- DL manuals

- Jeep

- Automobile

- 200 Cherokee

- Service Manual

Jeep 200 Cherokee Service Manual

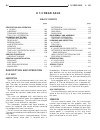

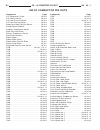

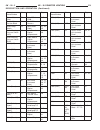

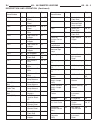

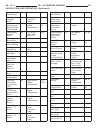

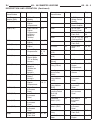

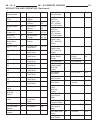

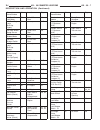

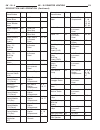

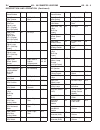

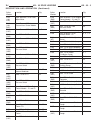

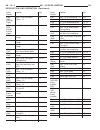

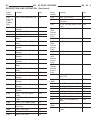

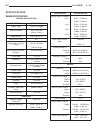

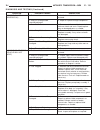

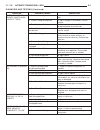

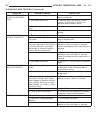

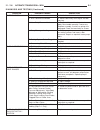

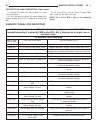

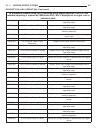

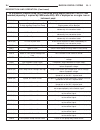

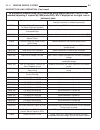

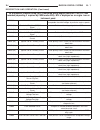

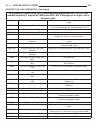

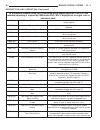

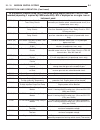

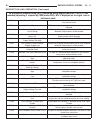

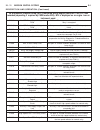

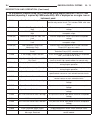

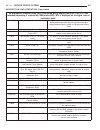

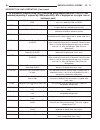

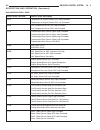

GROUP TAB LOCATOR

IN

Introduction

INa

Introduction

0

Lubrication and Maintenance

0a

Lubrication and Maintenance

2

Suspension

3

Differential and Driveline

5

Brakes

5a

Brakes

6

Clutch

6a

Clutch

7

Cooling System

7a

Cooling System

8A

Battery

8B

Starting System

8Ba

Starting Systems

8C

Charging System

8Ca

Charging System

8D

Ignition System

8E

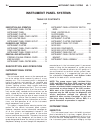

Instrument Panel Systems

8Ea

Instrument Panel Systems

8F

Audio Systems

8G

Horn Systems

8H

Vehicle Speed Control System

8Ha

Vehicle Speed Control System

8J

Turn Signal and Hazard Warning Systems

8K

Wiper and Washer Systems

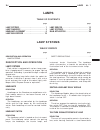

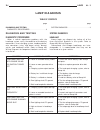

8L

Lamps

8La

Lamps

8M

Passive Restraint Systems

8N

Electrically Heated Systems

8O

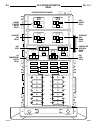

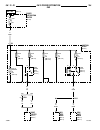

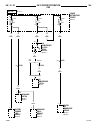

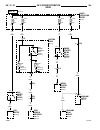

Power Distribution Systems

8P

Power Lock Systems

8Q

Vehicle Theft/Security Systems

8Qa

Vehicle Theft/Security Systems

8R

Power Seats Systems

8S

Power Window Systems

8T

Power Mirror Systems

8U

Chime/Buzzer Warning Systems

8V

Overhead Console Systems

8W

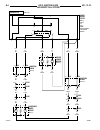

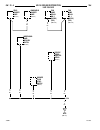

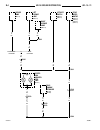

Wiring Diagrams

9

Engine

9a

Engine

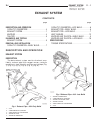

11

Exhaust System and Intake Manifold

11a

Exhaust System and Intake Manifold

13

Frame and Bumpers

13a

Frame and Bumpers

14

Fuel System

14a

Fuel System–2.5L Diesel Engine

19

Steering

19a

Steering

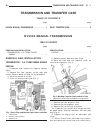

21

Transmission and Transfer Case

21a

Transmission and Transfer Case

22

Tires and Wheels

23

Body

24

Heating and Air Conditioning

24a

Heating and Air Conditioning

25

Emission Control Systems

25a

Emission Control System

Service Manual Comment Forms

Summary of 200 Cherokee

Page 1

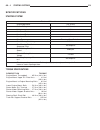

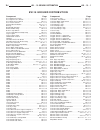

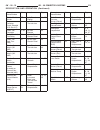

Group tab locator in introduction ina introduction 0 lubrication and maintenance 0a lubrication and maintenance 2 suspension 3 differential and driveline 5 brakes 5a brakes 6 clutch 6a clutch 7 cooling system 7a cooling system 8a battery 8b starting system 8ba starting systems 8c charging system 8ca...

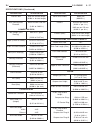

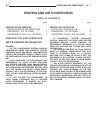

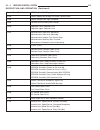

Page 2: Introduction

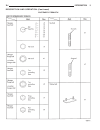

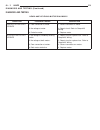

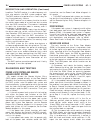

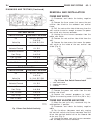

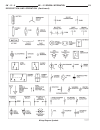

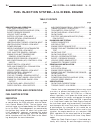

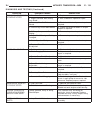

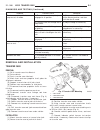

Introduction table of contents page page description and operation vehicle identification number . . . . . . . . . . 1 vehicle safety certification label . . . . . . 2 international symbols . . . . . . . . . . . . . . . . . 2 fastener identification . . . . . . . . . . . . . . . . . 3 fastener usage...

Page 3

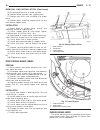

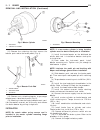

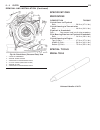

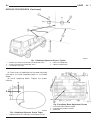

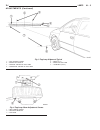

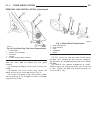

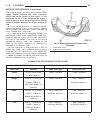

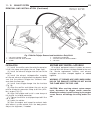

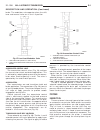

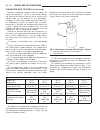

Vehicle safety certification label a vehicle safety certification label (fig. 1) is attached to every daimlerchrysler corporation vehi- cle. The label certifies that the vehicle conforms to all applicable federal motor vehicle safety standards. The label also lists: • month and year of vehicle manuf...

Page 4

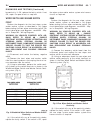

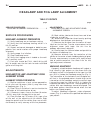

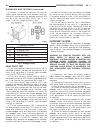

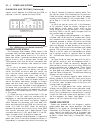

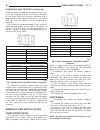

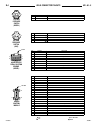

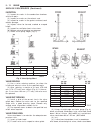

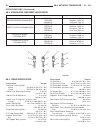

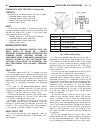

Fastener identification description grade/class identification the sae bolt strength grades range from grade 2 to grade 8. The higher the grade number, the greater the bolt strength. Identification is determined by the line marks on the top of each bolt head. The actual bolt strength grade correspon...

Page 5

Fastener identification 4 introduction xj description and operation (continued).

Page 6

Fastener strength xj introduction 5 description and operation (continued).

Page 7

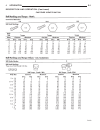

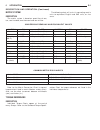

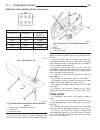

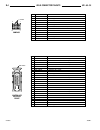

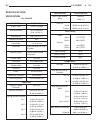

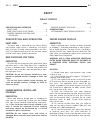

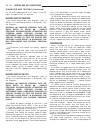

Metric system description the metric system is based on quantities of one, ten, one hundred, one thousand and one million. The following chart will assist in converting metric units to equivalent english and sae units, or vise versa. Conversion formulas and equivalent values multiply by to get multi...

Page 8

Metric conversion chart xj introduction 7 description and operation (continued).

Page 9

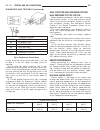

Torque specifications 8 introduction xj description and operation (continued).

Page 10: Introduction

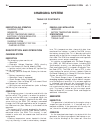

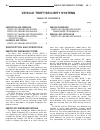

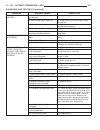

Introduction table of contents page page description and operation vehicle identification number . . . . . . . . . . 1 e-mark label . . . . . . . . . . . . . . . . . . . . . . . . . . 2 manufacturer plate . . . . . . . . . . . . . . . . . . . 2 description and operation vehicle identification number...

Page 11

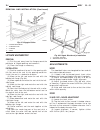

E-mark label description an e-mark label (fig. 1) is located on the rear shut face of the driver’s door. The label contains the following information: • date of manufacture • month-day-hour (mdh) • vehicle identification number (vin) • country codes • regulation number • regulation amendment number ...

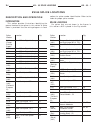

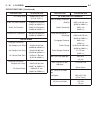

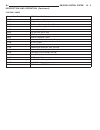

Page 12: Lubricants

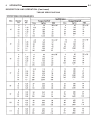

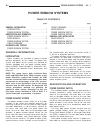

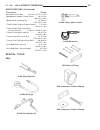

Lubrication and maintenance table of contents page page lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 maintenance schedules . . . . . . . . . . . . . . . . . 4 jump starting, towing and hoisting . . . . . 9 lubricants table of contents page page service procedures parts and ...

Page 13

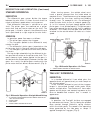

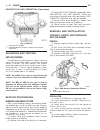

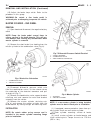

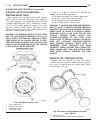

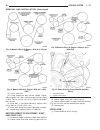

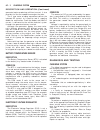

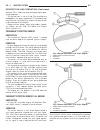

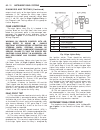

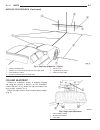

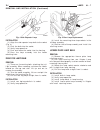

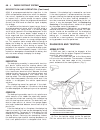

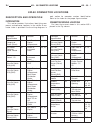

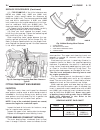

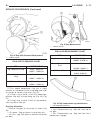

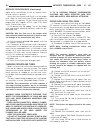

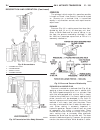

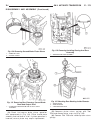

Api quality classification this symbol (fig. 2) on the front of an oil container means that the oil has been certified by the ameri- can petroleum institute (api) to meet all the lubri- cation requirements specified by dailmlerchrysler corporation. Refer to group 9, engine for gasoline engine oil sp...

Page 14

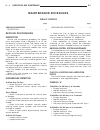

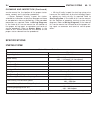

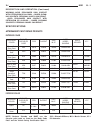

Specifications fluid capacities fuel tank all . . . . . . . . . . . . . . . . . . . . . . . . 76.4 l (20.2 gal.) engine oil w/filter change 2.5l . . . . . . . . . . . . . . . . . . . . . . . . . 3.8 l (4.0 qts.) 4.0l . . . . . . . . . . . . . . . . . . . . . . . . . 5.7 l (6.0 qts.) cooling system 2...

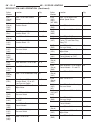

Page 15: Maintenance Schedules

Maintenance schedules table of contents page page service procedures description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 unscheduled inspection . . . . . . . . . . . . . . . . 4 service procedures description service and maintenance procedures for compo- nents and systems listed in...

Page 16

30,000 miles (48 000 km) or at 24 months • change engine oil. • replace engine oil filter. • replace air cleaner element. • replace spark plugs. • inspect drive belt, adjust tension as necessary. • lubricate steering linkage. • drain and refill automatic transmission fluid. • drain and refill transf...

Page 17

• lubricate steering linkage. • drain and refill automatic transmission fluid. • drain and refill transfer case fluid. • lubricate steering and suspension ball joints. Important: inspection and service should also be performed any time a malfunction is observed or sus- pected. Schedule “b” follow sc...

Page 18

45,000 miles (72 000 km) • change engine oil. • replace engine oil filter. • inspect engine air cleaner element, replace as necessary. • lubricate steering linkage. 48,000 miles (77 000 km) • change engine oil. • replace engine oil filter. • lubricate steering linkage. • drain and refill automatic t...

Page 19

87,000 miles (139 000 km) • change engine oil. • replace engine oil filter. • lubricate steering linkage. 90,000 miles (144 000 km) • change engine oil. • replace engine oil filter. • replace engine air cleaner element. • replace spark plugs. • inspect drive belt, adjust tension as necessary. • lubr...

Page 20

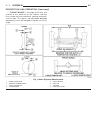

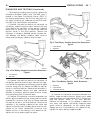

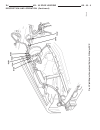

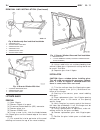

Jump starting, towing and hoisting table of contents page page service procedures jump starting procedure. . . . . . . . . . . . . . . 9 two-wheel-drive vehicle towing . . . . . . . 10 four-wheel-drive vehicle towing . . . . . . 10 emergency tow hooks . . . . . . . . . . . . . . . . . 11 hoisting re...

Page 21

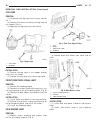

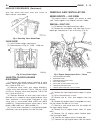

Caution: do not crank starter motor on disabled vehicle for more than 15 seconds, starter will over- heat and could fail. (6) allow battery in disabled vehicle to charge to at least 12.4 volts (75% charge) before attempting to start engine. If engine does not start within 15 sec- onds, stop cranking...

Page 22

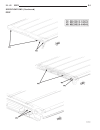

Towing-rear end lifted (wheel lift) (1) raise front of vehicle off ground and install tow dollies under front wheels. (2) attach wheel lift to rear wheels. (3) place transmission in neutral. (4) raise vehicle to towing height. (5) place transmission in park (automatic trans- mission) or first gear (...

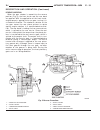

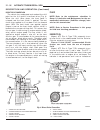

Page 23

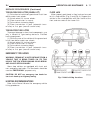

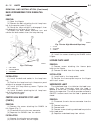

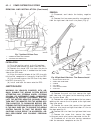

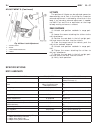

Caution: do not attempt to lift a jeep vehicle with a floor jack positioned under: • an axle tube. • a body side sill. • a steering linkage component. • a drive shaft. • the engine or transmission oil pan. • the fuel tank. • a front suspension arm. Note: use the correct sub-frame rail or frame rail ...

Page 24: Lubricants

Lubrication and maintenance table of contents page page lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 maintenance schedule. . . . . . . . . . . . . . . . . . . 2 lubricants table of contents page page specifications engine oil—diesel engines . . . . . . . . . . . . . . 1 flu...

