- DL manuals

- Jeanneau

- Boat

- SUN ODYSSEY 50DS

- Owner's Manual

Jeanneau SUN ODYSSEY 50DS Owner's Manual

Summary of SUN ODYSSEY 50DS

Page 1

Sun odyssey 50ds owner's manual c r o is ie r e 134949 index k.

Page 3: Welcome Aboard

-1/152 welcome aboard madam, sir, you have just taken delivery of your new jeanneau boat and we thank you for the confidence you have shown us in ordering a vessel of our brand. The whole jeanneau team welcomes you aboard. A jeanneau is made to last, in order to bring you all the pleasure you expect...

Page 5: Introduction

1/152 introduction the users of the boat are informed of the following: this user guide/owner's manual is not a maintenance or repair guide. In case of difficulty do not hesitate to call on the services of your concessionaire jeanneau. Any alterations which may affect the safety specifications of th...

Page 6

2/152 anyone on the deck shall wear a life jacket or a buoyancy aid. The safety regulations as defined by the sailing code and enforced by the ’’colreg’’ should be observed. Name plate: some of the data is shown on the manufacturer's plate fixed to the boat. The explanation of the data is given in t...

Page 7: History Of Updates

3/152 history of updates •index a ......................................................................................................................... 02/2008 •index b .................................................. Page 8-9-62 .................................................. 07/2008 •inde...

Page 9: Contents

5/152 contents introduction chapter 1 ...... Specifications and warranty ............................................Page 7 chapter 2 ...... Safety ........................................................................................Page 13 chapter 3 ...... Hull .....................................

Page 11

7/152 specifications and warranty technical specifications certification design category your boat 1.

Page 12

8/152 technical specifications l.O.A....................................................................................................................... 15,07 m hull length............................................................................................................... 14,75 m l.W.L...

Page 13

9/152 certification design category the sun odyssey 50ds model conforms to the directive 2003/44/ce. Sails classic jib reefer performance grand-voile ..............51,6 m 2 ................... 39 m 2 ..................... 54,3 m 2 génois .....................62,1 m 2 ................ 62,1 m 2 .........

Page 14

10/152 category a: at high sea this craft is designed to operate in winds that may exceed wind force 8 (beaufort scale) and in significant wave heights of 4 m and above. This craft is largely self-sufficient. Abnormal conditions such as hurricanes are excluded. Such conditions may be encountered on ...

Page 15

11/152 your boat version name of the boat ............................................................. Name of the owner ............................................................. Address ............................................................. .................................................

Page 17: Safety

13/152 safety safety equipment general information gas system recommendations for gas fight against fire bilge pump system emergency tiller 2.

Page 18

14/152 safety equipment swimming ladder (means of coming back onboard) (reference 1) liferaft (not supplied) (reference 2) liferaft in the aft quarterdeck locker. Note: if over 10 persons on board, 2 liferafts compulsory.

Page 19

15/152 general information dangers the major hazards concern: - the gas system. - the electrical system. - manoeuvring the vessel and the sails. - the motorisation. Please refer to the relevant paragraphs. Danger - fuel leaks or vapour represent a danger of fire and explosion. - leave the engine com...

Page 20

16/152 gas system location gas vent hole ref designation 1 gas cylinder locker 2 gas kill valve on bottle 3 gas pipe 4 gas rubber tubing 5 tap to turn off the gas 7 gas vent.

Page 21

17/152 note: same position for the other layouts. Opening valve / reheating gas closing (reference 1) a pictogram helps to locate it easily valve ref designation 1 valve on appliance 2 valve on cylinder 6 open valve 7 closed valve 2 gas cylinder locker (reference 2) s a f e t y.

Page 22

18/152 diagram - schematic diagram for gas system - europe version ref designation 1 regulator valve 2 gas cylinder 3 drain 4 connection kit - gas bottle 5 rubber washers 6 pictogram 7 connection kit - gas copper 8 pvc girdled sleeve 9 gas appliance connection kit gaz gaz 8 3 2 4 1 6 9 7 5.

