- DL manuals

- JCM

- Print Server

- TSP-01

- Instruction Manual

JCM TSP-01 Instruction Manual

Summary of TSP-01

Page 1

2002 jcm – american, corp. Office: (800) 683-7248 technical support: (702) 651-3444 fax: (702) 651-0214 e-mail: techsupport@jcm-american.Com web-site: www.Jcm-american.Com thermal printer series - 100 jcm part no. 960-000038.

Page 2: Table of Contents

Table of contents introduction.............................................................................................................................. 1 model classification ................................................................................................................ 2 gener...

Page 3: Introduction

Introduction the thermal security printer – tsp-01 the tsp-01 is a multi-purpose printer that is suitable for any application requiring quality printing ability. Jcm provides the thermal paper specifica- tions for optimum performance (see page x), while allowing the customer the freedom to create a ...

Page 4: Model Classification

Model classification how to read the model classification number category 813 tsp printer tsp – x x – x x – x xx – x x –xxx (1) (2) (3) (4)(5)(6) (7) (8) (1) tsp thermal security printer (2) cpu 01 4 mb eprom w/barcode verify (3) mounting & cable bracket configuration 00 no mounting brackets, no cab...

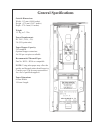

Page 5: General Specifications

General specifications outside dimensions width : 113 mm (4.448 inches) height : 67.5 mm (2.657 inches) depth : 279.4 mm (11 inches) weight 1.5 kg, or 3.3 lbs power requirements dc 24v (+10%, -5%) 3a (50% print ratio) paper hopper capacity 250 standard. Optional hopper extensions for 500 pre-cut pie...

Page 6

General specifications: cont’d paper rejection function - . R.A.W - read after write when sensors detect double paper, or a barcode print failure condition, the paper is sent to an internal reject area and an error code is sent to the host application. The reject area has a capacity of 5 sheets. Ins...

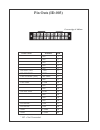

Page 7: Dip Switch Settings

Dip switch settings dip switches off 4 3 2 1 off 4 3 2 1 off 4 3 2 1 off 4 3 2 1 off 4 3 2 1 normal operating setting - this is the default setting for normal communication via the host application. Dip switch #1: off = barcode check on = no barcode check others are default to off position coupon pr...

Page 8: Thermal Paper Specifications

Thermal paper specifications 1. Overview this specification is for thermally coated tickets designed for use with the jcm tsp-01 thermal printer. 2. General characteristics 2.1 tickets to be pre-cut sheets. 2.2 ticket edges must be smooth to prevent double feeding. 2.3 ticket size: 65 ± 1 mm x 156 ±...

Page 9

4. Paper curl the deformation (curl and warp) of papers used for tsp-01 printers is limited as follows. Deformation to be measured after paper has been stabilized for a minimum of 48 hours at 20 ± 5 o c, 55 ± 15% rh. 5. Thermal side printing 5.1 ticket shall have the text: “insert this side up” prep...

Page 10

6.2 it is recommended that non-thermal side printing be pre-approved by jcm american corp. Prior to use to ensure no negative impacts on print or printer reliability. 7. Packaging 7.1 paper shall be packaged in cartons or boxes designed to protect tickets from damage. 7.2 packaging must shield ticke...

Page 11

Paper positioning guide positioning sensor and doubler paper sensor positioning sensor exit sensor positioning sensor & double page sensor positioning sensor and double page sensor barcode sensor 9.

Page 12: Pin Outs (Id-003)

Pin outs (id-003) function signal pin n/c 1 n/c 2 n/c 3 n/c 4 n/c 5 rs-232ctxd txd 6 rs-232crxd rxd 7 led power (24v) rctr24 8 n/c 9 led gnd com 10 n/c 11 n/c 12 rs-232 gnd gnd 13 n/c 14 n/c 15 n/c 16 dc24vdc 24v 17 dc24vdc 24v 18 gnd pgnd 19 gnd pgnd 20 * n/c = not connected green edge of ribbon 10

Page 13: Installation

Installation 1. Install the printer mount- ing frame in the host machine using the appro- priate mounting holes in the bottom of the frame. 2. Attach the ribbon cable to the host machine. 3. Slide the printer into the frame by pushing in on the arm covering the eprom. Attach the ribbon cable to the ...