Page 25: Maintenance Schedule

Maintenance schedule table of contents page page description and operation maintenance schedule—diesel engine . . . 2 service procedures schedule—a . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 schedule—b . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 description and operation mai...

Page 26

• replace air filter element. • replace drive belt. • check engine smoke. • replace engine coolant. 70 000 km • change engine oil. • change engine oil filter. 80 000 km • change engine oil. • change engine oil filter. • replace air filter element. • drive belt visual inspection. • replace fuel filte...

Page 27

55 000 km • change engine oil. • change engine oil filter. 60 000 km • change engine oil. • change engine oil filter. • replace air filter element. • drive belt visual inspection. • replace fuel filter/water separator element. 65 000 km • change engine oil. • change engine oil filter. 70 000 km • ch...

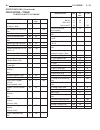

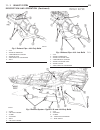

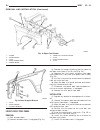

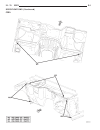

Page 28: Suspension

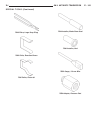

Suspension table of contents page page alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 front suspension . . . . . . . . . . . . . . . . . . . . . . . 7 rear suspension . . . . . . . . . . . . . . . . . . . . . . . 16 alignment table of contents page page description and opera...

Page 29

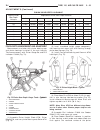

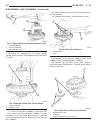

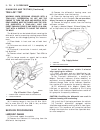

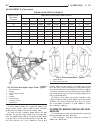

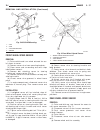

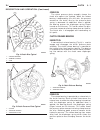

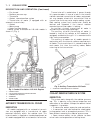

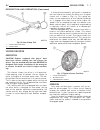

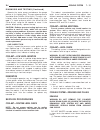

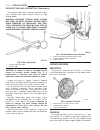

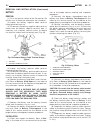

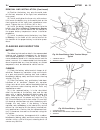

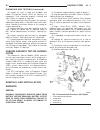

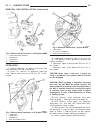

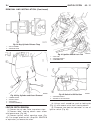

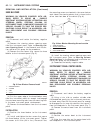

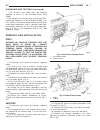

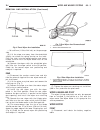

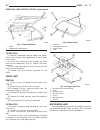

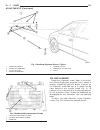

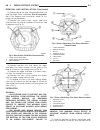

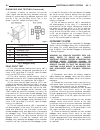

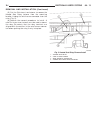

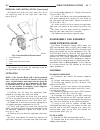

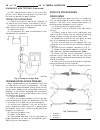

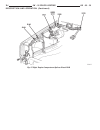

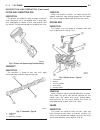

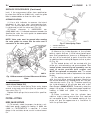

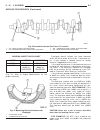

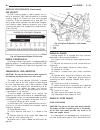

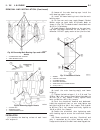

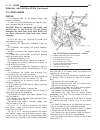

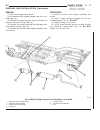

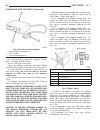

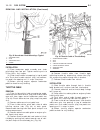

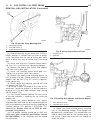

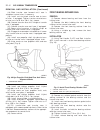

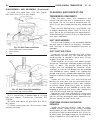

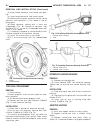

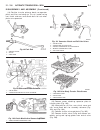

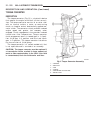

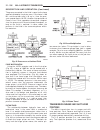

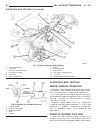

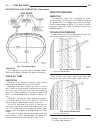

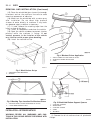

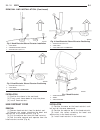

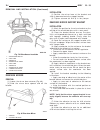

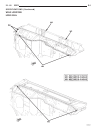

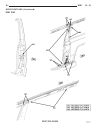

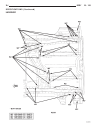

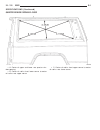

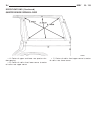

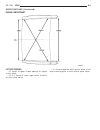

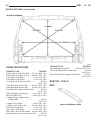

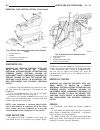

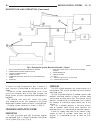

• thrust angle is the angle of the rear axle relative to the centerline of the vehicle. Incorrect thrust angle can cause off-center steering and exces- sive tire wear. This angle is not adjustable, damaged component(s) must be replaced to correct the thrust angle. Fig. 1 wheel alignment measurements...

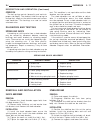

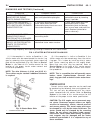

Page 30

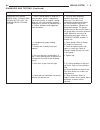

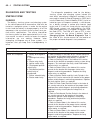

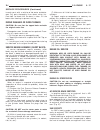

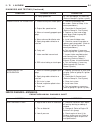

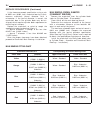

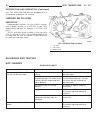

Diagnosis and testing suspension and steering system condition possible causes correction front end noise 1. Loose or worn wheel bearings. 1. Adjust or replace wheel bearings. 2. Loose or worn steering or suspension components. 2. Tighten or replace components as necessary. Excessive play in steerin...

Page 31

Condition possible causes correction knocking, rattling or squeaking 1. Worn shock bushings. 1. Replace shock. 2. Loose, worn or bent steering/ suspension components. 2. Inspect, tighten or replace components as necessary. 3. Shock valve. 3. Replace shock. Improper tracking 1. Loose, worn or bent tr...

Page 32

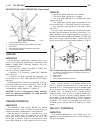

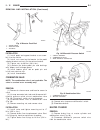

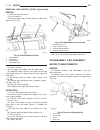

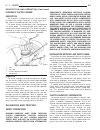

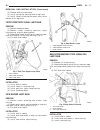

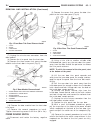

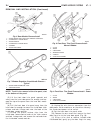

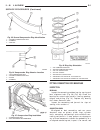

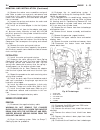

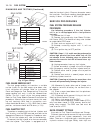

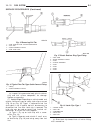

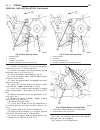

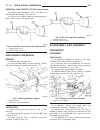

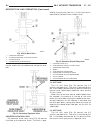

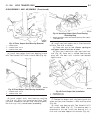

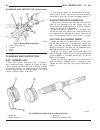

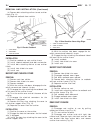

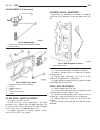

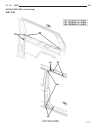

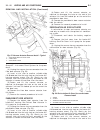

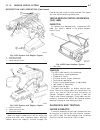

Bolts as shown (fig. 4) and tighten to 49 n·m (36 ft. Lbs.). Note: make sure the toe setting does not change during clamp tightening. (4) adjust the left wheel toe position with the tie rod. Turn the sleeve until the left wheel is at specifi- cations. Position the clamp bolts as shown (fig. 4) and t...

Page 33

Note: make sure the toe setting does not change during clamp tightening. (4) adjust the right wheel toe position with the tie rod. Turn the sleeve until the right wheel is at cor- rect toe-in specifications. Position the clamp bolts to their original position and tighten to 27 n·m (20 ft. Lbs.). Not...

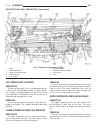

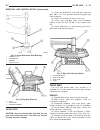

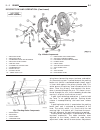

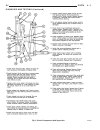

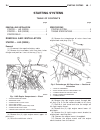

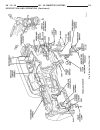

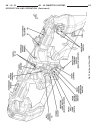

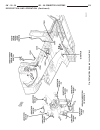

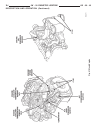

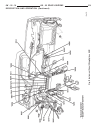

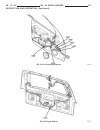

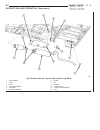

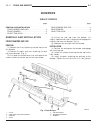

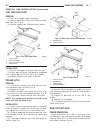

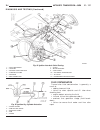

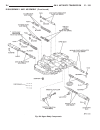

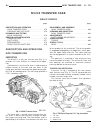

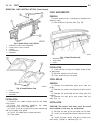

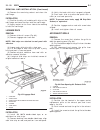

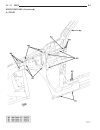

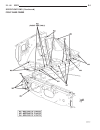

Page 34: Front Suspension

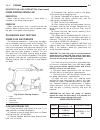

Front suspension table of contents page page description and operation suspension components . . . . . . . . . . . . . . . . 7 shock absorbers . . . . . . . . . . . . . . . . . . . . . . 7 jounce bumper. . . . . . . . . . . . . . . . . . . . . . . . . 7 coil springs and isolators . . . . . . . . . ....

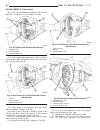

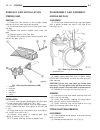

Page 35

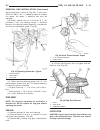

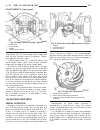

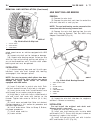

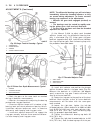

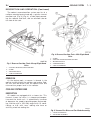

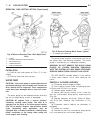

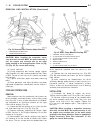

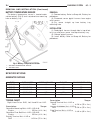

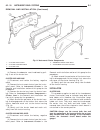

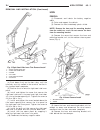

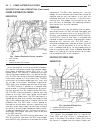

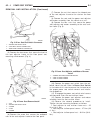

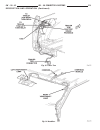

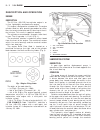

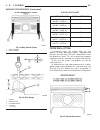

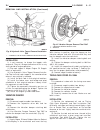

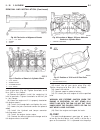

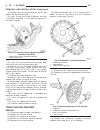

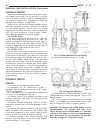

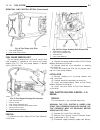

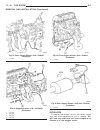

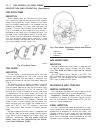

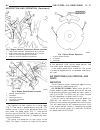

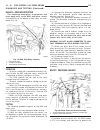

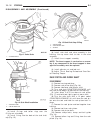

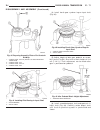

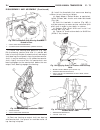

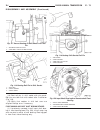

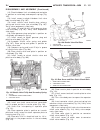

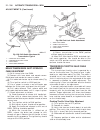

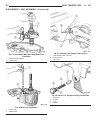

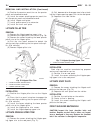

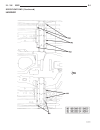

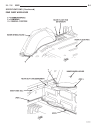

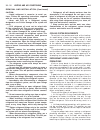

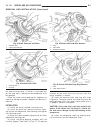

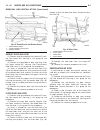

Coil springs and isolators description the coil springs mount up in the wheelhouse which is part of the unitized body bracket. A rubber dough- nut isolator is located between the top of the spring and the bracket. The bottom of the spring seats on a axle pad and retained with a clip. Operation the c...

Page 36

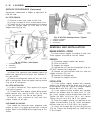

Stabilizer bar description the spring steel bar extends across the underside of the chassis frame rails. Links are connected from the bar to the axle brackets. The stabilizer bar and links are isolated by rubber bushings. Operation the stabilizer bar is used to control vehicle body roll during turns...

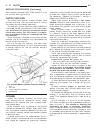

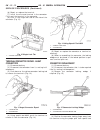

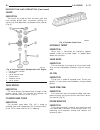

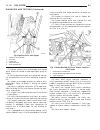

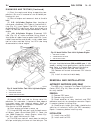

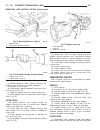

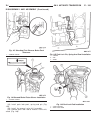

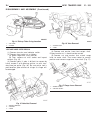

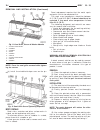

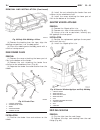

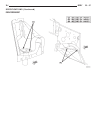

Page 37

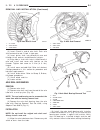

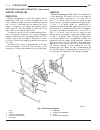

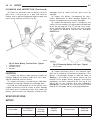

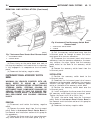

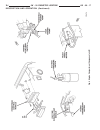

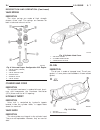

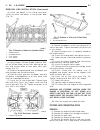

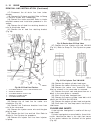

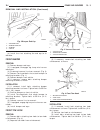

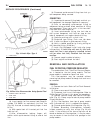

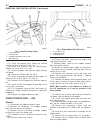

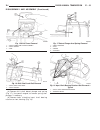

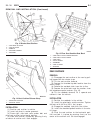

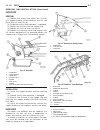

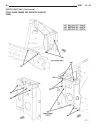

(8) lower the axle until the spring is free from the upper mount. Remove the coil spring clip and remove the spring. (9) pull jounce bumper out of mount. Installation (1) install jounce bumper into mount. (2) position the coil spring on the axle pad. Install the spring clip and bolt. Tighten bolt to...

