- DL manuals

- Jeep

- Automobile

- 1997 Grand Cherokee

- Service Manual

Jeep 1997 Grand Cherokee Service Manual

Summary of 1997 Grand Cherokee

Page 1

Welcome to the 1997 jeep grand cherokee (rhd & lhd) interactive electronic service manual! Click on vehicle to begin tweddle litho: dom parts cdrom demo 09/96 page 4.

Page 2

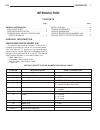

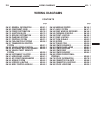

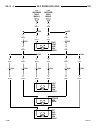

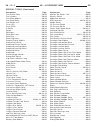

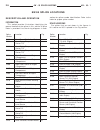

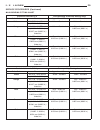

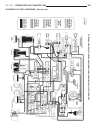

Group tab locator introduction 0 lubrication and maintenance 2 suspension 3 differential and driveline 5 brakes 7 cooling system 8a battery 8b starter 8c charging system 8d ignition system 8e instrument panel and systems 8f audio systems 8g horns 8h vehicle speed control system 8j turn signal and fl...

Page 3: Introduction

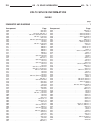

Introduction contents page page general information body code plate . . . . . . . . . . . . . . . . . . . . . 2 fastener identification . . . . . . . . . . . . . . . 3 international vehicle control and display symbols . . . . . . . . . . . . . . . . . . . . 3 metric system . . . . . . . . . . . . . ...

Page 4

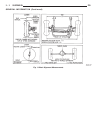

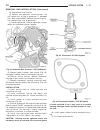

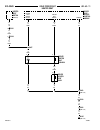

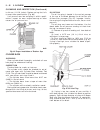

Vehicle safety certification label a vehicle safety certification label (fig. 1) is attached to every chrysler corporation vehicle. The label certifies that the vehicle conforms to all appli- cable federal motor vehicle safety standards. The label also lists: • month and year of vehicle manufacture....

Page 5

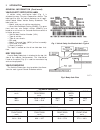

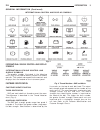

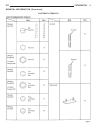

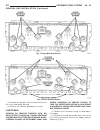

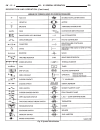

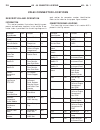

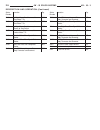

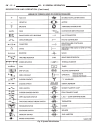

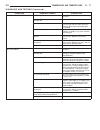

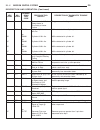

International vehicle control and display symbols international vehicle control and display symbols the graphic symbols illustrated in the following chart (fig. 3) are used to identify various instrument controls. The symbols correspond to the controls and displays that are located on the instrument...

Page 6

Fastener identification 4 introduction zg general information (continued).

Page 7

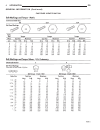

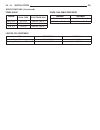

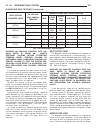

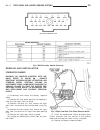

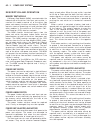

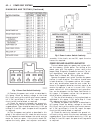

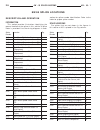

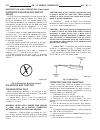

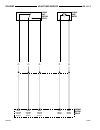

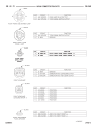

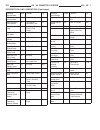

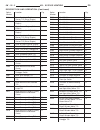

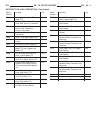

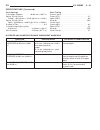

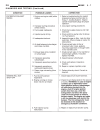

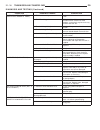

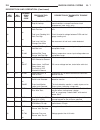

Fastener strength how to determine bolt strength mark class mark class hexagon head bolt bolt head no. Stud bolt no mark no mark hexagon flange bolt w/washer hexagon bolt no mark grooved hexagon head bolt two protruding lines hexagon flange bolt w/washer hexagon bolt two protruding lines welded bolt...

Page 8

Metric system warning: use of an incorrect fastener may result in component damage or per- sonal injury. Figure art, specifications and torque references in this service manual are identified in metric and sae format. During any maintenance or repair procedures, it is important to salvage metric fas...

Page 9

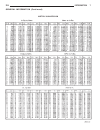

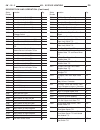

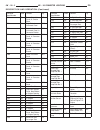

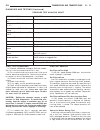

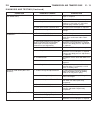

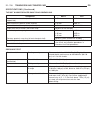

Metric conversion zg introduction 7 general information (continued).

Page 10

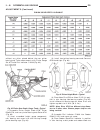

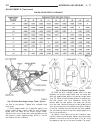

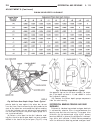

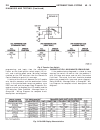

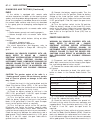

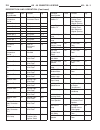

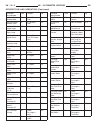

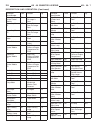

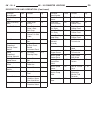

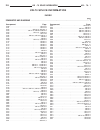

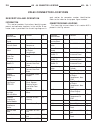

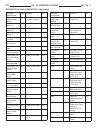

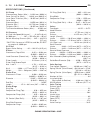

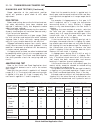

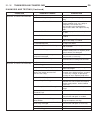

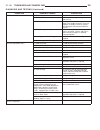

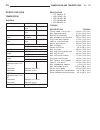

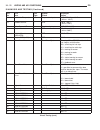

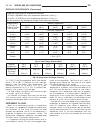

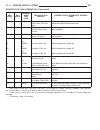

Torque specifications specified torque for standard bolts class diameter mm pitch mm specified torque hexagon head bolt hexagon flange bolt n·m kgf-cm ft.-lbf n·m kgf-cm ft.-lbf 48 in.-lbf 52 in.-lbf 56 in.-lbf 65 in.-lbf 69 in.-lbf 78 in.-lbf 8 introduction zg general information (continued).

Page 11: Introduction

Introduction contents page general information vehicle identification number (vin) . . . . 1 general information vehicle identification number (vin) the vehicle identification number (vin) plate is attached to the top left side of the instrument panel. The vin contains 17 characters that provide dat...

Page 13

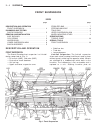

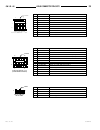

Lubrication and maintenance contents page page general information . . . . . . . . . . . . . . . . . . 1 jump starting, hoisting and towing . . . 8 maintenance schedules . . . . . . . . . . . . . . . 3 general information index page page general information classification of lubricants . . . . . . ....

Page 14

Engine oil sae grade rating indicates engine oil viscosity an sae viscosity grade is used to specify the vis- cosity of engine oil. Sae 30 specifies a single viscos- ity engine oil. Engine oils also have multiple viscosities. These are specified with a dual sae vis- cosity grade which indicates the ...

Page 15

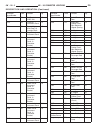

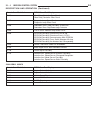

Maintenance schedules index page page general information introduction . . . . . . . . . . . . . . . . . . . . . . . . 3 schedule—a . . . . . . . . . . . . . . . . . . . . . . . . . 3 schedule—b . . . . . . . . . . . . . . . . . . . . . . . . . 5 unscheduled inspection . . . . . . . . . . . . . . 3 ...

Page 16

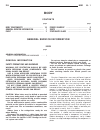

• replace spark plugs. • inspect drive belt. • lubricate steering linkage. • drain and refill automatic transmission fluid. • drain and refill transfer case fluid. 37,500 miles (60 000 km) or at 30 months • change engine oil. • replace engine oil filter. • lubricate steering linkage (4x4 only). 45,0...

Page 17

**recommended for proper vehicle performance for vehicles built for sale in california. Important: inspection and service should also be performed anytime a malfunction is observed or suspected. Schedule—b 3,000 miles (5 000 km) • change engine oil. • replace engine oil filter. • lubricate steering ...

Page 18

51,000 miles (82 000 km) • change engine oil. • replace engine oil filter. • flush and replace engine coolant. • lubricate steering linkage (4x4 only). 54,000 miles (86 000 km) • change engine oil. • replace engine oil filter. • lubricate steering linkage (4x4 only). 57,000 miles (91 000 km) • chang...

Page 19

• inspect brake linings. 99,000 miles (158 000 km) • change engine oil. • replace engine oil filter. • lubricate steering linkage (4x4 only). 102,000 miles (163 000 km) • change engine oil. • replace engine oil filter. • lubricate steering linkage (4x4 only). 105,000 miles (168 000 km) • change engi...

Page 20

Jump starting, hoisting and towing index page page service procedures emergency tow hooks . . . . . . . . . . . . . . . 10 four-wheel-drive vehicle towing . . . . 10 hoisting recommendations . . . . . . . . . . 10 jump starting procedure . . . . . . . . . . . . . 8 towing recommendations . . . . . ....

Page 21

Onds, stop cranking engine and allow starter to cool (15 min.), before cranking again. Disconnect cable clamps as follows: • disconnect black cable clamp from engine ground on disabled vehicle. • when using a booster vehicle, disconnect black cable clamp from battery negative terminal. Disconnect re...

Page 22

2wd—automatic transmission provided the transmission is operable, tow only in neutral at speeds not to exceed 30 mph (50 km/h) and distances less than 15 miles (25km/h). If the vehicle is to be towed more than 15 miles, the propeller shaft should be disconnected or place tow dollies under rear wheel...

Page 23

Lubrication and maintenance contents page page general information . . . . . . . . . . . . . . . . . . 1 maintenance schedule . . . . . . . . . . . . . . . . . 2 general information index page page specifications engine oil—diesel engines . . . . . . . . . . . . 1 fluid capacities . . . . . . . . . ...

Page 24

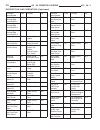

Maintenance schedule index page page general information maintenance schedule—diesel engine . 2 schedule—a . . . . . . . . . . . . . . . . . . . . . . . . . . 2 schedule—b . . . . . . . . . . . . . . . . . . . . . . . . . . 3 general information maintenance schedule—diesel engine the following are e...

Page 25

60 000 km • change engine oil. • change engine oil filter. • replace air filter element. • check glow plug operation. • replace drive belt. • check engine smoke. • replace engine coolant. 70 000 km • change engine oil. • change engine oil filter. 80 000 km • change engine oil. • change engine oil fi...

Page 26

• check glow plug operation. • replace fuel filter/water separator element. 45 000 km • change engine oil. • change engine oil filter. 50 000 km • change engine oil. • change engine oil filter. • replace air filter element. • check drive belt tension. • check glow plug operation. 55 000 km • change ...

Page 27: Suspension

Suspension contents page page alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 front suspension . . . . . . . . . . . . . . . . . . . . . 4 rear suspension . . . . . . . . . . . . . . . . . . . . . 11 alignment index page page general information wheel alignment . . . . . . . . . ...

Page 28

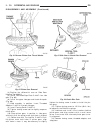

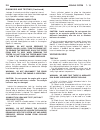

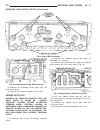

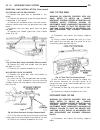

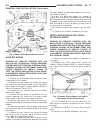

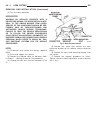

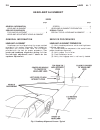

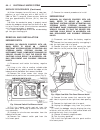

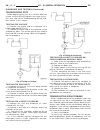

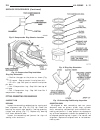

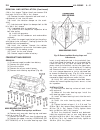

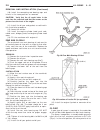

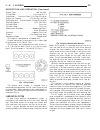

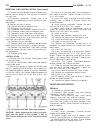

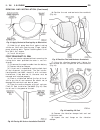

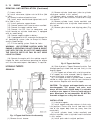

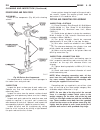

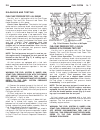

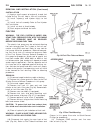

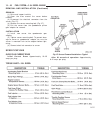

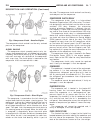

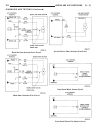

Fig. 1 wheel alignment measurements camber wheel center- line negative cam- ber angle pivot cen- terline scrubradius positive camber (not shown) top of wheel outboard true ver- tical toe a front of vehicle negative toe (toe out) b > a positive toe (toe in) b trust angle angle of rear axle relative t...

Page 29

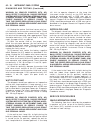

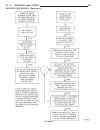

Diagnosis and testing pre-alignment inspection before starting wheel alignment, the following inspection is necessary and must be completed. (1) inspect tires for size, air pressure and tread wear. (2) inspect front wheel bearings for wear or adjust- ment. (3) inspect front wheels and tires for exce...

Page 30

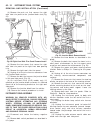

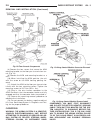

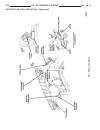

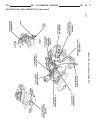

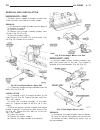

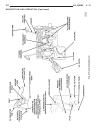

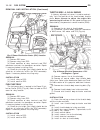

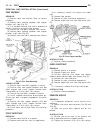

Front suspension index page page description and operation front suspension . . . . . . . . . . . . . . . . . . . . 4 diagnosis and testing shock diagnosis . . . . . . . . . . . . . . . . . . . . . 5 removal and installation axle bushing . . . . . . . . . . . . . . . . . . . . . . . . . 7 coil sprin...

