Summary of SEW MINI DELUX

Page 1

Service manual sew mini delux.

Page 2: Contents

Contents service access (1) face cover .................................................................................................................... 1 service access (2) front cover ..................................................................................................................

Page 3: Service Access (1)

1 sew mini service access (1) face cover 1. Remove the face cover by removing the setscrew (a). Face cover (a).

Page 4: Service Access (2)

2 sew mini service access (2) front cover to remove 1. Remove the face cover. 2. Pull out the dial and remove the set screws (a) - (e). 3. Loosen the set screws (f) - (g). 4. Remove the front cover. Note: do not remove the set screws (h). To attach 5. Follow the above procedure in reverse. Dial fron...

Page 5: Adjusting Thread Tension

3 sew mini adjusting thread tension to adjust 1. Remove the face cover and the front cover. 2. Turn the adjusting screw (c) in the direction of (a) when the upper thread tension is too tight. Turn the adjusting screw (c) in the direction of (b) when the upper thread tension is too loose. 3. Attach t...

Page 6

4 sew mini adjusting needle drop position the clearance between the needle and side edges of the needle hole should be 0.2 mm or more when the maximum width zigzag stitch ( ) is selecte. And the neddle should drop in the center of the needle hole when the straight stitch is ( ) selected. To adjust 1...

Page 7: Adjusting Needle Swing

5 sew mini to adjust 1. Remove the front cover. 2. Set the pattern selector dial at maximum zigzag width ( ). 3. Loosen two setscrews. 4. Adjust the needle swing by turning the handwheel, while holding the worm so as not to rotate it, until the needle swing starts at 1.2mm above the needle plate aft...

Page 8

6 sew mini adjusting needle to hook timing the amount of ascending travel of the needle from the right lowest position to where the hook point meets the right side of the needle should be 1.7 to 2.3mm in the maximum width zigzag stitch ( ). 1. Select the maximum width zigzag stitch ( ). 2. Remove th...

Page 9: And Hook Point

7 sew mini adjusting clearance between needle and hook point to adjust 1. Select the maximum width zigzag stitch ( ). 2. Remove the presser foot, needle plate (a) and bobbin holder (b). 3. Turn the handwheel toward you to bring the hook point behind the needle. 4. Loosen 2 setscrews (c) and adjust t...

Page 10: Adjusting Needle Bar Height

8 sew mini adjusting needle bar height the standard distance between the upper edge of the needle eye and the upper surface of the hook race should be in the range of 2.7 - 3.3mm when the hook point meets the right side of the needle in its ascending travel from the right lowest position of the maxi...

Page 11: Adjusting Stitch Length

9 sew mini adjusting stitch length when select the maximum stitch ( ), stitch length should be 3.0mm. 1. Set the pattern selector dial at maximum stitch length ( ). 2. If the stitch length is longer than 3.0mm, turn the adjusting screw in the direction (a). If the stitch length is shorter than 3.0mm...

Page 12

10 sew mini disengagement of cam follower to check too narrow clearance between the cam follower and the top convex of zigzag cam may often cause difficulty in turning of the pattern selector dial, or can not correct pattern. 1. Set the pattern selector dial at " ". 2. Remove the face cover and fron...

Page 13

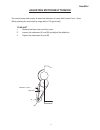

11 sew mini adjusting motor belt tension the correct motor belt tension is when the deflection of motor belt is about 7mm - 9mm. (when pushing the motor belt by finger with a 100 gram load.) to adjust 1. Remove the face cover and front cover. 2. Loosen the setscrews (a) and (b) and adjust the deflec...

Page 14: Setting Position

12 sew mini setting position of parts on upper and lower shaft upper shaft lower shaft the setting positions of the parts on the lower shaft are as shown below. The setting angle of the upper shaft bevel gear setscrew (a), lower shaft bevel gear setscrew (b) and the feed cam (c) setting mark should ...