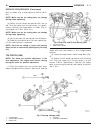

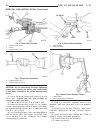

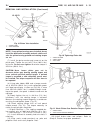

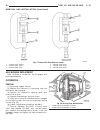

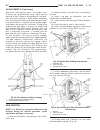

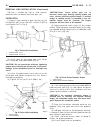

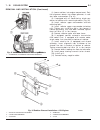

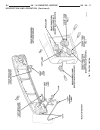

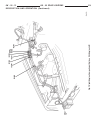

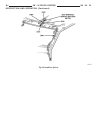

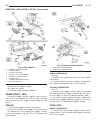

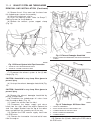

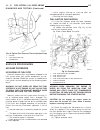

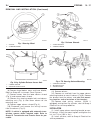

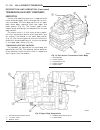

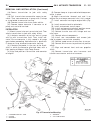

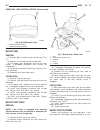

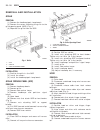

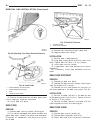

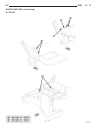

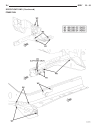

Page 38

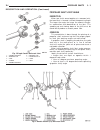

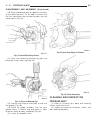

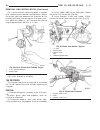

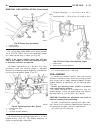

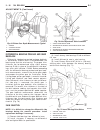

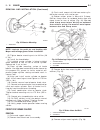

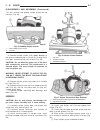

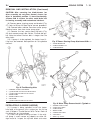

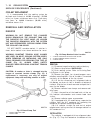

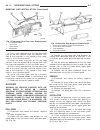

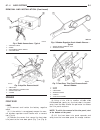

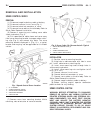

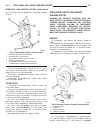

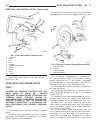

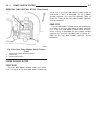

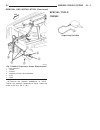

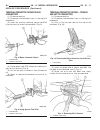

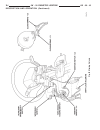

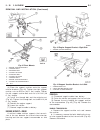

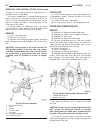

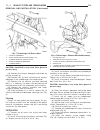

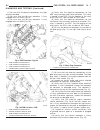

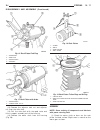

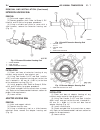

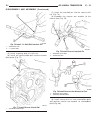

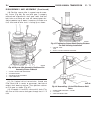

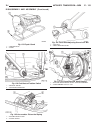

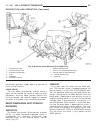

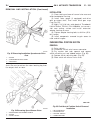

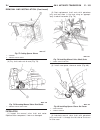

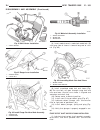

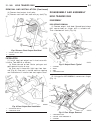

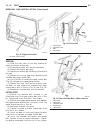

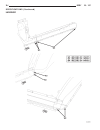

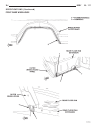

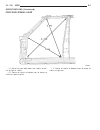

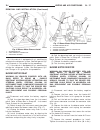

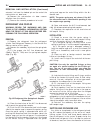

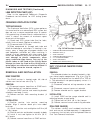

Upper suspension arm removal (1) raise and support the vehicle. (2) remove the upper suspension arm nut and bolt at the axle bracket. (3) remove the nut and bolt at the frame rail and remove the upper suspension arm (fig. 3). Installation (1) position the upper suspension arm at the axle and frame r...

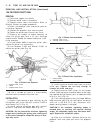

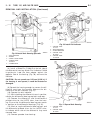

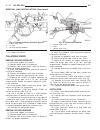

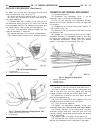

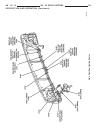

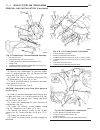

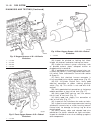

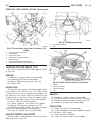

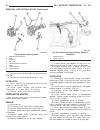

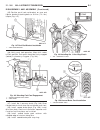

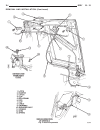

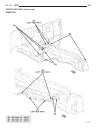

Page 39

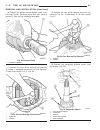

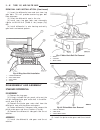

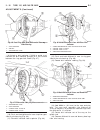

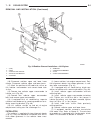

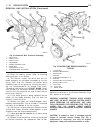

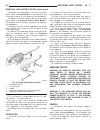

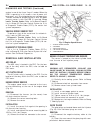

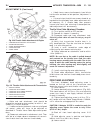

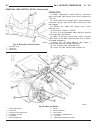

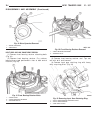

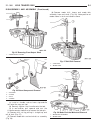

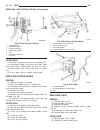

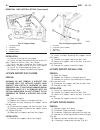

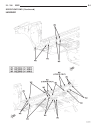

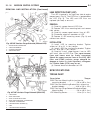

Stabilizer bar removal (1) raise and support the vehicle. (2) remove nuts, retainers and grommets from the links at the stabilizer bar (fig. 6). (3) remove the links mounting nuts and bolts from the axle brackets. (4) remove the stabilizer bar clamps from the body rails. Remove the stabilizer bar. I...

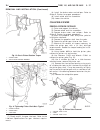

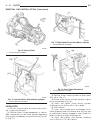

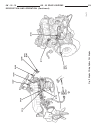

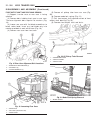

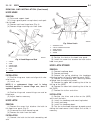

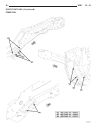

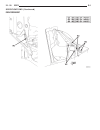

Page 40

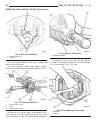

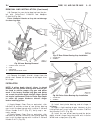

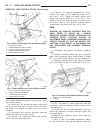

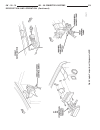

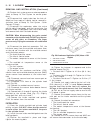

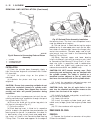

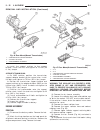

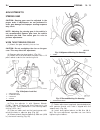

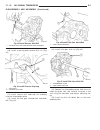

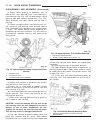

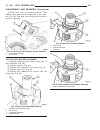

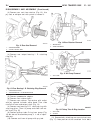

(5) remove the hub bearing mounting bolts from the back of the steering knuckle. Remove hub bear- ing from the steering knuckle and off the axle shaft. Installation (1) install the hub bearing and brake dust shield to the knuckle. (2) install the hub bearing to knuckle bolts and tighten to 102 n·m (...

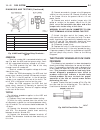

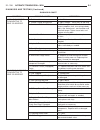

Page 41

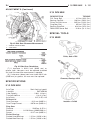

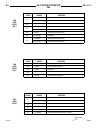

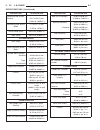

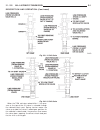

Specifications torque chart description torque shock absorber upper nut . . . . . . . . . . . . . . . 22 n·m (16 ft. Lbs.) lower nut . . . . . . . . . . . . . . . 23 n·m (17 ft. Lbs.) suspension arm upper front nut . . . . . . . . . . . . . . . 74 n·m (55 ft. Lbs.) rear nut . . . . . . . . . . . . ....

Page 42

Description torque track bar bracket bolts . . . . . . . . . . . . . . . . . . 125 n·m (92 ft. Lbs.) nut . . . . . . . . . . . . . . . . . . . 100 n·m (74 ft. Lbs.) support bolts . . . . . . . . . . . . . 42 n·m (31 ft. Lbs.) hub/bearing bolts . . . . . . . . . . . . . . . . . . 102 n·m (75 ft. Lbs....

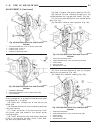

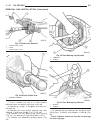

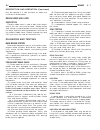

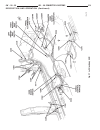

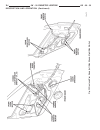

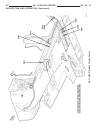

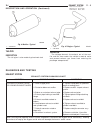

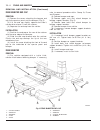

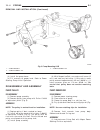

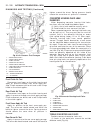

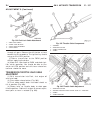

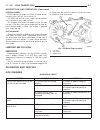

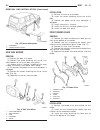

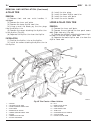

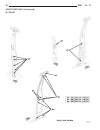

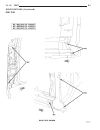

Page 43: Rear Suspension

Rear suspension table of contents page page description and operation suspension component . . . . . . . . . . . . . . . . 16 shock absorbers . . . . . . . . . . . . . . . . . . . . . 16 jounce bumpers. . . . . . . . . . . . . . . . . . . . . . . 16 stabilizer bar . . . . . . . . . . . . . . . . . ....

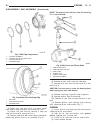

Page 44

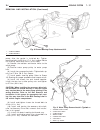

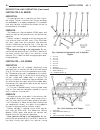

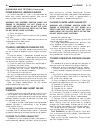

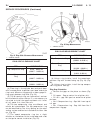

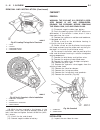

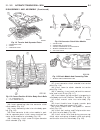

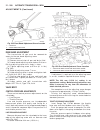

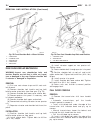

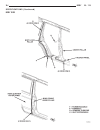

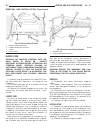

Operation the leaf springs control ride quality and maintain proper ride height. The shackles allow the springs to change their length as the vehicle moves over various road conditions. The bushings are used to isolate axle/road noise. Diagnosis and testing spring and shock a knocking or rattling no...

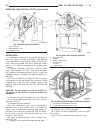

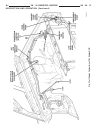

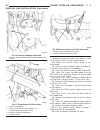

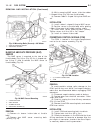

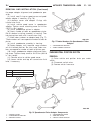

Page 45

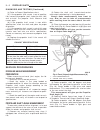

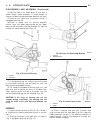

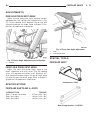

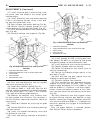

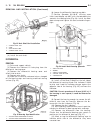

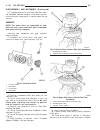

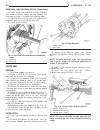

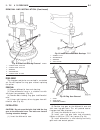

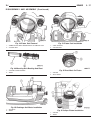

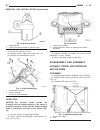

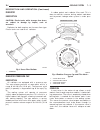

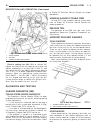

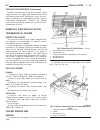

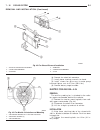

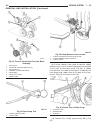

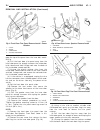

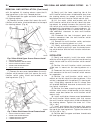

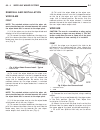

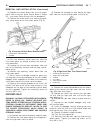

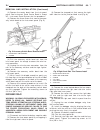

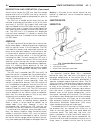

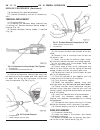

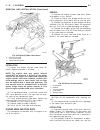

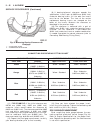

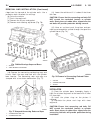

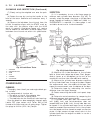

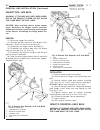

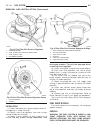

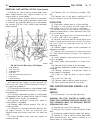

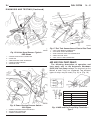

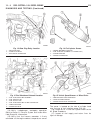

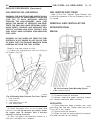

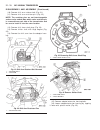

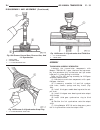

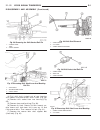

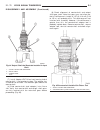

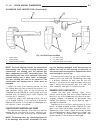

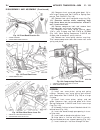

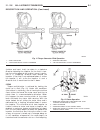

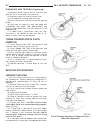

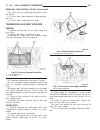

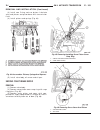

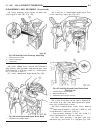

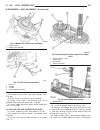

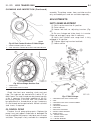

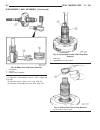

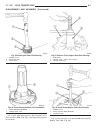

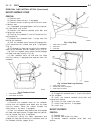

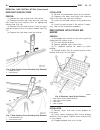

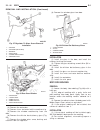

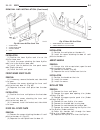

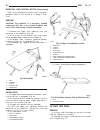

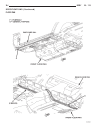

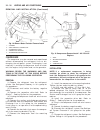

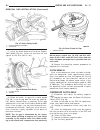

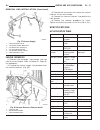

Leaf spring removal (1) raise vehicle at body rails. (2) remove the wheel and tire assemblies. (3) support axle with hydraulic jack to relieve axle weight. (4) disconnect the stabilizer bar link from the spring bracket stud. (5) remove nuts, u-bolts and spring bracket from axle. (6) remove nut and b...

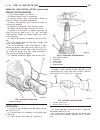

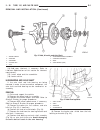

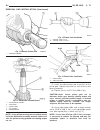

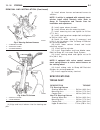

Page 46

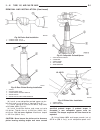

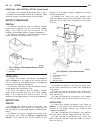

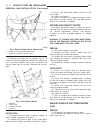

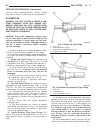

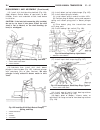

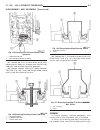

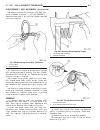

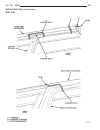

(1) assemble tools shown (fig. 3). Tighten nut at the socket wrench end of the threaded rod until the bushing is forced out. (2) assemble and align the bushing installation tools. (3) align the bushing with the spring eye or shackle eye and tighten the nut at the socket wrench end of the threaded ro...

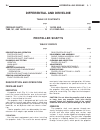

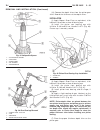

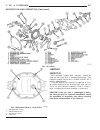

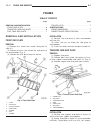

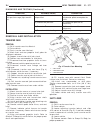

Page 48: Differential And Driveline

Differential and driveline table of contents page page propeller shafts . . . . . . . . . . . . . . . . . . . . . . . 1 tube, 181, and 186 fbi axle . . . . . . . . . . . . . . 16 194 rbi axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 8 1/4 rear axle . . . . . . . . . . . . . . . . ....

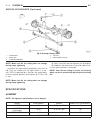

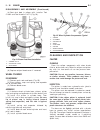

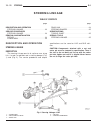

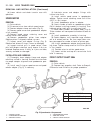

Page 49

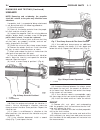

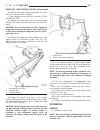

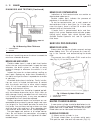

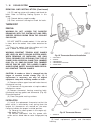

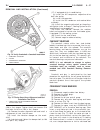

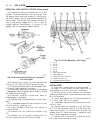

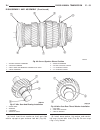

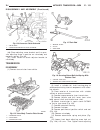

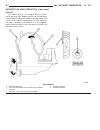

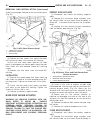

Shaft to operate at different angles. The slip joints (or yokes) permit contraction or expansion (fig. 2). Before undercoating a vehicle, the propeller shaft and the u-joints should be covered to pre- vent an out-of-balance condition and driveline vibration. Caution: use original equipment replaceme...