Page 31

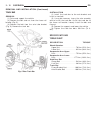

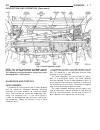

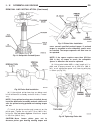

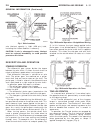

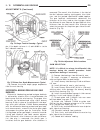

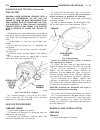

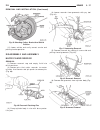

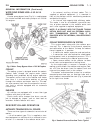

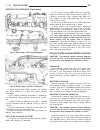

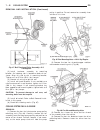

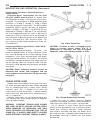

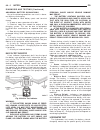

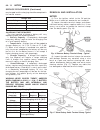

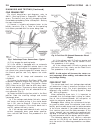

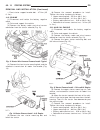

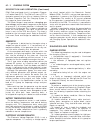

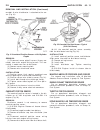

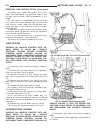

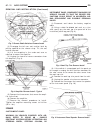

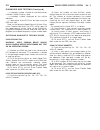

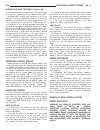

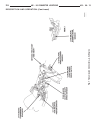

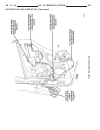

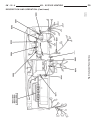

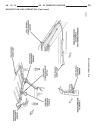

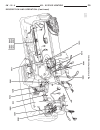

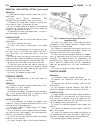

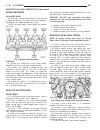

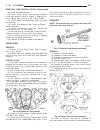

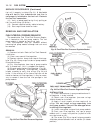

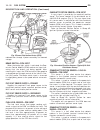

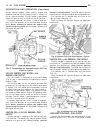

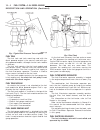

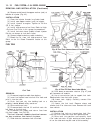

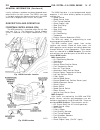

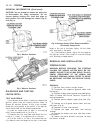

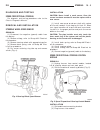

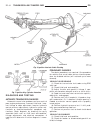

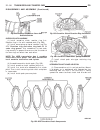

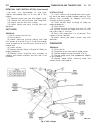

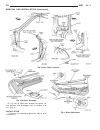

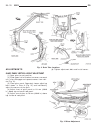

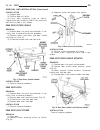

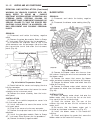

Replaceable ball studs attached to the axle tube yokes. Shock absorbers: the shock absorbers dampen jounce and rebound motion of the vehicle over vari- ous road conditions. The top of the shock absorbers are bolted to the body. The bottom of the shocks are bolted to the axle brackets. Coil springs: ...

Page 32

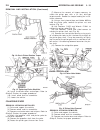

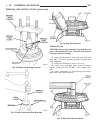

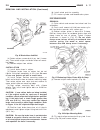

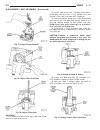

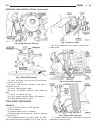

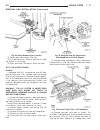

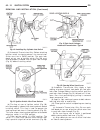

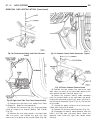

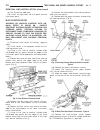

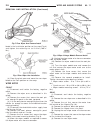

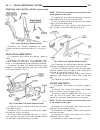

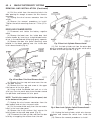

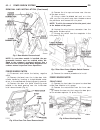

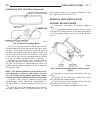

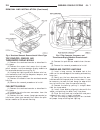

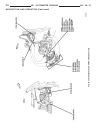

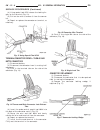

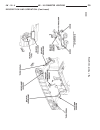

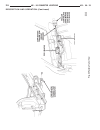

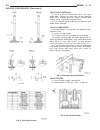

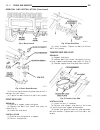

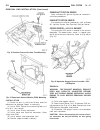

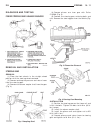

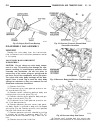

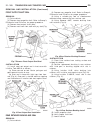

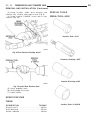

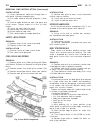

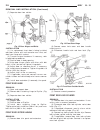

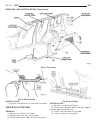

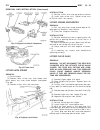

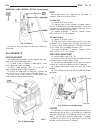

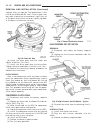

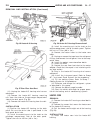

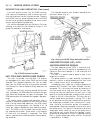

(5) disconnect the stabilizer bar link and shock absorber from the axle. (6) disconnect the track bar from the frame rail bracket. (7) disconnect the drag link from the pitman arm. (8) lower the axle until the spring is free from the upper mount. Remove the coil spring retainer bolt (fig. 2) and rem...

Page 33

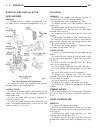

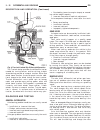

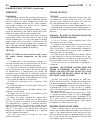

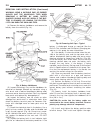

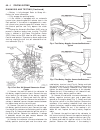

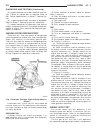

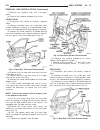

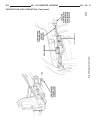

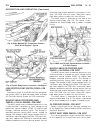

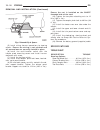

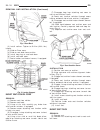

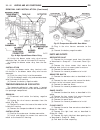

(7) tighten the frame bracket nut to 176 n·m (130 ft. Lbs.). (8) check the alignment if new parts were installed. Upper suspension arm removal (1) raise and support the vehicle. (2) remove the upper suspension arm nut and bolt at the axle bracket (fig. 4). (3) remove the nut and bolt at the frame ra...

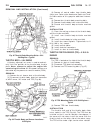

Page 34

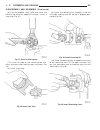

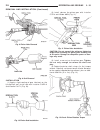

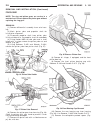

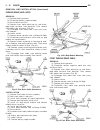

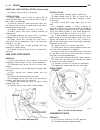

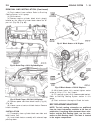

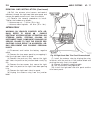

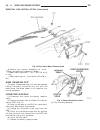

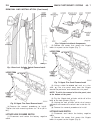

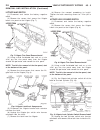

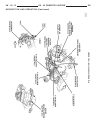

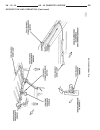

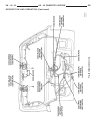

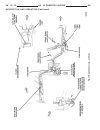

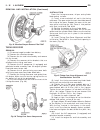

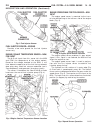

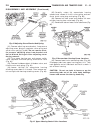

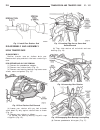

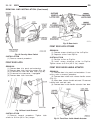

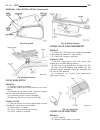

(2) remove upper link nuts (fig. 7) and separate links from the stabilizer bar with remover mb-990635. (3) remove the stabilizer bar clamps bolts from the frame rails and remove the stabilizer bar. (4) remove the stabilizer bar link nuts from the axle brackets (fig. 7). Installation (1) position the...

Page 35

(5) remove the hub mounting bolts and remove hub bearing from the steering knuckle and axle shaft. Installation (1) install the hub bearing and brake dust shield to the knuckle. (2) install the hub to knuckle bolts and tighten to 102 n·m (75 ft. Lbs.). (3) install the hub washer and nut. Tighten the...

Page 36

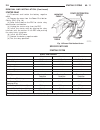

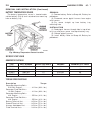

Specifications torque chart description torque shock absorber upper nut . . . . . . . . . . . . . . . . 23 n·m (17 ft. Lbs.) lower nut . . . . . . . . . . . . . . 28 n·m (250 in. Lbs.) suspension arm upper nuts . . . . . . . . . . . . . . . . . . . . 75 n·m (55 ft. Lbs.) suspension arm lower axle br...

Page 37

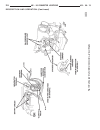

Rear suspension index page page description and operation rear suspension . . . . . . . . . . . . . . . . . . . . 11 diagnosis and testing shock diagnosis . . . . . . . . . . . . . . . . . . . . 12 removal and installation coil spring . . . . . . . . . . . . . . . . . . . . . . . . . 12 lower suspen...

Page 38

Diagnosis and testing shock diagnosis a knocking or rattling noise from a shock absorber may be caused by movement between mounting bushings and metal brackets or attaching compo- nents. These noises can usually be stopped by tight- ening the attaching nuts. If the noise persists, inspect for damage...

Page 39

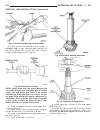

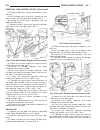

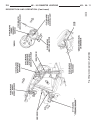

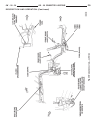

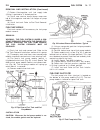

Lower suspension arm removal (1) raise and support the vehicle. (2) remove the lower suspension arm nut and bolt at the axle bracket (fig. 3). (3) remove the nut and bolt (fig. 3) at the frame rail and remove the lower suspension arm. Installation (1) position the lower suspension arm at the axle br...

Page 40

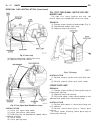

Track bar removal (1) raise and support the vehicle. (2) remove the bolt and nut from the frame rail bracket (fig. 5). (3) remove the bolt from the axle tube bracket (fig. 5). Remove the track bar. Installation (1) install the track bar to the axle bracket and install a new bolt. (2) it may be neces...

Page 41: Suspension

Suspension contents page page alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 front suspension . . . . . . . . . . . . . . . . . . . . . 6 rear suspension . . . . . . . . . . . . . . . . . . . . . 14 alignment index page page general information wheel alignment . . . . . . . . . ...

Page 42

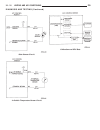

Service procedures pre-alignment before starting wheel alignment, the following inspection and necessary corrections must be com- pleted. Refer to suspension and steering system diagnosis chart for additional information. (1) inspect tires for size, air pressure and tread wear. (2) inspect front whe...

Page 43

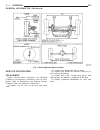

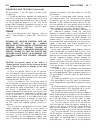

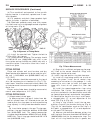

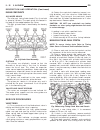

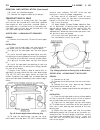

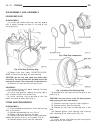

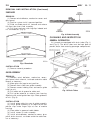

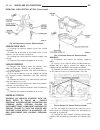

Wheel alignment before each alignment reading the vehicle should be jounced (rear first, then front). Grasp each bumper at the center and jounce the vehicle up and down three times. Always release the bumper in the down position. Camber the wheel camber angle is preset. This angle is not adjustable ...

Page 44

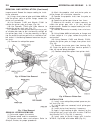

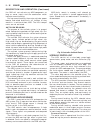

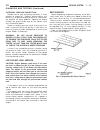

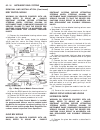

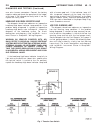

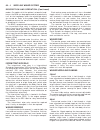

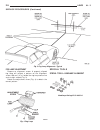

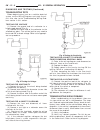

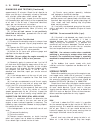

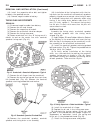

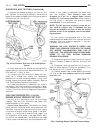

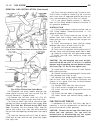

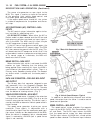

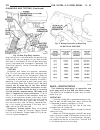

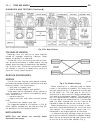

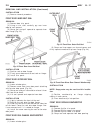

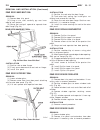

Caster can be adjusted by loosening and rotating the cams on the lower suspension arm (fig. 2). Changing caster angle will also change the front propeller shaft angle. The propeller shaft angle has priority over caster. Refer to group 3, differential and driveline for additional infor- mation. Toe p...

Page 45

• vehicles with 2.5l engine: 27 n·m (20 ft. Lbs.) • vehicles with 4.0l engine: 27 n·m (20 ft. Lbs.) • vehicles with 5.2l engine: 49 n·m (36 ft. Lbs.) note: make sure the toe setting does not change during clamp tightening. (4) adjust the right wheel toe position with the tie rod. Turn the sleeve unt...

Page 46

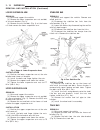

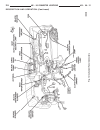

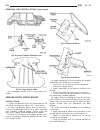

Front suspension index page page description and operation front suspension . . . . . . . . . . . . . . . . . . . . 6 diagnosis and testing shock diagnosis . . . . . . . . . . . . . . . . . . . . . 7 removal and installation axle bushing . . . . . . . . . . . . . . . . . . . . . . . . . 9 coil sprin...

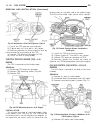

Page 47

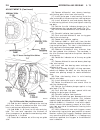

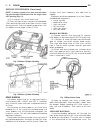

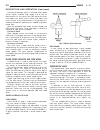

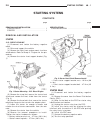

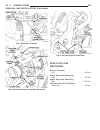

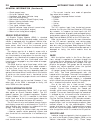

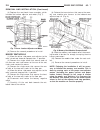

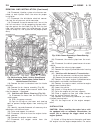

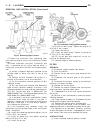

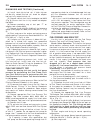

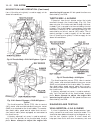

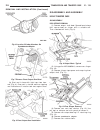

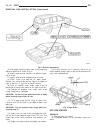

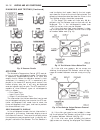

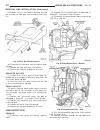

Note: the service procedures and torque specifi- cations are the same for lhd and rhd vehicles. The following service procedures and pictures were developed with a lhd vehicle. Diagnosis and testing shock diagnosis a knocking or rattling noise from a shock absorber may be caused by movement between ...

