- DL manuals

- Jeanneau

- Boat

- 64

- Owner's Manual

Jeanneau 64 Owner's Manual

Summary of 64

Page 1

Owner's manual c r o is ie r e 159881 index a.

Page 3: Contents

- 3 - contents introduction ..................................................................................................................... 9 welcome ......................................................................................................................... 9 notes on reading thi...

Page 4

- 4 - 6 safety ......................................................................................................................... 37 6.1 preventing man overboard situations and the means of getting someone back onboard .............................................................................

Page 5

- 5 - 8.3 ac system (110 v or 220 v)..................................................................................... 99 8.3.1 ac shore socket................................................................................................ 100 8.3.2 layout diagram ...................................

Page 6

- 6 - 13 water systems ...................................................................................................... 155 13.1 general points ..................................................................................................... 155 13.2 using a valve ............................

Page 7

- 7 - 16 deck fittings.......................................................................................................... 209 16.1 general points..................................................................................................... 209 16.1.1 polyester ............................

Page 9: Introduction

- 9 - introduction welcome you have just taken delivery of your new jeanneau yachts boat and we thank you for the confidence you have shown us in ordering a vessel of our brand. The whole jeanneau yachts team welcomes you aboard. A jeanneau yachts is made to last, in order to bring you all the pleas...

Page 10

- 10 - this manual has been produced to help you enjoy using your boat in all safety. It contains the details of the boat and of all the equipment provided and installed on your boat, as well as the instructions for their use. Read it carefully and really get to know your boat before using it. This ...

Page 11

- 11 - notes on reading this manual the various symbols used throughout the manual for crucial safety information are as follows: - while some of the information and illustrations in this manual may show details which are slightly different from those found on your boat, the key information remains ...

Page 13

- 13 - 1 technical specifications 1.1 construction model ................................................................................................................Jeanneau 64 architect / interior design .................................................. Philippe briand / andrew winch builder ....

Page 14

- 14 - 1.5 capacities total mass of the liquid content of fixed tanks when they are full .................................... 5 701 kg fuel capacity: tank 1 (*) ..................................................................................... 500 l tank 2 (*) .......................................

Page 15

- 15 - 2 design categories and displacement - some of the data is shown on the manufacturer's plate fixed to the boat. The explanation of the data is given in the appropriate chapters of this manual. - the recommended maximum load includes the weight of all the people onboard, of provisions, persona...

Page 16

- 16 - if some of those onboard are children, the total number of people allowed onboard may be increased, provided that:: - the total weight of the children does not exceed 37,5 kg ; and that - the total weight of all allowed onboard (based on about 75 kg per adult) is not exceeded. - do not exceed...

Page 17

- 17 - 2.3 design categories category a: at high sea this craft is designed to operate in winds that may exceed wind force 8 (beaufort scale) and in significant wave heights of 4 m and above. This craft is largely self-sufficient. Abnormal conditions such as hurricanes are excluded. Such conditions ...

Page 19

- 19 - 3 stability and buoyancy 3.1 stability data - fully laden displacement was used to evaluate the stability and buoyancy of the boat. The value of this displacement can be found in paragraph ’ technical specifications ’ at the beginning of this manual. - any changes in the distribution of loads...

Page 20

- 20 - 3.2 access to the boat access to the cockpit note: it is essential that the guardrail is closed when sailing.. Access to companionway aft platform gangway mechanism.

Page 21

- 21 - access to the engine compartment starboard aft head compartment starboard aft cabin cupboard - galley companionway 3 s t a b il it y a n d b u o y a n c y.

Page 22

- 22 - access to aft cabin access to garage - it is imperative that both the cockpit and the engine compartment are kept closed when at sea. - when at sea close the guardrail side-opening or openings. - slamming an access hatch may cause injury : always close the hatch gently and carefully. - do not...

Page 23

- 23 - 4 manoeuvrability - this boat was tested using the stability rating stix, which is a worldwide safety measurement of stability and which takes account of the length of the vessel, its displacement, hull dimensions, stability characteristics and flooding proofness. This test produced the follo...

