- DL manuals

- Jeep

- Automobile

- KJ 2005

- Service Manual

Jeep KJ 2005 Service Manual

Summary of KJ 2005

Page 1

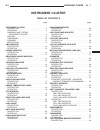

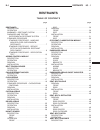

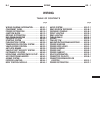

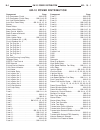

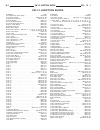

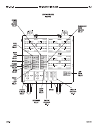

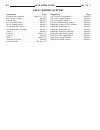

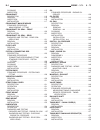

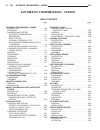

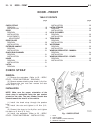

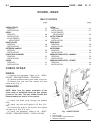

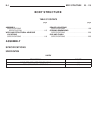

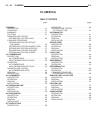

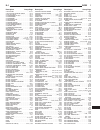

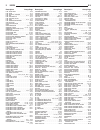

Group tab locator introduction 0 lubrication & maintenance 2 suspension 3 differential & driveline 5 brakes 6 clutch 7 cooling 8a audio/video 8b chime/buzzer 8e electronic control modules 8f engine systems 8g heated systems 8h horn 8i ignition control 8j instrument cluster 8l lamps 8m message system...

Page 2: Introduction

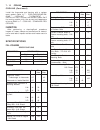

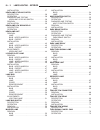

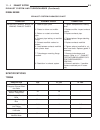

Introduction table of contents page page fastener identification description . . . . . . . . . . . . . . . . . . . . . . . . . . 1 fastener usage description description . . . . . . . . . . . . . . . . . . . . . . . . 4 description . . . . . . . . . . . . . . . . . . . . . . . . 4 international symb...

Page 3

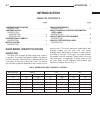

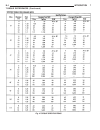

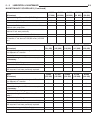

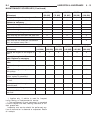

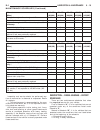

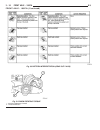

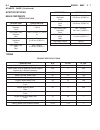

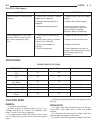

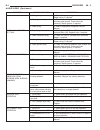

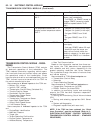

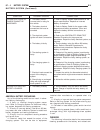

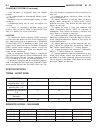

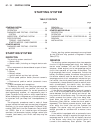

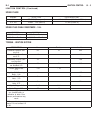

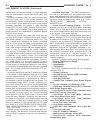

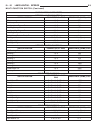

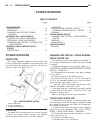

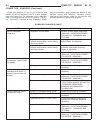

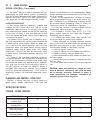

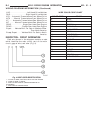

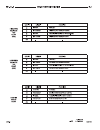

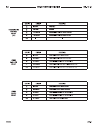

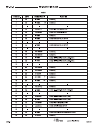

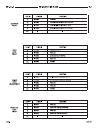

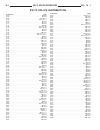

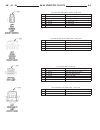

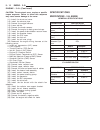

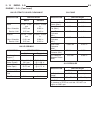

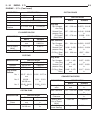

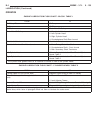

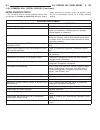

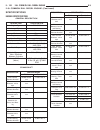

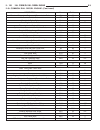

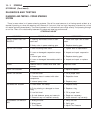

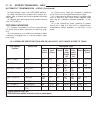

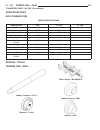

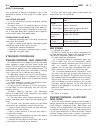

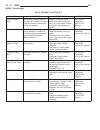

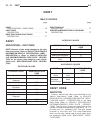

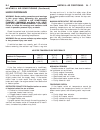

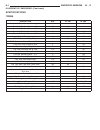

Bolt markings and torques - u. S. Customary bolt markings grade 5 grade 8 bolt dia. N·m ft. Lbs n·m ft. Lbs 1/4 - 20 10 95* 14 125* 1/4 - 28 10 95* 17 150* 5/16 - 18 22 200* 30 270* 5/16 - 24 26 240* 33 300* 3/8 - 16 40 30 55 40 3/8 - 24 47 35 60 45 7/16 - 14 68 50 88 65 7/16 - 20 74 55 95 70 1/2 - ...

Page 4

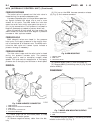

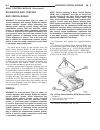

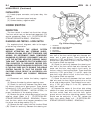

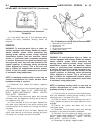

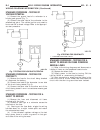

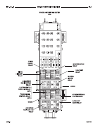

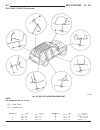

Fig. 1 fastener strength kj introduction 3 fastener identification (continued).

Page 5: Fastener Usage

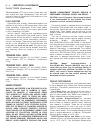

Fastener usage description description warning: use of an incorrect fastener may result in component damage or personal injury. Fasteners and torque specifications references in this service manual are identified in metric and sae format. During any maintenance or repair procedures, it is important ...

Page 6

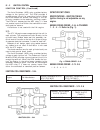

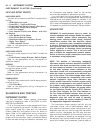

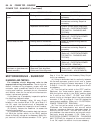

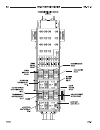

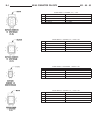

Fig. 3 metric conversion chart kj introduction 5 metric system (continued).

Page 7: Torque References

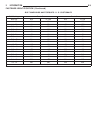

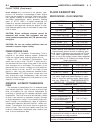

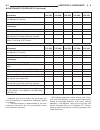

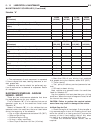

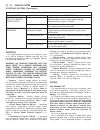

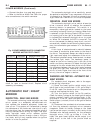

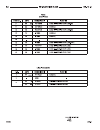

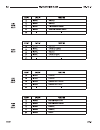

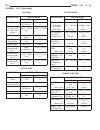

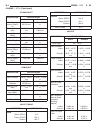

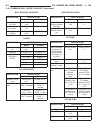

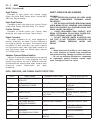

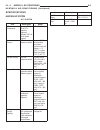

Conversion formulas and equivalent values multiply by to get multiply by to get in-lbs x 0.11298 = newton meters (n·m) n·m x 8.851 = in-lbs ft-lbs x 1.3558 = newton meters (n·m) n·m x 0.7376 = ft-lbs inches hg (60° f) x 3.377 = kilopascals (kpa) kpa x 0.2961 = inches hg psi x 6.895 = kilopascals (kp...

Page 8

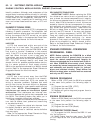

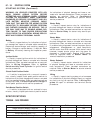

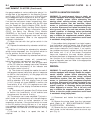

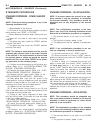

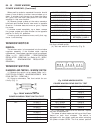

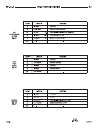

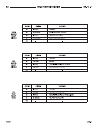

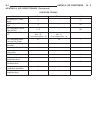

Fig. 4 torque specifications kj introduction 7 torque references (continued).

Page 9: Vehicle Emission Control

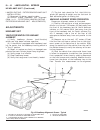

Vehicle emission control information (veci) label description all models have a vehicle emission control infor- mation (veci) label. Daimlerchrysler permanently attaches the label in the engine compartment (fig. 5). The label cannot be removed without defacing label information and destroying label....

