- DL manuals

- Jbc

- Rework stations

- AM 6500

- Instruction Manual

Jbc AM 6500 Instruction Manual

Instructions manual

US Version

0781056-0405

WARRANTY

ENGLISH

The JBC 2 years warranty, guarantees

this equipment against all manufacturing

defects, covering the replacement of

defective parts and all necessary labour.

Warranty does not cover product wear

due to use or mis-use.

In order for the warranty to be valid,

equipment must be returned, postage

paid, to the dealer where it was purchased

enclosing this, fully filled in, sheet.

DATE OF PURCHASE

STAMP OF DEALER

SERIAL Nº

✂

AM 6500

R E W O R K S TAT I O N

MANUFACTURED BY

JBC Industrias, S.A.

Ramón y Cajal, 3 - 08750 MOLINS DE REI

BARCELONA - SPAIN

Tel.: +34 93 325 32 00 - Fax: +34 93 680 49 70

http://www.jbctools.com e-mail:info@jbctools.com

Summary of AM 6500

Page 1

Instructions manual us version 0781056-0405 warranty english the jbc 2 years warranty, guarantees this equipment against all manufacturing defects, covering the replacement of defective parts and all necessary labour. Warranty does not cover product wear due to use or mis-use. In order for the warra...

Page 2

1 we appreciate the trust you have placed in jbc in purchasing this station. It is manufactured to the most stringent quality standards in order to give you the best possible service. Before turning on your station, we recommend you read these instructions carefully. Extractor stand ref.0932845 20 t...

Page 3

2 specifications the am 6500 is a rework station for through-hole and smt boards. - am 6500 120v ref. 6500100 it contains 4 modules which cover the main rework tasks: - hot air for desoldering any size of smd components. The station uses the exclusive jbc system, based on protectors-extractors and h...

Page 4

3 control unit technical specifications - maximum power soldering iron 50w - maximum power desoldering iron 75w - power heating unit 900w - temperature selection of the soldering part: 200 to 700°f (±5%) - temperature selection hot air: 300 to 850°f (±5%) - air flow regulation: 6-45 l/min - self-con...

Page 5

4 operation led lights red led -on- when lit, it indicates that the station is plugged in the mains. Green led -ready- when lit, it indicates that the system is ready and correctly set for working. The green led light is on after a few seconds, is the time needed to carry on the self-checking system...

Page 6

5 operation description of controls - pedal: hot air is produced when it is held down. Releasing it the heater is disconnected, though the turbine continues to operate until the air temperature falls below 212°f. - buttons: activates or desactivates the hot-air flow. After a function-time of two min...

Page 7

6 - use the pedal or the heat button to start the self-contained hot-air pump, directing it with a circular movement at the component terminals and taking care to distribute the heat evenly. - when the soldering flux turns liquid the extractor will automatically lift the component. B) extractor: - s...

Page 8

7 there are different models of protectors and extractors as accessories. The measurements of all the extractors and protectors are given on page 27 of instructions manual. C) tripod: for small components for which an extractor cannot be used, we recommend use of tripod 20 ref. 0932050, as shown in ...

Page 9

8 2210/2225 handpiece ref. 2210000 for great precision tasks, like smd solders, etc. 2245 handpiece ref. 2245000 for general soldering tasks in professional electronics. These soldering irons have a wide range of cartridges with different models of tips. The 2 2 4 5 - 0 0 9 c a r t r i d g e a n d 2...

Page 10

9 operating incidents the suction cup does not adhere to the component. Deficient aspiration, vacuum. 1 verify if the suction cup is well placed and in perfect condition. Possible errors in the case of malfunction, the control unit interrupts the connection. F o l l o w i n g a l i s t o f t h e m o...

Page 11

10 dr 5600 desoldering iron the am 6500 station includes the following: - dr 5600 desoldering ironref. 5600000 with the 5600-003 tip ref.5600003. Power desoldering iron: 75w. - dr 8500 desoldering iron standref. 0788500. - external desoldering air filter ref. 0821830. - set of accessories ref. 07805...