Page 50

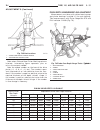

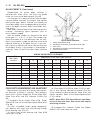

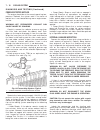

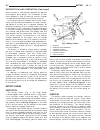

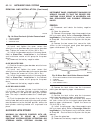

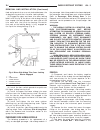

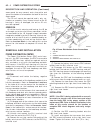

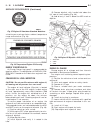

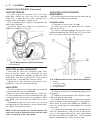

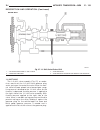

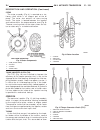

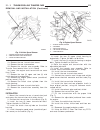

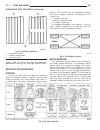

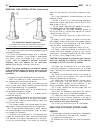

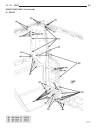

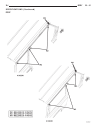

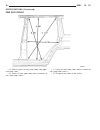

Propeller shaft joint angle description when two shafts come together at a common joint, the bend that is formed is called the operating angle. The larger the angle, the larger the amount of angu- lar acceleration and deceleration of the joint. This speeding up and slowing down of the joint must be ...

Page 51

Propeller shaft speed (rpm) is the main factor in determining the maximum allowable operating angle. As a guide to the maximum normal operating angles refer to (fig. 5). Diagnosis and testing vibration tires that are out-of-round, or wheels that are unbalanced, will cause a low frequency vibration. ...

Page 52

Unbalance note: removing and re-indexing the propeller shaft 180° relative to the yoke may eliminate some vibrations. If propeller shaft is suspected of being unbalanced, it can be verified with the following procedure: (1) raise the vehicle. (2) clean all the foreign material from the propel- ler s...

Page 53

(4) refer to runout specifications chart. (5) if the propeller shaft runout is out of specifica- tion, remove the propeller shaft, index the shaft 180°, and re-install the propeller shaft. Measure shaft runout again. (6) if the propeller shaft runout is now within specifications, mark the shaft and ...

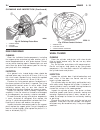

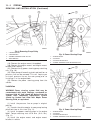

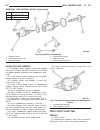

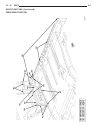

Page 54

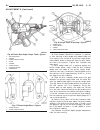

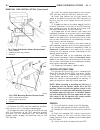

This measurement will give you the pinion shaft or input yoke angle (b). (7) subtract smaller figure from larger (c minus b) to obtain axle input operating angle. Refer to rules given below and the example in (fig. 12) for additional information. Fig. 11 rear (input) angle measurement (b) 1 – pinion...

Page 55

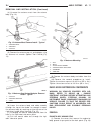

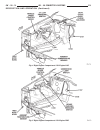

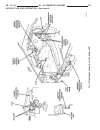

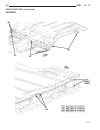

• good cancellation of u–joint operating angles (within 1°). • operating angles less than 3°. • at least 1/2 of one degree continuous operating (propeller shaft) angle. Removal and installation front propeller shaft removal (1) hoist and support vehicle on safety stands. (2) remove the crossmember/s...

Page 56

Installation (1) slide the slip yoke on the transmission/transfer case output shaft. Align the installation reference marks at the axle yoke and install the propeller shaft (fig. 16). (2) tighten the u-joint strap/clamp bolts at the axle yoke to 19 n·m (14 ft. Lbs.) torque. (3) crimp clamp to hold d...

Page 57

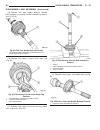

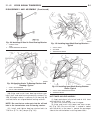

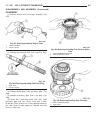

(4) set the yoke in an arbor press or vise with a socket whose inside diameter is large enough to receive the bearing cap positioned beneath the yoke. (5) position the yoke with the grease fitting, if equipped, pointing up. (6) place a socket with an outside diameter smaller than the upper bearing c...

Page 58

(4) press the bearing cap into the yoke bore enough to install a snap ring. (5) install a snap ring. (6) repeat step 3 and step 4to install the opposite bearing cap. If the joint is stiff or binding, strike the yoke with a soft hammer to seat the needle bearings. (7) add grease to lube fitting, if e...

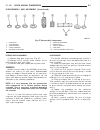

Page 59

Assembly during assembly, ensure that the alignment marks on the link yoke and propeller shaft yoke are aligned. (1) apply extreme pressure (ep) n.L.G.I. Grade 1 or 2 grease to inside of yoke bores to aid in installa- tion. (2) fit a cross into the propeller shaft yoke (fig. 27). (3) place a bearing...

Page 60

(6) flip the propeller shaft yoke and install the bearing cap onto the opposite trunnion. Install a snap ring (fig. 30). (7) fit the link yoke on the remaining two trun- nions and press both bearing caps into place (fig. 31). (8) install snap rings. (9) install the centering kit assembly inside the ...

Page 61

(10) place two bearing caps on opposite trunnions of the remaining cross. Fit the open trunnions into the link yoke bores and the bearing caps into the centering kit (fig. 33). (11) press the remaining two bearing caps into place and install snap rings (fig. 34). (12) tap the snap rings to allow the...

Page 62

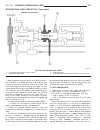

Adjustments rear axle pinion input angle adjust the rear axle pinion input angle on vehicles equipped with leaf springs with tapered shims (fig. 37). Install tapered shims between the springs and axle pad to correct the angle. Refer to group 2, sus- pension, for additional information. Front axle pi...

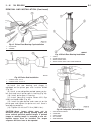

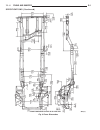

Page 63

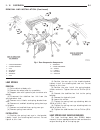

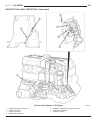

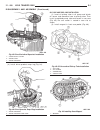

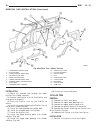

Tube, 181, and 186 fbi axle table of contents page page description and operation 181 fbi axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 186 fbi axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 stand...

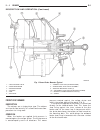

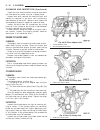

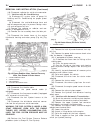

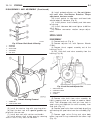

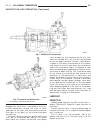

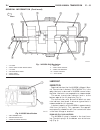

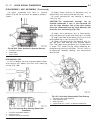

Page 64

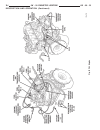

Operation the axle receives power from the transfer case through the front propeller shaft. The front propeller shaft is connected to the pinion gear which rotates the differential through the gear mesh with the ring gear bolted to the differential case. The engine power is transmitted to the axle s...

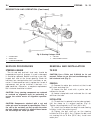

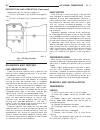

Page 65

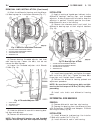

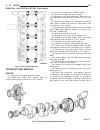

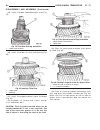

Standard differential description the differential gear system divides the torque between the axle shafts. It allows the axle shafts to rotate at different speeds when turning corners. Each differential side gear is splined to an axle shaft. The pinion gears are mounted on a pinion mate shaft and ar...

Page 66

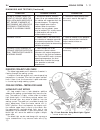

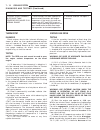

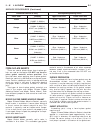

Diagnosis and testing general information axle bearing problem conditions are usually caused by: • insufficient or incorrect lubricant. • foreign matter/water contamination. • incorrect bearing preload torque adjustment. • incorrect backlash. Axle gear problem conditions are usually the result of: •...

Page 67

Condition possible causes correction differential gears scored 1. Insufficient lubrication. 1. Replace scored gears. Fill differential with the correct fluid type and quantity. 2. Improper grade of lubricant. 2. Replace scored gears. Fill differential with the correct fluid type and quantity. 3. Exc...

Page 68

Gear noise axle gear noise can be caused by insufficient lubri- cant, incorrect backlash, tooth contact, worn/damaged gears, or the carrier housing not having the proper offset and squareness. Gear noise usually happens at a specific speed range. The noise can also occur during a specific type of dr...

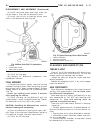

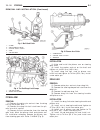

Page 69

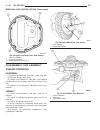

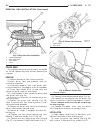

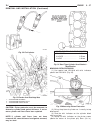

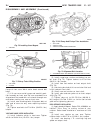

(6) apply a bead of mopar t silicone rubber seal- ant, or equivalent, to the housing cover (fig. 3). Install the housing cover within 5 minutes after applying the sealant. (7) install the cover and any identification tag. Tighten the cover bolts in a criss–cross pattern to 41 n·m (30 ft. Lbs.) torqu...

Page 70

(13) align the previously made marks on the pro- peller shaft and the yoke. (14) install the straps and bolts to hold the propel- ler shaft to the yoke. (15) check and fill axle lubricant. Refer to the lubricant specifications in this group for the quan- tity necessary. (16) install the wheel and ti...

Page 71

(6) compress the vise jaws to force the bearing cap into the larger socket (receiver). (7) release the vise jaws. Remove the sockets and bearing cap that was partially forced out of the yoke. (8) repeat the above procedure for the remaining bearing cap. (9) remove the remaining bearing cap, bearings...

Page 72

Caution: do not exceed the minimum tightening torque when installing the pinion yoke retaining nut at this point. Damage to the pinion bearings may result. (3) install the pinion washer and a new nut on the pinion gear. Tighten the nut only enough to remove the shaft end play. (4) tighten pinion nut...

Page 73

186 fbi pinion shaft seal removal (1) raise and support the vehicle. (2) remove wheel and tire assemblies. (3) remove brake rotors and calipers. Refer to group 5, brakes, for proper procedures. (4) mark the propeller shaft and pinion yoke for installation reference. (5) remove the propeller shaft fr...

Page 74

(7) check and fill the gear lubricant. Refer to the lubricant specifications for gear lubricant require- ments. (8) install the brake rotors and calipers. Refer to group 5, brakes, for proper procedures. (9) install wheel and tire assemblies. (10) lower the vehicle. Collapsible spacer removal w/pini...

Page 75

Removal w/pinion removed (1) raise and support the vehicle. (2) remove wheel and tire assemblies. (3) remove brake rotors and calipers. Refer to group 5, brakes, for proper procedures. (4) mark the propeller shaft and pinion yoke for installation reference. (5) remove the propeller shaft from the yo...

Page 76

Note: if new pinion bearings were installed, do not install the differential assembly and axle shafts until after the pinion bearing preload and rotating torque are set. (7) install the pinion washer and a new nut on the pinion gear. Tighten the nut to 217 n·m (160 ft. Lbs.) minimum. Do not over-tig...

Page 77

(14) add gear lubricant, if necessary. Refer to lubricant specifications of this section for lubricant requirements. (15) install wheel and tire assemblies. (16) lower vehicle. Hub bearing and axle shaft if the axle shaft and hub bearing are being removed in order to service another component, the a...

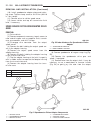

Page 78

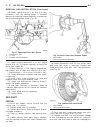

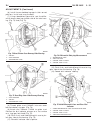

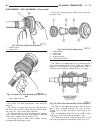

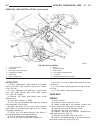

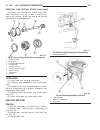

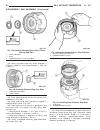

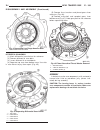

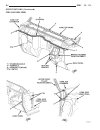

Installation (1) thoroughly clean the axle shaft (fig. 22) and apply a thin film of mopar t wheel bearing grease, or equivalent, to the shaft splines, seal contact sur- face, and hub bore. (2) install the brake rotor shield to the knuckle. (3) install the hub bearing and axle shaft assem- bly, or ax...

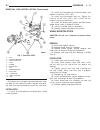

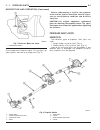

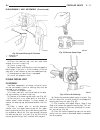

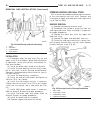

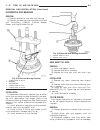

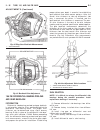

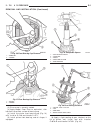

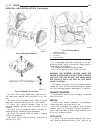

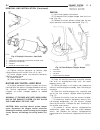

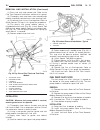

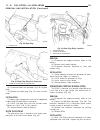

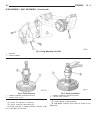

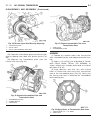

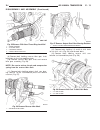

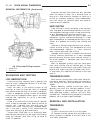

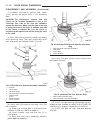

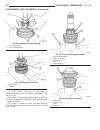

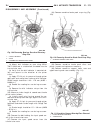

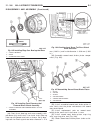

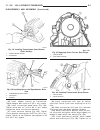

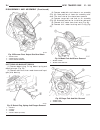

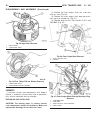

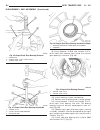

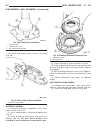

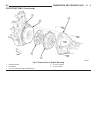

Page 79

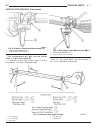

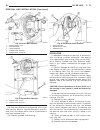

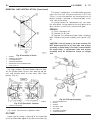

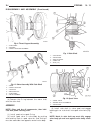

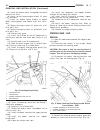

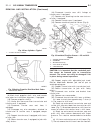

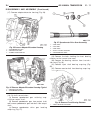

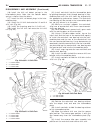

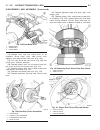

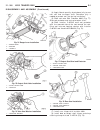

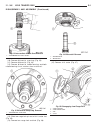

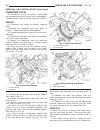

Upper ball stud replacement (1) position tools as shown to remove and install ball stud (fig. 26). Lower ball stud replacement (1) position tools as shown to remove and install ball stud (fig. 27). Knuckle installation (1) position the steering knuckle on the ball studs. (2) install and tighten the ...

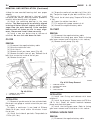

Page 80

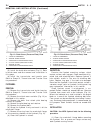

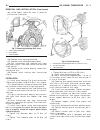

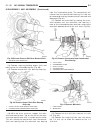

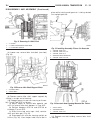

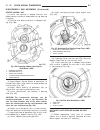

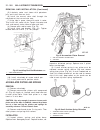

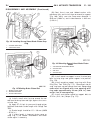

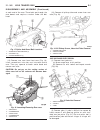

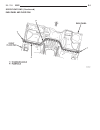

Axle bushing replacement refer to group 2, suspension, for the proper axle bushing procedures. Differential removal (1) raise and support vehicle. (2) remove the lubricant fill hole plug from the differential housing cover. (3) remove the differential housing cover and allow fluid to drain. (4) remo...