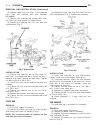

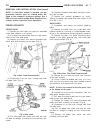

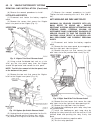

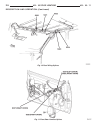

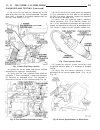

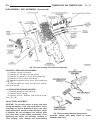

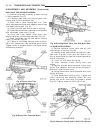

Page 48

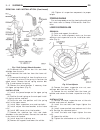

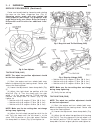

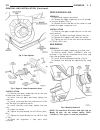

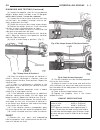

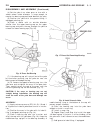

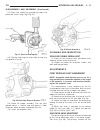

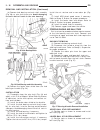

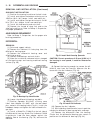

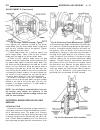

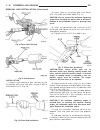

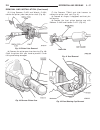

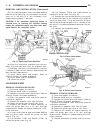

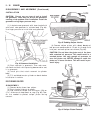

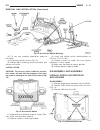

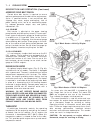

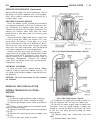

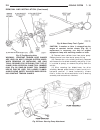

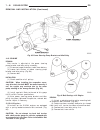

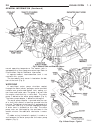

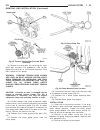

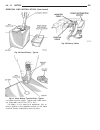

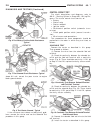

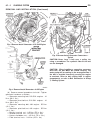

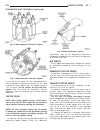

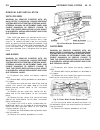

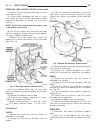

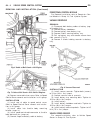

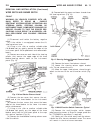

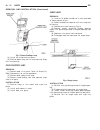

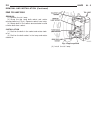

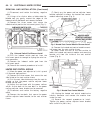

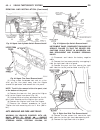

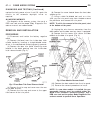

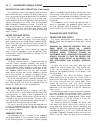

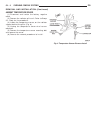

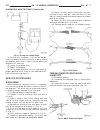

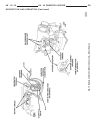

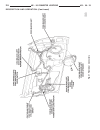

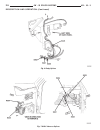

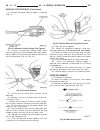

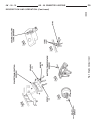

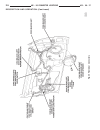

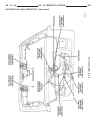

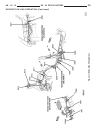

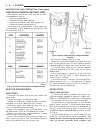

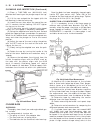

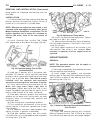

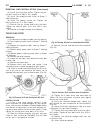

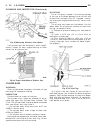

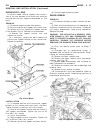

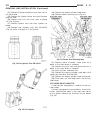

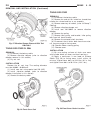

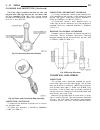

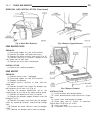

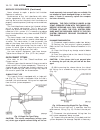

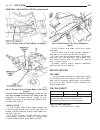

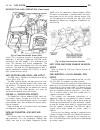

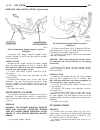

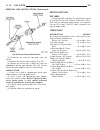

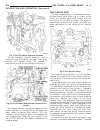

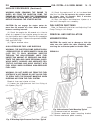

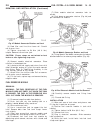

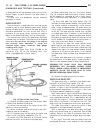

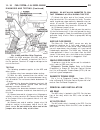

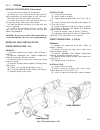

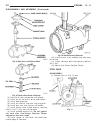

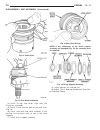

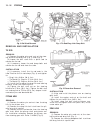

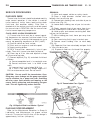

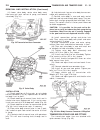

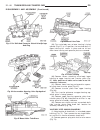

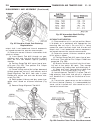

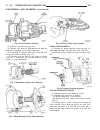

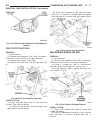

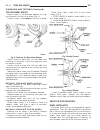

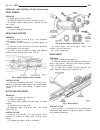

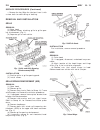

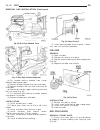

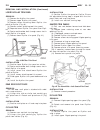

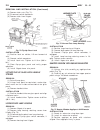

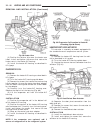

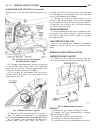

Removal and installation shock absorber removal (1) remove the nut, retainer and grommet from the upper stud in the engine compartment (fig. 2). (2) remove the lower nuts and bolts from the axle bracket. Remove the shock absorber. Installation (1) position the lower retainer and grommet on the upper...

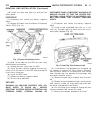

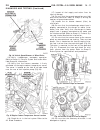

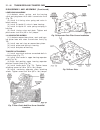

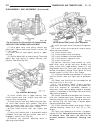

Page 49

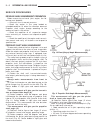

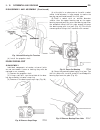

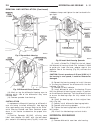

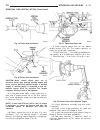

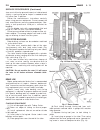

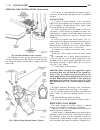

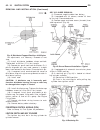

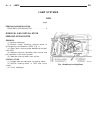

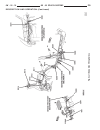

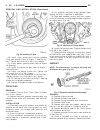

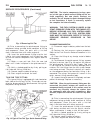

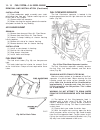

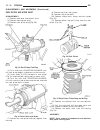

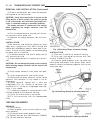

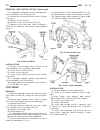

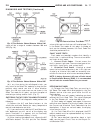

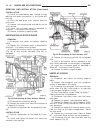

Installation (1) position the lower suspension arm at the axle bracket and frame rail bracket. (2) install the rear bolts and finger tighten the new nuts. (3) install a new cam bolt, cam and new nut in the axle. Re-align the reference marks. (4) install the bolts and finger tighten the new nuts. (5)...

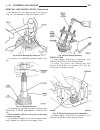

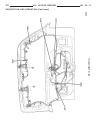

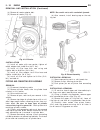

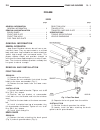

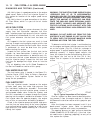

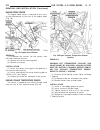

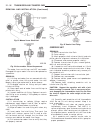

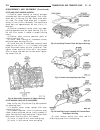

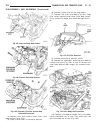

Page 50

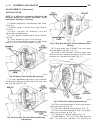

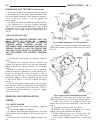

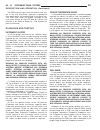

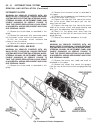

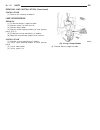

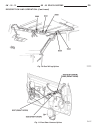

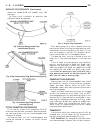

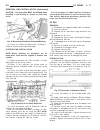

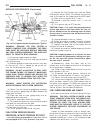

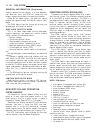

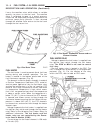

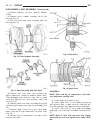

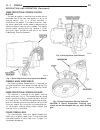

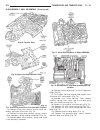

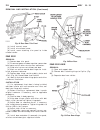

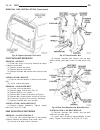

Installation (1) position new bushing, receiver and installer on axle (fig. 6). (2) install the bushing by tightening the long nut. (3) remove tools and install the upper suspension arm. Stabilizer bar removal (1) raise and support the vehicle. (2) remove upper link bolts (fig. 7) and separate links...

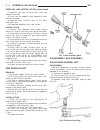

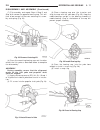

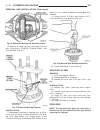

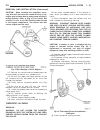

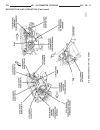

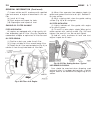

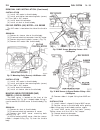

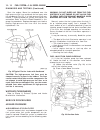

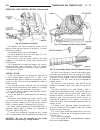

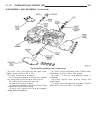

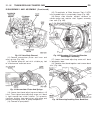

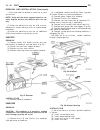

Page 51

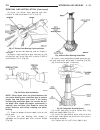

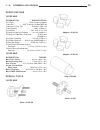

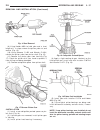

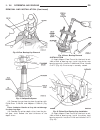

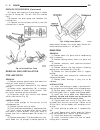

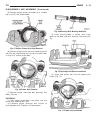

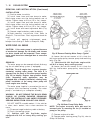

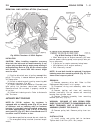

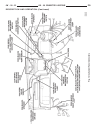

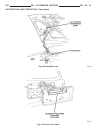

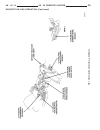

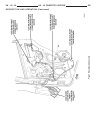

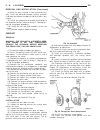

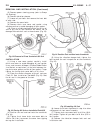

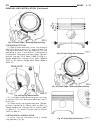

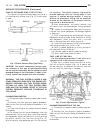

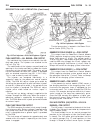

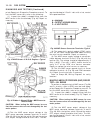

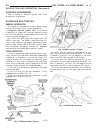

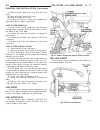

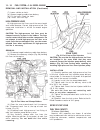

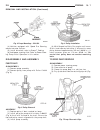

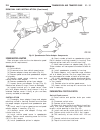

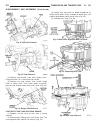

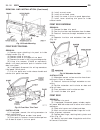

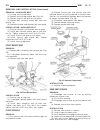

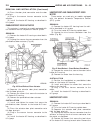

Hub bearing removal (1) raise and support the vehicle. (2) remove the wheel and tire assembly. (3) remove the brake caliper, rotor and abs wheel speed sensor, refer to group 5 brakes. (4) remove the cotter pin, nut retainer and axle hub nut (fig. 9). (5) remove the hub mounting bolts and remove hub ...

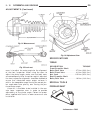

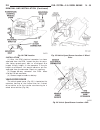

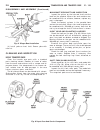

Page 52

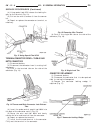

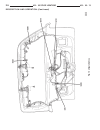

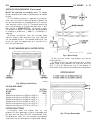

(4) remove stud from hub with remover c-4150a (fig. 10). Installation (1) install new stud into hub flange. (2) install three washers onto stud, then install lug nut with the flat side of the nut against the washers. (3) tighten lug nut until the stud is pulled into the hub flange. Verify that the s...

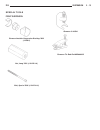

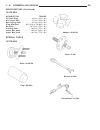

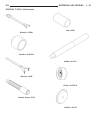

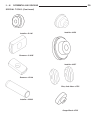

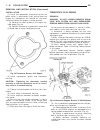

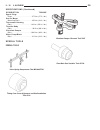

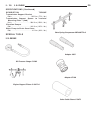

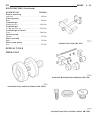

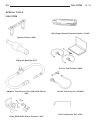

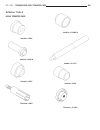

Page 53

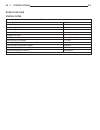

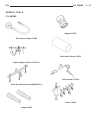

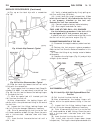

Special tools front suspension remover/installer suspension bushing 7932 (j-35581) nut, long 7603 (j-21474–18) bolt, special 7604 (j-21474–19) remover c-4150a remover tie rod end mb-990635 zg suspension 2 - 13.

Page 54

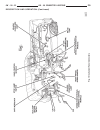

Rear suspension index page page description and operation rear suspension . . . . . . . . . . . . . . . . . . . . 14 diagnosis and testing shock diagnosis . . . . . . . . . . . . . . . . . . . . 15 removal and installation coil spring . . . . . . . . . . . . . . . . . . . . . . . . . 15 lower suspen...

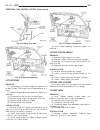

Page 55

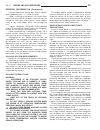

Diagnosis and testing shock diagnosis a knocking or rattling noise from a shock absorber may be caused by movement between mounting bushings and metal brackets or attaching compo- nents. These noises can usually be stopped by tight- ening the attaching nuts. If the noise persists, inspect for damage...

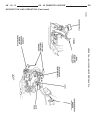

Page 56

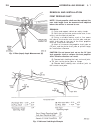

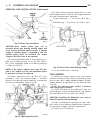

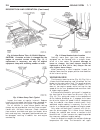

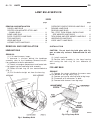

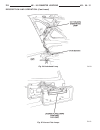

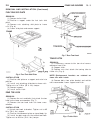

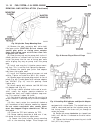

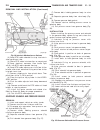

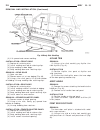

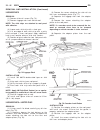

Lower suspension arm removal (1) raise and support the vehicle. (2) remove the lower suspension arm nut and bolt at the axle bracket (fig. 3). (3) remove the nut and bolt (fig. 3) at the frame rail and remove the lower suspension arm. Installation (1) position the lower suspension arm at the axle br...

