611411000 c-1028 310800260 accessory set screwdriver (small) bobbin seam ripper (unit) needle set (unit) darning plate buttonhole foot (unit...