- DL manuals

- Jeanneau

- Boat

- CAP CAMARAT 7.5 WA series 2

- Owner's Manual

Jeanneau CAP CAMARAT 7.5 WA series 2 Owner's Manual

Summary of CAP CAMARAT 7.5 WA series 2

Page 1

Cap camarat 7.5 wa owner's manual 992030 index b.

Page 3: Contents

- 3 - contents introduction ..................................................................................................................... 7 welcome ......................................................................................................................... 7 notes on reading thi...

Page 4

- 4 - 7 electrical system ................................................................................................. 39 7.1 general information about the electrical system .............................. 39 7.2 dc installation (12 v) ...............................................................

Page 5

- 5 - 12 steering system ..................................................................................................... 83 12.1 general points....................................................................................................... 83 12.2 layout diagram............................

Page 7: Introduction

- 7 - introduction welcome you have just taken delivery of your new jeanneau boat and we thank you for the confidence you have shown us in ordering a vessel of our brand. The whole jeanneau team welcomes you aboard. A jeanneau is made to last, in order to bring you all the pleasure you expect from a...

Page 8

- 8 - this manual has been produced to help you enjoy using your boat in all safety. It contains the details of the boat and of all the equipment provided and installed on your boat, as well as the instructions for their use. Read it carefully and really get to know your boat before using it. This o...

Page 9

- 9 - notes on reading this manual the various symbols used throughout the manual for crucial safety information are as follows: - while some of the information and illustrations in this manual may show details which are slightly different from those found on your boat, the key information remains t...

Page 11

- 11 - 1 technical specifications 1.1 construction model ...................................................................................... Cap camarat 7.5 wa series2 architect / interior design ................................................... Michael peters / sarrazin design builder ...........

Page 12

- 12 - 1.5 capacities total mass of the liquid content of fixed tanks when they are full....................................370 kg fuel capacity.......................................................................................................................280 l fresh water capacity..............

Page 13

- 13 - 2 design categories and displacement - some of the data is shown on the manufacturer's plate fixed to the boat. The explanation of the data is given in the appropriate chapters of this manual. - the recommended maximum load includes the weight of all the people onboard, of provisions, persona...

Page 14

- 14 - if some of those onboard are children, the total number of people allowed onboard may be increased, provided that: - the total weight of the children does not exceed 37,5 kg; and that - the total weight of all allowed onboard (based on about 75 kg per adult) is not exceeded. - do not exceed t...

Page 15

- 15 - 2.1 design categories category a: at high sea the boat is designed to sail in winds that may exceed beaufort force 8 and in waves of a significant height of 4 metres and more. This craft is largely self-sufficient. Abnormal conditions such as hurricanes are excluded. Such conditions may be en...

Page 17

- 17 - 3 stability and buoyancy 3.1 stability data - this boat as been assess as capable of supported the weight of the crew, even in the event of flooding. - fully laden displacement was used to evaluate the stability and buoyancy of the boat. The value of this displacement can be found in paragrap...

Page 18

- 18 - access to companionway access - aft quarterdeck blocked a trapdoor located on the stern deck at the level of the engine well allows access to: - the engine tightening on the aft bulkhead. This access trapdoor must be closed by hand without using any particular tool (especially a winch handle ...

Page 19

- 19 - 4 manoeuvrability - it is important to take additional precautions in very strong winds or in a confused sea or breaking waves. - maximum rated power of boat propulsion: 1 x 221 kw. - do not install an engine in this boat with a higher rated power than that indicated on the manufacturer's pla...

Page 20

- 20 - 4.1 visibility from the steering station visibility from the steering station may be obstructed when the boat is trimmed at a steep angle or due to other factors caused by one or more of the following conditions: - angle of engine trim control switch (in boats equipped with an engine trim con...

Page 21

- 21 - 4.1.1 navigation lights the navigation lights run on dc power. Control: steering station navigation lights mooring light location: starboard aft quarterdeck the only function of the samson post is to support the navigation light. Any other use is dangerous and forbidden. Mooring light / conne...

Page 23

- 23 - 5 safety 5.1 preventing man overboard situations and the means of getting someone back onboard 5.1.1 prevention of man overboard - the zones outside the working deck area are the hatched areas below - the "working deck" means those areas outside where people stand or walk during normal use of...