Page 25

- 25 - 5 rigging and sails 5.1 rigging diagram 5.1.1 classical mast 5 r ig g in g a n d s a il s.

Page 26

- 26 - 5.2 standing rigging sails dimensions 1 2 3 4 5 6 7 8.

Page 27

- 27 - detail reference designation quantity 1 forestay 1 2 backstay 2 3 v1 2 4 v2 2 5 v3d4 2 6 d1 2 7 d2 2 8 d3 2 forestay - 16 mm diameter backstay - 12 mm diameter v1 - 16 mm diameter v2 - 14 mm diameter 5 r ig g in g a n d s a il s.

Page 28

- 28 - v3d4 - 12 mm diameter d1 - 14 mm diameter d2 - 12 mm diameter d3 - 10 mm diameter.

Page 29

- 29 - hydraulic backstay tank access: garage cable adjustment: cockpit location - lever: cockpit 5 r ig g in g a n d s a il s.

Page 30

- 30 - 5.3 running rigging - inspect the halyards for wear and condition. - regularly check the condition of the jam cleat jaws. - regularly clean the backstay blocks with fresh water. - avoid aggressive gybing in order to reduce premature wear on the sheets, attachment points and the gooseneck. - i...

Page 31

- 31 - 5.4 sails general points - the working life of a sail mainly depends on its being regularly maintained. - when sailing, trim the sails properly in accordance with the stresses in order to reduce the harmful strains on the fabric. - avoid wear and tear: protect against chafing on gear with rou...

Page 32

- 32 - 5.5 deck fitting general points - inspect each piece of deck gear regularly (blocks, shackles, swivels, jam cleats, etc): check that there are no cracks, corrosion or deformation. - when replacing a piece of deck gear, make sure that you use a type with the same strength specifications. - if ...

Page 33

- 33 - rinse winches regularly with fresh water - rinse winches regularly with fresh water. - dismantle, clean and lubricate each winch annually. Parts that have been damaged or worn may need replacing. Foot switch operation relay load controller access to elements: ceilings - galley / side cabin 1....

Page 34

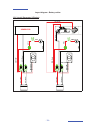

- 34 - layout diagram - electric winch 1. Winch 2. Engine 3. Operation relay 4. Load controller 5. Waterproof switches 6. Fuse 7. Breaker 8. Service battery - refer to the manufacturer's instructions for use and maintenance. - avoid bulky clothing, long hair and jewellery that might become caught in...

Page 35

- 35 - captive winches - the captive winch is an electric winch powered by dc current. - the captive winch allows the manoeuvre to be controlled remotely and stows the lines.. Layout diagram - captive winch 1. Captive drum 2. Foot switch 3. Electric engine 4. Operation relay 5. Breaker 6. Fuse 7. Co...

Page 36

- 36 - 5.7 electric genoa furling system operation - leave several turns of the furling line around the drum. - furl/unfurl the genoa slowly so that the furling line is always under light tension thus avoiding any riding turns in the drum. - never slacken the genoa halyard when furling/unfurling the...

Page 37

- 37 - 6 safety 6.1 preventing man overboard situations and the means of getting someone back onboard 6.1.1 prevention of man overboard - the zones outside the working deck area are the hatched areas below - the ’ working deck ’ means those areas outside where people stand or walk during normal use ...

Page 38

- 38 - 6.1.2 getting back onboard the means for getting back onboard must be able to be deployed by one person alone in the water, with no other help. Fitting a means of climbing back onboard: - some types of equipment for getting back onboard have a locking device when folded up: it is important to...

Page 39

- 39 - 6.2 storing the life-raft the life-raft(not supplied) must be stored in the space provided for it (ref 1). A pictogram helps to locate it easily. 6.3 securing moveable items before putting to sea, carefully read the launching instructions shown on the liferaft. When at sea, never padlock or l...

