Summary of Skyline S5

Page 1

Service manual skyline s5.

Page 2

Index changing external parts face cover ...........................................................................................................................................1 belt cover ..............................................................................................................

Page 3: Changing External Parts

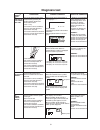

1 changing external parts face cover to remove: 1. Remove the setscrews a. Remove the face cover. To attach: 1. Follow the above procedure in reverse. Setscrew a face cover belt cover to remove: 1. Remove the setscrews a and b. 2. Loosen the setscrew c. 3. Remove the belt cover from the main body. B...

Page 4: Changing External Parts

2 changing external parts flange plate pin fig. 2 top cover to remove: 1. Raise the carrying handle and remove the setscrew a. 2. Open the top cover. Pull out the flange plate from the bobbin winder spindle (see fig. 2). 3. Remove the setscrews b and c. 4. Open the face cover. Close the top cover. R...

Page 5: Changing External Parts

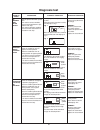

3 changing external parts machine base to remove: 1. Remove the setscrews a. 2. Remove the machne base. To attach: 1. Follow the above procedure in reverse. Setscrew a setscrew a setscrew a setscrew a machine base base cover to remove: 1. Remove the setscrews b. 2. Remove the base cover. To attach: ...

Page 6: Changing External Parts

4 free arm cover to remove: 1. Remove the machine base and base cover (see page 3). Press the needle plate release lever to remove the needle plate. Needle plate release lever needle plate changing external parts 2. Remove the pin. Loosen the setscrew. 3. Unlock the hook a (inside of the machine bas...

Page 7: Changing External Parts

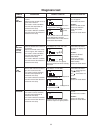

5 changing external parts setscrew a setscrew a front cover to remove: 1. Remove the top cover, belt cover, base cover, machine base and free arm cover (see pages 1-4). 2. Loosen the setscrews a (inside of the machine base). Setscrew b setscrew c setscrew d 3. Remove the setscrew b. 4. Loosen the se...

Page 8: Changing External Parts

6 changing external parts fig. 1 rear cover setscrew a setscrew b fig. 2 setscrews c rear cover to remove: 1. Lower the presser foot. 2. Remove the belt cover, top cover and base cover (see pages 1, 2 and 3). 3. Loosen the setscrews a and b (see fig. 1). Remove the setscrews c (see fig. 2) 4. Push t...

Page 9

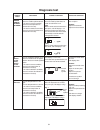

7 slide volume printed circuit board l1 (underside of the arm) printed circuit board a connection replacing electronic components printed circuit board a note: do not disconnect the connectors by pulling on cord. To disconnect the connectors, grasp the connector, not the cord. To remove: 1. Remove t...

Page 10

8 setscrew cs rings printed circuit board f t o remove: 1. Remove the front cover (see page 5). 2. Disconnect the connector from the printed circuit board a (see page 7). 3. Remove the cs rings. 4. Remove the setscrews, and the printed circuit board f. To attach: 1. Follow the above procedure in rev...

Page 11

9 switching power supply unit to remove: 1. Remove the belt cover, the top cover and the front cover (see pages 1, 2 and 5). 2. Loosen the setscrew a. Remove the cord guide plate. (see fig. 1) 3. Disconnect the switching power supply connector from the switching power supply unit.(see fig. 2) 4. Rem...

Page 12

10 200 g pressure 5 mm setscrews setscrews dc motor to remove: 1. Remove the belt cover, the top cover and the front cover (see pages 1, 2 and 5). 2. Disconnect the dc motor connector from the printed circuit board a (see page 7). 3. Remove the motor belt. 4. Remove the setscrews (2 pcs), and the dr...

Page 13

11 replacing electronic components thread tension unit to remove: 1. Remove the top cover and the front cover (see pages 1 and 5). 2. Disconnect the solenoid 1 thread tension release connector from the printed circuit board a (see page 7). 3. Remove the spring on the thread tension release lever (se...

