- DL manuals

- Jeanneau

- Boat

- MERRY FISHER 755

- Owner's Manual

Jeanneau MERRY FISHER 755 Owner's Manual

Summary of MERRY FISHER 755

Page 1

Merry fisher 755 owner's manual 982813 index e.

Page 3: Welcome Aboard

-1/106 welcome aboard madam, sir, you have just taken delivery of your new jeanneau boat and we thank you for the confidence you have shown us in ordering a vessel of our brand. The whole jeanneau team welcomes you aboard. A jeanneau is made to last, in order to bring you all the pleasure you expect...

Page 5: Introduction

1/106 introduction the users of the boat are informed of the following: this user guide/owner's manual is not a maintenance or repair guide. In case of difficulty do not hesitate to call on the services of your concessionaire jeanneau. Any alterations which may affect the safety specifications of th...

Page 6

2/106 anyone on the deck shall wear a life jacket or a buoyancy aid. The safety regulations as defined by the sailing code and enforced by the ’’colreg’’ should be observed. Name plate: some of the data is shown on the manufacturer's plate fixed to the boat. The explanation of the data is given in t...

Page 7: History of Updates

3/106 history of updates •index a .................................................................................................................. 11/2013 •index b .................................................................................................................. 05/2014 •index c .....

Page 9: Contents

5/106 contents introduction chapter 1 ...... Specifications and warranty ............................................Page 7 chapter 2 ...... Safety ........................................................................................Page 13 chapter 3 ...... Hull .....................................

Page 11: Specifications and Warranty

7/106 specifications and warranty technical specifications certification design category your boat 1.

Page 12

8/106 technical specifications - merry fisher 755 l.O.A......................................................................................................................... 7,70 m hull length............................................................................................................

Page 13: Specifications and Warranty

9/106 design category design category wind force (beaufort scale) significant height of waves to be considered (in metres h 1/3) vessel designed for navigation: a - "at high sea" b - "in open sea" c - "near to the coast" d - "in sheltered waters" over 8 up to and including 8 up to and including 6 up...

Page 14

10/106 category a: at high sea the boat is designed to sail in winds that may exceed beaufort force 8 and in waves of a significant height of 4 metres and more. This craft is largely self-sufficient. Abnormal conditions such as hurricanes are excluded. Such conditions may be encountered on extended ...

Page 15: Specifications and Warranty

11/106 your boat version name of the boat ............................................................. Name of the owner ............................................................. Address ............................................................. .................................................

Page 17: Safety

13/106 safety safety equipment general information gas system recommendations for gas fight against fire bilge pump system instructions in the event of steering gear failure 2.

Page 18

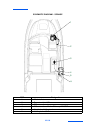

14/106 safety equipment swimming ladder (means of coming back onboard) reference 1 position of the liferaft (not supplied) reference 2 swimming ladder (reference 1) closed open liferaft (reference 2).

Page 19: Safety

15/106 general information dangers the major hazards concern: - the gas system. - the electrical system. - the handling of the vessel. - the motorisation. Please refer to the relevant paragraphs. Danger - fuel leaks or vapour represent a danger of fire and explosion. - leave the engine compartment v...

Page 20

16/106 gas system compartment gas cylinder locker closed locker open supply valve warning - for all recommendations concerning gas: refer to chapter 2, «safety». - don't use a solution containing ammonia. - don't use a flame to detect leaks. - don't smoke, don't use a naked flame when you change the...

Page 21: Safety

17/106 gas system diagram ref designation 1 hot plate 2 valve hot plate 3 gas cylinder locker 4 gas system 5 regulator valve 6 gas cylinder 2 safety.

Page 22

18/106 diagram - location - gas system ref designation 1 cooker 2 supply valve - gas 3 connector 4 regulator valve 5 gas cylinder locker 6 drain 1 2 3 4 5 6.

Page 23: Safety

19/106 recommendations for gas type of cylinder: butane, service pressure 10 kg/cm 2 or according to current standards of your country). Close the valves on the system and on the cylinder when the appliances are not used. Close the valves before you change cylinders and immediately in case of emerge...

Page 24

20/106 emergency evacuation and location of extinguishers emergency exits in case of fire: - sliding hatch - passageway recommended positioning of portable extinguishers (not supplied): - galley.

Page 25: Safety

21/106 fight against fire it is the owner's or the skipper's responsibility: - to have the extinguishers checked in pursuance of the instructions given. - use extinguisher replacements with equivalent features (same capacity and fire resistance) if the ones in place are out of date or have been used...

