- DL manuals

- Janome

- Sewing Machine

- Sewing Machine

- Instruction Book

Janome Sewing Machine Instruction Book

Summary of Sewing Machine

Page 1

Instruction book.

Page 2: Danger

Important safety instructions this appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsi...

Page 3

1 section i. Names of parts names of parts ............................................................. 2 standard accessories ................................................... 3 extension table ............................................................. 3 section ii. Getting ready to sew conne...

Page 4

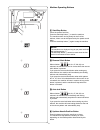

2 q w e r t y u i o !0 !1 !2 !3 !4 !5 !7 !8 !9 @0 !6 @1 @2 @3 @4 @5 @6 @7 @8 @9 #0 #1 #2 #4 #5 #6 #7 names of parts q extension table (accessory box) w needle plate e needle threader r thread cutter t face cover y presser foot pressure dial u thread take-up lever i thread tension dial o spool pin !0...

Page 5

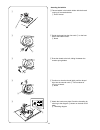

3 q w e r t y u i o !0 !1 !2 !3 !4 !5 standard accessories q bobbin w spool pin felt e needle set r additional spool pin t satin stitch foot f y zipper foot e u automatic buttonhole foot r i overedge foot c o blind hem foot g !0 seam ripper (buttonhole opener) !1 screwdriver key !2 lint brush !3 sma...

Page 6

4 section ii. Getting ready to sew connecting the power supply • using the foot control turn off the power switch q. Insert the foot control plug w into the foot control jack e. Insert the machine plug r into the power inlet t. Insert the power supply plug y into the wall outlet u. Turn on the power...

Page 7

5 speed control slider sewing speed can be varied by the speed control slider according to your sewing needs. To increase sewing speed, slide the slider to the right. To decrease sewing speed, slide the slider to the left. Controlling sewing speed depress the foot control to start the machine. The f...

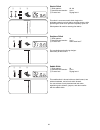

Page 8

6 q q q q q start/stop button lower the presser foot lifter. Press the start/stop button q to start the machine. The machine starts running slowly for the first few stitches; it then runs at the speed set by the speed control slider. Press the start/stop button q again to stop the machine. Notes: •t...

Page 9

7 t t t t t cursor buttons use these buttons to move the cursor u. Press button to move the cursor to right. Press button to move the cursor to left. Y y y y y value set buttons use these buttons to change the set value. Move the cursor under the digit you would like to change. Press button to incre...

Page 10

8 presser foot pressure dial the presser foot pressure dial should be set at “6” for regular sewing. Reduce the pressure to “3” for applique, cutwork, drawn work, basting and embroidery. Set the pressure to “2” to “4” when sewing chiffon, lace, organdy and other fine fabrics. Velour and knits with a...

Page 11

9 changing the needle z x c selecting thread and needles for general sewing, use needle size 11/75 or 14/90. A fine thread and needle should be used for sewing lightweight fabrics, so the fabric will not be marred. Heavy fabrics require a needle large enough to pierce the fabric without fraying the ...

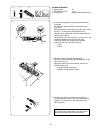

Page 12

10 bobbin winding • removing the bobbin gently slide the hook cover release button q to the right and remove the hook cover plate w. Lift out the bobbin. Q hook cover release button w hook cover plate • horizontal spool pin lift up the spool pin q. Place a spool of thread on the spool pin with the t...

Page 13

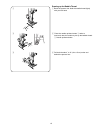

11 z x c • winding the bobbin note: set the speed control slider at its fastest position for bobbin winding. X c v b q m z draw the thread from the spool. X guide the thread around the thread guide. Note: for safety purposes, the machine will stop automatically 2 minutes after the start of bobbin wi...

Page 14

12 • inserting the bobbin z place a bobbin in the bobbin holder with the thread running off counterclockwise. Q end of thread z x c v b x guide the thread into the first notch w on the front side of the bobbin holder. W notch c draw the thread to the left, sliding it between the tension spring blade...

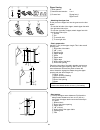

Page 15

13 z x c v b w z c v b x z draw the end of the thread around the upper thread guide. Threading the machine • threading the machine caution: turn off the power switch before threading the machine. X while holding the thread near the spool w, draw the end of the thread down around the check spring hol...

Page 16

14 q z x v w e w r note: the needle threader can be used with a #11 to #16 needle or a blue tipped needle. Thread sizes 50 to 90 are recommended. Needle threader caution: turn off the power switch when using the needle threader. T c z lower the presser foot. Raise the needle to its highest position....

Page 17

15 drawing up the bobbin thread z raise the presser foot. Hold the needle thread lightly with your left hand. X press the needle up/down button q twice to lower and raise the needle to pick up the bobbin thread. Q needle up/down button c pull both threads 4˝ to 6˝ (10 to 15 cm) under and behind the ...