Page 23

19/152 recommendations for gas type of cylinder: butane, service pressure 10 kg/cm 2 or according to current standards of your country). Close the valves on the system and on the cylinder when the appliances are not used. Close the valves before you change cylinders and immediately in case of emerge...

Page 24

20/152 diagram - schematic diagram for gas system - us version never obstruct the fast access to the components of the gas system. Keep the taps of the empty cylinders turned off and the cylinders disconnected. Keep the protection, lids, covers and taps in their places. Don't use the gas cylinder st...

Page 25

21/152 position of gas bottle the locker for storing gas bottles can be reached through the cockpit under the foldaway seat. The locker can accommodate 2 gas bottles. The locker is equipped with bottle fastening straps. Fight against fire it is the owner's or the skipper's responsibility: - to have ...

Page 26

22/152 emergency evacuation and location of extinguishers position of portable extinguishers (not supplied) -near to the stanchion -starboard aft cabin -under map table -in cockpit locker emergency exits in case of fire -deck hatch of the fore cabin -companionway.

Page 27

23/152 extinguishers the extinguishers are part of the compulsory equipment. An extinguisher or a fire blanket shall be set less than 2 m from any flame appliance. Extinguishers must be placed less than 5 m from any berth. It is compulsory for an extinguisher to be placed less than 2 m away from the...

Page 28

24/152 note: same position for the other layouts. Fuel supply valve access extinguisher aperture of the engine compartment a pictogram helps to locate it easily.

Page 29

25/152 the engine compartment has a port that makes it possible to inject the extinguishing product inside without opening the usual access hatches. Instructions to follow in case of a fire in the engine compartment bilge: - stop the engine. - switch off power and stop fuel supply. - block off the a...

Page 30

26/152 use of the manual bilge pump bilge pump system procedure to be followed - switch on the electric bilge pump. - if necessary activate the manual pump. - identify the source of the leak by tasting the water and decide on the relevant action to be taken: • freshwater = watertank leak. • seawater...

Page 31

27/152 electric bilge pumps the first electric bilge pump is loated in the well in the middle of the mess room. The second electric bilge pump is located in the plumbing panel behind the starboard mess room backboard.. You can energize the electric bilge pump from the electrical panel. On the electr...

Page 32

28/152 use steers frank of help.

Page 33

29/152 emergency tiller the emergency tiller is in an aft locker and shall be easy to get to. To operate the tiller: - use a winch handle and unscrew the tiller cover situated at the back of the cockpit. - insert the tiller into the rudder stock and make sure it is fully secure in the square. - if t...

Page 35: Hull

31/152 hull maintenance of the hull lifting 3.

Page 36

32/152 lifting wetted area: 45 m² precaution - consult the harbourmaster's office to find out the conditions of water use and the maintenance area for cleaning your vessel. - it is necessary to seek the advice of your concessionnaire with regard to gel-coat repairs. Precaution - when applying the an...

Page 37

33/152 maintenance of the hull the materials and equipments of your boat have been selected because of their high quality and performance and ease of maintenance. However you shall carry out a minimum maintenance in order to protect your boat from outside attacks (salt, sun, electrolysis ...). Prefe...

Page 39: Deck

35/152 deck navigation mooring lines towing stability prevention of man overboard mooring maintenance of the deck 4.

Page 40

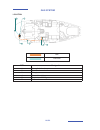

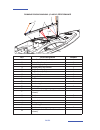

36/152 navigation deck layout the maximum weight of the outboard engine (not supplied) on the pushpits should not exceed 20 kg. A. Mooring cleats (jack-lines to be fixed to the mooring cleats) b. Towing: • at the bow, to be towed • at the stern, to tow c. Swimming ladder (means of coming back onboar...

Page 41: Deck

37/152 mooring lines a sufficient number of mooring lines suitably sized and suitable for the environment shall be on board for mooring your boat. - always manoeuvre your boat using the engine. - make allowance for the current and wind when you handle your boat. - protect your boat to the highest de...

Page 42

38/152 stability breaking waves represent a serious danger for stability and for taking in water. Close the companionway doors and hatches in heavy seas. During sailing keep all the portholes, windows and doors closed. - the stability is reduced when you add weight in the upper parts. - stability ma...