Page 10: Vehicle Certification

Vehicle identification number decoding chart position interpretation code = description 1 country of origin 1 = manufactured by daimlerchrysler corporation 2 make j = jeep 3 vehicle type 4 = mpv w/o side airbags. 8 = mpv with side airbags. 4 gross vehicle weight rating f = 4001 - 5000 lbs. G = 5001 ...

Page 12: Lubrication & Maintenance

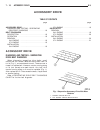

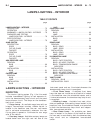

Lubrication & maintenance table of contents page page international symbols description . . . . . . . . . . . . . . . . . . . . . . . . . . 1 parts & lubricant recommendation description lubricant recommendations . . . . . . . . . 1 fluid types . . . . . . . . . . . . . . . . . . . . . . . . . 2 flu...

Page 13: Fluid Types

Body component fluid, lubricant, and genuine part hinges: door & hood mopar t engine oil swing gate mopar t multi-purpose lube nlgi grade 2 ep, gc-lb latches: door, hood/safety catch, swing gate mopar t multi-purpose lube nlgi grade 2 ep, gc-lb seat regulator & track mopar t multi-purpose lube nlgi ...

Page 14

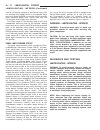

Container identification standard engine oil identification notations have been adopted to aid in the proper selection of engine oil. The identifying notations are located on the front label of engine oil plastic bottles and the top of engine oil cans (fig. 4). This symbol means that the oil has bee...

Page 15

This is normal. Atf+4 also has a unique odor that may change with age. Consequently, odor and color cannot be used to indicate the fluid condition or the need for a fluid change. Fluid additives daimlerchrysler strongly recommends against the addition of any fluids to the transmission, other than th...

Page 16: Fluid Capacities

Must always be a minimum of 44 percent, year- round in all climates. If percentage is lower, engine parts may be eroded by cavitation. Maximum protec- tion against freezing is provided with a 68 percent antifreeze concentration, which prevents freezing down to -67.7°c (-90°f). A higher percentage wi...

Page 17: Maintenance Schedules

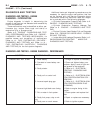

Maintenance schedules description maintenance schedules - gasoline engines there are two maintenance schedules that show the required service for your vehicle. First is schedule ( b ( . It is for vehicles that are operated under the conditions that are listed below and at the beginning of the schedu...

Page 18

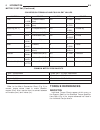

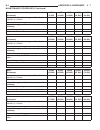

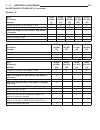

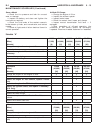

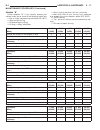

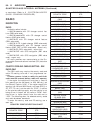

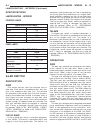

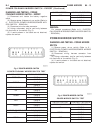

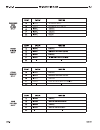

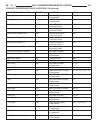

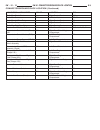

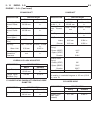

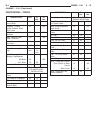

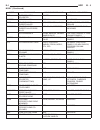

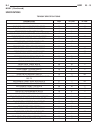

Miles 3,000 6,000 9,000 12,000 15,000 (kilometers) (5 000) (10 000) (14 000) (19 000) (24 000) change the engine oil and engine oil filter, if not replaced at 3 months. X x x x x rotate the tires. X x inspect the engine air filter element, replace if necessary. X inspect the brake linings. X drain a...

Page 19

Miles 48,000 51,000 54,000 57,000 60,000 (kilometers) (77 000) (82 000) (86 000) (91 000) (96 000) replace the ignition cables (2.4l only). X inspect the brake linings. X x drain and refill the front and rear axle fluid‡ x x drain and refill the automatic transmission fluid, and replace main sump fi...

Page 20

Miles 93,000 96,000 99,000 102,000 105,000 (kilometers) (149 000) (154 000) (158 000) (163 000) (168 000) change the engine oil and engine oil filter, if not replaced at 3 months. X x x x x rotate the tires. X x inspect the engine air filter element, replace if necessary. X inspect the brake linings...

Page 21

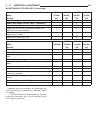

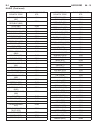

Schedule “a” miles 6,000 12,000 18,000 24,000 30,000 (kilometers) (10 000) (19 000) (29 000) (38 000) (48 000) [months] [6] [12] [18] [24] [30] change the engine oil and engine oil filter. X x x x x rotate the tires. X x x x x inspect the engine air filter element, and replace if necessary. X replac...

Page 22

Miles 84,000 90,000 96,000 102,000 (kilometers) (134 000) (144 000) (154 000) (163 000) [months] [84] [90] [96] [102] change the engine oil and engine oil filter. X x x x rotate the tires. X x x x inspect the engine air filter element, and replace if necessary. X replace the spark plugs. X inspect a...

Page 23

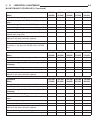

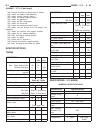

Maintenance schedules - diesel engine there are two maintenance schedules that show the required service for your vehicle. First is schedule ( b ( . It is for vehicles that are operated under the conditions that are listed below and at the beginning of the schedule. • day or night temperatures are b...

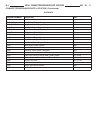

Page 24

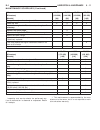

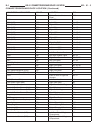

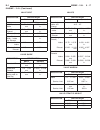

Miles 37,500 43,750 50,000 56,250 62,500 (kilometers) (60 000) (70 000) (80 000) (90 000) (100 000) change the engine oil and engine oil filter. X x x x x inspect the engine air filter element. Replace as necessary. X x x x x replace the engine air filter element. X x x replace the fuel filter/water...

Page 25

Schedule “a” miles 12,500 25,000 37,500 50,000 (kilometers) (20 000) (40 000) (60 000) (80 000) change the engine oil and engine oil filter. X x x x inspect the engine air filter element. Replace as nec- essary. X x x x replace the engine air filter element. X x replace the fuel filter/water separat...

Page 26

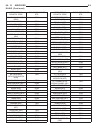

Once a month • check the tire pressure and look for unusual wear or damage. • inspect the battery, and clean and tighten the terminals as required. • check the fluid levels of the coolant reservoir, brake master cylinder, and transmission, and add as needed. • check all lights and all other electric...

Page 27

Kilometers 120 000 132 000 144 000 156 000 (miles) (75,000) (82,500) (90,000) (97,500) [months] [60] [66] [72] [78] replace the spark plugs. X inspect and replace the pcv valve, if necessary. L x inspect the brake linings. X inspect the drive belt and replace as needed. Not required if previously re...

Page 28

Schedule “b” follow schedule “b” if you usually operate your vehicle under one or more of the following conditions. • day or night temperatures are below 0°c (32°f). • stop and go driving. • extensive engine idling. • driving in dusty conditions. • short trips of less than 16.2 km (10 miles). • more...

Page 29

Kilometers 77 000 82 000 86 000 91 000 96 000 (miles) (48,000) (51,000) (54,000) (57,000) (60,000) replace the spark plugs. X inspect and replace the pcv valve, if neces- sary. L x replace the ignition cables (2.4l only). X inspect the brake linings. X x drain and refill the front and rear axle flui...

Page 30

Kilometers 149 000 154 000 158 000 163 000 168 000 (miles) (93,000) (96,000) (99,000) (102,000) (105,000) change the engine oil and engine oil filter. X x x x x rotate the tires. X x inspect the engine air filter element, replace if necessary. X inspect the brake linings. X drain and refill the fron...