Page 57

Installation (1) install the track bar to the axle bracket and install a new bolt. (2) it may be necessary to pry the axle assembly over to install the track bar. Install the track bar to the frame rail bracket. Loosely install the bolt and flag nut. (3) remove the supports and lower the vehicle. (4...

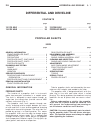

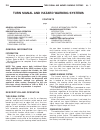

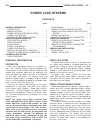

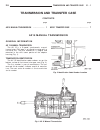

Page 59: Differential And Driveline

Differential and driveline contents page page 181 fbi axle . . . . . . . . . . . . . . . . . . . . . . . . . . 15 194 rbi axle . . . . . . . . . . . . . . . . . . . . . . . . . 50 216 rba axle . . . . . . . . . . . . . . . . . . . . . . . . . 87 propeller shafts . . . . . . . . . . . . . . . . . . ....

Page 60

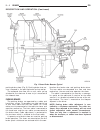

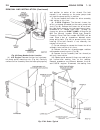

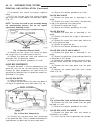

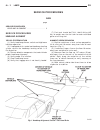

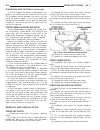

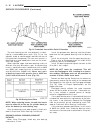

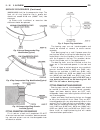

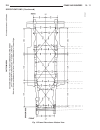

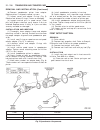

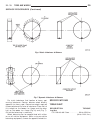

Front propeller shaft there are two front propeller shafts used on zj vehicles. Both shafts use a double cardan joint at the transfer case end. The difference between the two shafts is how they connect to the front axle and how they handle the variation in length required by sus- pension travel. The...

Page 61

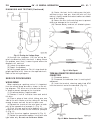

Lubrication the slip yoke on the one style of front propeller shaft is equipped with a lubrication fitting. Use a multi-purpose nlgi grade 2 ep lubricant. The fac- tory installed universal joints are lubricated for the life of the vehicle and do not need lubrication. All universal joints should be i...

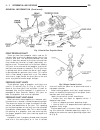

Page 62

Also make alignment reference marks (fig. 6) on the propeller shaft yoke and axle, or transmission, yoke prior to servicing. This helps to eliminate possi- ble vibration. Caution: do not allow the propeller shaft to drop or hang from any propeller shaft joint during removal. Attach the propeller sha...

Page 63

(3) inspect the propeller shaft for missing balance weights, broken welds, and bent areas. If the pro- peller shaft is bent, it must be replaced. (4) inspect the universal joints to ensure that they are not worn, are properly installed, and are cor- rectly aligned with the shaft. (5) check the unive...

Page 64

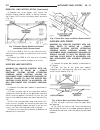

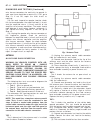

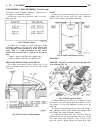

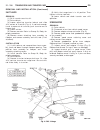

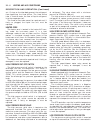

Service procedures driveline angle measurement preparation before measuring universal joint angles, the fol- lowing must be done; • inflate all tires to correct pressure. • check the angles in the same loaded or unloaded condition as when the vibration occurred. Propeller shaft angles change accordi...

Page 65

Removal and installation front propeller shaft note: if front propeller shaft must be replaced, the new shaft length must be measured and adjusted before the vehicle is returned to use. Removal (1) raise and support vehicle on safety stands. (2) shift the transmission and transfer case, if nec- essa...

Page 66

(7) separate the rear universal joint from the transfer case yoke. (8) push rear of propeller shaft upward to clear transfer case yoke. (9) separate front universal joint, or cv joint, from front axle. (10) separate propeller shaft from vehicle. Installation (1) position front propeller shaft under ...

Page 67

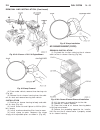

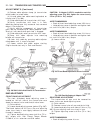

(4) set the yoke in an arbor press or vise with a socket whose inside diameter is large enough to receive the bearing cap positioned beneath the yoke. (5) position the yoke with the grease fitting, if equipped, pointing up. (6) place a socket with an outside diameter smaller than the upper bearing c...

Page 68

(8) install the propeller shaft. Double cardan joint disassembly individual components of cardan universal joints are not serviceable. If worn or leaking, they must be replaced as an assembly. (1) remove the propeller shaft. (2) using a soft drift, tap the outside of the bear- ing cap assembly to lo...

Page 69

(7) flip assembly and repeat step 4, step 5, and step 6 to remove the opposite bearing cap. This will then allow removal of the cross centering kit assem- bly and spring (fig. 23). (8) press the remaining bearing caps out the other end of the link yoke as described above to complete the disassembly....

Page 70

(6) flip the propeller shaft yoke and install the bearing cap onto the opposite trunnion. Install a snap ring (fig. 27). (7) fit the link yoke on the remaining two trun- nions and press both bearing caps into place (fig. 28). (8) install snap rings. (9) install the centering kit assembly inside the ...

Page 71

(11) press the remaining two bearing caps into place and install snap rings (fig. 31). (12) tap the snap rings to allow them to seat into the grooves (fig. 32). (13) check for proper assembly. Flex the joint beyond center, it should snap over-center in both directions when correctly assembled (fig. ...

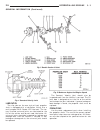

Page 72

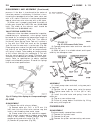

Cams is to adjust the caster angle for the alignment of the front suspension. When using the cams to adjust the pinion angle, make sure that both cams are moved equally. After the pinion angle is adjusted, the front suspension alignment should be checked to ensure that side-to-side caster angles var...

Page 73

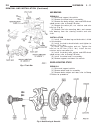

181 fbi axle index page page general information 181 fbi axle . . . . . . . . . . . . . . . . . . . . . . . . . . 15 lubricant specifications . . . . . . . . . . . . 15 description and operation standard differential . . . . . . . . . . . . . . . 16 diagnosis and testing bearing noise . . . . . . . ...

Page 74

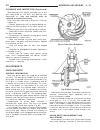

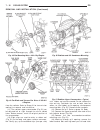

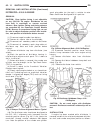

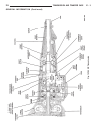

• lubricant for axles intended for heavy-duty or trailer tow use is sae 75w–140 synthetic gear lubricant. The 181 fbi axle lubricant capacity is 1.2 l (2.5 pts.). Caution: if axle is submerged in water, lubricant must be replaced immediately to avoid possible premature axle failure. Description and ...

Page 75

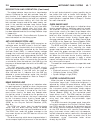

Driving condition. These conditions are acceleration, deceleration, coast, or constant load. When road testing, accelerate the vehicle to the speed range where the noise is the greatest. Shift out-of-gear and coast through the peak–noise range. If the noise stops or changes greatly: • check for insu...

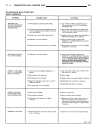

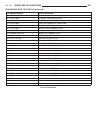

Page 76

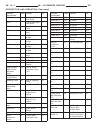

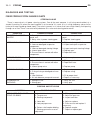

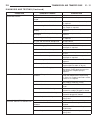

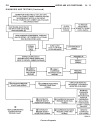

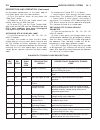

Front axles diagnosis condition possible causes correction wheel noise 1. Wheel loose. 1. Tighten loose nuts. 2. Faulty, brinelled wheel bearing. 2. Faulty or brinelled bearings must be replaced. Axle shaft noise 1. Misaligned axle shaft tube. 1. Inspect axle shaft tube alignment. Correct as necessa...

Page 77

Continued condition possible causes correction loss of lubricant 2. Worn axle shaft seals. Replace worn seals. 3. Cracked differential housing. 3. Repair or replace housing as necessary. 4. Worn drive pinion gear shaft seal. 4. Replace worn drive pinion gear shaft seal. 5. Scored and worn yoke. 5. R...

Page 78

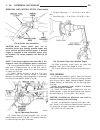

Service procedures lubricant change (1) raise and support the vehicle. (2) remove the lubricant fill hole plug from the differential housing cover. (3) remove the differential housing cover and drain the lubricant from the housing. (4) clean the housing cavity with a flushing oil, light engine oil o...

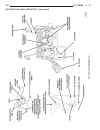

Page 79

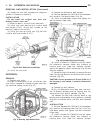

(8) install the stabilizer bar links to the axle brackets. Tighten the nut to 95 n·m (70 ft. Lbs.) torque. (9) install the drag link and tie rod to the steering knuckles. Refer to group 2, suspension, for proper procedures. (10) install the steering damper to the axle bracket and tighten the nut to ...

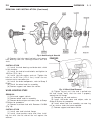

Page 80

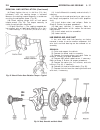

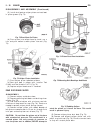

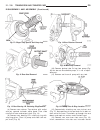

Installation (1) pack the bearing caps 1/3 full of wheel bearing lubricant. Apply extreme pressure (ep), lithium–base lubricant to aid in installation. (2) position the spider in the yoke. Insert the seals and bearings. Tap the bearing caps into the yoke bores far enough to hold the spider in positi...

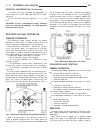

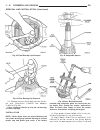

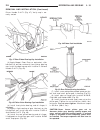

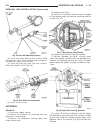

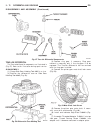

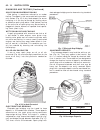

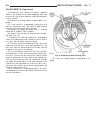

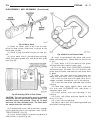

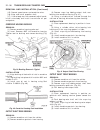

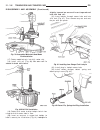

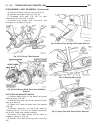

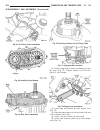

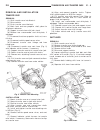

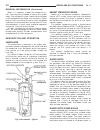

Page 81

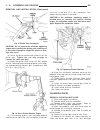

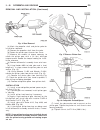

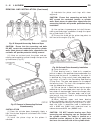

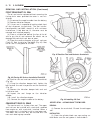

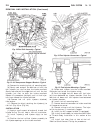

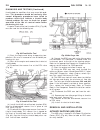

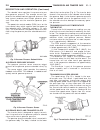

Caution: seal must not be dimpled, stretched or out of shape in any way. If seal is not shaped cor- rectly, equalize pressure in seal and shape it by hand. (8) clamp large sealing boot clamp onto axle shaft using crimper c-4975-a. Place crimping tool c-4975-a over bridge of clamp (fig. 9). (9) tight...

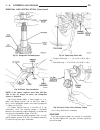

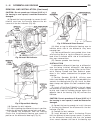

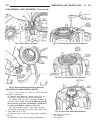

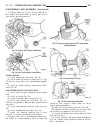

Page 82

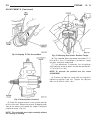

Caution: do not exceed the minimum tightening torque when installing the pinion yoke retaining nut at this point. Damage to collapsible spacer or bear- ings may result. (3) install the pinion washer and a new nut on the pinion gear. Tighten the nut only enough to remove the shaft end play. (4) rotat...

Page 83

Torque wrench. Record the torque reading for instal- lation reference. (8) using a short piece of pipe and holder 6958 to hold the pinion yoke, or pinion flange, remove the pinion nut and washer. (9) use remover c-452 and wrench c-3281 to remove the pinion yoke, or flange, (fig. 16). (10) use remove...

Page 84

(6) if the original pinion bearings are being used, install differential assembly and axle shafts, if neces- sary. Note: if new pinion bearings were installed, do not install the differential assembly and axle shafts until after the pinion bearing preload and rotating torque are set. (7) install the...

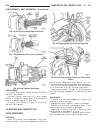

Page 85

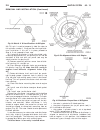

(9) slowly tighten the nut in 6.8 n·m (5 ft. Lbs.) increments until the rotating torque is achieved. Measure the rotating torque frequently to avoid over crushing the collapsible spacer (fig. 23). (10) check rotating torque with an inch pound torque wrench (fig. 23). The torque necessary to rotate t...

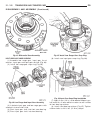

Page 86

(8) remove hub bearing and axle shaft assembly (fig. 26), or axle shaft from axle. Avoid damaging the axle shaft oil seals in the axle housing. (9) remove the brake rotor shield from the hub bearing or knuckle (fig. 24). Installation (1) thoroughly clean the axle shaft (fig. 24) and apply a thin fil...

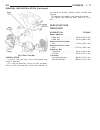

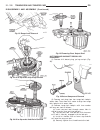

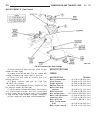

Page 87

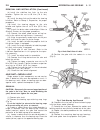

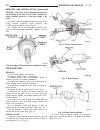

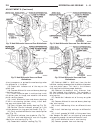

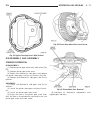

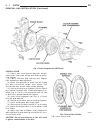

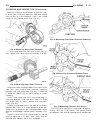

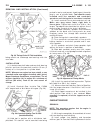

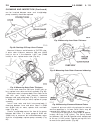

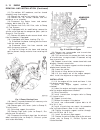

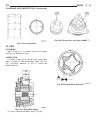

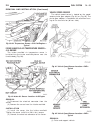

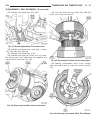

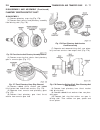

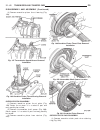

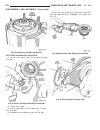

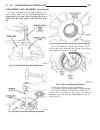

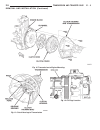

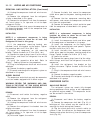

Fig. 28 upper ball stud remove/install removal installation fig. 29 lower ball stud remove/install special tool 6289–12 special tool 6289–4 zg differential and driveline 3 - 29 removal and installation (continued).