Page 40

- 40 - 6.4 deck layout 1. Outboard engine (the outboard engine is not supplied). 2. Lifebuoy support bracket (the ring lifebuoy is not supplied). The maximum weight of the outboard engine on the pushpits must not exceed 20 kg..

Page 41

- 41 - 6.5 information about the risks of flooding and about the boat's stability 6.5.1 openings in hull view top reference designation valve 1 cockpit scupper yes 2 drainage - collector - waste water yes 3 wc evacuation to sea yes 4 earthing plate x 2 (generator & dc/ac converter) not 5 sea water i...

Page 42

- 42 - on the port side reference designation valve 1 vent hole - collector - waste water not 2 black water tank not 3 water tank vent x 2 not 4 vent hole - collector - waste water not 5 black water tank not 6 black water tank not 7 heating exhaust not 8 draining of manual bilge pump not 9 chain loc...

Page 43

- 43 - on the starboard side reference designation valve 1 electric bilge pump draining not 2 drainage - air conditioning (pump sea water) yes 3 drainage - air conditioning (condensation water) yes 4 vent hole - fuel tank not 5 black water tank not 6 vent hole - collector - waste water not 7 water t...

Page 44

- 44 - 6.5.2 bilge pumps and drainage general points - the inner moulding of the hull has channelling: the drainage channels. The drainage channels allow the water to drain down to the lowest point in the boat, where it can be discharged.. So it is important to allow the water to flow freely down to...

Page 45

- 45 - manual bilge pump operation: i- put the lever on the manual bilge pump. Ii- repeatedly work the lever up and down to its fullest extent. The manual bilge pump lever must remain accessible at all times. The manual bilge pump is in the cockpit (ref 1). The bilge pump lever is located close to i...

Page 46

- 46 - electric bilge pumps - the bilge pumps are powered by dc. - location of the electric bilge pumps: ref 3 & 3’. - the switch for the electric bilge pump is located on the switch panel (ref 4). - the electric bilge pump must only be used to discharge stagnant water at the bottom of the bilge. It...

Page 47

- 47 - bilge pump maintenance please refer to the manufacturer's notes on the instructions for checking and maintaining the bilge pumps. - the bilge pumps system is not designed to deal with water coming in through breaches in the hull. - keep the water level in the bilges to the minimum. - never st...

Page 48

- 48 - diagram of the layout - drying out the bilge pipe - bilge pump system (40 mm diameter) reference designation 1 electric bilge pump (skipper's cabin/sail locker) 2 electric bilge pump (saloon) 3 activator 4 manual bilge pump 5 intake strainer 6 non-return valve 7 kitchen sink evacuation throug...

Page 49

- 49 - 6.6 emergency systems in case of steering gear failure e mergency tiller emergency tiller the emergency tiller is designed only to be able to continue underway at a reduced speed in case of steering gear failure. Location of components instructions in the event of steering gear failure i. Uns...

Page 51

- 51 - 7 information relating to fire risks and risks of explosion 7.1 propulsion engines and other fuel-burning equipment 7.2 electrical system 7.3 gas system the risks associated with motorisation are described in the motorisation chapter. The risks associated with other fuel-burning equipment are...

Page 52

- 52 - 7.4 fire-prevention and fire-fighting equipment 7.4.1 fire-fighting equipment portable fire-extinguishers and fire blanket (not supplied) - when in use, this boat must be equipped with portable fire extinguishers of the following extinguishing capacity and located in the following places: the...

Page 53

- 53 - maintenance of the fire-fighting equipment the owner/person operating the boat must: - get the fire-fighting equipment checked at the frequency shown on the equipment ; - replace portable fire extinguishers, if outdated or discharged, by extinguishing apparatus of equal capacity ; - provide a...

Page 54

- 54 - 7.4.2 fixed extinguishing system with manual control - this boat is fitted with a fixed fire extinguishing system protecting the engine compartment. - procedure to follow in the event of fire in the engine compartment: - stop the engine and fan, - switch off power and stop fuel supply, - clos...