Page 31

• more than 50% of your driving is at sustained high speeds during hot weather, above 32° c (90° f). • trailer towing. • taxi, police, or delivery service (commercial ser- vice). Most vehicles are operated under the conditions listed for schedule 9 b 9 . Use the schedule that best describes your dri...

Page 32

Kilometers 120 000 km 140 000 km 160 000 km 180 000 km replace the engine air filter element. X x replace the fuel filter/water separator unit. X x x x flush and replace the engine coolant. X inspect the ball joints. X x x x inspect the brake linings. X x drain and refill the automatic transmission ...

Page 33

Kilometers 60 000 km 70 000 km 80 000 km 90 000 km 100 000 km change the engine oil and engine oil filter. X x x x x inspect the engine air filter element. Replace as necessary. X x replace the engine air filter element. X x x replace the fuel filter/water separator unit. X x x inspect the engine ac...

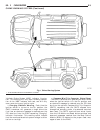

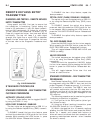

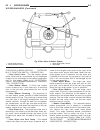

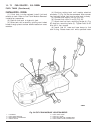

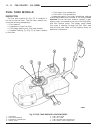

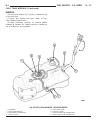

Page 34: Fluid Fill/check

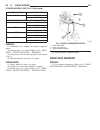

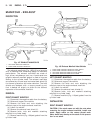

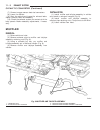

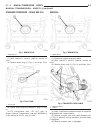

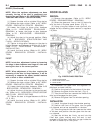

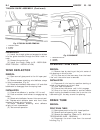

Fluid fill/check locations description the fluid check/fill point locations are located in each applicable service manual section. Hoisting standard procedure - hoisting recommendations refer to the owner’s manual for emergency vehicle lifting procedures. When properly positioned, a floor jack can b...

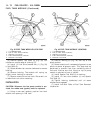

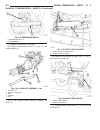

Page 35: Towing

Caution: when using another vehicle as a booster, do not allow vehicles to touch. Electrical systems can be damaged on either vehicle. To jump start a disabled vehicle: (1) raise hood on disabled vehicle and visually inspect engine compartment for: • generator drive belt condition and tension. • fue...

Page 36

Safety precautions caution: the following safety precautions must be observed when towing a vehicle: • secure loose and protruding parts. • always use a safety chain system that is inde- pendent of the lifting and towing equipment. • do not allow towing equipment to contact the disabled vehicle’s fu...

Page 37

(3) raise the front of the vehicle off the ground and install tow dollies under front wheels. (4) attach wheel lift device to rear wheels and raise vehicle to towing position. (5) attach safety chains. Route chains so not to interfere with tail pipe when vehicle is lifted. (6) turn the ignition swit...

Page 38: Suspension

Suspension table of contents page page suspension diagnosis and testing - suspension and steering system . . . . . . . . . . . . . . . . 1 wheel alignment . . . . . . . . . . . . . . . . . . . . . . 3 front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 rear . . . . . . . . . . ...

Page 39

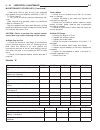

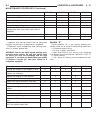

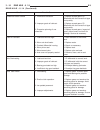

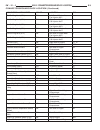

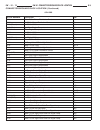

Condition possible causes correction vehicle leads or drifts from straight ahead direction on uncrowned road 1. Radial tire lead. 1. Cross front tires. 2. Brakes dragging. 2. Repair brake as necessary. 3. Weak or broken spring. 3. Replace spring. 4. Uneven tire pressure. 4. Adjust tire pressure. 5. ...

Page 40: Wheel Alignment

Wheel alignment table of contents page page wheel alignment description . . . . . . . . . . . . . . . . . . . . . . . . . . 3 operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 standard procedure standard procedure - height measurement . . . . . . . . . . . . . . . . . . . . . . . 4...

Page 41

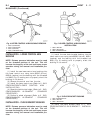

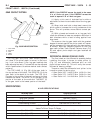

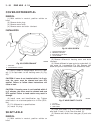

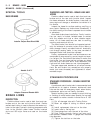

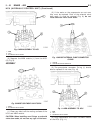

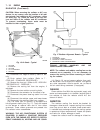

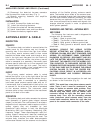

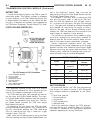

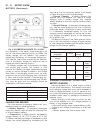

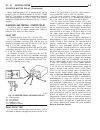

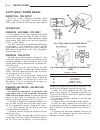

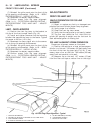

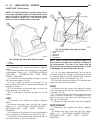

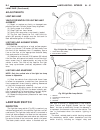

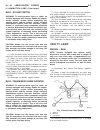

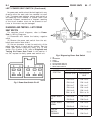

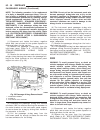

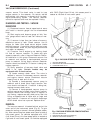

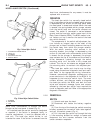

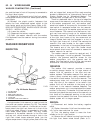

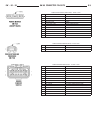

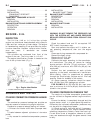

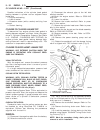

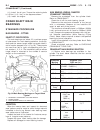

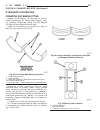

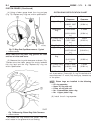

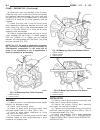

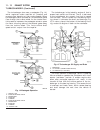

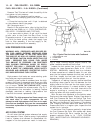

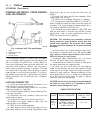

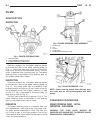

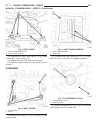

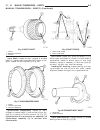

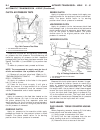

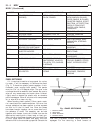

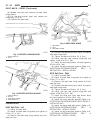

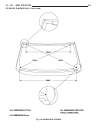

Sive tire wear. This angle is not adjustable, damaged component(s) must be replaced to correct the thrust angle (fig. 1) standard procedure standard procedure - height measurement ride height note: the suspension is non-adjustable. The vehicle suspension height should be measured before performing w...

Page 42

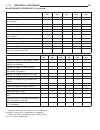

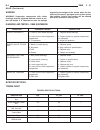

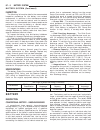

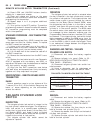

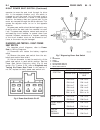

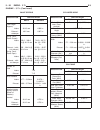

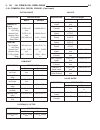

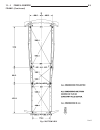

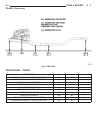

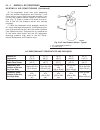

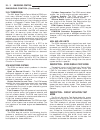

Measure- ment target minimum maximum front ride height distance ab 66.5 mm z=996.8 - 930.3 mm 56.5 mm 76.5 mm front cross ride height left - right 0.0 mm -10.0 mm 10.0 mm rear ride height distance cd 92.1 mm 82.1 mm 102.1 mm rear cross ride height left - right 0.0 mm -10.0 mm 10.0 mm standard proced...

