- DL manuals

- Jasic

- Welding System

- JT-200D

- Operator's Manual

Jasic JT-200D Operator's Manual

Summary of JT-200D

Page 1

Wilkinsonstar.Com tig 200 / 315 ac/dc digital series ac/dc mma / tig welding machine order code ! Jt-200d, jt-315d operator manual.

Page 2: Your New Product

Your new product thank you for selecting this jasic technology, wilkinson star product. This product manual has been designed to ensure that you get the most from your new product. Please ensure that you are fully conversant with the information provided paying particular attention to the safety pre...

Page 3: Safety Precautions

Safety precautions 1 these general safety norms cover both arc welding machines and plasma cutting machines unless otherwise noted. The equipment must only be used for the purpose it was designed for. Using it in any other way could result in damage or injury and in breach of the safety rules. Only ...

Page 4

Do not weld on coated metals, unless the coating is removed from the weld area, the area is well ventilated, and while wearing an air-supplied respirator. The coatings on many metals can give o ff toxic fumes if welded. Prevention against burns and radiation arc rays from the welding process produce ...

Page 5

Rf declaration equipment that complies with directive 2004/108/ec concerning electromagnetic compatibility (emc) and the technical requirements of en60974-10 is designed for use in industrial buildings and not those for domestic use where electricity is provided via the low voltage public distributi...

Page 6: Product Overview

Product overview 2 the jt-200d and 315d are a series of digital controlled ac/ dc pulsed tig/mma inverter welding machines with excellent performance and utilising advanced technology system. They it have various ac/dc modes such as ac square-wave tig, ac pulsed tig, dc tig, dc pulsed tig, ac mma (s...

Page 7

Are programmable, which o ff ers a facility for a user‘s special application. Remote control available the machine o ff ers an analog remote control mode (foot control), which can realise real-time adjustment of tig welding current over 10m away. Robot system for automatic welding available the machin...

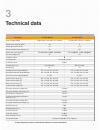

Page 8: Technical Data

Technical data 3 7 product design may vary due to continual improvements or customer requirements. Parameter jt-200d ac/dc jt-315d ac/dc input voltage range single-phase 190~250v ac, 50/60hz 3-phase 280~420v ac, 50/60hz rated input capacity (kva) 4.6 9 rated input power (kw) 4.2 8.4 recommended fuse...

Page 9: Controls

Controls 4 front view jt-200d 1. Control panel 2. Negative output socket 3. Torch gas connector 4. Torch switch connector 5. Remote control connector 6. Positive power connector 7. Mains switch 8. Adjustment control front view jt-315d 1. Control panel 2. Negative output socket 3. Torch gas connector...

Page 10

Rear view jt-200d 9 data plate 10 power cable input 11. Shield gas input connector 12. Serial number rear view jt-315d 9. Data plate 10. Power cable input 11. Water input connector 12. Shield gas input connector 13. Serial number 14. Mains switch 9.

Page 11

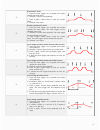

Control panel 1—welding mode selecting zone it is used to select the welding mode. Press the key in this zone to shift the welding mode among “” (ac square-wave tig), “” (ac pulsed tig), “” (dc tig), “” (dc pulsed tig), “” (ac smaw) and “” (dc smaw) with the corresponding led lit. However, if the le...

Page 12

11 5—tig parameter selecting zone hz % % hz 2 1 3 4 5 6 7 8 9 10 11 12 ! 6-mma parameter selection area 7—foot control selecting zone select the foot control to control the welding current by pressing the foot control key until the led is on. The welding current should be 30a at least (to avoid arc ...

Page 13

12 parameter setting operation hints selection and adjustment of parameters ● press “ ↓ ” in parameter display selecting zone to select the parameter to be displayed. ● press “ ↓ ” in welding mode selecting zone to select welding mode (totally 6 welding modes). ● press “ ← ”or “ → ” in tig parameter...

Page 14: Program Key Setting

Program key setting mma (dc ) note: t0—standby: no welding current; output voltage is the no-load voltage. T1—arc ignition: welding current is arc ignition current (i1). T3—arc burning: welding current is the pre-set current (i2). T4—short-circuit transfer: welding current is the short-circuit trans...

Page 15

Mma (ac) t0-arc ignition time (0.01~1s) t1-ac period (20ms) (i.E. Frequency=50hz) i0-arc ignition current (20~300a) i1-welding current (20~250a) in mma ac mode, the adjustment of all parameters is the same with that in mma dc mode except that the arc force is 0 fixed. Tig dc welding in the dc tig mo...

Page 16

Cleaning strength (100%*tc/tp): generally, in ac welding, when taking the electrode as the anode, the current is called the cathode current. Its main function is to break up the oxidized layer of the work piece, and the cleaning strength is the percentage cathode current holding in the ac period. Th...

