Jaspi Econature40 Installation And Operation Manual - Environmental Instructions

3

Environmental instructions

Packing

Packing is made of 100 % waste materials.

Dispose of packing in accordance with local

waste disposal requirements.

Removal from Service

The boiler should be delivered to a waste dis-

posal point for electric and electronic compo-

nents.

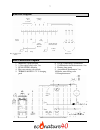

Operating Principle

ECONATURE-40 is a solid-fuel water-

heating boiler operating on a rotating combus-

tion principle designed for heating systems in

private houses. The rotating combustion tech-

nique used in ECONATURE-40 is even 30 %

more energy saving than the conservative

upper burning technique.

Firewood Burning Phases

D

RYING

: Dehumidification of firewood.

P

YROLYTIC DECOMPOSITION

: Wood starts to

break apart and change to coal and gas. Pyro-

lytic decomposition begins at a temperature

above 100 ºC; when the temperature exceeds

280ºC the resulting reaction causes heat re-

lease. Secondary combustion (the reaction

between pyrolytic gases and oxygen) begins

at a temperature over 600 ºC.

R

EMAINING COAL BURNING

: Remaining coal

burns after pyrolytic gases are removed.

After firewood starts to burn the temperature

must rise quickly since secondary burning

will not be efficient until the combustion tem-

perature is high enough. Efficient and clean

combustion implies full control over the burn-

ing process throughout its phases. The rotat-

ing combustion technique uses secondary

firewood burning efficiently where flue gases

provide additional burning in a separate firing

throat and obtain the hottest and cleanest

flame possible simultaneously reducing haz-

ardous flue gas emissions notably. During the

secondary burning process, the flame tem-

perature exceeds 1000 ºC making combustion

efficient and clean.