Page 43

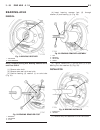

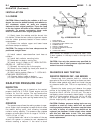

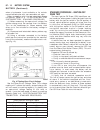

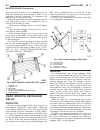

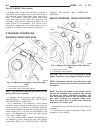

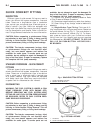

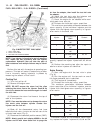

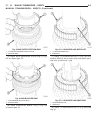

Camber move both of the cam bolts together in or out. This will change the camber angle significantly and caster angle slightly. (fig. 4) after adjustment is made tighten the cam bolt nuts to proper torque specification. Toe adjustment the wheel toe position adjustment is the final adjustment. (1) s...

Page 44: Front

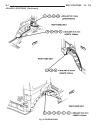

Front table of contents page page front description . . . . . . . . . . . . . . . . . . . . . . . . . . 7 warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 specifications torque chart . . . . . . . . . . . . . . . . . . . . . . 8 special tools front suspension . . . . . . . . . . ....

Page 45

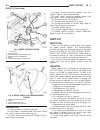

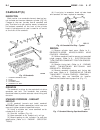

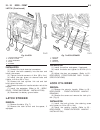

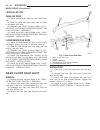

Warning warning: suspension components with rubber bushings must be tightened with the vehicle at nor- mal ride height. It is important to have the springs supporting the weight of the vehicle when the fas- teners are torqued. If springs are not at their normal ride position, vehicle ride comfort wi...

Page 46

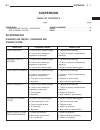

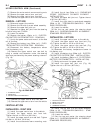

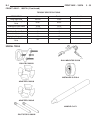

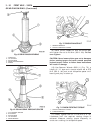

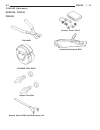

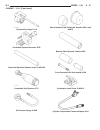

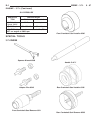

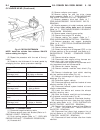

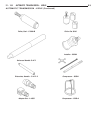

Description n·m ft. Lbs. In. Lbs. Stabilizer bar link upper nut 136 100 — stabilizer bar link lower nut 115 85 — hub/bearing bolt 130 96 — hub/bearing halfshaft nut 135 100 — upper ball joint nut 81 60 — lower ball joint nut 81 60 — wheel speed sensor 13.5 10 — special tools front suspension ball jo...

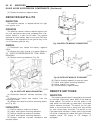

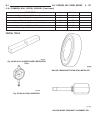

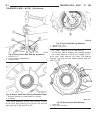

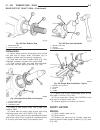

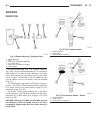

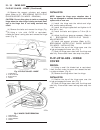

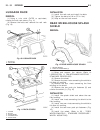

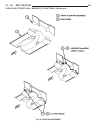

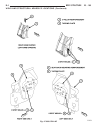

Page 47: Bushings

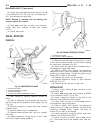

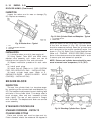

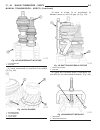

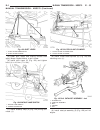

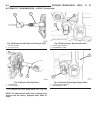

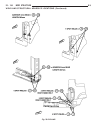

Bushings removal removal - stabilizer bar bushings (1) raise vehicle on hoist. (2) remove the stabilizer bushing clamps. (3) remove the stabilizer bushings from the stabi- lizer bar. Removal - lower control arm bushing (1) remove the lower control arm (refer to 2 - suspension/front/lower control arm...

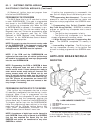

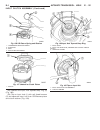

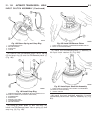

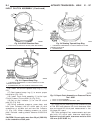

Page 48

Installation - lower control arm bushing note: extreme pressure lubrication must be used on the threaded portions of the tool. This will increase the longevity of the tool and insure proper operation during the removal and installation pro- cess. (1) install the new lower control arm bushings into t...

Page 49: Hub / Bearing

Installation - upper control arm bushings note: extreme pressure lubrication must be used on the threaded portions of the tool. This will increase the longevity of the tool and insure proper operation during the removal and installation pro- cess. (1) install the new upper control arm bushings into ...

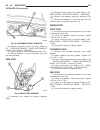

Page 50: Lower Ball Joint

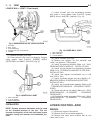

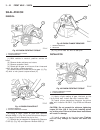

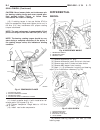

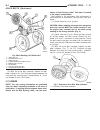

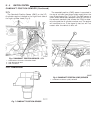

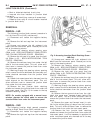

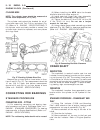

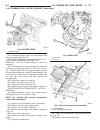

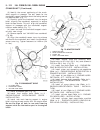

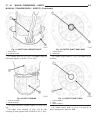

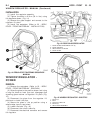

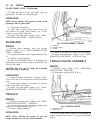

Caution: never allow the disc brake caliper to hang from the brake hose. Damage to the brake hose will result. Provide a suitable support to hang the caliper securely. (4) remove the disc brake rotor. (refer to 5 - brakes/hydraulic/mechanical/rotors - removal). (5) remove the wheel speed sensor. (re...

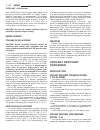

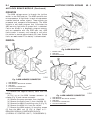

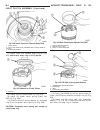

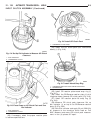

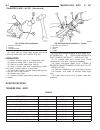

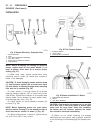

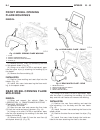

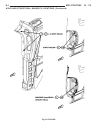

Page 51: Lower Control Arm

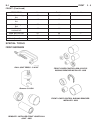

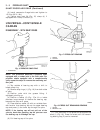

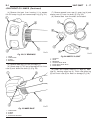

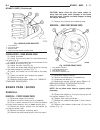

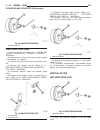

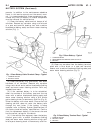

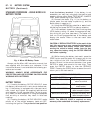

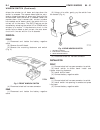

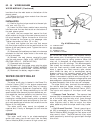

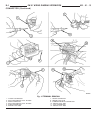

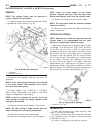

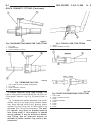

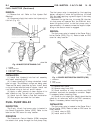

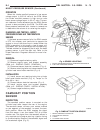

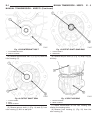

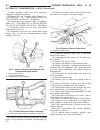

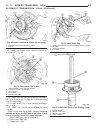

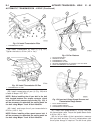

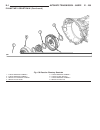

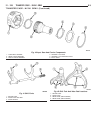

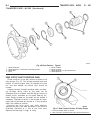

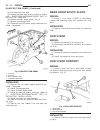

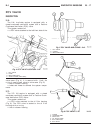

(7) remove the ball joint boot. (8) press the ball joint from the steering knuckle using special tools c-4212–f (press), 8859-2 (receiver) and 8859-1 (driver) (fig. 9). Installation note: extreme pressure lubrication must be used on the threaded portions of the tool. This will increase the longevity...