Page 43: Deck

39/152 closure companionway 1. Sliding hatch 2. Access door to companion ladder 3. Lock and key 4. Door latch opening deck hatches opening portlight closure hatch cover closure swimming ladder 4 deck.

Page 44

40/152 mooring as a rule, set the anchor in at least 3 times the depth of water. Anchoring without windlass - have your boat pointed into the wind and without speed. - pay out the chain while moving back slowly. - once the anchor snags, make it fast by reversing slightly. - secure the hawser or the ...

Page 45: Deck

41/152 electric windlass - breaker 1. Bow fitting 2. Mooring locker 3. Windlass 12v 1600w 4. Opening - mooring locker 5. Handle position 6. Clinch 7. Remote control 8. Chain lifter 12mm diameter 9. Handle storage location of cutouts and circuit breaker in rear port cabin below the berth. 1. Battery ...

Page 46

42/152 anchoring by hand with use of a manual windlass - release the windlass brake using the handle located in the chain locker so as to allow the chain lifter to turn freely and to release the anchor from the stem fitting - re-engage the brake and let the anchor hang until the mooring position is ...

Page 47: Deck

43/152 maintenance of the deck preferably wash your boat on shore. Use as few cleaning agents as possible. Don't use solvents or aggressive detergent agents (refer to chapter 3 "hull"). Don't discharge cleaning agents into the water. Regularly brush the deck with a degreasing shampoo and fresh water...

Page 49: Steering System

45/152 steering system steering gear 5.

Page 50

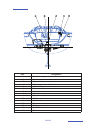

46/152 schematic diagram view overall access to the steering cables through the aft cockpit locker (helmsman's seat) 1. Steering wheel 2. Steering gear 3. Ropes 4. Sheaves 5. Emergency tiller 6. Chains.

Page 51

47/152 steering gear maintenance - regularly check: • the tension in the steering cables. • the tightness of the steering system components. - don't tighten the steering cables excessively. - lubricate all the elements. Maintain the nylon, ertalon or teflon bushes with only a suitable lubricant. Not...

Page 52

48/152 cable adjustment - steering system the steering gear is assembled and pre-adjusted at the factory, however, only actual use at sea will enable the steering cable to find its definitive postion around the wheel drum. For this reason, it is necessary to re-adjust the gear after the first few se...

Page 53: Rigging And Sails

49/152 rigging and sails standing rigging running rigging winches setting the sails sails 6.

Page 54

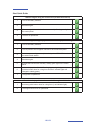

50/152 standing rigging version: classic/jib reefer reference designation number 1 forestay 1 2 backstay 2 3 v1 2 4 d1 2 5/7 v2/d3 2 6 d2 2.

Page 55

51/152 standing rigging your jeanneau dealer was responsible for stepping the mast of your boat. After masting your vessel and after having sailed for the first time it is necessary to seek the help of a qualified specialist in order to carry out a rigging check. Maintenance before each trip, carefu...

Page 56

52/152 note: the genoa halyard is handled at the foot of the mast classical mainsail ref rope designation number 1 reef 3 (optional equipment) 1 2 reef 2 (automatic) 1 3 reef 1 (automatic) 1 4 foot tuning line 1 5 kicking strap 1 6 mainsail sheet 1 7 sheet traveler adjustment 2 8 main halyard 1.

Page 57

53/152 running rigging furling mainsail . Ref rope designation number 1 foot tuning line 1 2 mainsail safety block stopper 1 3 kicking strap 1 4 mainsail sheet 1 5 sheet traveler adjustment 2 6 main halyard 1 6 r ig g in g a n d s a il s.

Page 58

54/152 running rigging mainsail (classic) performance . Ref rope designation number 1 traveller mainsail (classic) 1 2 mainsail track 1 3 swivel single pulley 6 4 simple pulley with becket 1 5 single frame pulley 3 6 single frame pulley 4 7 cheek block 2 8 single clutch 2 a reef 1 b reef 3 c foot tu...