Page 88

Knuckle installation (1) position the steering knuckle on the ball studs. (2) install and tighten the bottom retaining nut to 109 n·m (80 ft. Lbs.) torque. Install new cotter pin. (3) install and tighten the top retaining nut to 101 n·m (75 ft. Lbs.) torque. Install new cotter pin. (4) install the h...

Page 89

(13) mark or tag the differential bearing cups to indicate which side of the differential they were removed from. (14) remove spreader from housing. Installation if replacement differential bearings or differential case are being installed, differential side bearing shim requirements may change. Ref...

Page 90

(2) remove the bearings from the differential case with puller/press c-293-pa, c-293-39 blocks, and plug sp-3289 (fig. 37). Installation if replacement differential side bearings or differ- ential case are being installed, differential side bear- ing shim requirements may change. Refer to the differ...

Page 91

Removal (1) remove differential assembly from axle hous- ing. (2) mark pinion yoke, or flange, and propeller shaft for installation alignment. (3) disconnect propeller shaft from pinion yoke, or flange. Using suitable wire, tie propeller shaft to underbody. (4) using holder 6958 to hold yoke, or fla...

Page 92

(11) remove the rear pinion bearing from the pin- ion with puller/press c–293-pa and adapters c–293–39 (fig. 46). Place 4 adapter blocks so they do not damage the bearing cage. Installation note: pinion depth shims are placed between the rear pinion bearing cup and axle housing to achieve proper rin...

Page 93

Driver handle c–4171 (fig. 47). Verify cup is cor- rectly seated. (3) apply mopar t door ease, or equivalent, stick lubricant to outside surface of front pinion bearing cup. Install the bearing cup with installer d-130 and handle c–4171 (fig. 48). (4) install front pinion bearing, and oil slinger, i...

Page 94

Note: if the spacer requires more than 352 n·m (260 ft. Lbs.) of torque to crush, the collapsible spacer is defective. (10) using holder 6958, a short length of 1 in. Pipe, and torque wrench (set at 352 n·m (260 ft. Lbs.)), crush collapsible spacer until bearing end play is taken up (fig. 53). (11) ...

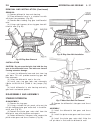

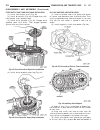

Page 95

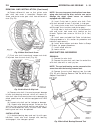

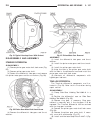

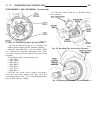

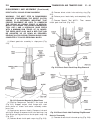

Removal (1) remove differential from axle housing. (2) place differential case in a suitable vise with soft metal jaw protectors. (fig. 55) (3) remove bolts holding ring gear to differential case. (4) using a soft hammer, drive ring gear from dif- ferential case (fig. 55). Installation caution: do n...

Page 96

(4) install the roll pin to hold the pinion mate shaft in the differential case (fig. 59). (5) install the ring gear. (6) lubricate all differential components with hypoid gear lubricant. Final assembly (1) scrape the residual sealant from the housing and cover mating surfaces. Clean the mating surf...

Page 97

Wash bearings with solvent and towel dry, or dry with compressed air. Do not spin bearings with compressed air. Cup and bearing must be replaced as matched sets only. Clean axle shaft tubes and oil channels in housing. Inspect for; • smooth appearance with no broken/dented sur- faces on the bearing ...

Page 98

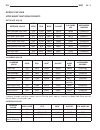

Without any shims placed behind the rear pinion bearing cup. Take measurements with pinion gauge set 6774 and dial indicator c-3339 (fig. 63). (1) assemble pinion height block 6739, pinion block 6733, and rear pinion bearing onto screw 6741 (fig. 63). (2) insert assembled height gauge components, re...

Page 99

Flush against the rearward surface of the pinion height block (fig. 63). Hold scooter block in place and zero the dial indicator face to the pointer. Tighten dial indicator face lock screw. (7) with scooter block still in position against the pinion height block, slowly slide the dial indicator prob...

Page 100

Shim selection note: it is difficult to salvage the differential side bearings during the removal procedure. Install replacement bearings if necessary. (1) remove differential side bearings from differ- ential case. (2) remove factory installed shims from differen- tial case. (3) install ring gear o...

Page 101

Shims to compress, or preload the new bearings when the differential is installed. (15) rotate dial indicator out of the way on the guide stud. (16) remove differential case and dummy bearings from axle housing. (17) install the pinion gear in axle housing. Install the pinion yoke, or flange, and es...

Page 102

(34) rotate the differential case several times to seat the side bearings. (35) position the indicator plunger against a ring gear tooth (fig. 76). (36) push and hold ring gear upward while not allowing the pinion gear to rotate. (37) zero dial indicator face to pointer. (38) push and hold ring gear...

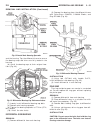

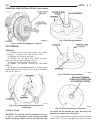

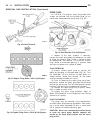

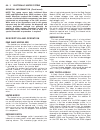

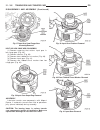

Page 103

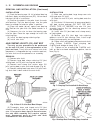

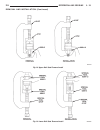

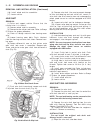

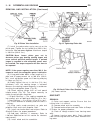

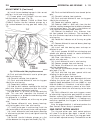

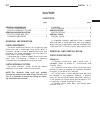

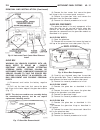

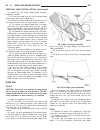

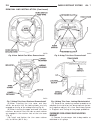

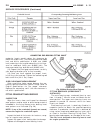

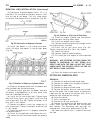

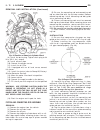

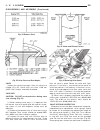

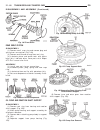

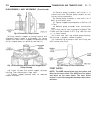

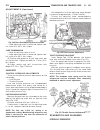

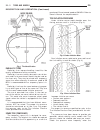

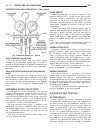

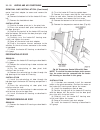

Fig. 78 gear tooth contact patterns drive side of ring gear teeth heel toe coast side of ring gear teeth toe heel desirable contact pattern. Pattern should be centered on the drive side of tooth. Pattern should be centered on the coast side of tooth, but may be slightly toward the toe. There should ...

Page 104

181 fbi axle description torque fill hole plug . . . . . . . . . . . . . . 34 n·m (25 ft. Lbs.) diff. Cover bolt . . . . . . . . . . . . 41 n·m (30 ft. Lbs.) bearing cap bolt . . . . . . . . . . . 61 n·m (45 ft. Lbs.) ring gear bolt . . . . . . 95–122 n·m (70–90 ft. Lbs.) axle nut . . . . . . . . . ...

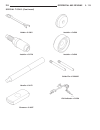

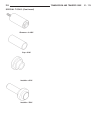

Page 105

Driver—c-3716-a handle—c-4171 installer—d-146 remover—d-149 installer—w-162-d cup—8109 remover/installer—6289 installer—6761 zg differential and driveline 3 - 47 special tools (continued).

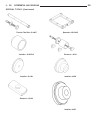

Page 106

Installer—6752 installer discs—8110 turnbuckle—6797 tool set, pinion depth—6774 gauge block—6733 puller—7794-a installer—c-4975-a 3 - 48 differential and driveline zg special tools (continued).

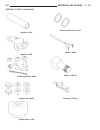

Page 107

Spanner—6958 installer—c-3972-a spreader—w-129-b adapter kit—6987 pilot stud—c-3288-b remover—c-4345 installer—d-130 installer—w-262 zg differential and driveline 3 - 49 special tools (continued).

Page 108

194 rbi axle index page page general information 194 rbi axle . . . . . . . . . . . . . . . . . . . . . . . . . 50 lubricant specifications . . . . . . . . . . . . 50 description and operation standard differential . . . . . . . . . . . . . . . 51 trac-lok operation . . . . . . . . . . . . . . . . ....

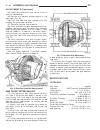

Page 109

Axle lubricant capacity is 1.66l (3.50 pts.) total, including the friction modifier if necessary. Caution: if axle is submerged in water, lubricant must be replaced immediately to avoid possible premature axle failure. Description and operation standard differential the differential gear system divi...

Page 110

The trac-lok design provides the differential action needed for turning corners and for driving straight ahead during periods of unequal traction. When one wheel looses traction, the clutch packs transfer addi- tional torque to the wheel having the most traction. Trac-lok differentials resist wheel ...

Page 111

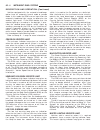

Level. Where axle bearing damage is slight, the noise is usually not noticeable at speeds above 30 mph. Low speed knock low speed knock is generally caused by a worn u–joint or by worn side–gear thrust washers. A worn pinion gear shaft bore will also cause low speed knock. Vibration vibration at the...

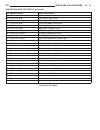

Page 112

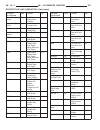

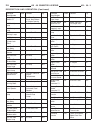

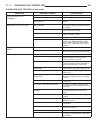

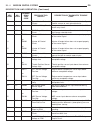

Condition possible causes correction wheel noise 1. Wheel loose. 1. Tighten loose nuts. 2. Faulty, brinelled wheel bearing. 2. Faulty or brinelled bearings must be replaced. Axle shaft noise 1. Misaligned axle shaft tube. 1. Inspect axle shaft tube alignment. Correct as necessary. 2. Bent or sprung ...

Page 113

Condition possible causes correction loss of lubricant 2. Worn axle shaft seals. Replace worn seals. 3. Cracked differential housing. 3. Repair or replace housing as necessary. 4. Worn drive pinion gear shaft seal. 4. Replace worn drive pinion gear shaft seal. 5. Scored and worn yoke. 5. Replace wor...

Page 114

Trac–lok test warning: when servicing vehicles with a trac–lok differential do not use the engine to turn the axle and wheels. Both rear wheels must be raised and the vehi- cle supported. A trac–lok axle can exert enough force if one wheel is in contact with a surface to cause the vehicle to move. T...

Page 115

(2) position a suitable lifting device under the axle. (3) secure axle to device. (4) remove the wheels and tires. (5) remove the brake rotors and calipers from the axle. Refer to group 5, brakes, for proper procedures. (6) disconnect parking brake cables from brackets and lever. (7) remove wheel sp...

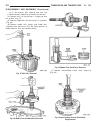

Page 116

Installation (1) apply a light coating of gear lubricant on the lip of pinion seal. Install seal with installer c-3972-a and handle c–4171 (fig. 10). (2) install yoke on the pinion gear with screw 8112, cup 8109, and holder 6958 (fig. 11). Caution: do not exceed the minimum tightening torque when in...

Page 117

(9) install the brake rotors and calipers. Refer to group 5, brakes, for proper procedures. (10) install wheel and tire assemblies. (11) lower the vehicle. Collapsible spacer removal w/pinion installed (1) raise and support the vehicle. (2) remove wheel and tire assemblies. (3) remove rear brake rot...

Page 118

(4) mark the propeller shaft and pinion yoke for installation reference. (5) remove the propeller shaft from the yoke. (6) rotate the pinion gear three or four times. (7) measure the amount of torque necessary to rotate the pinion gear with a (in. Lbs.) dial-type torque wrench. Record the torque rea...

Page 119

Caution: never loosen pinion gear nut to decrease pinion gear bearing rotating torque and never exceed specified preload torque. If preload torque or rotating torque is exceeded a new col- lapsible spacer must be installed. The torque sequence will then have to be repeated. (9) using yoke holder 695...

Page 120

(16) install wheel and tire assemblies. (17) lower vehicle. Axle shaft removal (1) raise and support vehicle. Ensure that the transmission is in neutral. (2) remove wheel and tire assembly. (3) remove brake caliper and rotor. Refer to group 5, brakes, for proper procedure. (4) clean all foreign mate...

Page 121

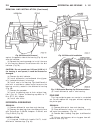

(2) install axle shaft bearing with installer 6436 and handle c–4171. Ensure that the part number on the bearing is against the installer. (3) install the new axle shaft seal with installer 6437 and handle c–4171 (fig. 26). (4) install the axle shaft. Differential removal (1) raise and support vehic...

Page 122

Caution: do not spread over 0.38 mm (0.015 in). If the housing is over–spread, it could be distorted or damaged. (9) spread the housing enough to remove the dif- ferential case from the housing. Measure the dis- tance with the dial indicator (fig. 30). (10) remove the dial indicator. (11) while hold...

Page 123

And the housing. Tap the differential case to ensure the bearings cups and shims are fully seated in the housing. (6) install the bearing caps at their original loca- tions (fig. 33). (7) loosely install differential bearing cap bolts. (8) remove axle housing spreader. (9) tighten the bearing cap bo...

Page 124

(1) invert the differential case and start two ring gear bolts. This will provide case-to-ring gear bolt hole alignment. (2) invert the differential case in the vise. (3) install new ring gear bolts and alternately tighten to 95–122 n·m (70–90 ft. Lbs.) torque (fig. 56). (4) install differential in ...

Page 125

(5) using remover c–452 and wrench c–3281, remove the pinion yoke from pinion shaft (fig. 39). (6) remove the pinion gear from housing (fig. 40). Catch the pinion with your hand to prevent it from falling and being damaged. (7) use remover 7794-a and slide hammer to remove the pinion shaft seal (fig...

Page 126

(10) remove the rear bearing cup from housing (fig. 43). Use remover d-149 and handle c–4171. (11) remove the collapsible preload spacer (fig. 44). (12) remove the rear bearing from the pinion with puller/press c-293-pa and adapters c-293-40 (fig. 45). Place 4 adapter blocks so they do not damage th...

Page 127

(4) install the pinion front bearing cup with installer d–130 and handle c–4171 (fig. 47). (5) install pinion front bearing, and oil slinger, if equipped. (6) apply a light coating of gear lubricant on the lip of pinion seal. Install seal with installer c-3972-a and handle c–4171 (fig. 48). Note: pi...