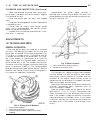

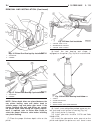

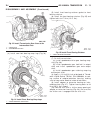

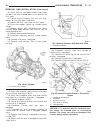

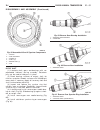

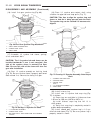

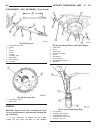

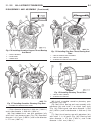

Page 81

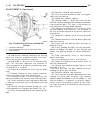

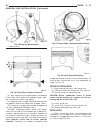

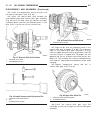

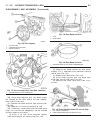

(8) install a guide pin c-3288-b at the left side of the differential housing. Attach dial indicator c-3339 to guide pin. Load the lever adapter against the opposite side of the housing (fig. 30) and zero the indicator. Caution: do not spread over 0.50 mm (0.020 in). If the housing is over-spread, i...

Page 82

Installation if replacement differential bearings or differential case are being installed, differential side bearing shim requirements may change. Refer to the differ- ential bearing preload and gear backlash proce- dures in this section to determine the proper shim selection. (1) position spreader...

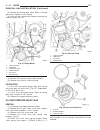

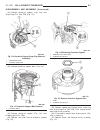

Page 83

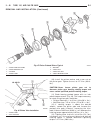

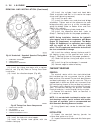

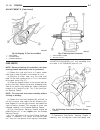

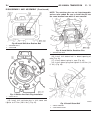

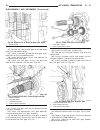

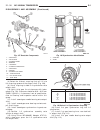

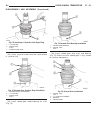

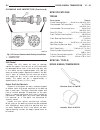

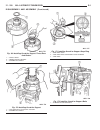

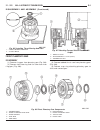

Differential side bearings removal (1) remove differential case from axle housing. (2) remove the bearings from the differential case with puller/press c-293-pa, c-293-39 adapter blocks, and plug sp-3289 (fig. 35). Installation if replacement differential side bearings or differ- ential case are bei...

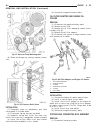

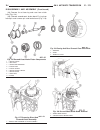

Page 84

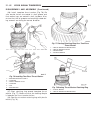

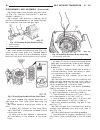

(4) using holder 6958 to hold yoke, remove the pinion nut and washer. (5) using remover c-452 and holder c-3281, remove the pinion yoke from pinion shaft (fig. 38). (6) remove the pinion gear and preload shims from housing (fig. 39). Catch the pinion with your hand to prevent it from falling and bei...

Page 85

(8) remove the rear pinion bearing cup and oil slinger from the axle housing (fig. 41). Use remover d-149 and handle c–4171. Record the thickness of the oil slinger for future reference. (9) remove the rear pinion bearing from the pin- ion with puller/press c–293-pa and adapters c-293-39 (fig. 42). ...

Page 86

(3) apply mopar t door ease, or equivalent, stick lubricant to outside surface of front pinion bearing cup. Install the bearing cup with installer d-144 and handle c–4171 (fig. 44). (4) install front pinion bearing, and oil slinger, if equipped. (5) apply a light coating of gear lubricant on the lip...

Page 87

(10) install the pinion washer and a new nut on the pinion gear. Tighten the nut to 217 n·m (160 ft. Lbs.). Caution: never loosen pinion gear nut to decrease pinion gear bearing rotating torque and never exceed specified preload rotating torque. (11) check bearing preload torque with an inch pound t...

Page 88

(14) if the maximum tightening torque is reached prior to achieving the desired rotating torque, remove the pinion yoke and decrease the thickness of the preload shim pack. Decreasing the shim pack thick- ness 0.025 mm (0.001 in.) will increase the rotating torque approximately 0.9 n·m (8 in. Lbs.)....

Page 89

(6) remove the pinion and collapsible spacer from housing (fig. 52). Catch the pinion with your hand to prevent it from falling and being damaged. (7) remove the front pinion bearing cup, bearing, oil slinger, if equipped, and pinion seal with remover c-4345 and handle c–4171 (fig. 53). (8) remove t...

Page 90

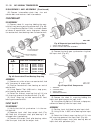

(10) remove the rear pinion bearing from the pin- ion with puller/press c–293-pa and adapters c–293–39 (fig. 56). Place 4 adapter blocks so they do not damage the bearing cage. (11) remove the depth shim/oil slinger from the pinion shaft. Record the thickness of the depth shim/ oil slinger. Installa...

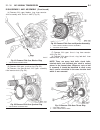

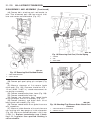

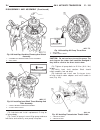

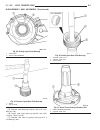

Page 91

(6) install a new collapsible preload spacer on pin- ion shaft and install pinion in housing (fig. 61). (7) install yoke with installer w-162-b, cup 8109, and holder 6958 (fig. 62). (8) install the pinion washer and a new nut onto the pinion. Tighten the nut to 216 n·m (160 ft. Lbs.) minimum. Do not...

Page 92

Bearing end play is taken up (fig. 63). If more than 353 n·m (260 ft. Lbs.) is needed to begin to collapse the spacer, the spacer is defective and must be replaced. (10) slowly tighten the nut in 6.8 n·m (5 ft. Lb.) increments until the rotating torque is achieved. Measure the rotating torque freque...

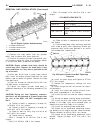

Page 93

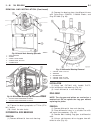

(1) invert the differential case and start two ring gear bolts. This will provide case-to-ring gear bolt hole alignment. (2) invert the differential case in the vise. (3) install new ring gear bolts and alternately tighten to 95–122 n·m (70–90 ft. Lbs.) torque (fig. 66). (4) install differential in ...

Page 94

(3) install the pinion gear mate shaft. Align the roll pin holes in shaft and the differential case. (4) install the roll pin to hold the pinion mate shaft in the differential case (fig. 69). (5) install the ring gear. (6) lubricate all differential components with hypoid gear lubricant. Final assem...

Page 95

• wear and damage to pinion gear mate shaft, pinion gears, side gears and thrust washers. Replace as a matched set only. • ring and pinion gear for worn and chipped teeth. • ring gear for damaged bolt threads. Replaced as a matched set only. • pinion yoke for cracks, worn splines, pitted areas, and ...

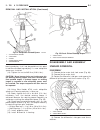

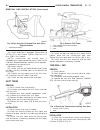

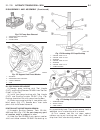

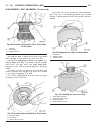

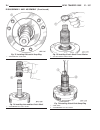

Page 96

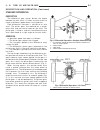

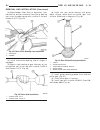

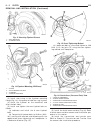

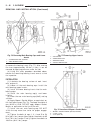

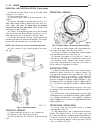

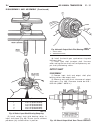

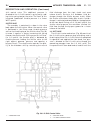

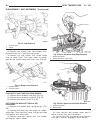

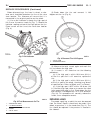

Pinion depth measurement and adjustment measurements are taken with pinion bearing cups and pinion bearings installed in the axle housing. Take measurements with pinion gauge set and dial indicator c-3339 (fig. 73). (1) assemble pinion height block 6739, pinion block 6733, and rear pinion bearing on...

Page 97

Height block (fig. 73). Hold scooter block in place and zero the dial indicator face to the pointer. Tighten dial indicator face lock screw. (7) with scooter block still in position against the pinion height block, slowly slide the dial indicator probe over the edge of the pinion height block. (8) s...

Page 98

Note where old and new pinion marking columns intersect. Intersecting figure represents plus or minus the amount needed. Note the etched number on the face of the drive pinion (–1, –2, 0, +1, +2, etc.). The numbers repre- sent thousands of an inch deviation from the stan- dard. If the number is nega...

Page 99

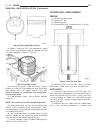

(1) assemble pinion height block 6739, pinion block 6733, and rear pinion bearing onto screw 6741 (fig. 79). (2) insert assembled height gauge components, rear bearing and screw into axle housing through pinion bearing cups (fig. 80). (3) install front pinion bearing and cone-nut 6740 hand tight (fi...

Page 100

Differential side bearing cones. The proper shim thickness can be determined using slip-fit dummy bearings d-348 in place of the differential side bear- ings and a dial indicator c-3339. Before proceeding with the differential bearing preload and gear back- lash measurements, measure the pinion gear...

Page 101

(9) attach a dial indicator c-3339 to guide stud. Position the dial indicator plunger on a flat surface between the ring gear bolt heads (fig. 87). (10) push and hold differential case to pinion gear side of axle housing (fig. 88). (11) zero dial indicator face to pointer (fig. 88). (12) push and ho...

Page 102

(17) install the pinion gear in axle housing. Install the pinion yoke and establish the correct pinion rotating torque. (18) install differential case and dummy bearings d-348 in axle housing (without shims), install bear- ing caps and tighten bolts snug. (19) seat ring gear side dummy bearing (fig....

Page 103

186 fbi differential bearing preload and gear backlash introduction differential side bearing preload and gear backlash is achieved by selective shims positioned behind the differential side bearing cones. The proper shim thickness can be determined using slip-fit dummy bearings d-348 in place of th...

Page 104

(6) install the marked bearing caps in their correct positions. Install and snug the bolts (fig. 95). (7) using a dead-blow type mallet, seat the differ- ential dummy bearings to each side of the axle hous- ing (fig. 96) and (fig. 97). (8) thread guide stud c-3288-b into rear cover bolt hole below r...

Page 105

Shims to compress, or preload the new bearings when the differential is installed. (15) rotate dial indicator out of the way on the guide stud. (16) remove differential case and dummy bearings from axle housing. (17) install the pinion in the axle housing. Install the pinion yoke and establish the c...

Page 106

(25) subtract 0.002 in. (0.05 mm) from the dial indicator reading to compensate for backlash between ring and pinion gears. This total is the thickness shim required to achieve proper backlash. (26) subtract the backlash shim thickness from the total preload shim thickness. The remainder is the shim...

Page 107

Fig. 105 gear tooth contact patterns 3 - 60 tube, 181, and 186 fbi axle xj adjustments (continued).

Page 108

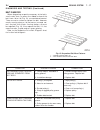

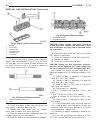

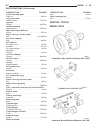

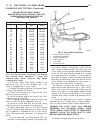

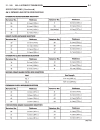

Specifications 181 fbi axle axle type . . . . . . . . . . . . . . . . . . . . . . . . . . Hypoid lubricant–std. . . . . Sae thermally stable 80w–90 lubricant–heavy duty . . . Sae 75w–140 synthetic lube capacity . . . . . . . . . . . . . . . 1.48 l (3.13 pts.) axle ratio . . . . . . . . . . . . . . ....

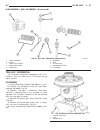

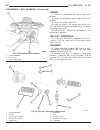

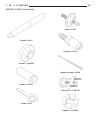

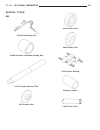

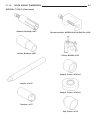

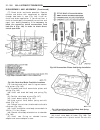

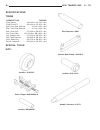

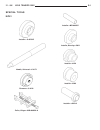

Page 109

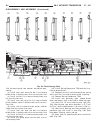

Dial indicator—c-3339 driver—c-3716-a handle—c-4171 installer—d-146 remover—d-149 installer—w-162-d cup—8109 remover/installer—6289 installer—6761 installer—6752 3 - 62 tube, 181, and 186 fbi axle xj special tools (continued).

Page 110

Installer discs—8110 turnbuckle—6797 tool set, pinion depth—6774 gauge block—6733 spanner—6958 installer—c-3972-a spreader—w-129-b adapter kit—6987 pilot stud—c-3288-b remover—d-147 xj tube, 181, and 186 fbi axle 3 - 63 special tools (continued).

Page 111

Installer—d-144 installer—w-262 3 - 64 tube, 181, and 186 fbi axle xj special tools (continued).

Page 112: 194 Rbi Axle

194 rbi axle table of contents page page description and operation 194 rbi axle . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 standard differential . . . . . . . . . . . . . . . . . 66 trac-lok y differential . . . . ....

Page 113

Lubricant description a multi-purpose, hypoid gear lubricant which con- forms to the following specifications should be used. Mopar t hypoid gear lubricant conforms to all of these specifications. • the lubricant should have mil–l–2105c and api gl 5 quality specifications. • lubricant is a thermally...

Page 114

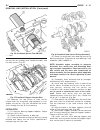

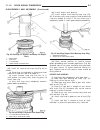

In the trac-lok y differential, part of the ring gear torque is transmitted through clutch packs which contain multiple discs. The clutches will have radial grooves on the plates, and concentric grooves on the discs or bonded fiber material that is smooth in appearance. Operation in operation, the t...

Page 115

Diagnostic chart condition possible causes correction wheel noise 1. Wheel loose. 1. Tighten loose nuts. 2. Faulty, brinelled wheel bearing. 2. Replace bearing. Axle shaft noise 1. Misaligned axle tube. 1. Inspect axle tube alignment. Correct as necessary. 2. Bent or sprung axle shaft. 2. Inspect an...

Page 116

Condition possible causes correction loss of lubricant 1. Lubricant level too high. 1. Drain lubricant to the correct level. 2. Worn axle shaft seals. 2. Replace seals. 3. Cracked differential housing. 3. Repair as necessary. 4. Worn pinion seal. 4. Replace seal. 5. Worn/scored yoke. 5. Replace yoke...

Page 117

Gear noise axle gear noise can be caused by insufficient lubri- cant, incorrect backlash, tooth contact, worn/damaged gears, or the carrier housing not having the proper offset and squareness. Gear noise usually happens at a specific speed range. The noise can also occur during a specific type of dr...

Page 118

Trac–lok y test warning: when servicing vehicles with a trac–lok y differential do not use the engine to turn the axle and wheels. Both rear wheels must be raised and the vehi- cle supported. A trac–lok y axle can exert enough force if one wheel is in con- tact with a surface to cause the vehicle to...

Page 119

Removal and installation rear axle removal (1) raise and support the vehicle. (2) position a suitable lifting device under the axle. (3) secure axle to device. (4) remove the wheels and tires. (5) remove the brake drums from the axle. Refer to group 5, brakes, for proper procedures. (6) disconnect p...

Page 120

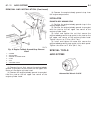

(10) use a suitable pry tool or slide hammer mounted screw to remove the pinion gear seal. Installation (1) apply a light coating of gear lubricant on the lip of pinion seal. Install seal with installer c-3972-a and handle c-4171 (fig. 8). (2) install yoke on the pinion gear with screw 8112, cup 810...

Page 121

(11) lower the vehicle. Collapsible spacer removal w/pinion installed (1) raise and support the vehicle. (2) remove wheel and tire assemblies. (3) remove rear brake drums. Refer to group 5, brakes, for proper procedures. (4) mark the propeller shaft and pinion yoke for installation reference. (5) re...