Page 26

22/106 extinguishers the extinguishers are part of the compulsory equipment. An extinguisher or a fire blanket shall be set less than 2 m from any flame appliance. Extinguishers must be placed less than 5 m from any berth. An extinguisher shall be less than 1 m from the steering station. The extingu...

Page 27: Safety

23/106 fuel supply valve - location how to apply in case of fire compartment fuel tank: - stop the engine. - inject the extinguishing product through the aperture. - wait. Location - on the fuel tank 2 safety.

Page 28

24/106 manual bilge pump location arm - pump operation 0,7/blow warning - the bilge pump system is not designed to provide buoyancy to the boat in case of damage. - the bilge pump system is designed to drive out the water being either sea spray or leaks but absolutely not the water coming through a ...

Page 29: Safety

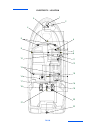

25/106 bilge pump system - location 2 1 2 3 4 12 13 5 6 7 8 9 10 11 safety.

Page 30

26/106 ref designation 1 electric bilge pump draining 2 electric bilge pump - compartment tank - petrol 3 manual bilge pump 4 drainage - aft quarterdeck 5 chain locker drain scuppers 6 washbasin - head 7 washbasin draining 8 galley sink 9 drainage - galley sink 10 drain - gas cylinder locker 11 drai...

Page 31: Safety

27/106 bilge pump system procedure to be followed - switch on the electric bilge pump. - if necessary activate the manual pump. - identify the source of the leak by tasting the water and decide on the relevant action to be taken: • freshwater = watertank leak. • seawater = breach of hull. Electric b...

Page 32

28/106 instructions in the event of steering gear failure - stop the engine. - drop anchor to avoid drifting. - find out if you can solve the problem yourself by looking at the engine manual. - request help..

Page 33: Hull

29/106 hull maintenance of the hull lifting 3.

Page 34

30/106 lifting wetted area: 16 m² precaution - consult the harbourmaster's office to find out the conditions of water use and the maintenance area for cleaning your vessel. - it is necessary to seek the advice of your concessionnaire with regard to gel-coat repairs. Precaution - when applying the an...

Page 35: Hull

31/106 maintenance of the hull the materials and equipments of your boat have been selected because of their high quality and performance and ease of maintenance. However you shall carry out a minimum maintenance in order to protect your boat from outside attacks (salt, sun, electrolysis ...). Prefe...

Page 37: Deck

33/106 deck navigation - deck layout mooring lines towing stability prevention of man overboard mooring maintenance of the deck 4.

Page 38

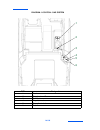

34/106 navigation - deck layout p a. Mooring cleats aft - jack-lines to be fixed to the mooring cleats b. Towing: - at the bow, to be towed - at the stern, to tow c. Swimming ladder (means of coming back onboard) ring - handling: used to maneuver the boat on a trailer warning the sudden closing of a...

Page 39: Deck

35/106 mooring lines a sufficient number of mooring lines suitably sized and suitable for the environment shall be on board for mooring your boat. - always manoeuvre your boat using the engine. - make allowance for the current and wind when you handle your boat. - protect your boat to the highest de...

Page 40

36/106 opening / closure sliding hatch window lock access cockpit - to be kept closed when sailing access cockpit - open rod holder.

Page 41: Deck

37/106 stability breaking waves represent a serious danger for stability and for taking in water. Close the companionway doors and hatches in heavy seas. During sailing keep all the portholes, windows and doors closed. - the stability is reduced when you add weight in the upper parts. - stability ma...

Page 42

38/106 deck electric windlass - breaker location . Clinch 1. Bow fitting 2. Handle position 3. Stowage - remote control 4. Windlass 12v 5. Chain locker breaker 80a location: compartment tank - petrol operation relay location: head.

Page 43: Deck

39/106 operation when using the windlass the hatch must be open and the chain brake in position. Location of battery switch - compartment tank - petrol the windlass operates on the service batteries. Turn on the boat engine. Battery switches to be turned on: - battery switch - positive 4 deck.

Page 45: Deck

41/106 mooring as a rule, set the anchor in at least 3 times the depth of water. Anchoring without windlass - have your boat pointed into the wind and without speed. - pay out the chain while moving back slowly. - once the anchor snags, make it fast by reversing slightly. - secure the hawser or the ...