Page 18

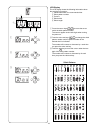

16 lcd display the lcd display shows the following information when the machine is turned on. Q identification letter for recommended foot w stitch pattern number e cursors r stitch width t stitch length q w e r t z x c z press the cursor keys to move the cursor under the stitch pattern number. The ...

Page 19

17 adjusting the needle thread tension for a straight stitch • correct tension q needle thread (top thread) w bobbin thread (bottom thread) e to loosen r to tighten the ideal straight stitch has threads locked between two layers of fabric, as illustrated (magnified to show detail). If you look at th...

Page 20

18 adjusting the needle thread tension for a zigzag stitch for an ideal zigzag stitch, the bobbin thread does not show on the right side (top side) of the fabric, and the needle thread shows slightly on the wrong side (bottom side) of the fabric. See the illustrations for the correct appearance. To ...

Page 21

19 q e w straight stitch sewing q stitch pattern: 00 or 01 w needle thread tension: 2 to 6 e presser foot: zigzag foot a • sewing from the edge of thick fabric the black button q on the zigzag foot locks the foot in the horizontal position. This is helpful when starting sewing from the far edge of t...

Page 22

20 needle plate the seam guides on the needle plate and the hook cover help you to measure seam allowance. The numbers on the needle plate indicate the distance between the center needle position q and the edge of the fabric w. Q center needle position w edge of the fabric q w number distance (cm) d...

Page 23

21 q e w q e w q e w q e w lock-a-matic stitch q stitch pattern: 02 w needle thread tension: 2 to 6 e presser foot: zigzag foot a r reverse button use this stitch to secure the beginning and the end of a seam with backstitching. When you reach the end of the seam, press the reverse stitch button r o...

Page 24

22 q e w q e w q e w stretch stitch q stitch pattern: 05, 06 w needle thread tension: 3 to 6 e presser foot: zigzag foot a saddle stitch q stitch pattern: 32 w needle thread tension: 3 to 6 e presser foot: zigzag foot a sculpture stitch q stitch pattern: 31 w needle thread tension: 3 to 6 e presser ...

Page 25

23 the zigzag stitch is one of the most useful and versatile stitches. It is used for overcasting, mending, appliqué, and also used as a decorative stitch. Note: use an interfacing when sewing on stretch fabrics such as knit, jersey or tricot. Q e w r u zigzag stitch q stitch pattern: 07 w needle th...

Page 26

24 q e w overcasting with zigzag stitch q stitch pattern: 07 w needle thread tension: 3 to 7 e presser foot: overedge foot c q e w multiple zigzag q stitch pattern: 08 w needle thread tension: 3 to 6 e presser foot: zigzag foot a this stitch is used to finish seams on synthetics and other fabrics th...

Page 27

25 q e w q e w overedge stitch q stitch pattern: 11 w thread tension dial: 3 to 7 e presser foot: overedge foot c this stitch pattern combines the straight and the zigzag stitches, using the overedge foot, to seam and overcast in one step. It is ideal for 1/4˝ (0.6 cm) seams on knits (when attaching...

Page 28

26 notes: • to sew the buttonholes 50 to 56, follow the same procedure as square bh (see page 27 to 28.). • the size of a buttonhole is automatically set by placing a button in the rear of automatic buttonhole foot r. • the button holder of the foot takes a button size of up to 1˝ (2.5 cm) in diamet...

Page 29

27 q e w square buttonhole q stitch pattern: 50 w thread tension dial: 1 to 5 e presser foot: automatic buttonhole foot r r buttonhole lever sign q w t y u i !0 o z x e r c v • to sew z press the needle up/down button to raise the needle. Attach the automatic buttonhole foot r snapping the pin w int...

Page 30

28 b b start the machine to sew the buttonhole. The buttonhole will be automatically sewn. The machine will sew the left row first. N m n the machine will sew the back bartack and the right row. M the machine will sew the front bartack, then it stops automatically. Note: if you start sewing the butt...

Page 31

29 adjusting the stitch width and density for buttonholes • adjusting the stitch width press the cursor buttons to move the cursor under the stitch width value “5.0” q (default setting). Press the button to decrease buttonhole width w. Press the button to increase buttonhole width e. The stitch widt...

Page 32

30 q e w keyhole buttonhole q stitch pattern: 55 w thread tension dial: 1 to 5 e presser foot: automatic buttonhole foot r r eyelet punch sewing procedure is the same as square buttonhole. Use the seam ripper and an eyelet punch r to open the buttonhole. The stitch width can be varied from 5.5 to 7....