Page 122

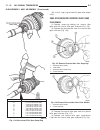

Note: if new pinion bearings were installed, do not install the differential assembly and axle shafts until after the pinion bearing preload and rotating torque are set. (7) install the yoke washer and a new nut on the pinion gear. Tighten the pinion nut until there is zero bearing end-play. (8) tig...

Page 123

(10) slowly tighten the nut in 6.8 n·m (5 ft. Lbs.) increments until the rotating torque is achieved. Measure the rotating torque frequently to avoid over crushing the collapsible spacer (fig. 18). (11) check rotating torque with a (in. Lbs.) torque wrench (fig. 18). The torque necessary to rotate t...

Page 124

Wheel speed sensor on vehicles equipped with abs brakes. (9) inspect axle shaft seal for leakage or damage. (10) inspect roller bearing contact surface on axle shaft for signs of brinelling, galling and pitting. If any of these conditions exist, the axle shaft and/or bearing and seal must be replace...

Page 125

(4) install the axle shaft. Differential removal (1) raise and support vehicle. (2) remove the lubricant fill hole plug from the differential housing cover. (3) remove the differential housing cover and allow fluid to drain. (4) remove axle shafts. (5) note the installation reference letters stamped...

Page 126

(14) retrieve differential case preload shims from axle housing. Mark or tag the differential case pre- load shims to indicate which side of the differential they were removed from. (15) remove spreader from housing. Installation if replacement differential bearings or differential case are being in...

Page 127

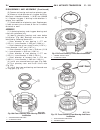

(9) tighten the bearing cap bolts to 77 n·m (57 ft. Lbs.) torque. (10) install the axle shafts. Differential side bearings removal (1) remove differential from axle housing. (2) remove the bearings from the differential case with puller/press c-293-pa, c-293-39 blocks, and plug sp-3289 (fig. 30). In...

Page 128

Installation caution: do not reuse the bolts that held the ring gear to the differential case. The bolts can fracture causing extensive damage. (1) invert the differential case and start two ring gear bolts. This will provide case-to-ring gear bolt hole alignment. (2) invert the differential case in...

Page 129

(7) use a suitable pry tool or a slide hammer mounted screw to remove the pinion shaft seal. (8) remove oil slinger, if equipped, and front pin- ion bearing. (9) remove the front pinion bearing cup with remover c-4345 and handle c–4171 (fig. 36). (10) remove the rear bearing cup from housing (fig. 3...

Page 130

(13) remove the depth shims from the pinion gear shaft. Record the thickness of the depth shims. Installation (1) apply mopar t door ease, or equivalent, stick lubricant to outside surface of bearing cup. (2) install the pinion rear bearing cup with installer d-146 and driver handle c–4171 (fig. 40)...

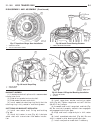

Page 131

(8) install the rear bearing and slinger, if equipped, on the pinion gear with installer w-262 (fig. 43). (9) install a new collapsible preload spacer on pin- ion shaft and install pinion gear in housing (fig. 44). (10) install pinion gear in housing. (11) install yoke with installer screw 8112, cup...

Page 132

(14) using yoke holder 6958 and a torque wrench set at 474 n·m (350 ft. Lbs.), crush collapsible spacer until bearing end play is taken up (fig. 46). Note: if the spacer requires more than 474 n·m (350 ft. Lbs.) torque to crush, the collapsible spacer is defective and must be replaced. (15) slowly t...

Page 133

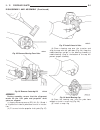

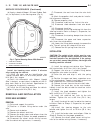

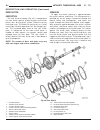

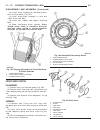

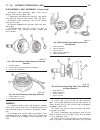

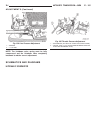

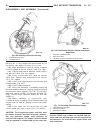

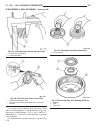

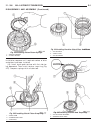

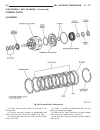

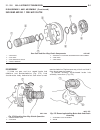

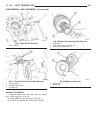

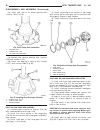

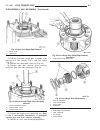

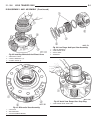

Disassembly and assembly standard differential disassembly (1) remove pinion mate shaft lock screw (fig. 49). (2) remove pinion mate shaft. (3) rotate the differential side gears and remove the differential pinion gears and thrust washers (fig. 50). (4) remove the differential side gears and thrust ...

Page 134

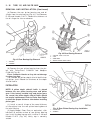

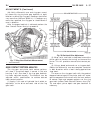

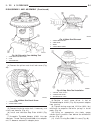

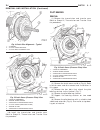

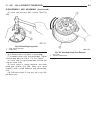

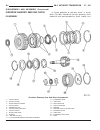

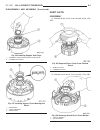

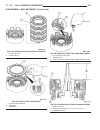

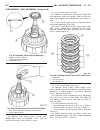

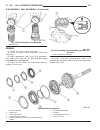

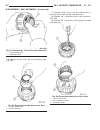

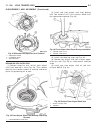

Trac-lok y differential the trac–lok y differential components are illus- trated in (fig. 51). Refer to this illustration during repair service. Disassembly (1) clamp side gear holding tool 6965 in a vise. (2) position the differential case on side gear holding tool 6965 (fig. 52). (3) remove ring g...

Page 135

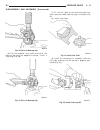

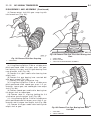

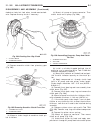

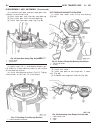

(7) assemble threaded adapter c-6960-1 into top side gear. Thread forcing screw c-6960-4 into adapter until it becomes centered in adapter plate. (8) position a small screw driver in slot of threaded adapter c-6960-1 (fig. 56) to prevent adapter from turning. (9) tighten forcing screw tool 122 n·m (...

Page 136

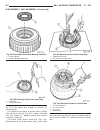

(10) using an appropriate size feeler gauge, remove thrust washers from behind the pinion gears (fig. 58). (11) insert turning bar c-6960-2 in case (fig. 59). (12) loosen the forcing screw c-6960-4 in small increments until the clutch pack tension is relieved and the differential case can be turned ...

Page 137

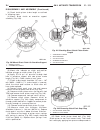

(17) remove differential case from side gear hold- ing tool 6965. Remove side gear, clutch pack retainer, and clutch pack. Keep plates in correct order during removal. Assembly note: the clutch discs are replaceable as com- plete sets only. If one clutch disc pack is damaged, both packs must be repl...

Page 138

(11) rotate case with turning bar c-6960-2 until the pinion mate shaft holes in pinion gears align with holes in case. It may be necessary to slightly tighten the forcing screw in order to install the pin- ion gears. (12) tighten forcing screw to 122 n·m (90 ft. Lbs.) maximum to compress the bellevi...

Page 139

Compensation for pinion depth variance is achieved with select shims. The shims are placed under the inner pinion bearing cone (fig. 65). If a new gear set is being installed, note the depth variance etched into both the original and replace- ment pinion gear. Add or subtract the thickness of the or...

Page 140

(6) place scooter block/dial indicator in position in axle housing so dial probe and scooter block are flush against the surface of the pinion height block. Hold scooter block in place and zero the dial indica- tor face to the pointer. Tighten dial indicator face lock screw. (7) with scooter block s...

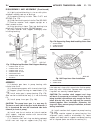

Page 141

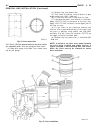

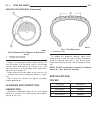

Differential bearing preload and gear backlash differential side bearing preload and gear backlash is achieved by selective shims inserted between the bearing cup and the axle housing. The proper shim thickness can be determined using slip-fit dummy bearings d-348 in place of the differential side b...

Page 142

(6) install the marked bearing caps in their correct positions. Install and snug the bolts. (7) using a dead-blow type mallet, seat the differ- ential dummy bearings to each side of the axle hous- ing (fig. 72) and (fig. 73). (8) thread guide stud c-3288-b into rear cover bolt hole below ring gear (...

Page 143

(14) add the dial indicator reading to the starting point shim thickness to determine total shim thick- ness to achieve zero differential end play. (15) add 0.008 in. (0.2 mm) to the zero end play total. This new total represents the thickness of shims to compress, or preload the new bearings when t...

Page 144

(38) verify differential case and ring gear runout by measuring ring to pinion gear backlash at eight locations around the ring gear. Readings should not vary more than 0.05 mm (0.002 in.). If readings vary more than specified, the ring gear or the differential case is defective. After the proper ba...

Page 145

Fig. 79 gear tooth contact patterns 3 - 98 194 rbi axle xj adjustments (continued).

Page 146

Specifications 194 rbi axle description specification axle type . . . . . . . . . . . . . . . Semi–floating hypoid lubricant . . . . . . . . Sae thermally stable 80w–90 lubricant trailer tow . . . . . . . Synthetic 75w–140 lube capacity . . . . . . . . . . . . . . . 1.66 l (3.50 pts.) friction modif...

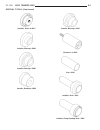

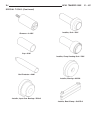

Page 147

Spanner—6958 installer screw—8112 cup—8109 handle—c-4171 driver—c-3716-a installer—d-130 installer—d-146 remover—c-4345 remover—d-149 installer—w-262 3 - 100 194 rbi axle xj special tools (continued).

Page 148

Installer—6436 installer—6437 disc, axle arbor—6732 gauge block—6735 tool set, pinion depth—6774 trac-lok tool set—6960 holder—6965 puller—7794-a starting point shim—8107 spreader—w-129-b xj 194 rbi axle 3 - 101 special tools (continued).

Page 149

Adapter kit—6987 guide pin—c-3288-b bearing remover tool set—6310 hub puller—6790 dial indicator—c-3339 3 - 102 194 rbi axle xj special tools (continued).

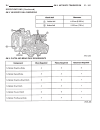

Page 150: 8 1/4 Rear Axle

8 1/4 rear axle table of contents page page description and operation 8 1/4 axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103 lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104 standard differential . . . . . . . . . . . . . . . . 105 trac-lok y differential . . ....

Page 151

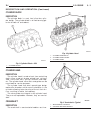

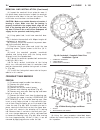

Lubricant description multi-purpose, hypoid gear lubricant should be used for rear axles with a standard differential. The lubricant should have a mil-l-2105c and api gl 5 quality specifications. Trac-lok differentials require the addition of 4 oz. Of friction modifier to the axle lubricant after se...

Page 152

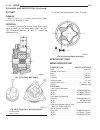

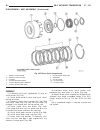

Standard differential description the differential gear system divides the torque between the axle shafts. It allows the axle shafts to rotate at different speeds when turning corners. Each differential side gear is splined to an axle shaft. The pinion gears are mounted on a pinion mate shaft and ar...

Page 153

The trac-lok y design provides the differential action needed for turning corners and for driving straight ahead during periods of unequal traction. When one wheel looses traction, the clutch packs transfer additional torque to the wheel having the most traction. Trac-lok y differentials resist whee...

Page 154

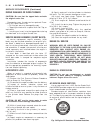

Diagnostic chart condition possible causes correction wheel noise 1. Wheel loose. 1. Tighten loose nuts. 2. Faulty, brinelled wheel bearing. 2. Replace bearing. Axle shaft noise 1. Misaligned axle tube. 1. Inspect axle tube alignment. Correct as necessary. 2. Bent or sprung axle shaft. 2. Inspect an...

Page 155

Condition possible causes correction loss of lubricant 1. Lubricant level too high. 1. Drain lubricant to the correct level. 2. Worn axle shaft seals. 2. Replace seals. 3. Cracked differential housing. 3. Repair as necessary. 4. Worn pinion seal. 4. Replace seal. 5. Worn/scored yoke. 5. Replace yoke...

Page 156

Gear noise axle gear noise can be caused by insufficient lubri- cant, incorrect backlash, tooth contact, worn/damaged gears, or the carrier housing not having the proper offset and squareness. Gear noise usually happens at a specific speed range. The noise can also occur during a specific type of dr...

Page 157

Trac–lok y test warning: when servicing vehicles with a trac–lok y differential do not use the engine to turn the axle and wheels. Both rear wheels must be raised and the vehi- cle supported. A trac–lok y axle can exert enough force if one wheel is in con- tact with a surface to cause the vehicle to...

Page 158

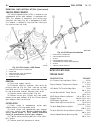

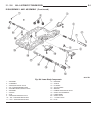

Removal and installation rear axle removal (1) raise and support the vehicle. (2) position a suitable lifting device under the axle. (3) secure axle to device. (4) remove the wheels and tires. (5) secure brake drums to the axle shaft. (6) disconnect the brake hose at the axle junction block. Do not ...

Page 159

(2) insert c–lock in end of axle shaft. Push axle shaft outward to seat c–lock in side gear. (3) insert pinion shaft into differential case and through thrust washers and differential pinions. (4) align hole in shaft with hole in the differential case and install lock screw with loctite t on the thr...

Page 160

(3) install a new axle seal with installer c-4076-b and handle c-4735-1. When the tool contacts the axle tube, the seal is installed to the correct depth. (4) coat the lip of the seal with axle lubricant for protection prior to installing the axle shaft. (5) install the axle shaft. Pinion seal remov...

Page 161

(6) position the pinion yoke on the end of the shaft with the reference marks aligned. (7) seat yoke on pinion shaft with installer c-3718 and wrench 6719. (8) remove the tools and install the pinion yoke washer. The convex side of the washer must face out- ward. Caution: do not exceed the minimum t...

Page 162

(2) mark the differential housing and the differen- tial bearing caps for installation reference (fig. 17). (3) remove bearing threaded adjuster lock from each bearing cap. Loosen the bolts, but do not remove the bearing caps. (4) loosen the threaded adjusters with wrench c-4164 (fig. 18). (5) hold ...

Page 163

Ring gear the ring gear and pinion are serviced in a matched set. Do not replace the ring gear without replacing the pinion. Removal (1) remove differential from axle housing. (2) place differential case in a suitable vise with soft metal jaw protectors. (fig. 22). (3) remove bolts holding ring gear...

Page 164

Pinion gear the ring gear and pinion are serviced in a matched set. Do not replace the pinion without replacing the ring gear. Removal (1) remove differential from the axle housing. (2) mark pinion yoke and propeller shaft for installation alignment. (3) disconnect propeller shaft from pinion yoke. ...

Page 165

(2) ensure cup is correctly seated. (3) apply mopar t door ease, or equivalent, stick lubricant to outside surface of bearing cup. (4) install the pinion front bearing cup (fig. 31) with installer d–130 and handle c–4171. (5) install pinion front bearing, and oil slinger, if equipped. (6) apply a li...

Page 166

Note: pinion depth shims are placed between the rear pinion bearing cone and pinion head to achieve proper ring and pinion gear mesh. If the factory installed ring gear and pinion are reused, the pinion depth shim should not require replace- ment. If required, refer to pinion gear depth to select th...