Page 46

42/106 anchoring by hand with use of a manual windlass - release the windlass brake using the handle located in the chain locker so as to allow the chain lifter to turn freely and to release the anchor from the stem fitting - re-engage the brake and let the anchor hang until the mooring position is ...

Page 47: Deck

43/106 maintenance of the deck preferably wash your boat on shore. Use as few cleaning agents as possible. Don't use solvents or aggressive detergent agents (refer to chapter 3 "hull"). Don't discharge cleaning agents into the water. Regularly brush the deck with a degreasing shampoo and fresh water...

Page 49: Steering System

45/106 steering system steering gear 5.

Page 50

46/106 location - steering system ref designation 1 steering rack 2 steering wheel 3 engine control lever 4 steering cable (hydraulic) 5 control cables 6 watertight bellows 7 piston 8 outboard 7 8 1 2 3 4 5 6.

Page 51: Steering System

47/106 steering gear steering and turns - the steering only works when the engine is running. It is impossible to make a turn without using the accelerator. - to turn, reduce speed, turn the wheel and then accelerate sufficiently to make the turn. - it stops under the effect of water resistance when...

Page 53: Interior

49/106 interior introduction interior maintenance maintenance of fabrics 6.

Page 54

50/106 introduction deck saloon interior accommodation.

Page 55: Interior

51/106 interior maintenance interior - take advantage of the fine weather to take the settee and berth cushions out. - put the cushions vertically if you leave the boat for long. - use blinds to protect the inside of the boat against uv rays. - carefully remove all crumbs. - make sure the bilges are...

Page 57: Interior

53/106 100% polyester/dralon jacquard if you cannot remove the fabric: - clean with the vacuum cleaner. - clean with a foam for synthetic fabrics (please refer to the product instructions). If you can remove the fabric: - hand wash with an ordinary washing powder at 30° c. In both cases, dry cleanin...

Page 59: Water and Sewage Water

55/106 water and sewage water water tanks water system - distribution water system - drainage sewage 7.

Page 60

56/106 water tank operation in order to prevent any handling mistakes, never fill the water and fuel tanks at the same time. During filling, avoid handling contaminants near the fillers. Open and close the filler caps with the suitable key. Check the filler cap seals for condition during filling. Th...

Page 61: Water and Sewage Water

57/106 water unit - 12v + filter clean /change the filter cockpit shower spray warning to avoid freezing during very cold spells and/or winter storage bleed the cockpit shower hose water system. Precaution - never operate the water system equipment when the valve is closed or the tank is empty (the ...

Page 62

58/106 operation waste water from the sink, washbasins and heads is drained off by thru-hull fittings with ball valves (the valve is closed when the valve handle is perpendicular to the hose, the valve is open when the valve handle is in line with the hose). All the floors have holes (limber holes) ...

Page 63: Water and Sewage Water

59/106 use of washbasin close the valves and turn off the taps after use. Sink (galley) washbasin (head) drainage drainage advice - recommendation - regularly check the valves and thru-hull seacocks for proper operation and watertightness. - turn off the valves when the water system is not in use. -...

Page 64

60/106 sewage use of the marine heads before you use the heads, check that the water intake valve and draining valve are open. To empty the bowl: - set the control lever of the pump slantwise (flush). - operate the pump. To dry the bowl: - set the lever back vertical (dry). - operate the pump. To av...

Page 65: Water and Sewage Water

61/106 sewage tank capacity: 80 litre location: head wc evacuation - deck filler cap 'waste' warning - the tanks' nominal capacity cannot be fully used due to the load and the need to maintain the correct trim. A 20% reserve should be kept. 7 water and sewage water.

Page 66

62/106 schematic diagram - sewage ref designation 1 marine toilet 2 seawater inlet - wc 3 wc evacuation - to sea 4 wc evacuation - deck - filler cap "waste" 5 vent hole - holding tank 6 holding tank - 80 litre 1 2 3 4 5 6.

Page 67: Water and Sewage Water

63/106 respect of the environment - remain informed of local regulations concerning the environment and follow the codes of best practice. - do not drain the contents of the sewage tank near the coast or in zones where it is forbidden. - make use of the port or marina pump facilities to drain the se...

Page 68

64/106 use of marine heads equipped with a waste holding tank (wht) open the water intake valve (valve handle parallel to the pipe). In the case of a direct discharge into the sea: open the draining valve. In case you store the waste waters in the tank: make sure the draining valve is closed (valve ...