Page 128

Caution: never loosen pinion gear nut to decrease pinion gear bearing rotating torque and never exceed specified preload torque. If preload torque or rotating torque is exceeded a new col- lapsible spacer must be installed. The torque sequence will then have to be repeated. (14) using yoke holder 69...

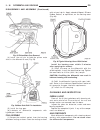

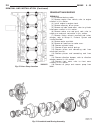

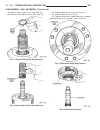

Page 129

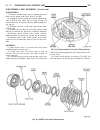

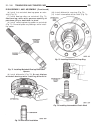

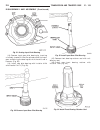

Disassembly and assembly standard differential disassembly (1) remove pinion gear mate shaft lock screw (fig. 55). (2) remove pinion gear mate shaft. (3) rotate the differential side gears and remove the pinion mate gears and thrust washers (fig. 56). (4) remove the differential side gears and thrus...

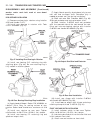

Page 130

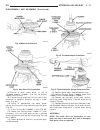

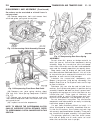

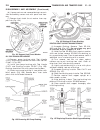

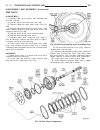

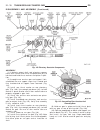

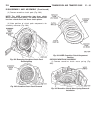

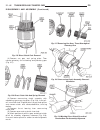

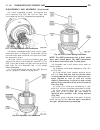

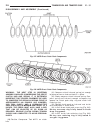

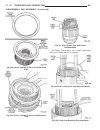

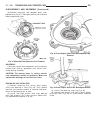

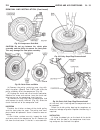

Trac-lok differential the trac–lok differential components are illustrated in (fig. 57). Refer to this illustration during repair service. Disassembly (1) clamp side gear holding tool 6965 in a vise. (2) position the differential case on side gear holding tool 6965 (fig. 58). (3) remove ring gear, i...

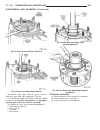

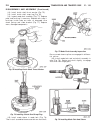

Page 131

(8) position a small screw driver in slot of threaded adapter c-6960-1 (fig. 62) to prevent adapter from turning. (9) tighten forcing screw tool 122 n·m (90 ft. Lbs.) maximum to compress belleville springs in clutch packs (fig. 63). (10) using an appropriate size feeler gauge, remove thrust washers ...

Page 132

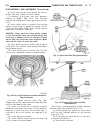

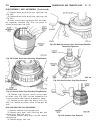

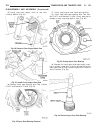

Lubricate each component with gear lubricant before assembly. (1) assemble the clutch discs into packs and secure disc packs with retaining clips (fig. 67). (2) position assembled clutch disc packs on the side gear hubs. (3) install clutch pack and side gear in the ring gear side of the differential...

Page 133

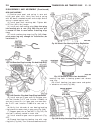

Tighten the forcing screw in order to install the pin- ion gears. (12) tighten forcing screw to 122 n·m (90 ft. Lbs.) maximum to compress the belleville springs. (13) lubricate and install thrust washers behind pinion gears and align washers with a small screw driver. Insert mate shaft into each pin...

Page 134

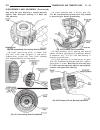

Presoak plates and disc plates and discs with fiber coating (no grooves or lines) must be presoaked in friction modifier before assembly. Soak plates and discs for a minimum of 20 minutes. Adjustments pinion gear depth general information ring and pinion gears are supplied as matched sets only. The ...

Page 135

Tor face to the pointer. Tighten dial indicator face lock screw. (7) with scooter block still in position against the pinion height block, slowly slide the dial indicator probe over the edge of the pinion height block. Observe how many revolutions counterclockwise the dial pointer travels (approxima...

Page 136

Ple, if the depth variance is –2, add +0.002 in. To the dial indicator reading. (10) remove the pinion depth gauge components from the axle housing differential bearing preload and gear backlash differential side bearing preload and gear backlash is achieved by selective shims inserted between the b...

Page 137

(13) add the dial indicator reading to the starting point shim thickness to determine total shim thick- ness to achieve zero differential end play. (14) add 0.008 in. (0.2 mm) to the zero end play total. This new total represents the thickness of shims to compress, or preload the new bearings when t...

Page 138

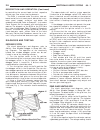

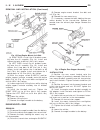

After the proper backlash is achieved, perform the gear contact pattern analysis procedure. Gear contact pattern analysis the ring and pinion gear teeth contact patterns will show if the pinion gear depth is correct in the axle housing. It will also show if the ring gear back- lash has been adjusted...

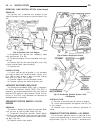

Page 139

Fig. 81 gear tooth contact patterns drive side of ring gear teeth heel toe coast side of ring gear teeth toe heel desirable contact pattern. Pattern should be centered on the drive side of tooth. Pattern should be centered on the coast side of tooth, but may be slightly toward the toe. There should ...

Page 140

Specifications 194 rbi axle description specification axle type . . . . . . . . . . . . . . . Semi–floating hypoid lubricant . . . . . . . . Sae thermally stable 80w–90 lubricant trailer tow . . . . . . . . Synthetic 75w–140 lube capacity . . . . . . . . . . . . . . . . 1.66 l (3.50 pts.) axle ratio...

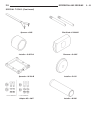

Page 141

Wrench—c-3281 installer—c-3972-a spanner—6958 installer screw—8112 cup—8109 handle—c-4171 driver—c-3716-a installer—d-130 zg differential and driveline 3 - 83 special tools (continued).

Page 142

Installer—d-146 remover—c-4345 remover—d-149 installer—w-262 installer—6436 installer—6437 disc, axle arbor—6732 gauge block—6735 3 - 84 differential and driveline zg special tools (continued).

Page 143

Tool set, pinion depth—6774 trac-lok tool set—6960 holder—6965 puller—7794-a starting point shim—8107 spreader—w-129-b adapter kit—6987 guide pin—c-3288-b zg differential and driveline 3 - 85 special tools (continued).

Page 144

Bearing remover tool set—6310 hub puller—6790 dial indicator—c-3339 3 - 86 differential and driveline zg special tools (continued).

Page 145

216 rba axle index page page general information 216 rba axle . . . . . . . . . . . . . . . . . . . . . . . . . 87 lubricant specifications . . . . . . . . . . . . 87 description and operation standard differential . . . . . . . . . . . . . . . 88 trac-lok operation . . . . . . . . . . . . . . . . ....

Page 146

Rba axle lubricant capacity is 2.25 l (4.75 pts.) total, including the friction modifier if necessary. Caution: if axle is submerged in water, lubricant must be replaced immediately to avoid possible premature axle failure. Description and operation standard differential the differential gear system...

Page 147

The trac-lok design provides the differential action needed for turning corners and for driving straight ahead during periods of unequal traction. When one wheel looses traction, the clutch packs transfer addi- tional torque to the wheel having the most traction. Trac-lok differentials resist wheel ...

Page 148

Level. Where axle bearing damage is slight, the noise is usually not noticeable at speeds above 30 mph. Low speed knock low speed knock is generally caused by a worn u–joint or by worn side–gear thrust washers. A worn pinion gear shaft bore will also cause low speed knock. Vibration vibration at the...

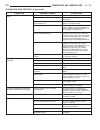

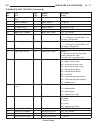

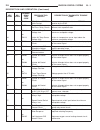

Page 149

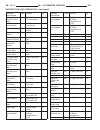

Condition possible causes correction wheel noise 1. Wheel loose. 1. Tighten loose nuts. 2. Faulty, brinelled wheel bearing. 2. Faulty or brinelled bearings must be replaced. Axle shaft noise 1. Misaligned axle shaft tube. 1. Inspect axle shaft tube alignment. Correct as necessary. 2. Bent or sprung ...

Page 150

Condition possible causes correction loss of lubricant 2. Worn axle shaft seals. Replace worn seals. 3. Cracked differential housing. 3. Repair or replace housing as necessary. 4. Worn drive pinion gear shaft seal. 4. Replace worn drive pinion gear shaft seal. 5. Scored and worn yoke. 5. Replace wor...

Page 151

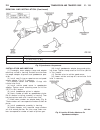

Trac–lok test warning: when servicing vehicles with a trac–lok differential do not use the engine to turn the axle and wheels. Both rear wheels must be raised and the vehi- cle supported. A trac–lok axle can exert enough force if one wheel is in contact with a surface to cause the vehicle to move. T...

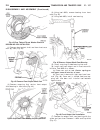

Page 152

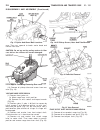

(2) position a suitable lifting device under the axle. (3) secure axle to device. (4) remove the wheels and tires. (5) remove the brake rotors and calipers from the axle. Refer to group 5, brakes, for proper procedures. (6) disconnect parking brake cables from brackets and lever. (7) remove wheel sp...

Page 153

Installation (1) apply a light coating of gear lubricant on the lip of pinion seal. Install seal with installer c-3972-a and handle c-4171 (fig. 10). (2) install yoke on the pinion gear with installer c-3718 and holder 6958 (fig. 11). Caution: do not exceed the minimum tightening torque when install...

Page 154

(5) if the rotating torque is low, use holder 6958 to hold the pinion yoke (fig. 13), and tighten the pinion shaft nut in 6.8 n·m (5 ft. Lbs.) increments until proper rotating torque is achieved. Caution: if the maximum tightening torque is reached prior to reaching the required rotating torque, the...

Page 155

(9) using holder 6958 to hold yoke and a short length of 1 in. Pipe, remove the pinion yoke nut and washer (fig. 14). (10) using remover c–452 and wrench c–3281, remove the pinion yoke from pinion shaft (fig. 15). (11) remove the pinion gear from housing (fig. 17). Catch the pinion with your hand to...

Page 156

(7) install the yoke washer and a new nut on the pinion gear. Tighten the nut to 298 n·m (220 ft. Lbs.) minimum. Do not over–tighten. Maximum torque is 380 n·m (280 ft. Lbs.). Caution: never loosen pinion gear nut to decrease pinion gear bearing rotating torque and never exceed specified preload tor...

Page 157

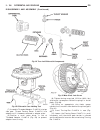

(6) rotate differential case so that pinion mate gear shaft lock screw is accessible. Remove lock screw and pinion mate gear shaft from differential case (fig. 23). (7) push axle shaft inward and remove axle shaft c–clip lock from the axle shaft (fig. 24). (8) remove axle shaft. Use care to prevent ...

Page 158

(4) inspect the axle shaft tube bore for roughness and burrs. Remove as necessary. Installation do not install the original axle shaft seal. Always install a new seal. (1) wipe the bore in the axle shaft tube clean. (2) install axle shaft bearing with installer 6436 and handle c–4171. Ensure part nu...

Page 159

Against the opposite side of the housing (fig. 28) and zero the indicator. (3) spread the housing enough to install the case in the housing. Measure the distance with the dial indicator (fig. 28). Caution: do not spread over 0.50 mm (0.020 in). If the housing is over-spread, it could be distorted or...

Page 160

Installation caution: do not reuse the bolts that held the ring gear to the differential case. The bolts can fracture causing extensive damage. (1) invert the differential case and start two ring gear bolts. This will provide case-to-ring gear bolt hole alignment. (2) invert the differential case in...

Page 161

Pinion gear note: the ring and pinion gears are service in a matched set. Do not replace the pinion gear without replacing the ring gear. Removal (1) remove differential assembly from axle hous- ing. (2) mark pinion yoke and propeller shaft for installation alignment. (3) disconnect propeller shaft ...

Page 162

(12) remove the rear bearing from the pinion with puller/press c-293-pa and adapters c-293-42 (fig. 42). Place 4 adapter blocks so they do not damage the bearing cage. (13) remove the pinion depth shims from the pin- ion gear shaft. Record the total thickness of the depth shims. Installation (1) app...

Page 163

(3) install pinion front bearing and oil slinger, if equipped. Apply a light coating of gear lubricant on the lip of pinion seal. Install seal with installer c-3972-a and handle c-4171 (fig. 45). Note: pinion depth shims are placed between the rear pinion bearing cone and pinion gear to achieve prop...

Page 164

Caution: never loosen pinion gear nut to decrease pinion gear bearing preload torque and never exceed specified preload torque. If preload torque is exceeded a new collapsible spacer must be installed. The torque sequence will have to be repeated. Note: if the spacer requires more than 280 ft. Lbs. ...

Page 165

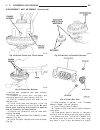

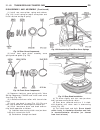

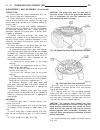

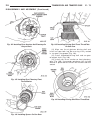

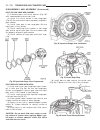

Disassembly and assembly standard differential disassembly (1) remove pinion gear mate shaft lock screw (fig. 55). (2) remove pinion gear mate shaft. (3) rotate the differential side gears and remove the pinion mate gears and thrust washers (fig. 56). (4) remove the differential side gears and thrus...

Page 166

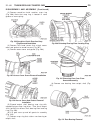

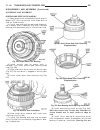

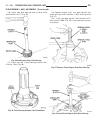

(7) assemble threaded adapter c–4487–3 into top side gear. Thread forcing screw c–4487–2 into adapter until it becomes centered in adapter plate. (8) position a small screw driver in slot of threaded adapter c–4487–3 (fig. 59) to prevent adapter from turning. (9) tighten forcing screw tool 122 n·m (...

Page 167

(13) rotate differential case until the pinion gears can be removed. (14) remove pinion gears from differential case. (15) remove forcing screw c–4487-2, step plate c-4487-1, and threaded adapter c-4487-3. (16) remove top side gear, clutch pack retainer, and clutch pack. Keep plates in correct order...