Page 33

31 q e w corded buttonhole q stitch pattern: 50 w thread tension dial: 1 to 5 e presser foot: automatic buttonhole foot r z use the same procedure as the square buttonhole procedure. Set the stitch width to match the thickness of the cord used. With the buttonhole foot raised, hook the filler cord o...

Page 34

32 q e w darning stitch q stitch pattern: 57 w thread tension dial: 3 to 6 e presser foot: automatic buttonhole foot r • starting to sew z pull the button holder q to the back. X place the garment under the foot. Press the needle up/down button twice. Move the fabric to the left to draw both threads...

Page 35

33 q e w q r t w r e tacking q stitch pattern: 58 w thread tension dial: 3 to 6 e presser foot: satin stitch foot f tacking is used to reinforce pockets, crotches and belt carriers where extra strength is needed. • start sewing start the machine and sew until the machine stops automatically. The mac...

Page 36

34 q e w zipper sewing q stitch pattern: 00 w needle thread tension: 1 to 4 e presser foot: zigzag foot a zipper foot e w e r • attaching the zipper foot fit the pin on the zipper foot into the groove on the foot holder. • to sew the left side of the zipper, attach zipper foot with the right-hand si...

Page 37

35 x c i o v !0 !1 b n !2 m zipper sewing (continued) x attach the zipper foot with the pin on the right. Sew through all the layers from the end of the zipper opening, guiding the zipper teeth along the edge of the foot. C stop the machine 2˝ (5 cm) before the foot reaches the slider on the zipper ...

Page 38

36 q e w blind hemming q stitch pattern: 13 or 14 w thread tension dial: 1 to 4 e presser foot: blind hem stitch foot g z fold a hem with the wrong side of the fabric up to form a 1/4˝~7/16˝ (0.4~0.7 cm) allowance. Q wrong side of fabric w 1/4˝~7/16˝ (0.4~0.7 cm) (1) on heavyweight fabrics that tend...

Page 39

37 q e w r button sewing q stitch pattern: 07 w needle thread tension: 3 to 7 e presser foot: satin stitch foot f r feed dog: dropped z lower the feed dog. X match the holes of button to the horizontal slot on the presser foot. C lower the foot to hold the button in place. V adjust the stitch width ...

Page 40

38 q e w scallop stitch q stitch pattern: 41 w thread tension dial: 3 to 6 e presser foot: zigzag stitch foot a sew the stitches approximately 3/8˝ (1 cm) inside the edge of the fabric. Trim the outside of the stitches as shown. Make sure you don’t cut the thread. Q e w applique q stitch pattern: 17...

Page 41

39 q e w patchwork piecing q stitch pattern: 30 and 37 w thread tension dial: 3 to 6 e presser foot: zigzag foot a w z place the patchwork pieces right sides together. Select stitch pattern 30. Align the edges of the fabrics to the 1/4˝ front seam guide e. Sew a precise 1/4˝ seam allowance. Q wrong ...

Page 42

40 q e w fagoting q stitch pattern: 43 w thread tension dial: 3 to 6 e presser foot: satin stitch foot f use this stitch to join two pieces of fabric to create an open work appearance and add design interest. Fold under each fabric edge 5/8˝ (1.5 cm) and press. Pin the two edges to paper or tear bac...

Page 43

41 cross stitch q stitch pattern: 46 w thread tension dial: 3 to 6 e presser foot: satin stitch foot f * stitch pattern 48 can also be used. Q e w you can make cross stitch designs with these patterns, in half the time it would take if embroidered by hand. * if you press the auto-lock button before ...

Page 44

42 q e w decorative stitch combinations q stitch pattern: 25 and 27 w thread tension dial: 3 to 6 e presser foot: satin stitch foot f to combine two units of pattern 25 and 27. Z sew pattern 25 and press the auto-lock button while sewing the second unit. The machine will stop automatically when the ...

Page 45

43 section v. Care of your machine cleaning the hook race and feed dog warning: • turn the power switch off and unplug the machine before cleaning. • do not dismantle the machine other than as explained in this section. Caution: do not store the machine in a high-humidity area, near a heat radiator,...

Page 46

44 audible signal pip pip-pip-pip pip-pip-peep peep the buzzer sounds when: normal operation invalid operation buttonhole sewing completed malfunction problems and warning signs cause try this the machine will not sew with the start/stop button because the foot control is connected. Disconnect the f...

Page 47

Troubleshooting condition the needle thread breaks. The bobbin thread breaks. The needle breaks. Skipped stitches seam puckering the cloth is not feeding smoothly. Stitches form loops below the works. The machine does not work. Buttonhole sewing is not sewn properly. The machine does not run smoothl...

Page 48

808-800-109(eng) printed in taiwan.