Page 69: Electrical Equipment

65/106 electrical equipment 12 v circuit - dc electrical circuit, 110-220 v equipment 8.

Page 70

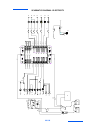

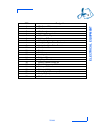

66/106 schematic diagram - electricity 10 2 250ma 44 43 42 41 40 do w n up 7.5a 10 a 15 a 10 a 10 a 10 a 10 a 10 a 10 a 10 a 10 a 10 a 10 a 1a 39 38 33 14 11 31 32 30 37 36 45 34 1w 1a o r 2 ,5 ² 4p 1a r 2 ,5 ² 1c 1a r 4 ² 3p 1a r 2 ,5 ² 1e 1a r 2 ,5 ² 35 25 a 1f 1 a or 2, 5² 1l1a j 2 ,5 ² 1h f 1 n2...

Page 71: Electrical Equipment

67/106 ref designation 1 switch - mooring light 2 switch - compass 3 switch - electric bilge pump - forward cabin 4 switch - electric bilge pump - compartment tank 5 switch - navigation lights 6 switch - starboard windscreen wiper 7 switch - port windscreen wiper 8 switch - windscreen washer 9 switc...

Page 72

68/106 electrical circuit, 12 vdc general recommendations - never work on a live electric fitting. - the batteries must be strongly fastened. - do not block the battery ventilation ducts, some of them may give off hydrogen which represents a danger of explosion. - the batteries must be handled with ...

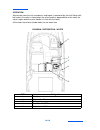

Page 73: Electrical Equipment

69/106 access to fuses hatch head warning always replace a fuse with one of the same size 8 20a 15a 10a 5a 3a electrical equipment.

Page 74

70/106 switches - wheelhouse 1. Navigation light - mooring light 2. Lighting 3. Water unit 4. Refrigeration unit 5. Electric bilge pump 6. Wiper 7. Windscreen washer wiper tank: location.

Page 75: Electrical Equipment

71/106 location battery switch battery switch - positive 8 electrical equipment.

Page 76

72/106 battery set batteries battery charging is achieved through the alternator coupled to the engine or through use of the 220 v shore charger. Keep the batteries charged enough (essential to ensure them a correct service life). Make the most of time alongside to use the 220 v shore charger so as ...

Page 77: Electrical Equipment

73/106 always check the condition of the batteries and charge system before putting to sea warning - never work on a live electric fitting - do not touch the battery terminals, danger of electric shock. Precaution - switch off the electrical system with the battery switches when the boat is unattend...

Page 78

74/106 electricity - location p 9 9 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22.

Page 79: Electrical Equipment

75/106 ref designation 1 windlass - 12v 2 windlass remote control 3 windlass fuse 4 lighting - forward cabin 5 motor - 12v - wiper 6 lighting - wc 7 compass light 8 navigation light - side - starboard 9 navigation light - side - port side 10 electronics box 11 fuse box 12 switches 13 loud speakers 1...

Page 80

76/106 electrical circuit, 110-220 v general recommendations certain vessels are equipped (as either standard or optional features depending on the model)with a 110 v or 220 v circuit. The following measures are recommended in order to avoid the danger of electrical shock and fire: - never work on a...

Page 81: Electrical Equipment

77/106 shore power socket - 220v shore power socket - 220v / 30a breaker 220v / 32a access - under the sink switch: general - water heater - 220 v socket 8 electrical equipment.

Page 82

78/106 equipment general introduction (as far as possible) use electric appliances with double insulation or with three conductors (neutral-live wire-ground). Electronic wire runs are available to complete the boat equipment. Do not install electronic instruments or repeaters less than 1,50 m away f...

Page 83: Electrical Equipment

79/106 lead lines the loch and depth sounder transducers are located in the engine compartment. Keep the log sensor cowl close to the instrument so as to be able to intervene in complete safety. Do not store material on top of the sensors. Auto pilot - to supply power to all elements switch on the "...

Page 85: Engine

81/106 engine general information engine fitting 9.

Page 86

82/106 general information type of motorisation your vessel is fitted with a gasoline-powered outboard engine. Transmission type is: sail-drive. Precautions of use, operating advice general point - in this vessel, do not install an engine with a greater power and weight than that recommended, this w...