Page 59

55/152 running rigging maintenance change any distorted or dented sheave. Inspect the pins of the sheaves at the top of the mast once a year. Lightly grease the sheave pins. Regularly check the condition of the jam cleat jaws. Inspect the halyards for wear and condition. Regularly clean the pulleys ...

Page 60

56/152 running rigging for the genoa ref rope designation number 1 genoa furler line 1 2 genoa sheet 2 3 sheet traveler adjustment 2 4 genoa halyard 1.

Page 61

57/152 furling mainsail - remove the hatch giving access to the furling mechanism. - spread out the sail on the deck. - fasten the head (strap) to the shackle of the upper swivel. Pay attention to the winding direction. - insert the foot adjustment line into the clew block. - slowly hoist the sail. ...

Page 62

58/152 running rigging (symmetric spi) ref rope designation number 1 spinnaker sheet 1 2 spinnaker guy 1 3 spinnaker boom downhaul 1 4 boom lift 1 5 spinnaker halyard 1.

Page 63

59/152 furling genoa - secure the head and halyard to the swivel. Secure the tack to the drum and sheets. - insert the bolt rope into the hole and hoist it and take care that you do not tear it. - have the halyard taut enough but hoist less taut than a sail on a normal stay. Hoist it until the horiz...

Page 64

60/152 automatic in-mast reefing block diagram advice - recommendation - at the end of the sailing season, and if possible before winter, leave your sails to a specialist to have efficient maintenance and repairs..

Page 65

61/152 sails the working life of a sail mainly depends on its being regularly maintained. When sailing, trim the sails properly in accordance with the stresses in order to reduce the harmful strains on the fabric. Avoid wear and tear: use protective items against chafing on the the accessories with ...

Page 66

62/152 hauling down the standard mainsail to haul down the mainsail: - haul up. - slacken off the kick strap. - take up the slack in the lazy bag ropes. - slacken off the mainsail halyard while taking up the reef lines to control the mainsail descent. - fold the mainsail into its lazy-bag. - take up...

Page 67: Interior

63/152 interior introduction interior maintenance maintenance of fabrics 7.

Page 68

64/152 introduction version: 2 aft cabins 1 forward cabin version: 1 aft cabin 2 forward cabins.

Page 69: Interior

65/152 interior maintenance interior - take advantage of the fine weather to take the settee and berth cushions out. - put the cushions vertically if you leave the boat for long. - use blinds to protect the inside of the boat against uv rays. - carefully remove all crumbs. - make sure the bilges are...

Page 70

66/152 access in engine compartment must be closed while sailing vegetable bin fixing - shower screen must be closed while sailing extension saloon mechanism.

Page 71: Interior

67/152 100% polyester/dralon jacquard if you cannot remove the fabric: - clean with the vacuum cleaner. - clean with a foam for synthetic fabrics (please refer to the product instructions). If you can remove the fabric: - hand wash with an ordinary washing powder at 30° c. In both cases, dry cleanin...

Page 73: Water And Sewage Water

69/152 water and sewage water water tanks water system - distribution water system - drainage sewage 8.

Page 74

70/152 water tanks forward water tank location: forward cabin capacity: 380 l aft water tank location: starboard aft cabin capacity: 235 l deck fillers gauge location: electrical panel refer to the instructions for use.

Page 75

71/152 water tanks operation in order to prevent any handling mistakes, never fill the water and fuel tanks at the same time. During filling, avoid handling contaminants near the fillers. Open and close the filler caps with the suitable key. Check the filler cap seals for condition during filling. T...

Page 76

72/152 plumbing board location: starboard saloon water system - distribution 1. Electric bilge pump 12v 2. Supply - aft tank 3. Supply - forward tank 4. Water unit 12v 5. Expansion tank water heater 1. Thermostatic mixer valve 2. Water heater 40l 220v precaution - never operate the water system equi...

Page 77

73/152 use of the washbasins and showers - close the valves and turn off the taps after use. Sea water foot pump / fresh water the footpump makes either seawater or freshwater available at the sink. The tap is located at the corner of the sink cupboard and the aft cabin door. Operate the 3-way valve...