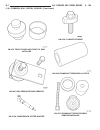

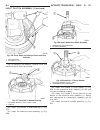

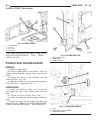

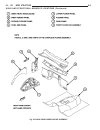

Page 52: Shock

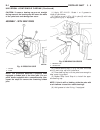

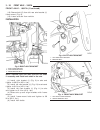

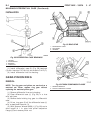

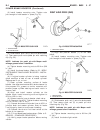

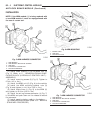

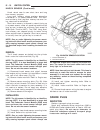

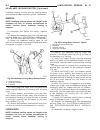

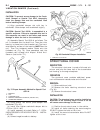

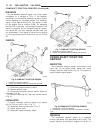

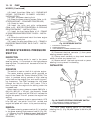

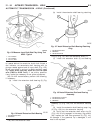

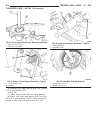

(4) remove the stabilizer link bolt at the lower control arm. (5) remove the lower ball joint nut. (6) separate the lower ball joint from the lower control arm using tool c-4150a. Note: marking the lower control arm pivot bolts front and rear will aid in the assembly procedure. (7) mark the lower co...

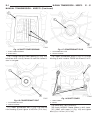

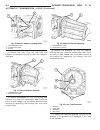

Page 53

(12) remove the shock assembly from the vehicle. (fig. 13) (13) remove the spring from the shock (if needed). (refer to 2 - suspension/front/spring - removal). Installation installation - left side (1) install the spring to the shock (if removed). (2) install the shock assembly to the vehicle. (3) i...

Page 54: Spring

(refer to 2 - suspension/front/stabilizer link - installation). (8) install the right tire and wheel assembly. (refer to 22 - tires/wheels/wheels - stan- dard procedure). (9) lower the vehicle. (10) install the cruise control servo mounting nuts. (11) install the airbox (refer to 9 - engine/air inta...

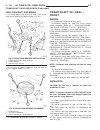

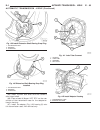

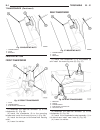

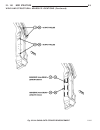

Page 55: Stabilizer Bar

(2) raise the lower control arm to the lower ball joint. (3) install the nut to the lower ball joint. Tighten the nut to 81 n·m (60 ft.Lbs.). (4) install the clevis bracket to the lower control arm. Tighten the bolt to 150 n·m (110 ft.Lbs.). (5) install the lower stabilizer link bolt at the lower co...

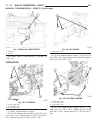

Page 56

(7) remove the cruise control servo mounting nuts. (8) remove the upper control arm rear bolt. (9) remove the upper control arm front bolt. (10) remove the upper control arm from the vehicle. Removal - left side (1) raise and support the vehicle. (2) remove the left side tire and wheel assembly. (3)...

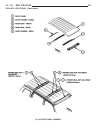

Page 57: Rear

Rear table of contents page page rear description . . . . . . . . . . . . . . . . . . . . . . . . . 20 warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 diagnosis and testing - rear suspension . . . . . . . . . . . . . . . . . . . . . . . . 21 specifications torque chart . . . . ....

Page 58

Warning warning: suspension components with rubber bushings must be tightened with the vehicle at nor- mal ride height. It is important to have the springs supporting the weight of the vehicle when the fas- teners are torqued. If springs are not at their normal ride position, vehicle ride comfort wi...

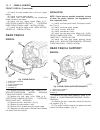

Page 59: Shock

Description n·m ft. Lbs. In. Lbs. Suspension arms lower body/axle bracket nut 163 120 — control arms to control arm bracket 101 75 — suspension arms lower frame bracket nut 163 120 — control arm bracket to rear differential 135 100 — rear differential damper to rear differential 61 45 — stabilizer b...

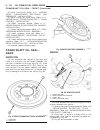

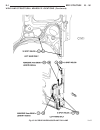

Page 60: Spring

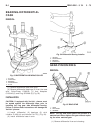

(4) tighten the upper mounting nuts to 108 n·m (80 ft. Lbs.). Tighten the lower mounting nuts to 115 n·m (85 ft. Lbs.). Spring removal (1) raise and support the vehicle. Position a hydraulic jack under the axle to support the axle. (2) remove the shock absorber lower bolt from the axle bracket. (3) ...

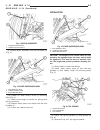

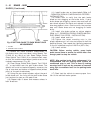

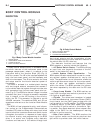

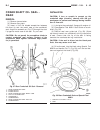

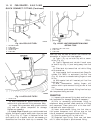

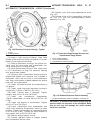

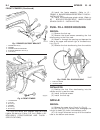

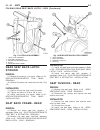

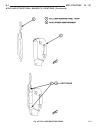

Page 61: Stabilizer Bar

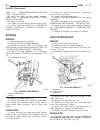

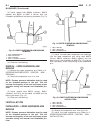

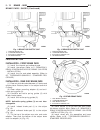

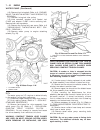

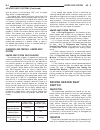

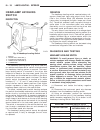

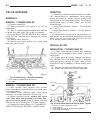

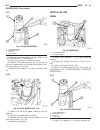

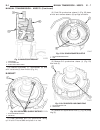

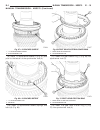

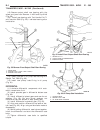

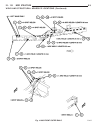

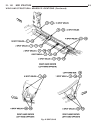

Stabilizer bar removal (1) raise and support the vehicle. (2) remove the stabilizer bar bolts from the lower suspension arm. (fig. 5). (3) remove the stabilizer bar. Installation (1) position the stabilizer bar over the axle and install the bolts to the lower suspension arm (fig. 6). Ensure the bar ...

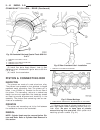

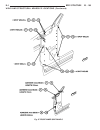

Page 62: Upper Control Arm

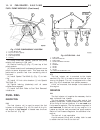

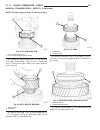

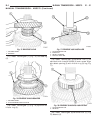

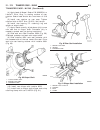

Installation (1) install special tools c-4212f (press), 8861-1 (receiver) and 8861-2 (driver) with the ball joint in place (fig. 9). (2) press the ball joint in the upper suspension arm. (3) remove the upper suspension arm from the vise. (4) reinstall the upper suspension arm (refer to 2 - suspensio...

Page 63: Lower Control Arm

(5) remove the supports and lower the vehicle. Lower control arm description the lower suspension arms are stamped steel and welded and use voided round bushings at the axle end and solid rubber at the body end of the arm. Operation the bushings provide isolation from the axle. The arms mount to the...

Page 64

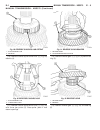

(3) install special tools 8862-4 (receiver), 8862-5 (spacer) and 8862-1 or 8862- 2 (driver) with the threaded rod 8839 and the bearing as shown (fig. 13) (4) press out the bushing. Removal - upper suspension arm bushing (1) remove the upper suspension arm (refer to 2 - suspension/rear/upper control ...

Page 65

Installation - upper suspension arm bushing note: extreme pressure lubrication must be used on the threaded portions of the tool. This will increase the longevity of the tool and insure proper operation during the removal and installation pro- cess. (1) install the new upper suspension arm bushings ...

Page 66: Differential & Driveline

Differential & driveline table of contents page page propeller shaft . . . . . . . . . . . . . . . . . . . . . . 1 half shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 front axle - 186fia . . . . . . . . . . . . . . . . . . . . 20 rear axle - 8 1/4 . . . . . . . . . . . . . . . . . . ...

Page 67

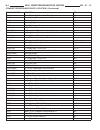

Driveline vibration drive condition possible cause correction propeller shaft noise 1. Undercoating or other foreign material on shaft. 1. Clean exterior of shaft and wash with solvent. 2. Loose u-joint clamp screws. 2. Install new clamps and screws and tighten to proper torque. 3. Loose or bent u-j...