Page 24

- 24 - 5.1.2 getting back onboard the means for getting back onboard must be able to be deployed by one person alone in the water, with no other help. Fitting a means of climbing back onboard: - some types of equipment for getting back onboard have a locking device when folded up: it is advisable to...

Page 25

- 25 - 5.2 storing the life-raft the life-raft(not supplied) must be stored in the space provided for it (ref 1). A pictogram helps to locate it easily. 5.3 securing moveable items before putting to sea, carefully read the launching instructions shown on the liferaft. When at sea, never padlock or l...

Page 26

- 26 - 5.4 information about the risks of flooding and about the boat's stability 5.4.1 openings in hull reference designation valve 1 cockpit scupper not 2 drainage - aft quarterdeck not 3 draining of aft electric bilge pump not 4 draining of manual bilge pump not 5 wc evacuation to sea yes 6 sea w...

Page 27

- 27 - 5.4.2 drainage system general points - the inner moulding of the hull has channelling: the drainage channels. The drainage channels allow the water to drain down to the lowest point in the boat, where it can be discharged. So it is important to allow the water to flow freely down to this lowe...

Page 28

- 28 - main drainage system electric bilge pumps - the bilge pumps are powered by dc. - location of the electric bilge pumps: ref 3 & 3’. - the electric bilge pump must only be used to discharge stagnant water at the bottom of the bilge. It must not be used to pump out any oil-based products (petrol...

Page 29

- 29 - secondary drainage system manual bilge pump the manual bilge pump is in the cockpit (ref 1). The bilge pump lever is located close to it (ref 2). Operation: i- put the lever on the manual bilge pump. Ii- repeatedly work the lever up and down to its fullest extent. The manual bilge pump lever ...

Page 30

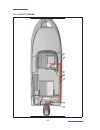

- 30 - diagram of the layout - drainage system reference designation 1 cockpit scupper 4 draining of aft electric bilge pump 5 draining of manual bilge pump 6 manual bilge pump 7 scuppers - aft quarterdeck 8 stuffing box - manual bilge pump suction 9 aft electric bilge pump 10 cockpit drainage 11 ga...

Page 31

- 31 - bilge pump maintenance please refer to the manufacturer's notes on the instructions for checking and maintaining the bilge pumps. 5.5 emergency systems in case of steering gear failure 1. Stop the engine. 2. Drop anchor to avoid drifting. 3. Find out if you can solve the problem yourself by l...

Page 33

- 33 - 6 information relating to fire risks and risks of explosion 6.1 propulsion engines and other fuel-burning equipment 6.2 electrical system the risks associated with motorisation are described in the motorisation chapter. - boats equipped with a 25kw or larger outboard engine must have onboard ...

Page 34

- 34 - 6.3 fire-prevention and fire-fighting equipment 6.3.1 fire-fighting equipment portable fire-extinguishers and fire blanket (not supplied) - when in use, this boat must be equipped with portable fire extinguishers of the following extinguishing capacity and located in the following places: the...

Page 35

- 35 - the fuel tank comparment is provided with an opening to allow the extinguisher contents to be discharged without the need to open the normal access hatches. Location of the port for the extinguisher: cockpit: cabin 6 in f o r m a t io n r e l a t in g t o f ir e r is k s a n d r is k s o f e ...

Page 36

- 36 - maintenance of the fire-fighting equipment the owner/person operating the boat must: - get the fire-fighting equipment checked at the frequency shown on the equipment; - replace portable fire extinguishers, if outdated or discharged, by extinguishing apparatus of equal capacity; - provide at ...

Page 37

- 37 - 6.4 emergency exits in case of fire designation location emergency exit companionway never: - obstruct the passages leading to the emergency exits and the hatches; - obstruct or block safety controls, for instance fuel shut off valves, gas taps, electrical system circuit-breakers; - obstruct ...

Page 38

- 38 -.

Page 39

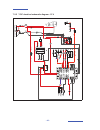

- 39 - 7 electrical system 7.1 general information about the electrical system reference designation 1 service battery 2 engine battery, battery switch, separator - batteries 3 fuses 4 switches / circuit breakers - steering station 7 d c i n s t a l l a t io n.

Page 40

- 40 - 7.2 dc installation (12 v) 7.2.1 battery use and distribution general points on board electrical power is direct current. The boat's electrical system comprises service batteries and the engine battery or batteries. The service batteries serve as the power supply for all the boat's electrical...