Page 168

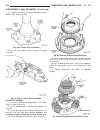

(4) position the differential case on side gear holding tool 6963-a. (5) install lubricated step plate c–4487–1 on side gear (fig. 66). (6) install the upper side gear and clutch disc pack (fig. 66). (7) hold assembly in position. Insert threaded adapter c–4487–3 into top side gear. (8) insert forci...

Page 169

(15) install pinion gear mate shaft and align holes in shaft and case. (16) install the pinion mate shaft lock screw finger tight to hold shaft during differential installation. If replacement side and/or pinion gears and thrust washers were installed, it is not neces- sary to measure the side gear ...

Page 170

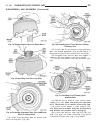

Pinion gear are etched into the face of each gear (fig. 67). A plus (+) number, minus (–) number or zero (0) is etched into the face of the pinion gear. This num- ber is the amount (in thousandths of an inch) the depth varies from the standard depth setting of a pinion etched with a (0). The standar...

Page 171

Pointer back to zero against the arbor bar, do not turn dial face. Continue moving the dial probe to the crest of the arbor bar and record the highest reading. If the dial indicator can not achieve the zero reading, the rear bearing cup or the pinion depth gauge set is not installed correctly. (9) s...

Page 172

Lash measurements, measure the pinion gear depth and prepare the pinion gear for installation. Estab- lishing proper pinion gear depth is essential to estab- lishing gear backlash and tooth contact patterns. After the overall shim thickness to take up differen- tial side play is measured, the pinion...

Page 173

(6) install the marked bearing caps in their correct positions. Install and snug the bolts. (7) thread guide stud c-3288-b into rear cover bolt hole below ring gear (fig. 75). (8) attach dial indicator c-3339 to guide stud c-3288-b. Position the dial indicator plunger on a flat surface between the r...

Page 174

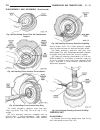

Adjusted within specifications to achieve desired tooth contact patterns. (1) apply a thin coat of hydrated ferric oxide, or equivalent, to the drive and coast side of the ring gear teeth. (2) wrap, twist, and hold a shop towel around the pinion yoke to increase the turning resistance of the pinion ...

Page 175

Fig. 78 gear tooth contact patterns drive side of ring gear teeth heel toe coast side of ring gear teeth toe heel desirable contact pattern. Pattern should be centered on the drive side of tooth. Pattern should be centered on the coast side of tooth, but may be slightly toward the toe. There should ...

Page 176

Specifications 216 rba axle description spec. Type . . . . . . . . . . . . . . . . . . . . Semi-floating hypoid axle ratios . . . . . . . . . . . . . . . . . . . . . . . . 3.55/3.73 ring gear diameter . . . . . . . . . . 216 mm (8.5 in.) gear backlash . . . 0.13–0.20 mm (0.005–0.008 in.) pinion dept...

Page 177

Holder—c-3281 installer—c-3718 handle—c-4171 remover—c-4307 installer—c-4308 installer—c-4340 guide pin—c-3288-b dial indicator—c-3339 zg differential and driveline 3 - 119 special tools (continued).

Page 178

Trac-lok tool set—c-4487 installer—c-3972-a installer—d-129 remover—d-103 spreader—w-129-b remover—6310 installer—6436 installer—6437 3 - 120 differential and driveline zg special tools (continued).

Page 179

Installer—6448 adapter—6790 pinion depth set—6955 adapter set—6956 gauge block—8144 starting point shim—8107 holder—6958 holder—6963-a remover—7794-a zg differential and driveline 3 - 121 special tools (continued).

Page 181: Brakes

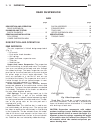

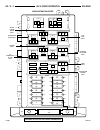

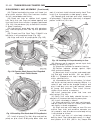

Brakes contents page page antilock brakes . . . . . . . . . . . . . . . . . . . . . 35 base brake system . . . . . . . . . . . . . . . . . . . . 1 base brake system index page page general information brake system . . . . . . . . . . . . . . . . . . . . . . . . 2 service warnings & cautions . . . . ...

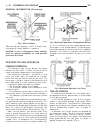

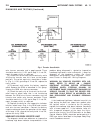

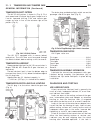

Page 182

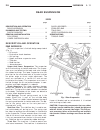

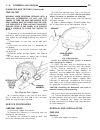

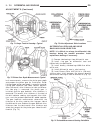

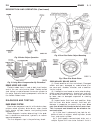

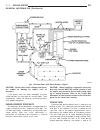

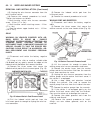

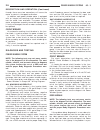

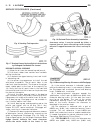

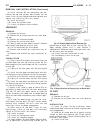

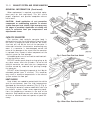

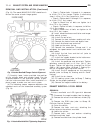

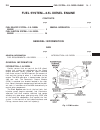

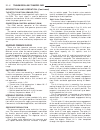

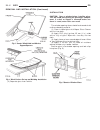

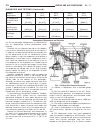

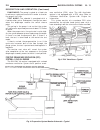

General information brake system all vehicles are equipped with power assist four- wheel disc brakes. Antilock (abs) brakes are also standard equipment on all models. Single piston, disc brake calipers are used front and rear. Ventilated disc brake rotors are used at the front and solid rotors are u...

Page 183

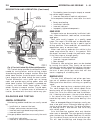

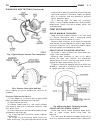

Through a hose attached to an intake manifold fitting at one end and to the booster check valve at the other. The vacuum check valve in the booster housing is a one-way device that prevents vacuum leak back. Power assist is generated by utilizing the pressure differential between normal atmospheric ...

Page 184

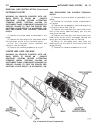

Parking brake shoes (fig. 5). Parking brake shoe ser- vice is covered in the parking brake service section. The outboard shoe now has an anti-rattle spring attached at the shoe rear. A wear strip is mounted to the inboard shoe. Parking brakes the parking brakes are operated by a cable and hand lever...

Page 185

Brake hoses and lines flexible rubber hose is used at both front brakes and at the rear axle junction block. Double walled steel tubing is used to connect the master cylinder to the major hydraulic braking components and then to the flexible rubber hoses. Diagnosis and testing base brake system base...

Page 186

Separated into layers, or contains a substance other than brake fluid. The system seals and cups will also have to be replaced after flushing. Use clean brake fluid to flush the system. (4) check parking brake operation. Verify free movement and full release of cables and pedal. Also note if vehicle...

Page 187

Mountain roads. Refer to the brake drag information in this section for causes. Brake pull front brake pull condition could result from: • contaminated lining in one caliper • seized caliper piston • binding caliper • loose caliper • rusty adapter/caliper slide surfaces • improper brake shoes • dama...

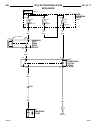

Page 188

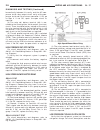

Switch circuit identification • terminals 1 and 2 are for brake sensor circuit. • terminals 5 and 6 are for the stop lamp circuit. • terminals 3 and 4 are for the speed control cir- cuit. Switch continuity test (1) check continuity between terminal pins 5 and 6 as follows: (a) pull plunger all the w...

Page 189

Faulty, replace the entire combination valve as an assembly. Pressure differential switch (1) have helper sit in drivers seat to apply brake pedal and observe red brake warning light. (2) raise vehicle on hoist. (3) connect bleed hose to a rear wheel cylinder and immerse hose end in container partia...

Page 190

Rotor with the wheel nuts and 4 or 5 large diameter flat washers on each stud. Use a dial indicator to check lateral runout (fig. 10). Maximum allowable rotor lateral runout is 0.13 mm (0.005 in.). Rear disc brake rotor rotor minimum thickness minimum usable thickness of the rear disc brake rotor is...

Page 191

The result of worn brake shoes, improper brake shoe adjustment, or improperly assembled brake parts. A “too loose” condition can also be caused by inop- erative or improperly assembled parking brake shoe parts. A condition where the parking brakes do not hold, will most probably be due to a wheel br...

Page 192

Note: if master cylinders has one reservoir open- ing, position both bleed tubes into the single reser- voir opening (fig. 14). (3) fill reservoir with fresh brake fluid. (4) press cylinder pistons inward with wood dowel. Then release pistons and allow them to return under spring pressure. Continue ...

Page 193

Stem must either be pressed inward, or held outward slightly. A spring clip tool or helper is needed to hold the valve stem in position. Follow the manufacturers instructions carefully when using pressure equipment. Do not exceed the tank manufacturers pressure recommendations. Gen- erally, a tank p...

Page 194

(9) tighten tool handle until plug gauge is seated on jaws of flaring tool. This will start the inverted flare. (10) remove the plug gauge and complete the inverted flare. (11) remove the flaring tools and verify that the inverted flare is correct. Removal and installation stop lamp switch removal (...

Page 195

(9) check and adjust brakelamp switch if neces- sary. Combination valve removal (1) remove brake lines that connect master cylin- der to combination valve (fig. 21). (2) disconnect brake lines that connect combina- tion valve to hcu. (3) disconnect wire from combination valve switch terminal. Be car...

Page 196

Installation (1) remove protective cover from end of primary piston. (2) bleed master cylinder. (3) slide master cylinder onto booster studs. Align booster push rod in cylinder primary piston and seat cylinder against booster. (4) install master cylinder mounting nuts and tighten nuts to 18 n·m (155...

Page 197

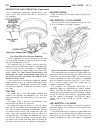

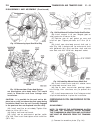

(4) rotate caliper rearward with pry tool if neces- sary. Then rotate caliper and brake shoes off mount- ing ledges. (5) remove caliper from vehicle. Installation (1) install brake shoes in caliper. (2) connect brake hose to caliper but do not tighten fitting bolt completely at this time. Be sure to...

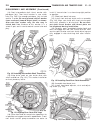

Page 198

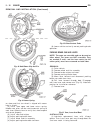

(6) remove outboard shoe by pressing one end of shoe inward to disengage shoe lug. Then rotate shoe upward until retainer spring clears caliper. Press opposite end of shoe inward to disengage shoe lug and rotate shoe up and out of caliper (fig. 30). (7) remove inboard shoe. Grasp ends of shoe and ti...

Page 199

(5) install and tighten caliper mounting bolts to 10-20 n·m (7-15 ft. Lbs.). Caution: if new caliper bolts are being installed, or if reason for repair was a drag/pull condition, check caliper bolt length. If the bolts have a shank length greater than 67.6 mm (2.66 in.), they will con- tact the inbo...

Page 200

(2) position caliper over rotor and into bracket. Be sure brake shoe tabs are properly seated on mount- ing bracket ledges. (3) connect rear brake hose to caliper. Use new washers on hose fitting and tighten hose fitting bolt to 24-38 n·m (216-336 in. Lbs.). (4) check brake hose position before proc...

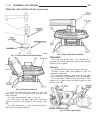

Page 201

Installation (1) clean brake shoe contact surfaces of caliper mounting bracket (fig. 40). Use wire brush or emery cloth. (2) install brake shoes in caliper. (3) install caliper over rotor and into mounting bracket. (4) verify that brake shoe lugs are properly seated on caliper mounting bracket (fig....

Page 202

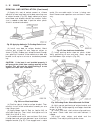

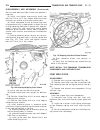

Parking brake hand lever removal (1) release parking brakes. (2) disconnect battery negative cable. (3) raise vehicle on hoist. (4) remove front cable adjusting nut and disen- gage cable tensioner from equalizer. Then remove front cable from tensioner (fig. 43). (5) disengage front cable from insert...

Page 203

Installation (1) connect front cable to lever assembly. (2) seat front cable in floor pan. (3) install lever assembly. (4) install console. (5) raise vehicle. (6) assemble front cable, cable tensioner and equalizer. (7) adjust parking brake system if new cable, or tensioner has been installed, or if...

Page 204

On shoes and that star wheel is aligned with access hole in shield. (4) install shoe upper and lower return spring. Needle nose pliers can be used to connect spring to each shoe. Operate lever to verify that shoes expand and retract properly. (5) install rotor and caliper. (6) adjust parking brake s...

Page 205

(2) engage cam in lever. Then simultaneously slide cam into place on splash shield and work lever through boot (fig. 52). (3) install parking brake shoes. (4) verify correct installation of cam and lever by pulling lever toward front of vehicle. Cam should expand both brake shoes as lever is pulled ...

Page 206

(2) apply thin coat of contact cement or silicone adhesive to new lever boot and to boot mounting area of caliper bracket (fig. 55). Apply adhesive to areas where boot and bracket contact one another. Adhe- sive is needed to hold boot in position when splash shield is attached to bracket. (3) instal...

Page 207

(11) lower vehicle and verify correct service and parking brake operation. Disassembly and assembly master cylinder reservoir removal (1) remove reservoir cap and empty fluid into drain container. (2) remove pins that retain reservoir to master cylinder. Use hammer and pin punch to remove pins (fig....

Page 208

Installation caution: do not use any type of tool to install the grommets. Tools may cut, or tear the grommets creating a leak problem after installation. Install the grommets using finger pressure only. (1) lubricate new grommets with clean brake fluid and install new grommets in cylinder body (fig...

Page 209

(5) remove caliper piston dust boot with suitable tool (fig. 67) and discard boot. (6) remove caliper piston seal with wood or plastic tool (fig. 68) and discard seal. Do not use metal tools as they will scratch piston bore. (7) remove caliper mounting bolt bushings and boots (fig. 69). Assembly (1)...

Page 210

(5) install dust boot on caliper piston and seat boot in piston groove (fig. 72). (6) press piston into caliper bore by hand, use a turn and push motion to work piston into seal (fig. 73). (7) press caliper piston to bottom of bore. (8) seat dust boot in caliper with installer tool c-4842 and tool h...

Page 211

Assembly (1) lubricate caliper piston bore and new piston seal with clean brake fluid. (2) install new piston seal in groove machined in piston bore. Be sure seal is fully seated and is not twisted. Press seal into place with fingertips. (3) lubricate caliper piston with clean brake fluid and start ...