Page 55

- 55 - reference designation location 1 fixed extinguisher (x 2) engine compartment 2 remote pull switches galley 7 in f o r m a t io n r e l a t in g t o f ir e r is k s a n d r is k s o f e x p l o s io n.

Page 56

- 56 - the position of the remote control handles is indicated by the pictogram shown below: 7.5 emergency exits in case of fire location: - companionway - the forward cabin deck hatch - deck hatch - skipper's cabin - deck hatch - aft cabin to enable functioning of the fixed fire extinguishers, the ...

Page 57

- 57 - never: - obstruct the passages leading to the emergency exits and the hatches ; - obstruct or block safety controls, for instance fuel shut off valves, gas taps, electrical system circuit-breakers ; - obstruct the access to the portable extinguishers stored in lockers ; - leave the boat unsup...

Page 59

- 59 - 8 electrical system 8.1 general information about the electrical system reference designation 1 generator battery & engine battery 2 power unit - 12v, relay box, circuit breakers, battery switch - 12v 3 power unit - 24v, circuit breakers, battery switch - 24v, power distributor 4 battery char...

Page 60

- 60 - - the risks of fire or explosion may result from careless use of the dc and ac systems. - the risks of electrocution may result from careless use of the ac system. Never: - work on a live electrical system ; - modify the elecrical system of the vessel or the relevant diagrams: it is important...

Page 61

- 61 - 8.2 dc installation (12 v or 24 v) 8.2.1 battery use and distribution general points the electricity onboard is direct current. The boat's electrical system comprises service batteries and the engine battery or batteries. The service batteries serve as the power supply for all the boat's elec...

Page 62

- 62 - battery set service batteries 4 x 210a (24 v circuit) access: starboard forward cabin spare service batteries 4 x 210a (24 v circuit) access: port forward cabin engine batteries + generator battery (1 x 50a + 1 x 50a) 12 v circuit battery - bow thruster 6 x 50a 24 v circuit.

Page 63

- 63 - maintenance - avoid charging batteries to a voltage greater than 14,6 v. - keep the batteries clean and dry. - regularly check that the terminals and connection cables are clean. If necessary, apply a thin coating of paraffin on the terminals, to prevent corrosion. - regularly recharge all of...

Page 64

- 64 - maintenance of watertight batteries - this type of battery needs no maintenance and does not produce any gas during normal use. No ventilation is needed. - the optimum temperature for use is between 10 degree c and 30 degrees c. Lower temperatures will reduce the available capacity. Higher te...

Page 65

- 65 - control panel for electrically controlled battery breakers location: companionway - starboard reference designation 1 negative ancillaries 2 service positive 3 engine negative 4 positive engine 5 generator positive 6 generator negative - turn off all battery breakers before leaving the vessel...

Page 66

- 66 - operation - a locking switch prevents accidental operation of the battery breaker control panel. To allow use of the battery breakers, unlock the locking switch. - the green light illuminates on the locking switch and on all the battery breaker control switches. This indicates that control of...

Page 67

- 67 - 8.2.3 power distributor - the electronic charge dividers isolate the battery banks from each other and allow the charge to be directed automatically to the battery with the lowest charge. They give the advantage of preventing a drop in voltage. - the charge divider is electronic. It is design...

Page 68

- 68 - 8.2.5 battery charger general points - the battery charger runs on ac power. - a breaker protects the electrical circuit. - the battery charger charges all of the batteries onboard, while keeping the service battery bank isolated from the engine's battery bank. - within its power limits, the ...

Page 69

- 69 - operation - the charger runs fully automatically. It can remain permanently connected to the batteries and does not need to be disconnected when starting the engine. - in some electrical circuits, there may be battery chargers coupled in parallel. Maintenance - before doing any maintenance, c...