Page 41

- 41 - battery set location: cockpit locker. Engine battery: 110a service battery: 110a 7 d c i n s t a l l a t io n.

Page 42

- 42 - maintenance - avoid charging batteries to a voltage greater than 14,6 v. - keep the batteries clean and dry. - regularly check that the terminals and connection cables are clean. If necessary, apply a thin coating of paraffin on the terminals, to prevent corrosion. - regularly recharge all of...

Page 43

- 43 - 7.2.2 battery switch - manual battery switches: to make the system live, manually turn the positive and negative battery isolator switches. 7.2.3 power distributor - the electronic charge dividers isolate the battery banks from each other and allow the charge to be directed automatically to t...

Page 44

- 44 - 7.2.4 electrical layout - 12 v deck reference designation 1 windlass 2 windlass relay 3 lighting 4 cabin lighting 5 lighting 6 cabin lighting 7 compass light 8 fuel gauge indicator 9 12 v socket 10 screenengine control 11 starboard navigation light 12 switches / circuit breakers 13 accelerato...

Page 45

- 45 - hull reference designation 1 electric bilge pump 2 masher (pump - wc evacuation to sea) 3 fuse - fuel gauge 4 electric bilge pump 5 engine battery 6 positive battery isolator switch 7 service battery 8 flaps 9 water unit 10 fridge 7 1 2 3 4 5 6 7 8 9 10 d c i n s t a l l a t io n.

Page 46

- 46 - 7.2.5 *1 dc electrical schematic diagram - 12 v.

Page 47

- 47 - reference designation 1 switch - navigation lights 2 switch - electric bilge pump 3 switch - water unit 4 compass light 5 rev counter - motor 6 trim indicators 7 fuel gauge indicator 8 starting - motor 9 12 v socket 10 water unit 11 port navigation light 12 starboard navigation light 13 moori...

Page 48

- 48 - 7.2.6 steering station reference designation 1 steering wheel 2 electronic instrument 3 steering compass 4 engine panel 5 12 v socket 6 switches / circuit breakers - from left to right: - navigation lights - electronic instrument - water unit 7 switches / circuit breakers - from left to right...

Page 49

- 49 - 7.2.7 fuses - a fuse protects an electrical circuit from a power surge. If it blows, you must replace it with another fuse of the same rating. Access: behind the helm position 1. Plus after contact - motor 2. Interior lighting 3. Electric bilge pump 4. Water unit 5. Navigation lights 6. Avail...

Page 50

- 50 - 7.2.8 anodes general points - the sacrificial anodes protect the boat's metal components from electrolysis. - a sacrificial anode is an expendable part, that by eroding (oxydisation), allows the current to flow. The anodes used are made of a metal that is more readily reductive than the metal...

Page 51

- 51 - 8 domestic appliances 8.1 fridge general points - the fridge is composed of 3 components: the compressor, the evaporator and the condenser. These components are connected by a closed circuit refrigerant gas circuit. The fridge is air-cooled. - the fridge is dc powered. It is designed to chill...

Page 52

- 52 - location: galley control.

Page 53

- 53 - 9 onboard comfort 9.1 electronic equipment the onboard electronics are powered by direct current. Lead lines - do not store material on top of the sensors. - do not cover the sensors in antifoul when antifouling the hull. - regularly clean the sensors. Control: steering station advice-recomme...

Page 55

- 55 - 10 water systems 10.1 general points - it is essential to rinse the entire on-board water system the first time the boat is used (the water system is protected in the factory by a dietary anti-freeze). - the water tanks may have had an anti-algae treatment using a copper sulphate based produc...

Page 56

- 56 - 10.2 using a valve the valve is shut when the valve handle is at right angles to the pipe, the valve is open when the valve handle is in line with the pipe. 10.3 fresh water system 1. Open valve 2. Closed valve - valves have a lifespan of approximately 5 years. It is essential to have all val...

Page 57

- 57 - water tank location: cockpit locker capacity: 80 litre water filler 10 w a t e r s y s t e m s.

Page 58

- 58 - 10.4 main plumbing equipment 10.4.1 water unit - the water unit is supplied by direct current. - it serves to feed all the boat's plumbing equipment with fresh water. It is fitted with a pressure switch that activates the flow when the pressure in the water system falls. - the water unit must...

Page 59

- 59 - 10.4.2 deck wash pump (sea water) - the deck wash pump is supplied by direct current. - the deck wash pump allows the deck or the boat's tender to be washed. Operation control: steering station - open the sea water intake valve. - select sea water/fresh water supply. - attach a hose to the co...