Page 78

74/152 water system drainage operation waste water from the sink, washbasins and heads is drained off by thru-hull fittings with ball valves (the valve is closed when the valve handle is perpendicular to the hose, the valve is open when the valve handle is in line with the hose). All the floors have...

Page 79

75/152 sink draining - galley shower draining 1. Drain plug - drainage 2. Drainage pump control 3. Pump - drainage 4. Shower tray draining washbasin draining - head version 8 w a t e r a n d s e w a g e w a t e r.

Page 80

76/152 toilet operation quiet flush (optional) 1. Rinsing out the bowl 2. Water filling to the left and bowl draining to the right seawater inlet - wc thru-hull seacock deck drainage.

Page 81

77/152 sewage use of the marine heads before you use the heads, check that the water intake valve and draining valve are open. To empty the bowl: - set the control lever of the pump slantwise (flush). - operate the pump. To dry the bowl: - set the lever back vertical (dry). - operate the pump. To av...

Page 82

78/152 execrement tanks 1. Deck filler - suction and rinsing 2. Tank vent hole 3. Thru-hull seacock layout and capacity of black waters reservoirs - bathrooms 3 cabins 2 version - starboard forward head compartment (optional) : 80 litre - port aft head compartment standard : 80 litre - bathrooms 3 c...

Page 83

79/152 use of marine heads equipped with a waste holding tank (wht) open the water intake valve (valve handle parallel to the pipe). In the case of a direct discharge into the sea: open the draining valve. In case you store the waste waters in the tank: make sure the draining valve is closed (valve ...

Page 84

80/152 to empty the tank: - in an authorized area, open the draining valve. - in a marina equipped with a system to suck the waste waters, put the sucking hose into the tank through the deck filler. Start the pump of the sucking system. The filler caps are opened and closed with an appropriate key. ...

Page 85: Electrical Equipment

81/152 electrical equipment general information 12 v dc system 110-220 v ac system equipment 9.

Page 86

8 2 /1 5 2 e l e c t r ic a l e q u ip m e n t p a n e l 1 2 v l o c a tio n : c h a rt ta b le $ $ $ $ $ $ 230 v ac prises ac ac plugs chargeur batterie battery charger chauffe-eau water heater of f 12v dc 10a max scheiber 12 v dc eclairage int. Cabin lights ac power reverse polarity prises ac ac p...

Page 87

83/152 general information electrical panel the electrical switchboard does not require any routine maintenance . In case an electric appliance is not energized, check: - the main power supply (batteries, battery switches). - the switches and circuit breakers on the line. - the relevant electrical u...

Page 89

85/152 electrical circuit, 12 v general recommendations - never work on a live electric fitting. - the batteries must be strongly fastened. - do not block the battery ventilation ducts, some of them may give off hydrogen which represents a danger of explosion. - the batteries must be handled with ca...

Page 90

86/152 battery set location: starboard aft cabin power: - service batteries: 3 x 110a - spare battery (optional): 110a - engine battery: 110a battery switch location: starboard aft cabin 1. Battery switch "common negative" 2. Battery switch "service positive" 3. Battery breaker - "positive terminal ...

Page 91

87/152 batteries battery charging is achieved through the alternator coupled to the engine or through use of the 220 v shore charger. Keep the batteries charged enough (essential to ensure them a correct service life). Make the most of time alongside to use the 220 v shore charger so as to start out...

Page 92

88/152 battery switch the electricity onboard is 12 v dc. The electrical system consists of service batteries. The batteries supply power to all the functions on board. The engine has its own battery. Switch on the electricity by turning the positive and negative battery switches. Warning - never wo...

Page 93

89/152 main components 12v refrigeration unit - central location: under the sink exchanger view interior / view outside 9 e l e c t r ic a l e q u ip m e n t.

Page 94

90/152 home cinema location: starboard saloon refrigeration unit - starboard location: under cooker warning - defrost the fridge regularly. - during long absence leave the fridge and icebox doors open to avoid mould developing..

Page 95

91/152 operation the televisions power, supplied by a transformer which is powered with batteries of service, operates at 12v. Starting up: first turn on the circuit breaker, then switch on the tv. The transformer is switched on and off automatically when you turn on or off the breaker. Inverter 12 ...