Page 87: Engine

83/106 danger - stop the engine and refrain from smoking during fuel tank filling. - make sure that the ventilation openings in the engine (and generator, if installed) compartment are well cleared. Warning - the tanks' nominal capacity cannot be fully used due to the load and the need to maintain t...

Page 88

84/106 epa version (united states environmental protection agency) - the maintenance of the complete petrol circuit system must be done professionally every year. It is advisable to clean the circuit only with soapy water. All the fuel circuit connections must be checked once a year. - when cleaning...

Page 89: Engine

85/106 location - system - fuel ref designation 1 fuel gauge indicator 2 fuel supply valve 3 280 litres fuel tank 4 fuel filter 7 fuel filler 10 fuel gauge transmitter 11 vent hole 9 engine.

Page 90

86/106 motor these instructions give detailed explanations on proper operation of the engine. - refill before the fuel tanks have almost run dry (the fuel system may be stopped for lack of fuel). - make sure you have enough fuel before sailing. Engine water intake valve the engine water valve is ess...

Page 91: Engine

87/106 fuel filter engine running problems may have different origins, including dirty fuel. The injection pump may wear out if there is water in the system. The water results either from the condensation resulting from an insufficiently filled tank, or from a filler cap either not closed properly o...

Page 92

88/106 wheelhouse - detail synoptic 1. Compass 2. Tachometer 3. Starting motor 4. 12 v socket 5. Electrical controls 6. Lever - motor 7. Steering wheel 8. Electrical controls 9. Electronic 10. Hifi 11. Gauge - tank - petrol.

Page 93: Engine

89/106 the instrument panel has all the testing functions of the engine and it does not require any special precaution (refer to engine leaflet). Check the clutch and accelerator cables (lubricate the end fittings and forks). Cutout danger attach the cutout to the pilot at engine start. 9 engine.

Page 94

90/106 visibility from the steering station the international regulations to prevent collision at sea (colreg) and the course regulations make mandatory a permanent and proper surveillance and the respect of priority. Make sure there is no other boat on your way. The visibility from the steering sta...

Page 95: Engine

91/106 navigation: reminder of some advice stability during sailing keep all the portholes, windows and doors closed. - the stability is reduced when you add weight in the upper parts. - stability may be reduced when towing a boat or when heavy weights are lifted with the davits. - breaking waves re...

Page 97: Launching

93/106 launching launching recommendations 10

Page 98

94/106 position of hoisting cradle and straps note: measurements are expressed in mm. 1000 3400

Page 99: Launching

95/106 launching recommendations a lot of skill and care is required to commission your jeanneau boat. The proper working of all your boat's equipment is the result of the quality of the commissioning operations. In order to remain completely under guarantee in the case of any failure of parts or ma...

Page 101: Winter Storage

97/106 winter storage laying up protection and maintenance 11.

Page 102

98/106 laying up - take ashore all the ship's log, the ropes that are not used for mooring, the galley equipment, supplies, clothes, the safety equipment, batteries, the gas cylinder. - mark again the safety equipment, check the expiration dates, have the liferaft overhauled. - take advantage of thi...

Page 103: Winter Storage

99/106 motor the engine winterization shall be carried out by a professional. Depending on the boat location, afloat or ashore, winterization is different. Here are a few major tasks to carry out: afloat - drain the cooling system and fill it with antifreeze. - shut off the battery switches, grease ...

Page 105: Appendixes

101/106 appendixes certificates of standards epa 12.

Page 106

102/106 certificates of standards epa pressure relief system deck fill 99dfpv series inst alla tion instructions 11/04 69485 rev . B sa ve these instructions caution: the vessel manufacturer must comply with the requirements of cfr 40 1060.202. Any questions can be directed to www .Attwoodmarine.Com...

Page 107: Appendixes

103/106 12 integra ted fuel demand v a lv e 99ifdv series inst alla tion instructions 2/12 69487 rev . C sa ve these instructions caution: the vessel manufacturer must comply with the requirements of cfr 40 1060.202. Any questions can be directed to www .Attwood.Com failure to follow these instructi...

Page 108

104/106 inle t control v a lv e 99icv series inst alla tion instructions 11/04 69482 rev . B sa ve these instructions caution: the vessel manufacturer must comply with the requirements of cfr 40 1060.202. Any questions can be directed to www .Attwoodmarine.Com failure to follow these instructions ma...

Page 109: Appendixes

105/106 12 appendixes.

Page 110

106/106.