Page 14: Mechanical Adjustment

12 mechanical adjustment nut setscrew a adjusting screw b presser foot 0.80 – 0.90 mm surface of needle plate feed dog hexagonal socket screw i setscrew d threaded hole c feed dog height when the foot pressure dial is at “7” and the presser foot a is lowered, the highest position of the feed dog sho...

Page 15: Mechanical Adjustment

13 to adjust: 1. Attach the needle #14. 2. Turn the power switch on. Select straight stitch. Check that the needle drop position is centered when the drop position is set at "4.5", and the clearance between the side of the needle and the needle hole is 0.2 mm or more when the needle position is set ...

Page 16: Mechanical Adjustment

14 should be pararell mechanical adjustment presser bar height the clearance between the presser foot and the surface of the needle plate should be 6 mm when the presser foot is raised. The presser foot (zigzag foot a) should be pararell to the slot of the feed dog teeth when attached. Zigzag foot a...

Page 17: Mechanical Adjustment

15 mechanical adjustment setscrew c setscrew b setscrew a hook base plate adjustment 1 1. Remove the bed cover (see page 3). 2. Turn the power switch on, and select the zigzag stitch pattern 11. Adjust the stitch width at its maximum (9.0). 3. Remove the presser foot, needle plate and bobbin holder....

Page 18: Mechanical Adjustment

16 mechanical adjustment master needle tip of hook -0.1 to +0.05 mm master needle left needle position right needle position 1. Remove the top cover (see page 2). 2. Remove the presser foot, the needle plate and the bobbin holder. (see page 4) * cover the needle plate with the fabric to prevent dama...

Page 19: Mechanical Adjustment

17 mechanical adjustment 3.70 to 4.00 mm lowest needle position needle #14 bobbin holder setscrews a hook tip of hook hook hook timing the amount of ascending travel of the needle bar from its lowest position to the position (needle drop position 0.0) where the tip of the rotary hook exactly meets t...

Page 20: Mechanical Adjustment

18 mechanical adjustment 1. Attach the needle #14. 2. Turn the power switch on. Select straight stitch. Set the needle drop position at "0.0". * do not turn the switch off. 3. Remove the presser foot, the needle plate and the bobbin holder. (see page 4) * cover the needle plate with the fabric to pr...

Page 21: Mechanical Adjustment

19 mechanical adjustment presser bar lifter switch position adjustment presser bar lifter switch setscrew a 4 – 5.5 mm normal up position lowered position switch set plate to check: 1. While pressing the needle up/down and lock stitch buttons, turn the power switch on. The lcd displays "----". 2. Pr...

Page 22: Mechanical Adjustment

20 a a b b lower shaft bushing hexagonal socket screw (c) lower shaft gear hook driving gear lower shaft gear lower bushing of the front side lower bushing of the belt cover lower shaft bushing hexagonal socket screw (d) mechanical adjustment backlash between hook drive gear and lower shaft gear the...

Page 23: Mechanical Adjustment

21 even sensor upper shaft shield plate needle #14 surface of needle plate mechanical adjustment upper shaft shield plate position when the machine is set for zigzag stitch, the needle should start to swing 7.2 to 8.2 mm above the surface of the needle plate. 7.2 – 8.2 mm fig. 1 setscrew a feed sens...

Page 24: Mechanical Adjustment

22 pulling direction: (pulling speed 110 mm/sec.) mechanical adjustment upper thread tension the standard upper thread tension should be 75 to 90 grams when pulling the thread (while polyester thread size 50) at the speed of 110 mm/sec with the tension at "auto" (be sure the presser foot is lowered)...

Page 25: Mechanical Adjustment

23 threader plate supporter (a) pin (b) hook groove mechanical adjustment needle threader plate if the hook of the threader plate is damaged, change or adjust the part as follows: to remove: 1 push down the needle threader knob and pull the needle threader plate (a) down to remove it (see fig. 1). 2...