Page 60

- 60 - 10.4.3 cockpit shower - the cockpit shower allows the use of fresh water for rinsing off. 10.5 black water system (wc) general points - black water is human waste including the flushing water from the toilets. - close the valves after each use and above all when the boat is unattended. - regu...

Page 61

- 61 - 10.5.1 location diagram of black water system reference designation 6 marine toilet 7 sea water intake - wc 8 wc evacuation to sea 9 black water tank 10 wc evacuation gate valve - deck (filler cap ’waste’) 11 black water tank 10 6 7 8 9 10 11 w a t e r s y s t e m s.

Page 62

- 62 - your boat is fitted with a black water tank to minimise the smells coming from this tank, we advise the following use and maintenance: 1) holding tank - a black water tank is used solely for the temporary collection of water coming from the toilets. - the tank can be emptied in 2 ways: - by c...

Page 63

- 63 - 3) maintenance of black water tank - the risk of unpleasant odours forming increases when the waste water remains in the tank for a long time. - whenever possible empty the tank regularly even before it is full. - every time the tank is emptied put in about 5 litres of fresh water and add an ...

Page 64

- 64 - layout diagram of black water system emptying by gravity reference designation 1 wc 2 seawater intake valve 3 thru-hull seacock 4 black water tank 5 vent hole 6 "waste" deck connection.

Page 65

- 65 - using a marine toilet fitted with a tank emptied by gravity i. Open the sea water intake valve (ref 2). Ii. Fill the bowl by using the manual toilet pump. Iii. Using the toilet (ref 1). Iv.A. To empty the organic waste in the tank: - make sure the thru-hull seacock (ref 3) is closed. - empty ...

Page 66

- 66 - black water tank access: head capacity: 64 litre filler cap ’waste’ seawater intake valve - wc thru-hull seacock - wc.

Page 67

- 67 - chemical toilet general points the chemical toilets have two tanks: a tank for flushing and a tank for faecal matter. The system is completed by the use of chemical additives which dissolve faecal matter and minimise the smell. Operation - use an additive for sanitation for use with chemical ...

Page 68

- 68 - 10.6 waste water system general points - close the valves after each use and above all when the boat is unattended. - regularly check the valves and thru-hull seacocks for proper operation and watertightness. - regularly check the tightness of the flexible pipe clamps and connections. Advice-...

Page 69

- 69 - 11 engine 11.1 information about the risks of fire and of explosion of engines - make sure that the coolant is circulating properly. - ensure that ventilation openings in the compartment fuel tank are not obstructed. - stop the engine and refrain from smoking during fuel tank filling. - get y...

Page 70

- 70 - diagram of the layout - ventilation - petrol tank compartment 11.2 danger from moving mechanical parts - keep away from the moving parts of the engine (belts and moving parts or hot components) and the drive shafts etc.. - be careful if you have long hair, bulky clothing, rings etc (at risk o...

Page 71

- 71 - 11.3 general points - don't install an engine more powerful or heavier than recommended on this boat, this risks compromising the boat's stability. - make sure you have enough fuel before sailing. - don't close the fuel supply valve between each use of the engine (unless for a lengthy absence...

Page 72

- 72 - gauge - the fuel level is given by the gauge to the indicator on the steering station. - some of the gauges must be calibrated when you first fill the tanks: please consult your dealer. Deck filler location gauge fuel tank - the tanks' nominal capacity cannot be fully used due to the load and...

Page 73

- 73 - epa version (united states environmental protection agency) - the maintenance of the complete petrol circuit system must be done professionally every year. It is advisable to clean the circuit only with soapy water. All the fuel circuit connections must be checked once a year. - when cleaning...

Page 74

- 74 - 11.4 starting the engine before starting the engine, it is imperative: - to open the fuel supply valve; - to switch on the battery supply by using the battery isolator switches; - to put the control lever in neutral; - to attach the circuit-breaker to the pilot. Make a habit of looking to see...

Page 75

- 75 - 11.5 fuel circuit reference designation 1 outboard 2 supply pipe - fuel 3 fuel filter 4 fuel supply valve 5 fuel gauge transmitter 6 anti-flooding valve 7 pipe filling 8 vent hole 9 deck filler 10 fuel gauge indicator 11 1 3 4 5 6 7 8 9 2 10 e n g in e.

