- DL manuals

- JCM

- Printer

- TSP - 02

- Operation And Maintenance Manual

JCM TSP - 02 Operation And Maintenance Manual

Summary of TSP - 02

Page 1

2004 jcm – american, corp. Office: (800) 683-7248 technical support: (702) 651-3444 fax: (702) 651-0214 e-mail: techsupport@jcm-american.Com web-site: www.Jcm-american.Com tsp - 02 printer operation and maintenance manual (rev. B) jcm part no. 960-000051.

Page 3: Table of Contents

Table of contents introduction......................................................................................................................... 1 model classification ........................................................................................................... 2 general specifi...

Page 5: Introduction

Introduction the tsp - 02 printer the tsp – 02 printer is a multipurpose thermal printer that is suitable for any application requiring quality printing ability. Jcm provides the thermal paper specifications for optimum performance, while allowing the customer the freedom to create a unique 4-color ...

Page 6: Model Classification

Model classification how to read the model classification number tsp – x x – x x – x xx – x x –xxx (1) (2) (3) (4)(5)(6) (7) (8) (1) tsp thermal security printer (2) cpu 02 use fanfold paper, 4 mb eprom (3) mounting & cable bracket configuration 00 no mounting brackets, no cabling 01 no mounting bra...

Page 7: General

General specifications outside dimensions width : 113 mm (4.4 inches) height : 67.5 mm (2.65 inches) depth : 285.8 mm (11.2 inches) weight 2.5 kg (5.5 lbs) power requirements dc 24v (+10%, -5%) 3a (50% print ratio) paper hopper capacity 200 standard. With optional hopper extension, 400 and 600 ticke...

Page 8

General specifications: con’t installation indoors avoid direct sunlight a lengthwise installation angle between 0 0 and 45 o angle operating environment temperature : +5 0 c ~ +45 0 c (41 0 f ~ 113 0 f) humidity : 10 ~ 90% rh (no condensation) storage environment temperature : -25 0 c ~ +70 0 c (77...

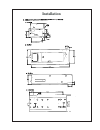

Page 9: Installation

Installation 5.

Page 10: Loading Paper

Loading paper set the packet of fan-folded paper beside the printer, making sure the index mark is positioned properly. Remove the band from the packet and drop it in the printer hopper. Turn the printer on. Place the top sheet of paper in the entry opening as shown in photo. The sheet of paper will...

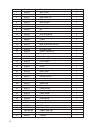

Page 11: Pin Assignments

Pin assignments a. Pin assignments (main connector on underside of printer) position name description 1 mreset hardware reset 2 rxd - i receive data (printer), photo-coupler isolation 3 vdd photo-coupler bias voltage. (dc+12 v or dc+13 v) 4 txd – i transmit data (printer), photo-coupler isolation 5 ...

Page 12: Dip Switch Settings

Dip switch settings dip switch 1 2 3 4 function 0 0 0 0 normal operation (interfaced with a host controller) 1 0 0 0 reserved 0 0 0 1 ticket print test 1 0 0 1 continuous ticket print test 0 1 0 1 reserved 1 1 0 1 sensor adjustment data 0 0 1 1 test pattern and version information 0 1 1 1 motor func...

Page 13

Sensor calibration - calibrate the mark and exit sensors. Continuous ticket printer test - printer will print one ticket after another (previously printed ticket does not have to be removed.). Sensor adjustment data - mark sensor and exit sensor adjustment data is printed on ticket. Test pattern and...

Page 14: Maintenance

Maintenance sensor adjustment procedure • make sure printer power is turned off • turn on all four dip switches • open the printer and insert the reference paper (part no. 501-000059) • turn on printer power • wait for the led to flash (on - 100ms, off - 1 sec.). You may need to wait 10 seconds • op...

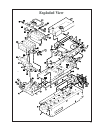

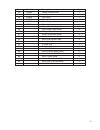

Page 15: Exploded View

Exploded view 11.

Page 16

No. Part no. Description qty. 1 079520 slide frame 1 2 079526 slide guide (l) 1 3 079527 slide guide (r) 1 4 079575 i/f assy. 1 5 079574 slide harness 1 6 079530 harness clamp 3 7 079517 unit base 1 8 079533 (b) 1 9 079519 unit lock 1 10 079538 unit lock spring 3 11 079537 unit lock bush 1 12 005663...

Page 17

No. Part no. Description qty. 42 072284 switch insulation seat 1 43 079540 hex. Spacer 2 44 079518 unit frame 1 45 079522 slide rail 1 46 079523 slide ring 2 47 079542 nylon washer 2 48 m3 x 6 pan wh p-tight (black) 2 49 m3 x 6 bind p-tight (black) 5 50 3 e-type clip 8 51 m2.6 x 4 w-sems (small) 3 5...

Page 18

925 pilot road, las vegas, nevada 89119 office: (800) 683-7248, tech. Support: (702) 651-3444, fax: (702) 651-0214 e-mail: techsupport@jcm-american.Com http://www.Jcm-american.Com.