Page 96

92/152 bow thruster elements location: forward cabin 1. Battery set: 2 x 50a 2. Engine 12v 3. Fuse nozzle control location: port cockpit breaker location: port aft cabin operation turn on the boat engine. Switch the battery switch "positive easements". The thruster earth is linked to the main batter...

Page 97

93/152 winches - electric circuit breakers location: port aft cabin winches - genoa: 125a winches great sailing: 125a 9 e l e c t r ic a l e q u ip m e n t.

Page 98

94/152 fuses location: back of electrical panel refer to the plans at the end of the handbook for the detail warning always replace a fuse with one of the same size. Location: port aft cabin 1. System - general 12v - 100a 2. Engine compartment ventilator 3. Auto pilot 20a 15a 10a 5a 3a.

Page 99

95/152 shore power socket shore power socket 220v 16a breaker 16a danger - unplug the dock before leaving the dock. Advice - recommendation - in order to reduce the risks of electic shock and fire: - before you plug in or unplug the boat/shore supply cable, switch off the shut off device connected t...

Page 100

96/152 main components 220v water heater location: starboard saloon 1. Socket 220v 2. Water heater 40 l control location: electrical panel.

Page 101

97/152 electrical circuit, 110-220 v general recommendations certain vessels are equipped (as either standard or optional features depending on the model)with a 110 v or 220 v circuit. The following measures are recommended in order to avoid the danger of electrical shock and fire: - never work on a...

Page 102

98/152 air conditioning layout of components breaker + shore power socket 220v (ref 1) compressor - aft cabin + drainage - sea water (ref 2) control panel (ref 3) - shore/generator switch - cbs compressors - breaker - seawater pump.

Page 103

99/152 relay box - seawater pump (ref 4) seawater inlet + seawater pump (ref 5) compressor - saloon (ref 6) maintenance of filters (to engage in regular): -close valves taken seawater. -unscrew the top of the filter. -clean the strainer. -put everything back in place. Drainage - sea water compressor...

Page 104

100/152 conditioned air outlets control box.

Page 105

101/152 air conditioning general points: the air-conditioning cools the air temperature inside the boat (only when the boat is floating in water). The cooling circuit consists of one or more compressors that operate independently. A compressor is called "reversible" because it can heat the boat if t...

Page 106

102/152 generator synoptic ref designation 1 fuel filter 2 sea water filter 3 water trap 4 anti-siphon valve 5 differential circuit breaker 6 generator 7 water - gas separator 8 seawater inlet 9 drainage - sea water 10 outlet.

Page 107

103/152 generator layout of components water trap + drainage - sea water - breaker 220v (ref 1) generator (ref 2) battery switch (ref 3) 9 e l e c t r ic a l e q u ip m e n t.

Page 108

104/152 earthing plate (ref 4) remote control + master switch (ref 5) seawater inlet (ref 6).

Page 109

105/152 generator - schema general points: a generator is a device that can produce electricity (220v or 110v) from a mechanical energy (fuel). The generator will fed the onboard equipment operating at 220v or 110v, moored or sailing. Operation: - open the raw water intake valves and evacuation valv...

Page 110

106/152 equipment general introduction (as far as possible) use electric appliances with double insulation or with three conductors (neutral-live wire-ground). Electronic wire runs are available to complete the boat equipment. Do not install electronic instruments or repeaters less than 1,50 m away ...

Page 111

107/152 maintenance clean the repeater dials with freshwater. Refer to the instructions before using any other produce. The use of alcohol must be avoided. Electronic lead lines the log and depth sounder sensors are located under the forward cabin floor. Keep the log sensor cowl close to the instrum...

Page 112

108/152 auto pilot layout of components in-line piston (ref 1) vessel management unit (ref 2) gyrocompass (ref 3) a pictogram helps to locate it easily.

Page 113

109/152 interface location: chart table 9 e l e c t r ic a l e q u ip m e n t.

Page 115: Engine

111/152 engine general information engine fitting 360° docking version 10

Page 116

112/152 fuel tank location: port aft cabin capacity: 240 l gauge location: electrical panel refer to the instructions for use deck filler.