Page 76

- 76 - 11.6 engine water intake valve the sea water intake plays a major role in keeping the engine running well. - keep the strainer under the hull as clean as possible; - brush the strainer whenever the boat is lifted out; - don't cover the strainer in antifoul. Sea water intake located directly o...

Page 77

- 77 - 11.7 fuel filter engine running problems may have different origins, including dirty fuel. The injection pump may wear out if there is water in the system. The water results either from the condensation resulting from an insufficiently filled tank, or from a filler cap either not closed prope...

Page 78

- 78 - 11.8 engine installation - the boat is designed for a single outboard engine. 11.9 engine control - the engine manufacturer's notes provide detailed explanations on how to operate the engine and keep it running well. - read the manufacturer's notes on use and maintenance of the engine. Contro...

Page 79

- 79 - 11.10 flaps general points - the flaps (trim control system) allow the pilot to adjust the boat's trim under way and thus to reduce fuel consumption. - the flaps run on dc power. - a fuse protects the electrical circuit. - they are operated by means of a push button situated on the wheelhouse...

Page 80

- 80 - general points the flaps are controlled electrically. The actuator is mechanical. The flaps need to be protected by an anode (see the chapter on electricity). Operation when the tabs are lowered, the bow of the boat has a tendency to lift out of the water. When the tabs are raised, the bow of...

Page 81

- 81 - layout diagram reference designation 1 mechanical actuator 2 control panel 3 control box 4 fuse 11 e n g in e.

Page 82

- 82 - 11.11 access to the engine the access to the engine is via: - the cockpit. 11.12 propeller - the propeller delivered with the boat represents the end result of trials carried out in collaboration with the engine manufacturer. Never change the propeller without first consulting a professional ...

Page 83

- 83 - 12 steering system 12.1 general points - the steering system is hydraulic. - the steering system is an important safety feature. For this reason, the annual inspection of the whole system must be carried out by a professional engineer. 12 s t e e r in g s y s t e m.

Page 84

- 84 - 12.2 layout diagram 5 4 6 7 3 1 2.

Page 85

- 85 - 12.3 hydraulic steering general points - steering is achieved by rotating the engine base. This rotation is done using a hydraulic ram. - protect the ram from any risk of impact, scratches or any other type of degradation. No impurities must ever penetrate the inside of the ram. - nothing mus...

Page 86

- 86 - replenishing and bleeding the circuit - this task must be carried out by a professional engineer: please consult your dealer. - use only oil iso 22. - the whole of the hydraulic circuit must be kept scrupulously clean: any impurity risks causing the deterioration of the steering gear. After e...

Page 87

- 87 - 13 deck fittings 13.1 general points 13.1.1 polyester - regularly brush the deck using a gentle de-greasing agent then rinse the deck with fresh water. - use as few cleaning agents as possible. - don't use solvents or aggressive detergent agents. - don't discharge cleaning agents into the wat...

Page 88

- 88 - 13.1.4 solid wood on exterior wooden panelling - wood exposed to harsh conditions, such as salty air and uv rays tends to become whiter and to lose its natural colour. This phenomenon has no effect on the intrinsic qualities of the wood, but can spoil its aesthetic appeal. - to maintain the c...

Page 89

- 89 - 13.2 equipment 13.2.1 water ski mast - the water-ski pole is only to be used for pulling someone standing on a wake-board or on water skis. Any other use is dangerous and forbidden (particularly pulling one or more people on a towed rubber ring). - the water ski pole is attached to the aft de...

Page 90

- 90 - 13.2.2 rod holder 13.2.3 seat cockpit 13.2.4 pilot seat.

Page 91

- 91 - 13.3 berthing, anchoring, towing 13.3.1 anchor points responsibility it is the responsibility of the owner/user of the boat to ensure that the berthing lines, towing cables, chains and mooring lines and the anchors are adequate for the intended use of the boat, i.E. That the lines or chains d...

Page 92

- 92 - 13.3.2 towing responsibility: it is important that the owner thinks through the actions required when securing a towing cable onboard. Location of attachment points a. Mooring cleats. B. Towing: - at the bow, to be towed - at the stern, to tow - generally the breaking strength of lines/chains...