Page 12

11 dr 5600 ref.5600000 desoldering tip heating element pushbutton vacuum pump vacuum hose desoldering iron cable solder tin deposit metal glass desoldering process use the tip model with a larger diameter than the pad to be desoldered, so as to achieve maximum aspiration and thermal efficiency. 1 ap...

Page 13

12 ref. 5600-001 5600-002 5600-003 5600-004 5600-005 5600-006 5600-007 5600 a ø (mm) b ø (mm) max. Pin ø (mm) 001 / 011 1.4 0.6 0.4 002 / 012 1.8 0.8 0.6 003 / 013 2.7 1 0.8 004 3.2 1.3 1.1 005 3.4 1.6 1.4 006 4.2 2 1.7 007 4.8 2.5 2.3 a ø b ø 5600-012 5600-013 5600-011 desoldering tips these tips a...

Page 14

13 solder tin deposits it can be chosen between two different deposit types: - metal ref. 0812630. - glass ref. 0812620. - place the new heating element. Check that the right extremity of the upper part of the heating element is inserted in the slot located inside the body of the desoldering iron (s...

Page 15

14 cleaning the vacuum pump valve open the control unit as follow: - disconnect the control unit. - turn it upside down, remove the fixing s c r e w s . - return the station to its normal position and lift up the lid. - undo the four screws fastening the pump cover. - clean the valve with a cloth da...

Page 16

15 mp 2260 pick & place pen the mp 2260 pick & place pen ref. 2260000 for the placing of smd is also delivered with the am 6500. The pen is connected to the plug vacuum of the station. Please find the connection plan on page 1. A set of straight and bent needles as well as a set of different sized s...

Page 17

16 ad 8210 soldering iron stand ref.0788210 2210/2225 handpiece ref. 2210000 2245 handpieceref. 2245000 2245 cartridges 2210 cartridges connector advanced handpieces range all the advanced soldering handpieces range can be connected to the am 6500 station. The am 6500 station includes the following ...

Page 18

17 alignment xx xxxxx important. - it is essential to insert the cartridge till the end for a good connection. Take the mark as reference. 2 - place the handpiece on top of the new cartridge, press it slightly down and remove the handpiece. Changing the handpiece's cartridge with the advanced system...

Page 19

18 jbc reserves the right to make technical changes without prior notification. Fume extractor accessories specially designed for the advanced series 2210/2225 and 2245 handpieces. Easily clips onto the handpiece and can be quickly removed for easy maintenance. For 2245 handpiece: standard ref.04950...

Page 20

19 ad 2200 soldering stations for specialized use with smd components assemblies. Jt 7000 hot-air flow repair station for desoldering all types of smd’s particulary qfps and plccs of any size. Te 5000 hot-air flow repair station designed for soldering and desoldering small and medium-sized smds. Ar ...

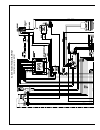

Page 21

20 electric wiring diagram valid from serial n. 99751.

Page 22

21.

Page 23

22.

Page 24

23.

Page 25

24.

Page 26

25.

Page 27

26.

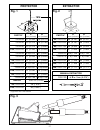

Page 28: Fig. 3

27 fig. 3 fig. 1 protector fig. 2 extractor part nº 0934035 9 (0.354") 13 (0.511") 0934040 9.5 (0.374") 19 (0.748") 0934080 9.5 (0.374") 21 (0.826") * 32 / 0932220 10 (0.393") 10 (0.393") 0934045 10.5 (0.413") 21 (0.826") 0934090 11 (0.433") 16 (0.629") * 24 / 0932235 12 (0.472") 17 (0.669") * 44 / ...

Page 29: Instructions Manual

Instructions manual us version 0781056-0405 warranty english the jbc 2 years warranty, guarantees this equipment against all manufacturing defects, covering the replacement of defective parts and all necessary labour. Warranty does not cover product wear due to use or mis-use. In order for the warra...