Page 167

Bearing end-play. It will not be possible at this point to achieve zero bearing end-play if a new collapsible spacer was installed. (13) tighten the nut to 285 n·m (210 ft. Lbs.). Caution: never loosen pinion nut to decrease pin- ion bearing rotating torque and never exceed spec- ified preload torqu...

Page 168

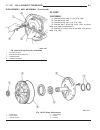

Assembly (1) install the differential side gears and thrust washers. (2) install the differential pinion gears and thrust washers. (3) install the pinion mate shaft. (4) align the hole in the pinion mate shaft with the hole in the differential case and install the pinion mate shaft lock screw. (5) l...

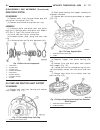

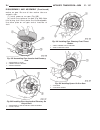

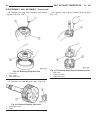

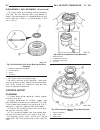

Page 169

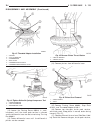

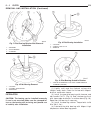

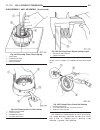

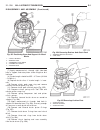

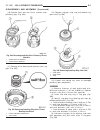

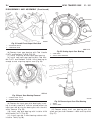

(4) remove the pinion mate shaft lock screw (fig. 40). (5) remove the pinion mate shaft. If necessary, use a drift and hammer (fig. 41). (6) install and lubricate step plate 8140–2 (fig. 42). (7) assemble threaded adapter 8140-1 into top side gear. Thread forcing screw 6960-4 into adapter until it b...

Page 170

(12) loosen the forcing screw 6960-4 in small increments until the clutch pack tension is relieved and the differential case can be turned using turning bar 6960-2. (13) rotate differential case until the differential pinions can be removed. (14) remove pinions from differential case. (15) remove fo...

Page 171

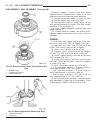

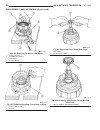

And clutch pack. Keep plates in correct order during removal. Assembly note: the clutch discs are replaceable as com- plete sets only. If one clutch disc pack is damaged, both packs must be replaced. Lubricate each component with gear lubricant before assembly. (1) assemble the clutch discs into pac...

Page 172

Slightly tighten the forcing screw in order to install the pinions. (12) tighten forcing screw to 122 n·m (90 ft. Lbs.) maximum to compress the belleville springs. (13) lubricate and install thrust washers behind pinions and align washers with a small screw driver. Insert mate shaft into each pinion...

Page 173

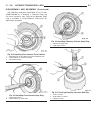

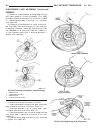

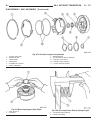

Adjustments 8 1/4 axle pinion gear depth general information ring gears and pinions are supplied as matched sets only. The identifying numbers for the ring gear and pinion are etched into the face of each gear (fig. 51). A plus (+) number, minus (–) number or zero (0) is etched into the face of the ...

Page 174

(7) with scooter block still in position against the pinion height block, slowly slide the dial indicator probe over the edge of the pinion height block. (8) slide the dial indicator probe across the gap between the pinion height block and the arbor bar with the scooter block against the pinion heig...

Page 175

• mark the gears so the same teeth are meshed during all backlash measurements. • maintain the torque while adjusting the bearing preload and ring gear backlash. • excessive adjuster torque will introduce a high bearing load and cause premature bearing failure. Insufficient adjuster torque can resul...

Page 176

Cedure described above. Continue to tighten the right-side adjuster and seat bearing cups until the torque remains constant at 102 n·m (75 ft. Lbs.) (7) measure the ring gear backlash. The range of backlash is 0.006 to 0.008 inch (0.15 to 0.203 mm). (8) continue increasing the torque at the right- s...

Page 177

Fig. 59 gear tooth contact patterns 3 - 130 8 1/4 rear axle xj adjustments (continued).

Page 178

(7) if clearance is 0.012 inch (0.305 mm) or greater, both side gears must be replaced (matched set) and the clearance measurements repeated. (8) if clearance (above) continues to be 0.012 inch (0.305 mm) or greater, the case must be replaced. Specifications 8 1/4 inch axle axle type . . . . . . . ....

Page 179

Handle—c-4171 installer—c-4076-b handle—c-4735-1 holder—6719 puller—c-452 installer—c-3718 adjustment rod—c-4164 puller/press—c-293–pa adapters—c-293-48 3 - 132 8 1/4 rear axle xj special tools (continued).

Page 180

Plug—sp-3289 adapters—c-293-47 installer—c-4340 holder—8138 installer—c-4345 remover—c-4307 installer—c-4308 installer—d-130 installer—6448 xj 8 1/4 rear axle 3 - 133 special tools (continued).

Page 181

Trac-lok y tools—8140 trac-lok y tools—6960 pinion gauge block—8540 arbor discs—8541 pinion gauge set 3 - 134 8 1/4 rear axle xj special tools (continued).

Page 182: Brakes

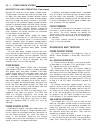

Brakes table of contents page page base brake system . . . . . . . . . . . . . . . . . . . . . . 1 antilock brakes . . . . . . . . . . . . . . . . . . . . . . . 33 base brake system table of contents page page description and operation brake system . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 183

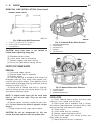

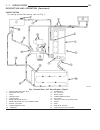

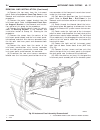

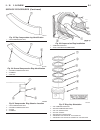

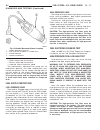

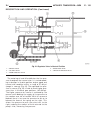

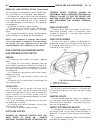

Description and operation brake system description power assist front disc and rear drum brakes are standard equipment. Disc brake components consist of single piston calipers and ventilated rotors. Rear drum brakes are dual shoe units with cast brake drums. The parking brake mechanism is lever and ...

Page 184

Red brake warning lamp description a red warning lamp is used for the service brake portion of the hydraulic system. The lamp is located in the instrument cluster. Operation the red warning light alerts the driver if a pres- sure differential exists between the front and rear hydraulic systems or th...

Page 185

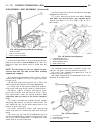

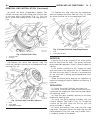

Front disc brakes description the calipers are a single piston type. The calipers are free to slide laterally, this allows continuous com- pensation for lining wear. Operation when the brakes are applied fluid pressure is exerted against the caliper piston. The fluid pressure is exerted equally and ...

Page 186

In summary, fluid pressure acting simultaneously on both piston and caliper, produces a strong clamp- ing action. When sufficient force is applied, friction will attempt to stop the rotors from turning and bring the vehicle to a stop. Application and release of the brake pedal gener- ates only a ver...

Page 187

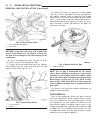

Ating levers forward, by means tensioner and cables. As the actuating lever is pulled forward, the parking brake strut (which is connected to both shoes), exerts a linear force against the primary brake shoe. This action presses the primary shoe into contact with the drum. Once the primary shoe cont...

Page 188

May be required if a new tensioner, or cables are installed, or disconnected. Brake hoses and lines description flexible rubber hose is used at both front brakes and at the rear axle junction block. Double walled steel tubing is used to connect the master cylinder to the major hydraulic braking comp...

Page 189

Pedal pulsation pedal pulsation is caused by components that are loose, or beyond tolerance limits. The primary cause of pulsation are disc brake rotors with excessive lateral runout or thickness vari- ation, or out of round brake drums. Other causes are loose wheel bearings or calipers and worn, da...

Page 190

Wheel and tire problems some conditions attributed to brake components may actually be caused by a wheel or tire problem. A damaged wheel can cause shudder, vibration and pull. A worn or damaged tire can also cause pull. Severely worn tires with very little tread left can produce a grab-like conditi...

Page 191

Ferential switch and valve have been actuated due to a leak in the hydraulic system. On models with abs brakes, the amber warning lamp only illuminates during the self test and when an abs malfunction has occurred. The abs lamp operates independently of the red warning lamp. For additional informati...

Page 192

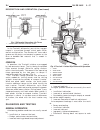

Combination valve pressure differential switch (1) have helper sit in drivers seat to apply brake pedal and observe red brake warning light. (2) raise vehicle on hoist. (3) connect bleed hose to a rear wheel cylinder and immerse hose end in container partially filled with brake fluid. (4) have helpe...

Page 193

The drum if machining causes the drum to exceed the maximum allowable diameter. Brake line and hoses flexible rubber hose is used at both front brakes and at the rear axle junction block. Inspect the hoses whenever the brake system is serviced, at every engine oil change, or whenever the vehicle is ...

Page 194

(3) fill reservoir with fresh brake fluid. (4) press cylinder pistons inward with wood dowel. Then release pistons and allow them to return under spring pressure. Continue bleeding operations until air bubbles are no longer visible in fluid. Base brake bleeding use mopar brake fluid, or an equivalen...

Page 195

Mounted on-vehicle lathe is recommended. This type of lathe trues the rotor to the vehicles hub/bearing. Caution: brake rotors that do not meet minimum thickness specifications before or after machining must be replaced. Brake drum machining the brake drums can be machined on a drum lathe when neces...

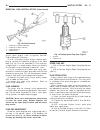

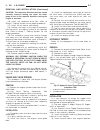

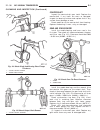

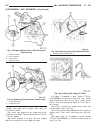

Page 196

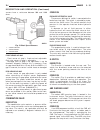

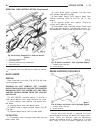

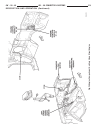

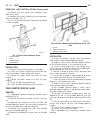

(4) position the tube in the flaring tool flush with the top of the tool bar (fig. 16). Then tighten the tool bar on the tube. (5) install the correct size adaptor on the flaring tool yoke screw. (6) lubricate the adaptor. (7) align the adaptor and yoke screw over the tube (fig. 16). (8) turn the yo...

Page 197

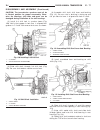

Installation (1) install pedal and support bracket as an assem- bly into the vehicle. (2) install nuts securing the booster to the pedal support bracket and nuts to the column bracket. (3) tighten nuts to 39 n·m (29 ft. Lbs.). (4) lubricate the brake pedal pin and bushings with mopar multi-mileage g...

Page 198

(3) remove mounting nuts from the combination valve bracket and remove the valve (fig. 20). (4) remove mounting nuts from the master cylin- der (fig. 21). (5) remove master cylinder. (6) remove cylinder cover and drain fluid. (7) if master cylinder reservoir requires service, refer to reservoir repl...

Page 199

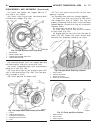

Note: lubricate the pedal pin and bushing with mopar multi-mileage grease before installation. (5) tighten booster mounting nuts to 39 n·m (29 ft. Lbs.). (6) install the knee blocker. (7) if original master cylinder is being installed, check condition of seal at rear of master cylinder. Replace seal...

Page 200

(7) tilt top of caliper outward with pry tool if nec- essary (fig. 27) and remove caliper. (8) remove caliper from vehicle. Installation (1) clean brake shoe mounting ledges with wire brush and apply light coat of mopar multi-mileage grease to surfaces (fig. 28). (2) install caliper by position notc...

Page 201

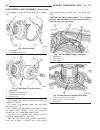

Caution: verify brake hose is not twisted or kinked before tightening fitting bolt. (5) bleed base brake system. (6) install wheel and tire assemblies. (7) remove supports and lower vehicle. (8) verify firm pedal before moving vehicle. Front disc brake shoes removal (1) raise and support vehicle. (2...

Page 202

Disc brake rotor removal (1) remove wheel and tire assemble. (2) remove caliper. (3) remove retainers securing rotor to hub studs (fig. 33). (4) remove rotor from hub. (5) if rotor shield requires service, remove front hub and bearing assembly. Installation (1) if new rotor is being installed, remov...

Page 203

Installation (1) apply bead of silicone sealer around cylinder mounting surface of support plate. (2) install cylinder mounting bolts and tighten to 20 n·m (15 ft. Lbs.). (3) connect brake line to cylinder. (4) install brake shoe return spring. (5) install brake drum. (6) install wheel and tire asse...

Page 204

(5) disconnect brake line at wheel cylinder. (6) remove wheel cylinder from support plate. (7) remove axle shaft, refer to group 3 for proce- dures. (8) remove bolts attaching support plate to axle and remove support plate. Installation (1) apply bead of silicone sealer around axle mounting surface ...

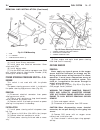

Page 205

Removal (1) release parking brakes. (2) raise vehicle. (3) remove adjusting nut from tensioner rod at the equalizer (fig. 38). (4) lower vehicle. (5) disengage front cable from the cable lever. (6) compress cable retainer with worm drive hose clamp and remove the cable from the parking brake lever b...

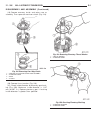

Page 206

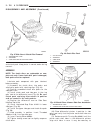

(3) clamp cylinder body in vise with brass protec- tive jaws. (4) loosen reservoir from grommets with pry tool (fig. 41). (5) remove reservoir by rocking it to one side and pulling free of grommets (fig. 42). (6) remove old grommets from cylinder body (fig. 43). Installation caution: do not use any ...

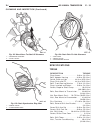

Page 207

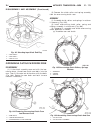

This will cushion and protect caliper piston during removal (fig. 45). (4) remove caliper piston with short bursts of low pressure compressed air. Direct air through fluid inlet port and ease piston out of bore (fig. 46). Caution: do not blow the piston out of the bore with sustained air pressure. T...

Page 208

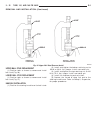

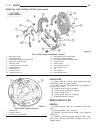

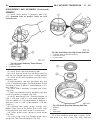

Fig. 48 piston seal removal 1 – remove seal with wood pencil or similar tool 2 – piston seal fig. 49 mounting bolt bushing and boot 1 – caliper slide bushing 2 – boot fig. 50 bushings and boots installation 1 – bushing 2 – boot fig. 51 piston seal installation 1 – seal groove 2 – piston seal fig. 52...

Page 209

(8) seat dust boot in caliper with installer tool c-4842 and tool handle c-4171 (fig. 54). (9) replace caliper bleed screw if removed. Wheel cylinder disassembly (1) remove push rods and boots (fig. 55). (2) press pistons, cups and spring and expander out of cylinder bore. (3) remove bleed screw. As...

Page 210

Rear drum brake cleaning clean the individual brake components, including the support plate and wheel cylinder exterior, with a water dampened cloth or with brake cleaner. Do not use any other cleaning agents. Remove light rust and scale from the brake shoe contact pads on the sup- port plate with f...

Page 211

Adjustments brake lamp switch (1) press and hold brake pedal in applied position. (2) pull switch plunger all the way out to fully extended position. (3) release brake pedal. Then pull pedal lightly rearward. Pedal will set plunger to correct position as pedal pushes plunger into switch body. Switch...

Page 212

(7) push and hold adjuster lever away from star wheel with thin screwdriver. (8) back off adjuster screw star wheel until brake drag is eliminated. (9) repeat adjustment at opposite wheel. Be sure adjustment is equal at both wheels. (10) install support plate access hole plugs. (11) adjust parking b...

