- DL manuals

- Jaspi

- Boiler

- PW

- Installation And Operation Manual

Jaspi PW Installation And Operation Manual

Summary of PW

Page 1

Electric boiler pw installation and operation manual jÄspi knows how to create warmth and comfort jaspi uk www.Northmangroup.Co.Uk telephone: 01392 247340 email: info@northmangroup.Co.Uk.

Page 2

1. Contents 1. Contents 2. Ec – compliance 3. Operating principle 3.1. Function diagram 4. Technical data 4.1. Equipment 4.2. Mounting to the wall 5. Piping installation 6. Electric wiring 6.1. To be considered during installation 6.2. External connections to the boiler terminal strip 6.3. Electric ...

Page 3

2. Ec – compliance ec compliance assurance kaukora oy tuotekatu 11, p.O.Box 21 21201 raisio, finland the assurance covers electric boiler jäspi pw. During manufacture proper manufacturing procedures have been used pursuant to the following directives and standards: 89/336/eec 92/31/eec 73/23/eec 93/...

Page 4

3.1. Function diagram.

Page 5

4. Technical data dimensions (mm) (axbxc) 660x470x250 weight 35 kg volume 3,5 l design pressure 2.5 bar max. Power 12.2 kw voltage 240 v, 1~ frequency 50/60 hz backup power 4 kw expansion tank volume 12 l circulation pump 180 mm, 25/40 r3/4” safety relief valve dn 15, 1.5 bar automatic deaeration sh...

Page 6

4.1. Equipment 1. Automatic heating system deaerator 2. Safety relief valve 3. Expansion tank 4. Immersion heating element 5. Foam isolation 6. Water level switch 7. Circulation pump 8. Pressure gauge 9. Wall bracket 10. Sensor probe 11. Safety valve pipe r20 12. Drain and filling valve r15 13. Retu...

Page 7

4.2. Mounting to the wall 1. Pull out two screws on top of the boiler (back side) and detach the bracket. 2. Mount the bracket to a reinforced wall with four screws. 3. Hang the boiler on the bracket hooks. 4. Attach the two screws pulled out on phase 1 on top of the boiler. 5. Put a drain valve to ...

Page 8

5. Piping installation complete installation form (section 11) after installation. Install piping in accordance with current regulations and ensure that pipes cannot break. - the unit should be installed vertically in a designated dry warm room. - check whether the expansion tank has sufficient volu...

Page 9

6.2. External connections to the boiler terminal strip power wire 240 v, 50/60 hz. Fuses and power wire determined for the unit according to the selected power rating. See table below for maximum power options. 6.3. Electric boiler power table step power (kw) current (a) 1 1.6 7 2 3.2 13 3 4.8 20 4 ...

Page 10

7. Electrical diagram.

Page 11

8. Boiler operation and maintenance prior to start-up, ensure that: - the boiler and the heating system are filled with water and circulation is working - the air vent is open for air escape - piping connections are sealed. Check also the internal factory made connections in the boiler piping. - the...

Page 12

9. Heat control with outdoor temperature control pw control automatically adjusts the temperature of heating system water. Need of heat varies according to outdoor temperature. Heating system water temperature is controlled via the heating curve. The colder outdoor temperature is, the warmer the hea...

Page 13

9.1. Front panel.

Page 14

9.2. Screen modes pw automatic control unit screens. Normally the screen visible is basic screen state, but when the timer is set or the unit receives power limitation or trouble messages, the screen varies between basic screen state and additional screen state..

Page 15

9.3. Settings heating control basic settings, heating curve selecting, fine adjusting and temperature limits..

Page 16

9.4. Temperature decrease this screen state is for selecting if a lower or higher heating setting is being used at a certain time of day..

Page 17

9.5. Maintenance menu for the installer only! The service menu is for setting main fuse size of the property and max. Power of the unit..

Page 18

10. Troubleshooting - in case of any trouble first ensure that it is not a case of power disruption or breakdown of main / group fuses. - ensure that there is enough water in the system (check water level). - ensure that the heating system pressure is at 1 to 1,5 bar. - check the circulation pump an...

Page 19

10.4. Resistance values of boiler sensors for pcb 901497 disconnect the sensor wire during measurement boiler sensor type 22k ntc 200232 outdoor sensor type 150r ntc 200035 indicate the unit number and year of manufacture upon order of spare parts. Outdoor temperature (ºc) outdoor sensor resistances...

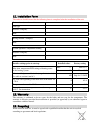

Page 20

11. Installation form the end user should ensure that the following form is completed after the installation of the unit. Unit number / year of manufacture unit type installer / company date wiring installer / company date system operation / adjustment training installer / company date installer set...