Page 68

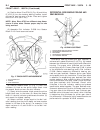

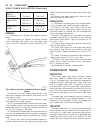

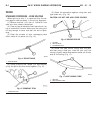

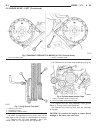

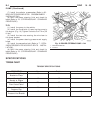

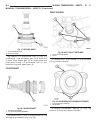

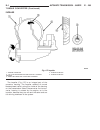

Positions, the source of the vibration may not be pro- peller shaft. (10) if vibration decreased, install a second clamp (fig. 2) and repeat the test. (11) if the additional clamp causes an additional vibration, separate the clamps (1) (fig. 3) (1/4 inch above and below the mark). Repeat the vibrati...

Page 69

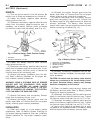

Note: always make measurements from front to rear and from the same side of the vehicle. (4) place inclinometer (1) (fig. 4) on yoke bearing cap (2) or pinion flange ring parallel to the shaft. Center bubble in sight glass and record measure- ment. This measurement will give you the transmis- sion o...

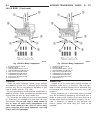

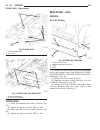

Page 70: Shaft-Propeller Front

Specifications torque specifications description n·m ft. Lbs. In. Lbs. Front shaft - companion flange bolts 30 22 - rear shaft - companion flange bolts 115 85 - special tools shaft-propeller front removal 2.8l diesel (1) with vehicle in neutral, position vehicle on hoist. (2) remove left side exhaus...

Page 71: Shaft-Propeller Rear

Gas engines (1) with vehicle in neutral, position vehicle on hoist. (2) mark companion flanges and c/v joints at the front and rear of the propeller shaft for installation reference. (3) remove bolts (1) (fig. 9) from the front and rear c/v joints (2). (4) push propeller shaft forward to clear trans...

Page 72

(2) mark a reference line (3) (fig. 11) across com- panion flanges (2) (4) and propeller shaft (1) for installation. (3) pry open clamp holding the dust boot (2) (fig. 12) to propeller shaft yoke, if equipped. (4) on 4x2 vehicles with manual transmission remover transmission companion flange (1) bol...

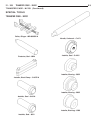

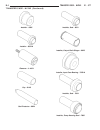

Page 73: Universal Joint-Single

(3) install companion flange bolts and tighten to 115 n·m (85 ft. Lbs.). (4) tighten dust boot (3) (fig. 15) clamp (4) if equipped with clamp c-4975a (1). Universal joint-single cardan disassembly - with snap rings note: this procedure describes a propeller shaft equipped with a cardan joint in the ...

Page 74

Caution: if cross or bearing cap are not straight during removal, the bearing cap will score the walls of the yoke bore and damage can occur. Assembly - with snap rings note: this procedure describes a propeller shaft equipped a cardan joint in the tube yoke. For pro- peller shafts equipped with a c...

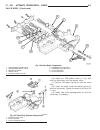

Page 75: Half Shaft

Half shaft table of contents page page half shaft caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 diagnosis and testing half shaft . . . . . . . . . . . . . . . . . . . . . . . . . 10 removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 installation . . . . . . ....

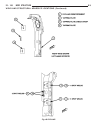

Page 76

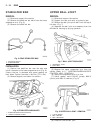

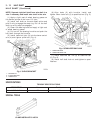

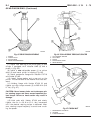

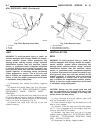

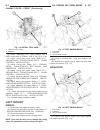

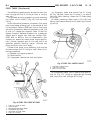

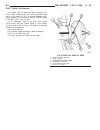

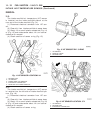

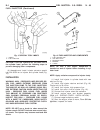

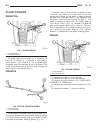

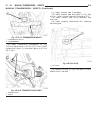

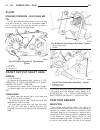

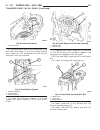

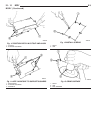

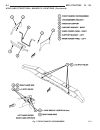

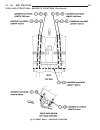

(3) remove stabilizer link (2) (fig. 1) from stabi- lizer bar (1). (4) remove clevis bracket (2) lower bolt (3) (fig. 2). (5) remover lower ball joint nut (3) and separate lower ball joint from the lower control arm (4) (fig. 3). (6) pull out on the steering knuckle and push the half shaft out of th...

Page 77

Note: seperate right half shaft from axle shaft in a vise if necessary and install axle shaft in the axle. (1) apply a light coat of wheel bearing grease on the female splines of the inner c/v joint. (2) install half shaft on the axle shaft spline and push firmly to engage the snap ring. Pull on the...

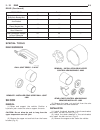

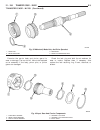

Page 78: Joint/boot-C/v Outer

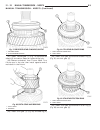

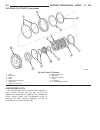

Joint/boot-c/v outer removal (1) place shaft in vise with soft jaws and support c/v joint. Caution: do not damage c/v housing or half shaft. (2) remove clamps (2) (4) with a cut-off wheel or grinder (fig. 7). (3) slide the boot down the shaft. (4) remove lubricant to expose the c/v joint snap ring. ...

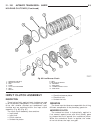

Page 79

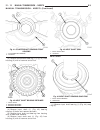

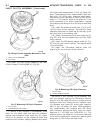

(10) remove ball (4) from the bearing cage (3) (fig. 10). (11) repeat step above until all six balls are removed from the bearing cage. (12) lift cage and inner race (2) upward and out from the housing (1) (fig. 11). (13) turn inner race 90° in the cage and rotate the inner race/hub out of the cage ...

Page 80

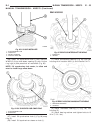

(4) rotate inner race/hub in the cage (1) (fig. 14). (5) insert cage into the housing (3) (fig. 15). (6) rotate cage 90° into the housing (1) (fig. 16). (7) apply lubricant included with replacement boot/joint to the ball races. Spread lubricant equally between all the races. (8) tilt inner race/hub...

Page 81: Joint/boot-C/v Inner

(11) push the joint onto the shaft until the snap ring (1) seats in the groove (3) (fig. 18). Pull on the joint to verify the span ring has engaged. (12) position boot on the joint in it’s original posi- tion. Ensure boot is not twisted and remove any excess air. (13) secure both boot clamps (2) (4)...

Page 82

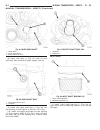

(4) remove lubricant from housing (1) to expose the c/v snap ring (2) and remove snap ring (fig. 21). (5) remove bearings (4) from the cage (1). (6) rotate cage (1) 30° and slide cage off the inner race (2) and down the shaft (3) (fig. 22). (7) remove spread inner race (1) snap ring (4) and remove r...

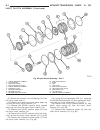

Page 83

Installation (1) apply a coat of grease supplied with the joint/ boot to the c/v joint components before assembling them. (2) place new clamps on the new boot and slide boot down the shaft. (3) slide cage (2) (fig. 25) onto the shaft (1) with the small diameter (3) end towards the boot. (4) install ...

Page 84

(7) apply grease to the inner race and bearings and install the bearings. (8) apply grease to the housing bore (4) (fig. 28) then install the bearing assembly (2) into the hous- ing (1). (9) install the housing snap ring (3) and verify it is seated in the groove. (10) fill the housing and boot with ...

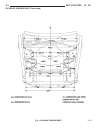

Page 85: Front Axle - 186Fia

Front axle - 186fia table of contents page page front axle - 186fia diagnosis and testing front axle - 186fia . . . . . . . . . . . . . . . . . 20 removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 installation . . . . . . . . . . . . . . . . . . . . . . . . . 26 adjustments . . . ...