Page 14: Operation

Operation loading the paper 1. Fan the pre-cut paper before placing it in the hopper. 2. Lift the spring-loaded pressure plate. 3. Place the paper stack in the hopper with the printed side down. 4. Release the pressure plate. Note: the hopper will hold 200 sheets of pre-cut paper unless the hopper e...

Page 15

9. Place the black calibration paper (part no. 501-000044) in the same position. 10. Close the printer head. 11. Move dip switch no. 4 to off (see fig. 4) 12. The led flashes 100 ms on, 1 sec. Off (see fig. 3). 13.Open printer head and remove the black calibration paper. 14.Place the white calibrati...

Page 16: Troubleshooting

When the printer receives a message from the host, it moves a single piece of paper from the hopper into the printer and prints the barcode information. The piece of paper is moved into another section where it is read to confirm accuracy. If there is an error condition, it moves the paper to the re...

Page 17: Troubleshooting (Cont.)

It may become necessary to increase the printer contrast if the host receives a contrast error message. Use a small flat- head screwdriver to adjust the contrast control wheel (lower numbers increase contrast). Make minor adjustments, then test the printer to verify the results. To replace the eprom...

Page 18: Troubleshooting (Cont.)

Troubleshooting (cont.) no power printer reject printer reject paper jam in hopper paper jam in printer printer will not accept print message from host 1. Ribbon cable not seated properly 2. Printer is not all the way in the frame double paper sensed a. Sheets automatically go to reject area b. Prin...

Page 19: Cleaning

Cleaning to clean the tsp-01 remove all paper from the hopper and use compressed air to blow out any residue. Concentrate on the rollers and the sensors. Open the head and use com- pressed air to remove any debris from the area. Then use a lint-free cloth and a 25% alcohol solution to gently clean t...

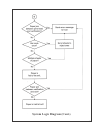

Page 20: System Logic Diagram

System logic diagram 18.

Page 21: System Logic Diagram (Cont.)

System logic diagram (cont.) 19.

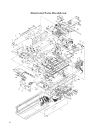

Page 22: Illustrated Parts Breakdown

Illustrated parts breakdown 20

Page 23

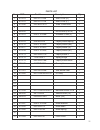

Parts list no. Edp part no. Description qty. 1 071874 0667pt0110b side cover (r) 1 2 071875 0667pt0111b side cover (l) 1 3 071846 0667bu0101a slide guide bush 3 4 5 025205 m3x5 bind (fe cr) 9 6 071872 0667pt0108b harness guide (l) 1 7 8 074078 0667ks0106 paper pusher spring 1 9 073770 0667pt0125a pa...

Page 24

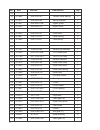

No. Edp part no. Description qty. 32 33 071884 0667cs0101 tension roller spring 2 34 071913 0667re0105 spring stopper 1 35 071921 0667re0113b upper guide 1 36 071920 0667re0112 reject lever 2 37 38 071836 0667sh0107 lock shaft 2 39 071881 0667ts0102 lever spring 2 40 071880 0667ts0101 lock spring 1 ...

Page 25

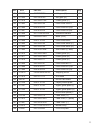

No. Edp part no. Description qty. 83 071903 0667ge0102 idol gear (a) 1 84 071905 0667ge0106 idol gear (b) 1 102 071918 0667re0110a lower guide (c) 1 103 071863 0667sh0104 pinch roller lever f 1 104 071890 0667ks0103 pinch roller sp(b)r 1 105 071891 0667ks0104 pinch roller sp(b)l 1 106 071848 667-314...

Page 26

925 pilot road, las vegas, nevada 89119 office: (800) 683-7248, tech. Support: (702) 651-3444, fax: (702) 651-0214 e-mail: techsupport@jcm-american.Com http://www.Jcm-american.Com.