Page 70

- 70 - layout diagram - battery cables 12 v circuit (generator & engine) - + x x a 1 d m - 9 5 m m ² 1 d m - 9 5 m m ² v m 2 2 1 v m 1 1vm100 1dm 1at -35mm² 1 b a - 9 5 m m ² 1 b a - 9 5 m m ² 1 c b - 1 0 m m ² 1 c b 1 - 1 0 m m ² 12v 115a 1cb2 -10mm² + - - + g e 2 - 7 0 m m ² g e 1 - 7 0 m m ² g e ...

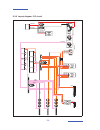

Page 71

- 71 - 24 v circuit (service) 8 - + - + - + - + - + - + - + - + 2 a t 1 - 3 5 m m ² 2at1 -35mm² 2 1 + - 2cb -70mm² 2cb1 - 70mm² 2cb2 - 10mm² 2cb3 -10mm² 2cb3 -10mm² 2cb2 -10mm² 2at2 -35mm² 2 0 a 2 0 a 3cb -70mm² 3cb2 -10mm² 3cb3 -10mm² 1 0 0 a 1 0 0 a 1 0 0 a 2 4 v 1 2 v 2 3 0 v /2 4 v 1 0 0 a 2 4 v...

Page 72

- 72 - 8.2.6 layout of the wiring looms in the hull - dc circuit.

Page 73

- 73 - 8.2.7 layout of the deck wiring looms - dc circuit 8 d c i n s t a l l a t io n.

Page 74

- 74 - dc/dc converter 24/12 v location: passageway - galley powers the following appliances: - hifi - electronic - vhf.

Page 75: -Hdqqhdx

- 75 - 8.2.8 electrical panel location: companionway - starboard 8 -hdqqhdx sdqhooljkw $8; dxwr rq rq wc wc wc qdyljdwlrq frqiruw sxpsv elojhsxpsv zdvwhsxpsv edwwhulhvvzlwfk dx[ 9%dwwhulhv 9%dwwhulhv jhqvhw%dwwhulhv lq rxw 21 21 iulgjh iulgjh oljkw qdy qdyolkjw prrulqjolkjw ghfn iuhvkzdwhu elojhsxps...

Page 76: $8;

- 76 - $8; dxwr rq rq wc wc wc lq rxw qdy qdyolkjw prrulqjolkjw $8; dxwr rq rq wc wc wc lq rxw qdy qdyolkjw prrulqjolkjw.

Page 77

- 77 - reference designation 1 electronic 2 navigation lights 3 mooring light 4 fridge - galley 5 fridge - cockpit 6 interior lighting 7 deck wash pump 8 water unit 9 available 10 masher - wc 1 (pump - wc evacuation to sea) 11 masher - wc 2 13 masher - wc 3 14 forward bilge pump 15 aft bilge pump 16...

Page 78

- 78 - 8.2.9 layout diagram - dc circuit - + - + - + - + - + 1dm -95mm² 1dm -95mm² 1 d m 1ba -95mm² 1ba -95mm² 1cb -10mm² 1cb1 -10mm² - + - + - + - + 2 a t 1 - 3 5 m m ² 2at1 -35mm² 2 1 + - 2cb -25mm² 2cb1 - 25mm² 2cb2 - 10mm² 2cb3 -10mm² 2cb3 -10mm² 2cb2 -10mm² 2at2 -35mm² 2 0 a 2 0 a 3cb -25mm² 3c...

Page 79

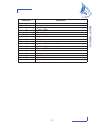

- 79 - 8.2.10 circuit breakers a circuit-breaker can be re-set (manually press the black button to restart it). Location: box - 12 v reference designation 1 control of the battery breaker 2 plus after contact - starboard 3 ventilator - engine compartment 4 control of the battery breaker 5 control of...

Page 80

- 80 - location: box - 24 v reference designation 1 supply - touch screen 2 supply - ventilation - box - 24 v 3 control of the battery breaker 4 electric bilge pump 5 shunt 6 shunt 1pc1 vc 1pc2 1na1 1sh1 1sh1 1 1ccb1 1ccb4 05 a 05 a 05 a 05 a 15 a 15 a 1 2 3 4 5 6.