Page 117

113/152 general information type of motorisation your vessel is fitted with an in-board diesel engine. Transmission type is: sail drive (sail drive version). The transmission is pod type (360 docking version). Precautions of use, operating advice general point - in this vessel, do not install an eng...

Page 118

114/152 engine fitting.

Page 119

115/152 diagram - location 10 e n g in e.

Page 120

116/152 ref designation 1 sail-drive engine 2 fuel tank 3 engine battery 4 battery isolation switch set 5 diesel filter 6 sea water filter 7 anti-siphon valve 8 water heater 9 engine control lever 10 water trap 11 outlet 12 expansion tank 13 engine panel 15 fuel filler 16 fan.

Page 121

117/152 main components of the engine 1. Sea water filter 2. Diesel filter 3. Ventilator 4. Expansion tank 10 e n g in e.

Page 122

118/152 engine these instructions give detailed explanations on proper operation of the engine. - refill before the fuel tanks have almost run dry (the fuel system may be stopped for lack of fuel). - make sure you have enough fuel before sailing. Engine water intake valve location view interior loca...

Page 123

119/152 access to the engine access to the engine is from the mess room. You can check the main parts thanks to side hatches. Engine water intake valve the water inlet valve of the engine is essential in the engine operation. - hold the strainer on the base in the best possible state of cleanliness....

Page 124

120/152 fuel supply valve.

Page 125

121/152 fuel filter engine running problems may have different origins, including dirty fuel. The injection pump may wear out if there is water in the system. The water results either from the condensation resulting from an insufficiently filled tank, or from a filler cap either not closed properly ...

Page 126

122/152 the instrument panel has all the testing functions of the engine and it does not require any special precaution (refer to engine leaflet). Check the clutch and accelerator cables (lubricate the end fittings and forks). Visibility from the steering station the international regulations to pre...

Page 127

123/152 advice - recommendation - when the engine is running, avoid making noise and chops near the other users. - respect speed limits. - if this boat is equipped with a fixed blade propeller, when sailing at speeds over 8 knots it is essential to leave the reverse gear control in neutral. - to sta...

Page 128

124/152 navigation: reminder of some advice stability during sailing keep all the portholes, windows and doors closed. - the stability is reduced when you add weight in the upper parts. - stability may be reduced when towing a boat or when heavy weights are lifted with the davits. - breaking waves r...

Page 129

125/152 360 docking version general points - the 360 docking transmission is an electronically controlled mechanical transmission. - this type of transmission operates without a reverse gear, reversing is achieved by rotating the pod 180 degrees. - the 360 docking system is powered by the service ba...

Page 130

126/152 start quick guide start the engine using the control lever (forward and reverse) 1 turn on all battery switches. 2 start the engine. 3 (if necessary) activate the bow thruster manually: steady green light on the control panel. 4 the lever is operational. Start the engine, using the joystick ...

Page 131

127/152 diagrammatic view reference designation 1 heat engine 2 pod rotary motor: make the pod under the waterline turn 270 to starboard 3 clutch actuator: enables gear engagement and disengagement 4 clutch: mechanical linkage between the engine and the propeller shaft 5 tcu: (transmission and clutc...

Page 132

128/152 layout of components rotating motor (ref 2) clutch actuator (ref 3) tcu housing (transmission and clutch management) (ref 5) vmu housing (vessel management unit) (ref 6) throttle actuator (ref 7).

Page 133

1 2 9 /1 5 2 l a y o u t 1 0 a x10 (only zf) control head harness termination resistor clutch actuator x4 x1 x8 x8 (k-line only zf) power power power power x9 b x4 autopilot (no zf) bow thruster (no zf) x5 c x3 x3 x3 x6 safety connector x6 normal x2 x2 b a x5 x3 main harness vmu t.C.U. Harness v.M.U...

Page 134

130/152 operation 1. General points - the "360 docking" system is a manoeuvring aid to facilitate coming alongside and leaving the dock. This system must not in any circumstances be used as a means of navigation, even during approach manoeuvres in port. - in some use modes of the system, especially ...