Page 86

• loose wheel lug nuts. • worn u-joints/cv joint. • loose/broken springs. • damaged axle shaft bearing(s). • loose pinion gear nut. • excessive pinion yoke run out. • bent axle shaft(s). Check for loose or damaged front-end components or engine/transmission mounts. These components can contribute to...

Page 87

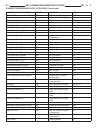

Condition possible causes correction differential cracked 1. Improper adjustment of the differential bearings. 1. Replace case and inspect gears and bearings for further damage. Set differential bearing pre-load properly. 2. Excessive ring gear backlash. 2. Replace case and inspect gears and bearing...

Page 88

Condition possible causes correction gear teeth broke 1. Overloading. 1. Replace gears. Examine other gears and bearings for possible damage. 2. Erratic clutch operation. 2. Replace gears and examine the remaining parts for damage. Avoid erratic clutch operation. 3. Ice-spotted pavement. 3. Replace ...

Page 89

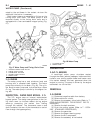

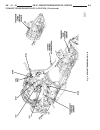

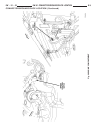

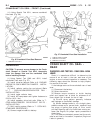

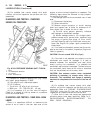

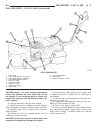

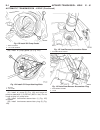

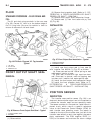

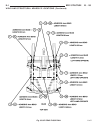

Removal (1) with vehicle in neutral, position vehicle on hoist. (2) remove skid plate. (3) remove differential housing (3) drain plug (2) and drain fluid (fig. 1). (4) mark front propeller shaft and pinion flange. Remove propeller shaft from pinion flange. (5) remove half shaft hub nuts. (6) remove ...

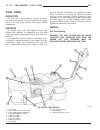

Page 90

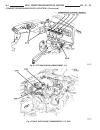

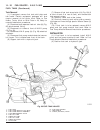

Note: right half shaft has a splined axle that may come out with the half shaft. (12) remove differential vent hose from cover and remove drain trough (1) nut (2) (fig. 5). (13) support axle with a lift/jack. (14) remove bolts from left front axle bracket (1) and cradle bracket bolt (fig. 6). (15) r...

Page 91

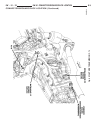

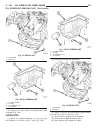

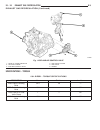

(18) remove bolt (2) from left rear axle bracket (1) frame mount (fig. 8). (19) lower axle and from vehicle. Installation note: separate right axle shaft from the half shaft if necessary and install axle shaft in the axle. (1) install right bracket (1) (fig. 9) to axle and tighten to 88 n·m (65 ft. ...

Page 92

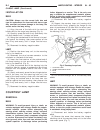

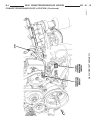

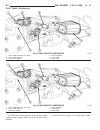

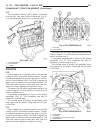

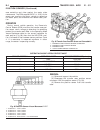

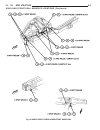

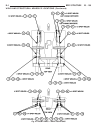

(7) install right front control arm cam bolt (1) (fig. 12) with marks aligned. (8) install lower ball joint into lower control arms (4) and tighten nuts (3). (9) align clevis with knuckles and install clevis bolts. (10) install stabilizer bar (1) (fig. 13) links (2) to lower control arms and install...

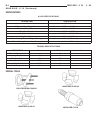

Page 93

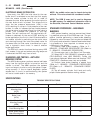

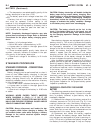

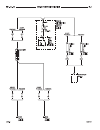

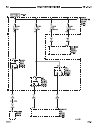

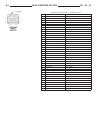

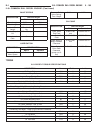

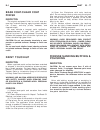

Pinion gear depth variance original pinion gear depth variance replacement pinion gear depth variance 2 4 2 3 2 2 2 1 0 +1 +2 +3 +4 +4 +0.008 +0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 0 +3 +0.007 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 0 2 0.001 +2 +0.006 +0.005 +0.004 +0.003 +0.002 +0.001 ...

Page 94

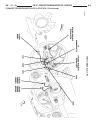

(4) position arbor disc 6732 (2) (fig. 16) and arbor d-115-3 (3) into the housing bearing cradles. Install differential bearing caps on arbor discs and tighten bolts to 41 n·m (30 ft. Lbs.). Note: arbor discs 6732 has different step diame- ters to fit other axles. Choose proper step for axle being s...

Page 95

Preload shim selection note: it is difficult to salvage the differential side bearings during the removal procedure. Install replacement bearings if necessary. (1) remove differential side bearings from differ- ential case. (2) install ring gear on differential case and tighten bolts to specificatio...

Page 96

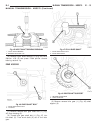

(8) with a dead-blow hammer (2) (fig. 22), seat the differential dummy bearings to the ring gear (3) side of the housing (1). (9) thread pilot stud c-3288-b (2) (fig. 23) into rear cover bolt hole below ring gear. (10) attach a dial indicator c-3339 (3) to the pilot stud. Position the dial indicator...

Page 97

The shim thickness required on the pinion side of the axle housing. (25) rotate dial indicator out of the way on pilot stud. (26) remove differential case and dummy bearings from the housing. (27) install side bearings and cups on differential case. (28) install spreader w-129-b with adapter set 698...

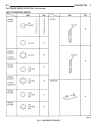

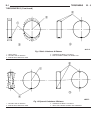

Page 98

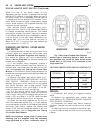

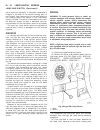

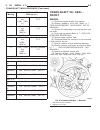

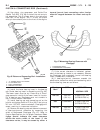

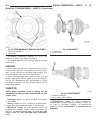

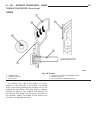

Gear contact pattern the ring gear and pinion teeth contact patterns will show if the pinion depth is correct in the hous- ing. It will also show if the ring gear backlash has been adjusted correctly. The backlash can be adjusted within specifications to achieve desired tooth contact patterns. The t...

Page 99

Fig. 30 pattern interpretation (gear cut 2 axis) fig. 31 pinion rotating torque 1 - pinion companion flange 2 - torque wrench 3 - 34 front axle - 186fia kj front axle - 186fia (continued).

Page 100

Torque specifications description n·m ft. Lbs. In. Lbs. Ring gear bolts 95-122 70-90 - differential bearing cap bolts 54-67 39-50 - differential cover bolts 19-26 14-19 - pinion nut 217-352 160-260 - left axle bracket bolts 61 45 - front axle bracket bolts 61 45 - right axle bracket bolts 88 65 - ax...

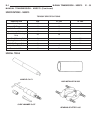

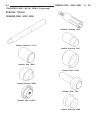

Page 101

Remover c-4307 installer c-4308 puller c-452 installer d-146 remover d-149 dummy bearings d-348 plug sp-3289 spreader w-129-b installer w-162-d installer 6448 3 - 36 front axle - 186fia kj front axle - 186fia (continued).

Page 102

Pinion depth set 6774 spanner wrench 6958 adapter kit 6987b remover 7794-a dummy shims 8107 cup 8109 remover 8420a installer 8681 kj front axle - 186fia 3 - 37 front axle - 186fia (continued).

Page 103: Cover-Differential

Cover-differential removal (1) with vehicle in neutral, position vehicle on hoist. (2) remove skid plate. (3) remove drain plug (2) (fig. 32) from housing (3) and drain fluid. (4) remove oil trough (1) (fig. 33) bolt from axle bracket. (5) remove oil trough nut (2) from differential cover. (6) loose...