Page 93

- 93 - 13.4 main elements of the chain locker 1. Bow fitting 2. Chain locker hatch 3. Remote control 4. Handle 5. Electric windlass 6. Chain rim - 8 mm diameter 7. Clinch windlass operations are dangerous: - always keep the anchor chain or rode free and unfouled. - carry out manoeuvres carefully and...

Page 94

- 94 - 13.5 electric windlass general points - the windlass is dc powered. - the windlass is designed for anchoring purposes: any other use is dangerous and forbidden. - an operation relay is fitted to the electrical circuit. - a circuit-breaker protects the power supply to the windlass. - the windl...

Page 95

- 95 - maintenance - once a year, dismantle, carefully wash and grease all the moving parts of the windlass. - regularly grease the supply terminals of the electric motor of the windlass and of the relay control box. Emergency anchoring procedure in the event of an electrical fault, it is possible t...

Page 96

- 96 - 13.6 mooring operation - before lowering the anchor, make sure that the chain or anchor rode is securely attached to the clinch. Advice-recommendation - before anchoring check the depth of water, the power of the current and the nature of the sea bed. - check the swinging area once the boat i...

Page 97

- 97 - 14 hull fittings 14.1 upholstery synthetic fabric stain removal if you can remove the fabric: - clean in the washing machine (use the program for delicate fabric) at 30°. - do not iron. - never use javel water. - do not dry-clean. - do not use a clothes drier. If you cannot remove the fabric:...

Page 98

- 98 - acrylic (bimini fabric type) maintenance to maintain the quality of the fabric, you are advised to spray it regularly with clarified water and to brush it with a soft brush (brush for clothes). It is advisable to clean thoroughly every 2 years. Stain removal follow these steps for routine cle...

Page 99

- 99 - 14.2 interior woodwork - clean the interior varnish using a de-greasing shampoo on a damp cloth. - polish the interior varnishing with a chamois leather. - if there are any stains or light scratches, it is possible to polish the varnish. Doing this can give the polished area more of a shine t...

Page 101

- 101 - 15 handling, transport 15.1 lifting plan note: measurements are expressed in mm. The position of the lifting slings is shown in the pictogram below: 15 h a n d l in g , t r a n s p o r t.

Page 102

- 102 - 15.2 lifting - before the first application of antifouling to the hull, you can lightly the hull using 400 µm or more wet and dry sandpaper. - the lower hull of your boat should be covered with an anti-fouling paint which will prevent the adhesion of marine growth. - the nature of the water ...

Page 103

- 103 - 15.3 upper limit of antifoul note: measurements are expressed in mm. 15 h a n d l in g , t r a n s p o r t.

Page 104

- 104 - 15.4 launch/lift out the initial commissioning of your boat will require a lot of skill and care. The proper working of all your boat's equipment is the result of the quality of the commissioning operations. This is why the initial launch must be overseen by your dealer. Before launching - r...

Page 105

- 105 - 15.5 winter storage - take advantage of laying up the boat to carry out a full inventory of the equipment. - check the expiry dates of the safety equipment. - have the liferaft overhauled. - empty the complete water system inside and outside and rinse it through with a mix of water and vineg...

Page 106

- 106 - 15.6 transport light displacement: .......................................................................................................1 928 kg included: - all structural elements; - the interior structure and furnishings; - interior equipment (plumbing circuit, galley, ventilation system...

Page 107

- 107 - 16 environment waste management: - throw all packaging in the recycling containers provided for this. - once a piece of equipment has completely stopped working, find out about the relevant recycling regulations from your nearest recycling centre or from your dealer. - make sure you follow t...

Page 109

- 1 0 9 - d in g h y : c e r t if ic a t e s o f s t a n d a r d s e p a pressure relief system deck fill 99dfpv series installation instructions 11/04 69485 rev. B save these instructions caution: the vessel manufacturer must comply with the requirements of cfr 40 1060.202. Any questions can be dir...

Page 110

Integrated fuel demand valve 99ifdv series installation instructions 2/12 69487 rev. C save these instructions caution: the vessel manufacturer must comply with the requirements of cfr 40 1060.202. Any questions can be directed to www.Attwood.Com failure to follow these instructions may result in ac...

Page 111

- 1 1 1 - inlet control valve 99icv series installation instructions 11/04 69482 rev. B save these instructions caution: the vessel manufacturer must comply with the requirements of cfr 40 1060.202. Any questions can be directed to www.Attwoodmarine.Com failure to follow these instructions may resul...

Page 112

- 112 -.