Page 135

131/152 3. Operation - turn on all battery switches. The bow thruster battery master switches will turn on automatically when the bow thruster control is picked up. - open the fuel supply valve(s) from the fuel tank(s). - open the engine water inlet valve. - switch on the navigation electronics (ele...

Page 136

132/152 the joystick is on stand-by: this means that it is ready for use. The «ready» led is a steady red. The engine is controlled by the engine control lever. Place a hand on the joystick and press the button for 1 second. The green leds illuminate when the button is released. The 2 leds are illum...

Page 137

133/152 using the joystick push the joystick forwards. The boat moves forwards. The acceleration is proportional to the position of the joystick. Push the joystick back. The boat moves backwards. The acceleration is proportional to the position of the joystick. Push the joystick to port. The boat mo...

Page 138

134/152 several movements can be combined push the joystick to starboard + turn the joystick clockwise. The boat moves to starboard but the bow swings more quickly than the stern. Push the joystick to starboard + turn the joystick anti-clockwise. The boat moves to starboard but the stern swings more...

Page 139

135/152 turn the joystick anti-clockwise. The boat turns to port (virtually pivoting around its keel). Forward or reverse acceleration is proportional to the position of the joystick. Turn the joystick clockwise. The boat turns to starboard (virtually pivoting around its keel). Forward or reverse ac...

Page 140

136/152 quit joystick mode explanatory note regarding the joystick in flashing red «ready» led mode: when the red «ready» led is flashing, this indicates that a malfunction has been detected in the system. This malfunction may occur when the engine is started or the joystick is used. In some cases, ...

Page 141

137/152 5. Mode warm up (warming up the engine) warm up mode is a mode in which the engine is disengaged and accelerated. To engage the 'warm up' position, press the button and keep it pressed whilst moving the throttle to the first forward notch, then release the button. Warm-up is only possible in...

Page 142

138/152 7. Maintenance - after every 250-hours of use, or once a year depending on the level of use, the boat must be lifted out to change the pod oil. - during cranage: it is imperative to engage forward gear for several seconds to position the engine base of the boat correctly under the crane befo...

Page 143

139/152 8. Protection components of the 360 docking system lighted safety fuses reference designation 1 supply vhs 1 after engine contact 2 supply vhs 2 after engine contact 3 vmu power supply vmu 4 vmu power supply tcu 1 5 vmu power supply tcu 2 6 supply vmu after engine contact 7 supply tcu after ...

Page 145: Launching

141/152 launching launching recommendations stepping the mast 11.

Page 146

142/152 position of hoisting cradle and straps note: measurements are expressed in mm..

Page 147

143/152 launching recommendations a lot of skill and care is required to commission your jeanneau boat. The proper working of all your boat's equipment is the result of the quality of the commissioning operations. In order to remain completely under guarantee in the case of any failure of parts or m...

Page 148

144/152 after launching - check the sounder and speedometer fittings for tightness if need be. - open the valves and make sure that they are tight with the hull and relevant hose. - check the stuffing box for watertightness (refer to chapter 11 "stuffing box"). Before starting the engine, refer to c...

Page 149: Winter Storage

145/152 winter storage laying up protection and maintenance 12.

Page 150

146/152 laying up - take ashore all the ship's log, the ropes that are not used for mooring, the galley equipment, supplies, clothes, the safety equipment, batteries, the gas cylinder. - mark again the safety equipment, check the expiration dates, have the liferaft overhauled. - take advantage of th...

Page 151

147/152 engine the engine winterization shall be carried out by a professional. Depending on the boat location, afloat or ashore, winterization is different. Here are a few major tasks to carry out: afloat - drain the cooling system and fill it with antifreeze. - shut off the battery switches, greas...

Page 153: Personal Notes

149/152 personal notes jeanneau (establishment of the company spbi) bp 529 - 85505 les herbiers cedex - france tel. (33) 02 51 64 20 20 - fax (33) 02 51 67 37 65 internet : http://www.Jeanneau.Com(fr). T h e p re s e n t d o c u m e n t is n o t c o n tr a c tu a l a n d s in c e w e c o n s ta n tl...

Page 155

151/152.

Page 156

152/152.