Page 17

Higher frequency to the peak pulsed current with lower frequency, some special welding requirements can be met. Complicated complex waveform dc pulsed welding can be obtained by selecting the operation mode 18/19 or self- programming in pulsed welding mode. A typical waveform of complex waveform dc ...

Page 18

17 ! 1s 1s 4 standard 4t mode: ① push the torch trigger: arc is ignited and current reaches the initial value. ② release it: current rises gradually. ③ push it again: current drops to pilot arc current value. ④ release it: arc stops. 5 double operation 4t mode: ① push the torch trigger: arc is ignit...

Page 19

18 1s 10 cycle double operation mode without initial current: ① " push the torch trigger: arc is ignited and current rises gradually. The torch trigger can be released at any time. ② " push the torch trigger and release it at once: current drops to pilot arc current value. ③ " push the torch trigger...

Page 20

When reading the above table, please note: • whether the arc is ignited by hf or by striking the electrode, and no matter what kind of operation mode is selected, after arc is ignited successfully, it enters into initial current, and later into operational mode control. • some operation modes adopt ...

Page 21: Installation

Installation 5 unpacking check the packaging for any signs of damage. Carefully remove the machine and retain the packaging until the installation is complete. Location the machine should be located in a suitable position and environment. Care should be taken to avoid moisture, dust, steam, oil or c...

Page 22: Operation

Operation before starting any welding activity ensure that you have suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the area. Mma (dc) after connecting the cables as above, make sure that all are correctly installed. Switch on the mains su...

Page 23

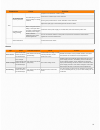

Maintenance and troubleshooting 6 the following operation requires su ffi cient professional knowledge on electric aspects and comprehensive safety knowledge. Make sure the input cable of the machine is disconnected from the electricity supply and wait for 5 minutes before removing the machine covers....

Page 24

23 phenomena phenomena cause solution the fan does not work or it works abnormally. The fan does not work or it works abnormally. The power cord is not well connected. Reconnect the power cord. The fan does not work or it works abnormally. The fan does not work or it works abnormally. Input failure ...

Page 25

Alarms 24 phenomena phenomena cause solution tig arc is hard to start but easy to break. The electrode you use is of poor quality or is badly oxidized. Replace it with electrode of better quality. Tig arc is hard to start but easy to break. The electrode you use is of poor quality or is badly oxidiz...

Page 26: Electrical Schematic

Electrical schematic 7 25.

Page 27: Parts List

Parts list 8 jt-200d 26 !.

Page 28

Jt-200d jt-315d no. Part no description no. Part no description 1 10040581 summary board 18 10022040 solenoid value 2 10006625 silicon bridge 19 10006520 encoder 3 10020434 bottom panel 20 10040130 control board 4 10020604 arc start board 21 10044448 front panel 5 10006560 reactor 22 10044430 panel ...

Page 29

Jt-315d 28 !.

Page 30: Machine

Jt-200d / jt-315d digital ac/dc pulse tig/mma welding machine order code ! Jt-200d, jt-315d © wilkinson star limited issue 1 january 2014 product is subject to change without notice xxix.

Page 31: Appendix

Appendix programming guide for users (tig mode) skip this chapter over if user-programming function (tig mode) is not to be used. 4 programmable tig operation modes (no.16-19) are available for this welding machine, and all the 4 modes are clearly defined when leaving the factory. Users can freely m...

Page 32

Mode codes. To plan and design a new tig operation mode is actually to design a code sequence group and to program it into the welding machine. The code sequence of operation mode is composed of the following. • operation mode code sequence : c0, c1, c2, c3, c4, c5, c6, c7, c8, c9 • in this sequence...

Page 33

① during welding, users always enter into operation mode control after the torch trigger is pushed and arc is successfully ignited, so users do not need to care about the arc ignition requirements of welding in the code design. ② operation mode control will be exited once arc stops. If users want to...

Page 34

Attached table 1 tig operation mode code sequences list 33 mode code sequences code sequences code sequences code sequences code sequences code sequences code sequences code sequences code sequences code sequences code sequences description (see text for details) 0 follow mode 1 1t/spot welding mode...

Page 35

Attached table 2 tig operation mode code function 34 code operation stipulation code operation stipulation 0x immediate executive code: execute order x immediately. 5x transfer code in torch trigger operation condition: wait for the torch trigger operation. Stop arc if triple or quartic operation, t...

Page 36

3. Operation mode programming after designing a group of operation code sequence, you can enter into the operation mode programming state and input the code sequence into the machine. The main steps of operation mode programming are described as below. ① access programming state press the tig parame...