- DL manuals

- Jasic

- Welding System

- Cut 45P

- Operator's Manual

Jasic Cut 45P Operator's Manual

Summary of Cut 45P

Page 1

Wilkinsonstar.Com cut 45p air plasma cutting machine order code ! Jp-45p operator manual.

Page 2: Your New Product

Your new product thank you for selecting this jasic technology, wilkinson star product. This product manual has been designed to ensure that you get the most from your new product. Please ensure that you are fully conversant with the information provided paying particular attention to the safety pre...

Page 3: Safety Precautions

Safety precautions 1 these general safety norms cover both arc welding machines and plasma cutting machines unless otherwise noted. The equipment must only be used for the purpose it was designed for. Using it in any other way could result in damage or injury and in breach of the safety rules. Only ...

Page 4

Do not weld on coated metals, unless the coating is removed from the weld area, the area is well ventilated, and while wearing an air-supplied respirator. The coatings on many metals can give off toxic fumes if welded. Prevention against burns and radiation arc rays from the welding process produce i...

Page 5

Rf declaration equipment that complies with directive 2004/108/ec concerning electromagnetic compatibility (emc) and the technical requirements of en60974-10 is designed for use in industrial buildings and not those for domestic use where electricity is provided via the low voltage public distributi...

Page 6: Product Overview

Product overview 2 this is a digital plasma cutting machine with high performance and using advanced technology. The cut45p is an ultra-portable plasma cutting system suitable for a variety of application requirements. It can be used in handheld cutting or with automated cutting systems. The cut45p ...

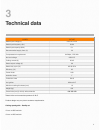

Page 7: Technical Data

Technical data 3 tested at the environment temperature of 40 0 c product design may vary due to customer requirements. Cutting speed guide - quality cut 12 mm at 500 mm/min 19 mm at 250 mm/min 6 model cut45p rated input voltage (v) 230v ac±15% rated input frequency (hz) 50/60 rated input capacity (k...

Page 8: Controls

Controls 4 panel layout front rear 7 1 air pressure guage 5 mains input cable 2 work return connector 6 mains on/off switch 3 torch connector 7 air inlet connection 4 current control knob.

Page 9

Front panel of cut45p no. Symbol function 1 power indicator: it illuminates when the machine is powered on, and it flashes after arc is successfully ignited. 2 overheating indicator: it illuminates when the working temperature of the igbt is too high. When in this state, the machine stops working. 3...

Page 10: Installation

Installation 5 unpacking check the packaging for any signs of damage. Carefully remove the machine and retain the packaging until the installation is complete. Location the machine should be located in a suitable position and environment. Care should be taken to avoid moisture, dust, steam, oil or c...

Page 11

Operation of the reducer valve embedded filter reducer the embedded filter reducer is correctly set when leaving factory, and users do not need to set it themselves in general. If users need to set the embedded filter reducer, the machine cover should be opened as shown in the above figure. Ensure t...

Page 12: Operation

Operation before starting any cutting activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the area. Check that all connections have been made as shown above check the following before starting the machine. 1) chec...

Page 13

Maintenance and troubleshooting 6 the following operation requires sufficient professional knowledge on electric aspects and comprehensive safety knowledge. Make sure the input cable of the machine is disconnected from the electricity supply and wait for 5 minutes before removing the machine covers. I...

Page 14: Electrical Schematic

Electrical schematic 7 13.

Page 15: Parts List

Parts list 8 cut 45p - (jp-45p) 14.

Page 16

15 no. Part no description no. Part no description 1 10004949 mains switch 20 10048680 rear panel 2 10048390 filter 21 10041723 gas connection 3 10048683 mid section plate 22 10041446 fan 4 10041724 handle 23 10048677 heatsink 5 10048647 control pcb 24 10007251 igbt 6 10048679 front panel 25 1004867...

Page 17: Order Code ! Jp-45P

Jp-45p air plasma cutting machine order code ! Jp-45p © wilkinson star limited issue 1 november 2014 product is subject to change without notice xvi.