Page 213

Only mopar brake fluid or an equivalent from a tightly sealed container. Caution: never use reclaimed brake fluid or fluid from an container which has been left open. An open container will absorb moisture from the air and contaminate the fluid. Caution: never use any type of a petroleum- based flui...

Page 214: Antilock Brakes

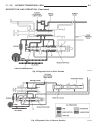

Antilock brakes table of contents page page description and operation antilock brake system . . . . . . . . . . . . . . . . 33 controller antilock brakes . . . . . . . . . . . 33 hydraulic control unit. . . . . . . . . . . . . . . . 34 wheel speed sensors and tone wheel . . 34 combination valve . . ...

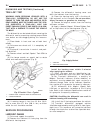

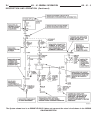

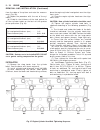

Page 215

Microprocessors. A logic block in each microprocessor receives identical sensor signals. These signals are processed and compared simultaneously. The cab contains a self check program that illuminates the abs warning light when a system fault is detected. Faults are stored in a diagnostic program me...

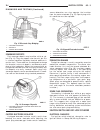

Page 216

Sensors have a resistance between 900 and 1300 ohms. Front sensor air gap front sensor air gap is fixed and not adjustable. Only rear sensor air gap is adjustable. Although front air gap is not adjustable, it can be checked if diagnosis indicates this is necessary. Front air gap should be 0.36 to 1....

Page 217

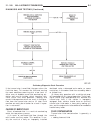

Diagnosis and testing antilock brakes the abs brake system performs several self-tests every time the ignition switch is turned on and the vehicle is driven. The cab monitors the systems input and output circuits to verify the system is oper- ating correctly. If the on board diagnostic system senses...

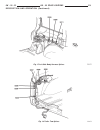

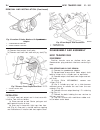

Page 218

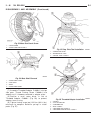

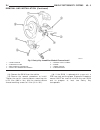

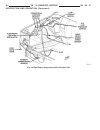

Front wheel speed sensor removal (1) raise vehicle and turn wheel outward for eas- ier access to sensor. (2) remove sensor wire from mounting brackets. (3) clean sensor and surrounding area with shop towel before removal. (4) remove bolt attaching sensor to steering knuckle and remove sensor (fig. 6...

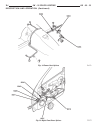

Page 219

(7) remove brake drum. (8) remove clips securing sensor wires to brake lines, rear axle and, brake hose. (9) unseat sensor wire support plate grommet. (10) remove bolt attaching sensor to bracket and remove sensor (fig. 8). Installation (1) if original sensor is being installed, remove any remaining...

Page 220

(2) disconnect switch harness. (3) remove switch mounting screws (fig. 11) (4) remove the acceleration switch. Installation caution: the mercury switch (inside the g-switch), will not function properly if the switch is installed incorrectly. Verify that the switch locating arrow is pointing to the f...

Page 221

Assembly (1) install the cab onto the hcu. (2) install the cab mounting screws and tighten to 1.8 n·m (16 in. Lbs.). (3) install pump motor connector to the cab. Specifications t0rque chart description torque g-sensor sensor bolt . . . . . . . . . . . . . . 3 n·m (27.5 in. Lbs.) bracket bolt . . . ....

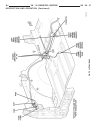

Page 222: Brakes

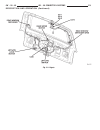

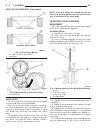

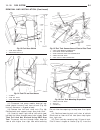

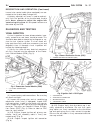

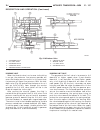

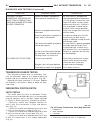

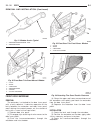

Brakes table of contents page page removal and installation brake booster – rhd diesel . . . . . . . . . . . . 1 master cylinder – rhd diesel . . . . . . . . . . 3 specifications torque specifications . . . . . . . . . . . . . . . . . . 4 removal and installation brake booster – rhd diesel removal (...

Page 223

(11) remove the retaining clip that secures the booster push rod to the brake pedal (fig. 4). (12) remove nuts attaching booster to passenger compartment side of dash panel (fig. 5). (13) working inside the engine compartment, posi- tion the coolant reservoir out of the way and remove the brake boos...

Page 224

(15) adjust the brake lamp switch. Refer to the procedure in this group. Warning: be certain a firm brake pedal is achieved prior to attempting to operate the vehicle. Master cylinder – rhd diesel removal (1) open hood and disconnect the negative battery cable note: pump the brake pedal several time...

Page 225

(4) install combination valve/bracket and retaining nuts. (5) install brake lines on cylinder and valve. Torque brake lines to 19 n·m (170 in. Lbs.). (6) connect differential pressure switch wire on the combination valve. (7) fill and bleed the brake system. Refer to the procedure in this group. (8)...

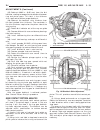

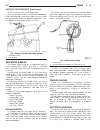

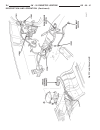

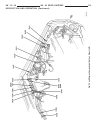

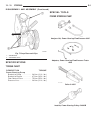

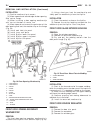

Page 226: Clutch

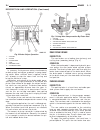

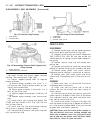

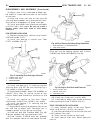

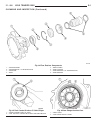

Clutch table of contents page page description and operation clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 clutch disc. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 clutch pressure plate . . ...

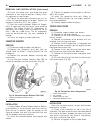

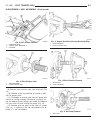

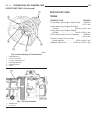

Page 227

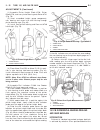

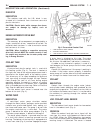

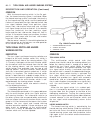

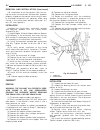

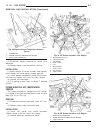

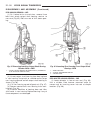

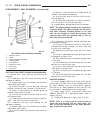

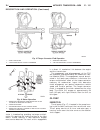

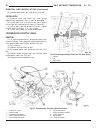

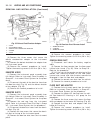

The clutch master cylinder push rod is connected to the clutch pedal. When the clutch pedal is depressed, the slave cylinder is operated by the clutch master cylinder mounted on the dash panel. The release fork is actuated by the hydraulic slave cylinder mounted on the transmission housing. The rele...

Page 228

Operation the clutch pressure plate assembly clamps the clutch disc against the flywheel. When the release bearing is depressed by the shift fork, the pressure exerted on the clutch disc by the pressure plate spring is decreased. As additional force is applied, the bearing presses the diaphragm spri...

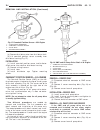

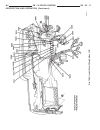

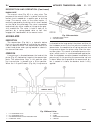

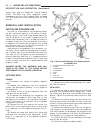

Page 229

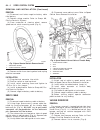

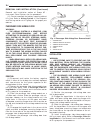

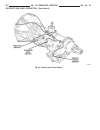

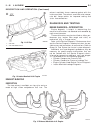

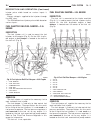

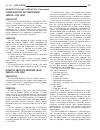

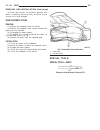

Hydraulic clutch linkage description the hydraulic linkage consists of a clutch master cylinder with integral reservoir, a clutch slave cylin- der and an interconnecting fluid line (fig. 7). The clutch master cylinder push rod is connected to the clutch pedal. The slave cylinder push rod is con- nec...

Page 230

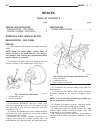

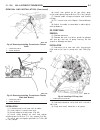

Fig. 8 clutch components and inspection xj clutch 6 - 5 diagnosis and testing (continued).

Page 231

Clutch contamination fluid contamination is a frequent cause of clutch malfunctions. Oil, water, or clutch fluid on the clutch disc and pressure plate surfaces will cause chatter, slip and grab. During inspection, note if any components are con- taminated with oil, hydraulic fluid, or water/road spl...

Page 232

Clutch cover and disc runout check the clutch disc before installation. Axial (face) runout of a new disc should not exceed 0.50 mm (0.020 in.). Measure runout about 6 mm (1/4 in.) from the outer edge of the disc facing. Obtain another disc if runout is excessive. Check condition of the clutch befor...

Page 233

Condition possible causes correction facing on flywheel side of disc torn, gouged, or worn. 1. Flywheel surface scored or nicked. 2. Correct surface condition if possible. Replace flywheel and disc as necessary. 2. Clutch disc sticking or binding on transmission input shaft. 2. Inspect components an...

Page 234

Condition possible causes correction clutch pedal squeak. 1. Pivot pin loose. 1. Tighten pivot pin if possible. Replace clutch pedal if necessary. 2. Master cylinder bushing not lubricated. 2. Lubricate master cylinder bushing. 3. Pedal bushings worn out or cracked. 3. Replace and lubricate bushings...

Page 235

Alent meeting standards sae j1703 and dot 3. Do not use any other type of fluid. Clutch fluid level the clutch fluid reservoir, master cylinder, slave cylinder and fluid lines are pre-filled with fluid at the factory during assembly operations. The hydraulic system should not require additional flui...

Page 236

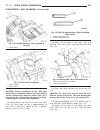

Caution: do not use an oxy/acetylene torch to remove the old gear, or to heat and expand a new gear. The high temperature of the torch flame can cause localized heating that will damage the fly- wheel. In addition, using the torch to heat a replace- ment gear will cause uneven heating and expansion....

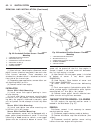

Page 237

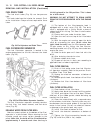

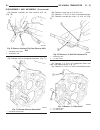

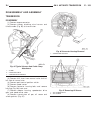

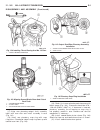

(c) starting 180 degrees from the last pilot bolt, tighten 3 large hole bolts 3/4s of the way (any sequence). (d) tighten 3 pilot hole bolts all the way (any sequence). (e) starting 180 degrees from last pilot bolt, tighten 3 large bolts all the way (any sequence). (11) apply light coat of mopar t h...

Page 238

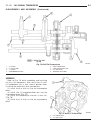

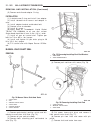

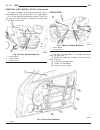

Clutch housing the clutch housing is removable and can be replaced when the transmission is out of the vehicle. The bolts attaching the housing to the transmis- sion case are located inside the housing (fig. 14). Recommended tightening torque for the clutch hous- ing-to-transmission bolts is 46 n·m ...

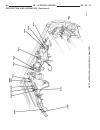

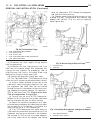

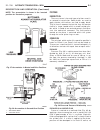

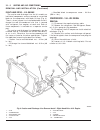

Page 239

Installation (1) be sure reservoir cover on clutch master cylin- der is tight to avoid spills. (2) position clutch linkage components in vehicle. Work connecting line and slave cylinder downward past engine and adjacent to clutch housing (fig. 16) or (fig. 17). (3) position clutch master cylinder on...

Page 240

(9) secure clutch fluid line in body and transmis- sion clips. (10) lower vehicle. (11) connect clutch interlock safety switch wires. Specifications torque description torque bolts, clutch cover 2.5 l . . . . . . . 31 n·m (23 ft. Lbs) bolts, clutch cover 4.0 l . . . . . . . 50 n·m (37 ft. Lbs) bolt/...

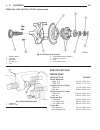

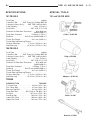

Page 242: Clutch

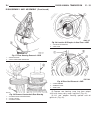

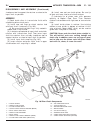

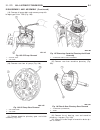

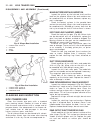

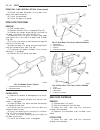

Clutch table of contents page page description and operation clutch components . . . . . . . . . . . . . . . . . . . . 1 clutch hydraulic system . . . . . . . . . . . . . . 1 removal and installation clutch cover and disc . . . . . . . . . . . . . . . . . 1 pilot bearing . . . . . . . . . . . . . . ...

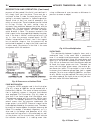

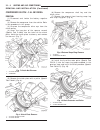

Page 243

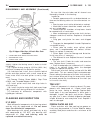

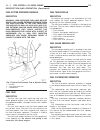

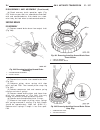

(3) check free operation of clutch disc by sliding disc onto transmission output shaft splines. Disc should slide onto splines freely without binding. (4) position the clutch disc on flywheel. Be sure side of disc marked “flywheel side” is positioned against flywheel (fig. 3). If disc is not marked,...

Page 244

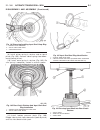

(10) install the transmission and transfer case. Refer to group 21, transmission and transfer case for procedure. Pilot bearing removal (1) remove the transmission and transfer case. Refer to group 21, transmission and transfer case for procedures. (2) remove the clutch cover and disc (fig. 6). Refe...

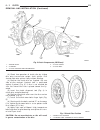

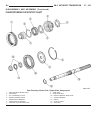

Page 245

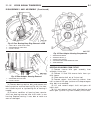

Installation caution: the bearing can be installed incorrectly if care is not exercised. Make sure the stamped let- ters on the bearing will be facing out (toward rear of vehicle) after installation. (1) lightly scuff sand the flywheel surface with 180 grit emery cloth. Clean the surface with mopar ...

Page 246

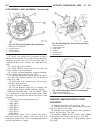

(5) install the clutch disc and cover (fig. 11). Refer to clutch cover and disc removal and installation in this group. (6) install the transmission and transfer case. Refer to group 21, transmission and transfer case for procedures. Flywheel removal (1) remove the transmission and clutch housing. R...

Page 247

(2) install new o-ring in the flywheel mounting flange (fig. 14). Use grease to hold the ring in place. (3) install the flywheel on the crankshaft and align the bolt holes. (4) install and tighten the new flywheel bolts as follows: (a) lubricate and install the 6 new flywheel bolts. (b) torque the 6...

Page 248

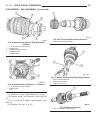

Flywheel ring gear removal (1) remove the transmission and transfer case. Refer to group 21, transmission and transfer case for removal and installation procedures. (2) remove the clutch cover and disc (fig. 17). Refer to clutch cover and disc removal and installa- tion in this group. (3) remove the...

Page 249

Specifications specifications description torque clutch cover to flywheel bolts . . . . . . . . . . . . . . . . . . . 50 n·m (37 ft. Lbs.) clutch housing to transmission bolts . . . . . . . . . . . . . . . . . . . 46 n·m (34 ft. Lbs.) flywheel to crankshaft bolts . . . . . See removal and installati...

Page 250: Cooling System