Page 212

(7) press caliper to bottom of bore after seating dust boot. Be sure to use wood block to protect piston and boot. (8) install caliper bleed screw, if removed. (9) install bushing and boot assemblies in caliper. Be sure boots are centered in caliper as shown. (10) apply silicone grease to interior o...

Page 213

(6) reinstall brake drums and wheel/tire assem- blies after brake shoe adjustment is complete. (7) lower vehicle enough for access to parking brake lever. Then fully apply parking brakes. Leave brakes applied until adjustment is complete. (8) raise vehicle and mark tensioner rod 6.5 mm (1/4 in.) fro...

Page 214

Front disc brake caliper brake booster type . . . . . . . . . . . . . . . . . . . . . . Dual diaphragm torque chart description torque brake pedal support bolt . . . . . . . . . 23-34 n·m (17-25 ft. Lbs.) pivot bolt/nut . . . . . . . . 27-35 n·m (20-26 ft. Lbs.) brake booster mounting nuts . . . . ....

Page 215

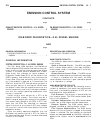

Antilock brakes index page page general information antilock brake system . . . . . . . . . . . . . . 35 description and operation abs system relays . . . . . . . . . . . . . . . . . . 38 abs warning lamp . . . . . . . . . . . . . . . . . . . 38 acceleration switch . . . . . . . . . . . . . . . . 38...

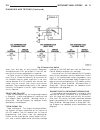

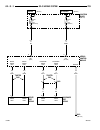

Page 216

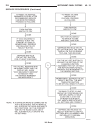

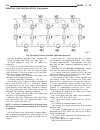

The cab will not activate any abs components as long as sensor inputs and the acceleration switch indicate normal braking. During normal braking, the master cylinder, power booster and wheel brake units all function as they would in a vehicle without abs. The hcu compo- nents are not activated. Anti...

Page 217

A pressure decrease cycle is initiated when speed sensor signals indicate high wheel slip at one or more wheels. At this point, the cab closes the inlet then opens the outlet valve, which also opens the return circuit to the accumulators. Fluid pressure is allowed to bleed off (decrease) as needed t...

Page 218

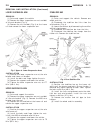

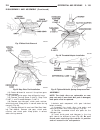

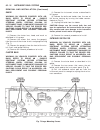

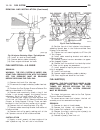

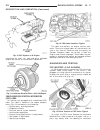

Acceleration switch the acceleration switch is located under the rear seat. The switch (fig. 4), provides an additional vehi- cle deceleration reference during 4wd operation. The switch is monitored by the cab at all times. The switch reference signal is utilized by the cab when all wheels are decel...

Page 219

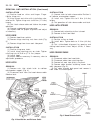

(3) install the brake lines to the hcu and tighten to 16 n·m (12 ft. Lbs.). (4) install cab harness connector and push-in connector release. (5) install steering gear shield. (6) install windshield reservoir and mounting bolts. (7) install air cleaner housing. (8) install negative battery cable to t...

Page 220

(8) remove sensor and wire assembly. Installation (1) apply mopar lock n’ seal or loctite 242 to sensor attaching bolt. Use new sensor bolt if original bolt is worn or damaged. (2) position sensor on steering knuckle. Seat sen- sor locating tab in hole in knuckle and install sensor attaching bolt fi...

Page 221

(3) tilt rear seat assembly forward for access to the switch. (4) disconnect switch harness (fig. 12). (5) remove bolts attaching switch to bracket and remove the switch. Installation caution: the mercury switch inside the accelera- tion switch, will only function properly if the locat- ing arrow is...

Page 222

Assembly (1) install the cab onto the hcu. (2) install the cab mounting screws and tighten to 1.8 n·m (16 in. Lbs.). (3) install pump motor connector to the cab. Specifications torque chart description torque acceleration sensor sensor bolt . . . . . . . . . . . . 8-9 n·m (71-83 in. Lbs.) bracket bo...

Page 223: Clutch

Clutch contents page page general information clutch components . . . . . . . . . . . . . . . . . . 1 clutch hydraulic system . . . . . . . . . . . . . 1 removal and installation clutch cover and disc . . . . . . . . . . . . . . . . 1 flywheel ring gear . . . . . . . . . . . . . . . . . . . 5 flywhe...

Page 224

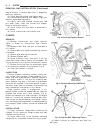

Installation (1) lightly scuff sand flywheel face with 180 grit emery cloth. Then clean surface with brake or carbu- retor cleaner. (2) lightly lubricate pilot bearing with mopar t high temperature bearing grease. (3) check free operation of clutch disc by sliding disc onto transmission output shaft...

Page 225

Pilot bearing removal (1) remove transmission and transfer case. (refer to group 21, transmissions and transfer case.) (2) remove clutch cover and disc. (3) remove the four bolts that attach the pilot bearing retainer to the flywheel (fig. 4). (4) remove the pilot bearing retainer. (5) support the b...

Page 226

Edge of chamfer in retainer bore (fig. 7). Reposition bearing if necessary. (2) install bearing retainer and tighten bolts. (3) lubricate pilot bearing with mopar t high tem- perature wheel bearing grease. (4) lightly scuff sand flywheel surface with 180 grit emery cloth. Clean the surface with mopa...

Page 227

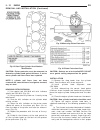

(4) install and tighten new flywheel bolts as fol- lows: (a) lubricate bolt threads with engine oil. (b) install and tighten bolts to initial torque of 20 n·m. Tighten bolts diagonally in pairs (fig. 10). (c) tighten each bolt and additional 60° turn. Continue tightening bolts in small increments to...

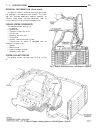

Page 229: Cooling System

Cooling system contents page page general information coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 cooling system components . . . . . . . . . . 2 cooling system . . . . . . . . . . . . . . . . . . . . . . 1 engine accessory drive belts . . . . . . . . . 1 radiator . . . . . ....

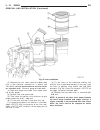

Page 230

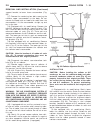

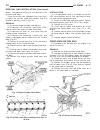

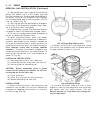

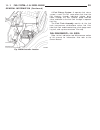

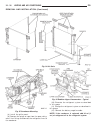

An optional factory installed maximum duty cool- ing package is available on most models. This pack- age will provide additional cooling capacity for vehicles used under extreme conditions such as trailer towing in high ambient temperatures. Cooling system components the cooling system consists of: ...

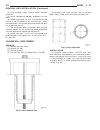

Page 231

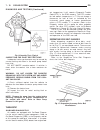

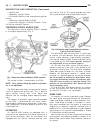

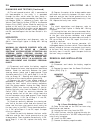

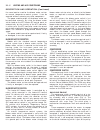

Water pump bypass hose—5.2/5.9l v-8 engines a water pump bypass hose (fig. 3) is used between the intake manifold and water pump on all 5.2/5.9l v-8 engines. Coolant the cooling system is designed around the coolant. Coolant flows through the engine water jackets absorbing heat produced during engin...

Page 232

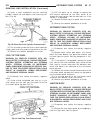

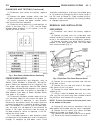

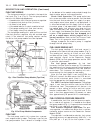

Accessory drive belt tension correct drive belt tension is required to ensure optimum performance of the belt driven engine acces- sories. If specified tension is not maintained, belt slippage may cause; engine overheating, lack of power steering assist, loss of air conditioning capac- ity, reduced ...

Page 233

The more common type of thermostat failure, usu- ally found on high mileage vehicles, is a thermostat failed in the shut position. The temperature gauge (if equipped) will give an indication of this condition. Depending upon length of time that vehicle is oper- ated, pressure cap may vent. This will...

Page 234

This causes the vacuum valve to open and coolant in reserve/overflow tank to be drawn through connect- ing hose into radiator. If the vacuum valve is stuck shut, radiator hoses will collapse on cool-down. A rubber gasket seals the radiator filler neck. This is done to maintain vacuum during coolant ...

Page 235

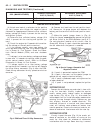

Caution: a number or letter is stamped into the tongue of constant tension clamps (fig. 11). If replacement is necessary, use only an original equipment clamp with matching number or letter. Inspect the hoses at regular intervals. Replace hoses that are cracked, feel brittle when squeezed, or swell ...

Page 236

Reacts and the fan speed is reduced to the previous disengaged speed. Caution: engines equipped with serpentine drive belts have reverse rotating fans and viscous fan drives. They are marked with the word reverse to designate their usage. Installation of the wrong fan or viscous fan drive can result...

Page 237

If the problem is sensed in a monitored circuit often enough to indicate an actual problem, a dtc is stored. The dtc will be stored in the pcm memory for eventual display to the service technician. If the problem is repaired or ceases to exist, the pcm can- cels the dtc after 51 engine starts. Certa...

Page 238

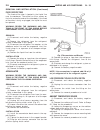

Inspecting for inlet restrictions inadequate heater performance may be caused by a metal casting restriction in the water pump heater hose inlet. Do not waste reusable coolant. If solution is clean, drain the coolant into a clean container for reuse. Warning: do not loosen the radiator draincock wit...

Page 239

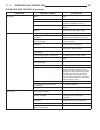

Serpentine drive belt diagnosis–4.0l 6-cylinder engine condition possible causes possible causes rib chunking (one or more ribs has separated from belt body) 1. Foreign objects imbedded in pulley grooves. 1. Remove foreign objects from pulley grooves. Replace belt. 2. Installation damage. 2. Replace...

Page 240

Serpentine drive belt diagnosis-5.2/5.9l 8-cylinder engines condition possible causes correction rib chunking (one or more ribs has separated from belt body) 1. Foreign objects imbedded in pulley grooves. 1. Remove foreign objects from pulley grooves. Replace belt. 2. Installation damage. 2. Replace...

Page 241

Preliminary checks engine cooling system overheating establish what driving conditions caused the com- plaint. Abnormal loads on the cooling system such as the following may be the cause. (1) prolonged idle, very high ambient temperature, slight tail wind at idle, slow traffic, traffic jams, high sp...

Page 242

Cooling system diagnosis condition possible causes correction temperature gauge reads low 1. Has a diagnostic trouble code (dtc) number 17 been set indicating a stuck open engine thermostat. 1. Refer to on-board diagnostics in the service manual text. Replace thermostat if necessary. If a diagnostic...

Page 243

Condition possible causes correction temperature gauge reads high or engine coolant warning lamp illuminates. Coolant may or may not be lost or leaking from cooling system 9. Coolant not flowing through system. 9. Check for coolant flow at radiator filler neck with some coolant removed, engine warm ...

Page 244

Condition possible causes correction detonation or pre-ignition (not caused by ignition system). Gauge may or may not be reading high 1. Engine overheating. 1. Check reason for overheating and repair as necessary. 2. Freeze point of antifreeze not correct. Mixture is too rich or too lean. 2. Check a...

Page 245

Condition possible causes correction heat odor 1. Various heat shields are used at certain drive line components. One or more of these shields may be missing. 1. Locate missing shields and replace or repair as necessary. 2. Is temperature gauge reading above the normal range? 2. Refer to the previou...

Page 246

Radiator coolant flow check the following procedure will determine if coolant is flowing through the cooling system. If engine is cold, idle engine until normal operating temperature is reached. Then feel the upper radiator hose. If hose is hot, the thermostat is open and water is circulating throug...

Page 247

Leakage. If no leaks are visible, inspect for internal leakage. Large radiator leak holes should be repaired by a reputable radiator repair shop. Internal leakage inspection remove the oil pan drain plug and drain a small amount of engine oil. Coolant, being heavier, will drain first, or operate eng...

Page 248

Warning: use extreme caution when the engine is operating. Do not stand in a direct line with the fan. Do not put your hands near the pulleys, belts or fan. Do not wear loose clothing. (6) start the engine and operate at 2400 rpm. Within ten minutes the air temperature (indicated on the dial thermom...

Page 249

Low coolant level-aeration if the coolant level in radiator drops below top of radiator core tubes, air will enter cooling system. Low coolant level can cause thermostat pellet to be suspended in air instead of coolant. This will cause thermostat to open later, which in turn causes higher coolant te...

Page 250

(1) with engine cold, slowly remove the radiator cap. Raise vehicle on a hoist and locate radiator draincock. • 4.0l engine: radiator draincock is located on the right/lower side of radiator facing to rear of vehi- cle. • 5.2/5.9l engines: radiator draincock is located on the left/lower side of radi...

Page 251

Cooling tube passages. For more information, refer to operating instructions supplied with flushing equip- ment. Have radiator cleaned more extensively by a radiator repair shop. Reverse flushing engine drain the cooling system. Remove the thermostat housing and thermostat. Install the thermostat ho...

Page 252

Installation (1) position cooler to vehicle. (2) install lower hose and hose clamp to cooler. Hose clamp screws must be facing towards rear of vehicle. Tighten clamp to 2 n·m (18 in. Lbs.) torque. (3) install upper hose and hose clamp at cooler. Hose clamp screws must be facing towards rear of vehic...

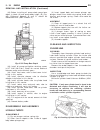

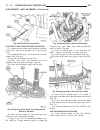

Page 253

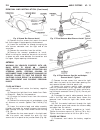

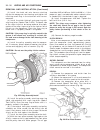

Warning: constant tension hose clamps are used on most cooling system hoses. When removing or installing, use only tools designed for servicing this type of clamp, such as special clamp tool (number 6094) (fig. 29) snap-on clamp tool (number hpc-20) may be used for larger clamps. Always wear safety ...

Page 254

(12) remove the four pump mounting bolts (fig. 31) and remove pump from vehicle. Discard old gas- ket. Note that one of the four bolts is longer than the other bolts. (13) if pump is to be replaced, the heater hose fit- ting must be removed. Note position of fitting before removal. Installation (1) ...

Page 255

Any of these conditions are found. Also check condi- tion of the thermal viscous fan drive. Refer to viscous fan drive in this group. The water pump can be removed without discharg- ing the air conditioning system (if equipped). Removal (1) disconnect negative battery cable from battery. (2) drain c...

Page 256