Page 26: Mechanical Adjustment

24 mechanical adjustment buttonhole lever adjustment to prepare: 1. While pressing the needle up/down and lock stitch buttons, turn the power switch on. The lcd display “----”. Press “5” key to enter the sesor test mode. 2. Attach the automatic buttonhole foot r. Place a piece of paper between the p...

Page 27: Mechanical Adjustment

25 end of thread cutter plate slit 0.4 to 1.2 mm edge of moving cutter sensor plate setscrew a b thread cutter switch thread cutter base plate moving cutter mechanical adjustment thread cutter the distance between the end of thread cutter plate slit and the edge of moving cutter should be in the ran...

Page 28: Mechanical Adjustment

26 mechanical adjustment setscrews a 2 mm top view side view end of yoke plunger solenoid position adjustment when the tension disk is closed, the clearance between the plunger and the end of yoke should be 2.0 mm. [to check] 1. While pressing the needle up/down and lock stitch buttons, turn the pow...

Page 29: Mechanical Adjustment

27 mechanical adjustment to adjust: 1. While pressing the needle up/down and lock stitch buttons, turn the power switch on. The lcd display “----”. Press “8” key. 2. Set the stretch stitch balance dial c at the setting mark d. 3. Sew test patterns and check the measurement of five of them. The range...

Page 30: Mechanical Adjustment

28 setscrews tp needle plate sensor switch setscrews tp needle plate base plate fixed cutter spacer micro switch base plate micro switch needle plate sensor knob needle plate 11 – 11.5 mm bottom side of needle plate actuator mechanical adjustment needle plate switch to check and adjustment: 1. Prepa...

Page 31: Mechanical Adjustment

29 mechanical adjustment needle plate replacing bar 1. While pressing the needle up/down and lock stitch buttons, turn the power switch on. The lcd display “----”. Press “5” key to enter the sensor test mode. Needle plate attached: needle plate for straight stitch attached: 2. Be sure that s symbol ...

Page 32: Diagnosis Test

30 note: 1. Be sure to disconnect the macine from the power supply when replacing parts. 2. The language on the lcd is english only. Preparation 1. Shift the bobbin winder spindle to the right. 2. Turn the drop feed lever to the right (away from you) to raise the feed dog. 3. Slide the speed adjusti...

Page 33: Diagnosis Test

31 lcd displays “04” and “bo”. When the bobbin winder spindle is moved to the right, buzzer sounds and the bobbin symbol appears on lcd. When the bobbin winder spindle is moved to the left, buzzer sounds and the bobbin symbol disappears. Correct condition sewing lamp and lcd backlight lit. Lcd displ...

Page 34: Diagnosis Test

32 correct condition step and items to check 05) presser foot lifter switch procedure defective condition turn the handwheel toward you. Lower the needle bar from its highest to lowest position. Raise the needle bar from its lowest position to highest position. If the result is correct condition, pr...

Page 35: Diagnosis Test

33 correct condition lcd displays “08” and “fc”. Lcd displays “09”, “fcut” and “-off”. Step and items to check 08) foot control procedure attach the foot control to the machine. Depress the foot control as far as it goes, then release it. If the result is correct condition, press the start/stop butt...

Page 36: Diagnosis Test

34 thread cutter symbol lcd displays “13” and “cut”. The thread cutter symbol will blink, and thread cutter motor will be initialized. 13) thread cutter motor, thread cutter solenoid turn the handwheel toward you to raise the needle bar at its highest position. Press the needle up/down button. If th...

Page 37: Diagnosis Test

35 14) needle plate lcd displays “15”. When the needle plate is attached to the machine, lcd displays “psz”. When the needle plate for straight stitch is attached to the machine, lcd displays “pss”. When nothing is attached to the machine, lcd displays “15” only. Attach the needle plate. Attach the ...

Page 38: Diagnosis Test

36 m “t5” will be shown on the lcd screen. Press u on the touch panel. C the key position adjustment screen appears and “t1” is shown on the right side of the screen. With the touch panel stylus w, press e on the touch panel of your machine. V “t2” will be shown on the lcd screen. Press r on the tou...