Page 104

Caution: if cover is not installed within 3 to 5 min- utes, the cover must be cleaned and new rtv applied. Failure to follow these instructions will result in a leak. (3) install differential housing cover (1) (fig. 36) and tighten bolts in a criss-cross pattern to 19-26 n·m (14-19 ft. Lbs.). (4) in...

Page 105: Shaft-Axle

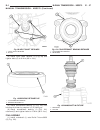

Shaft-axle removal (1) with vehicle in neutral, position vehicle on hoist. (2) remove right half shaft from vehicle. (3) remove snap ring and o-ring from axle shaft. (4) assemble remover 8420a blocks (3) (fig. 37) with hammer threads (2) on snap ring groove (1) on the shaft. Slide collar (4) over bl...

Page 106: Bearing-Axle

Installation (1) apply a light coat of lubricant on the lip of the shaft seal. (2) install new shaft seal with installer 8806 (2) (fig. 40) and handle c-4171(1). (3) install right axle shaft if removed. (4) install half shaft. Bearing-axle removal (1) remove half shaft. (2) remove axle shaft for rig...

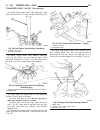

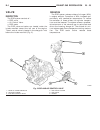

Page 107: Seal-Pinion

Seal-pinion removal (1) with vehicle in neutral, position vehicle on hoist. (2) remove brake calipers and rotors. (3) remove propeller shaft. (4) rotate pinion gear a minimum of ten times and verify the pinion rotates smoothly. (5) record torque to rotate the pinion gear (1) (fig. 43) with a inch po...

Page 108: Differential

Caution: never loosen pinion nut to decrease pin- ion rotating torque and never exceed specified pre- load torque. Failure to follow these instructions will result in damage. (4) rotate pinion a minimum of ten time and ver- ify pinion rotates smoothly. Rotate the pinion shaft (1) (fig. 46) with an i...

Page 109

(5) position spreader w-129-b (3) (fig. 49) onto differential locating holes and install the safety hold- down clamps (2). Tighten spreader turnbuckle (4) fin- ger-tight. (6) install a pilot stud c-3288-b (1) (fig. 50) at the left side of the differential housing. Attach dial indicator c-3339 (2) to...

Page 110

(3) remove pinion gear mate shaft. (4) rotate differential side gears (2) (fig. 52) and remove pinion gears (3) and thrust washers (1). (5) remove differential side gears and thrust washers. Assembly (1) install differential side gears (2) (fig. 53) and thrust washers. (2) install pinion mate gears ...

Page 111: Bearing-Differential

(2) install pilot stud c-3288-b to the left side of the differential housing. Attach dial indicator c-3339 to pilot stud. Load indicator plunger against the opposite side of the housing and zero the indicator. (3) spread housing while measuring the distance with the dial indicator. Caution: never sp...

Page 112: Gear-Pinion/ring

Installation (1) install differential case (2) (fig. 58) bearings (3) with installer c-3716-a (4) and handle c-4171(1). (2) install differential into the housing. Gear-pinion/ring removal note: the ring gear and pinion are serviced as a matched set. Never replace ring gear without replacing the matc...

Page 113

(6) remove pinion companion flange from pinion shaft with spanner wrench 6958 (1) (fig. 61) and remover c-452 (2). (7) remove pinion gear from housing with dead- blow hammer (1) (fig. 62).. (8) remove front pinion bearing cup, bearing, oil slinger and pinion seal with remover c-149 (1) (fig. 63) and...

Page 114

(10) remove collapsible spacer (1) (fig. 65) from pinion gear (3). (11) remove rear pinion bearing from the pinion (4) (fig. 66) with puller/press c-293-pa (1) and adapters c-293-42 (3). Remove oil slinger/pinion depth shim from the pinion shaft and record thick- ness. Installation (1) install front...

Page 115

(9) install pinion a new nut onto the pinion gear and tighten the nut to 216 n·m (160 ft. Lbs.). Do not over-tighten. Caution: never loosen pinion gear nut to decrease pinion rotating torque and never exceed specified preload torque. Failure to follow these instructions will result in damage. (10) u...

Page 116

(12) rotate the pinion a minimum of ten times. Verify pinion (1) (fig. 71) rotates smoothly and check rotating torque with an inch pound torque wrench (2). Pinion gear rotating torque is: • original bearings: 1 to 2.25 n·m (10 to 20 in. Lbs.). • new bearings: 1.69 to 2.82 n·m (15 to 25 in. Lbs.). (1...

Page 117: Rear Axle - 8 1/4

Rear axle - 8 1/4 table of contents page page rear axle - 8 1/4 diagnosis and testing . . . . . . . . . . . . . . . . 52 removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 installation . . . . . . . . . . . . . . . . . . . . . . . . . 56 adjustments . . . . . . . . . . . . . . . . ...

Page 118

• missing drive shaft balance weight(s). • worn or out-of-balance wheels. • loose wheel lug nuts. • worn u-joints/cv joint. • loose/broken springs. • damaged axle shaft bearing(s). • loose pinion gear nut. • excessive pinion yoke run out. • bent axle shaft(s). Check for loose or damaged front-end co...

Page 119

Condition possible causes correction differential gears scored 1. Insufficient lubrication. 1. Replace scored gears. Fill differential with the correct fluid type and quantity. 2. Improper grade of lubricant. 2. Replace scored gears. Fill differential with the correct fluid type and quantity. 3. Exc...

Page 120

Condition possible causes correction axle noise 1. Insufficient lubricant. 1. Fill differential with the correct fluid type and quantity. 2. Improper ring gear and pinion adjustment. 2. Check ring gear and pinion contact pattern. Adjust backlash or pinion depth. 3. Unmatched ring gear and pinion. 3....

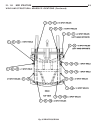

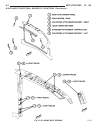

Page 121

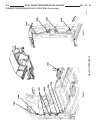

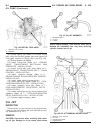

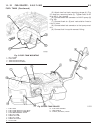

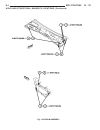

(9) remove shock absorbers from axle brackets (2) (fig. 3). (10) loosen all lower control arms (2) mounting bolts (fig. 4). (11) lower axle enough to remove coil springs and spring insulators. (12) remove lower control arm bolts from the axle brackets (1). (13) lower and remove the axle. Installatio...

Page 122

(5) install upper control arm ball joint (1) into axle bracket and tighten pinch bolt (2) to torque specifica- tion (fig. 7). (6) install shock absorbers and tighten bolts (2) to torque specification (fig. 8). (7) install stabilizer bar and tighten nuts to torque specification. (8) install brake com...

Page 123

Compensation for pinion depth variance is achieved with select shims (4). The shims are placed behind the rear pinion bearing (fig. 10). If installing a new gear, note the depth variance number of the original and replacement pinion. Add or subtract this number from the original depth shim/oil sling...

Page 124

• mark the gears so the same teeth are meshed during all backlash measurements. • maintain the torque while adjusting the bearing preload and ring gear backlash. • excessive adjuster torque will introduce a high bearing load and cause premature bearing failure. Insufficient adjuster torque can resul...

Page 125

Note: the differential bearing cups will not always immediately follow the threaded adjusters as they are moved during adjustment. To ensure accurate bearing cup responses to the adjustments: • maintain the gear teeth engaged (meshed) as marked. • the bearings must be seated by rapidly rotat- ing th...

Page 126

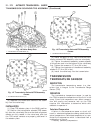

By moving ring away from the pinion gear using the adjusters. Ring gear is too far away from the pinion gear, drive side heel (1) coast side heel (2) (fig. 19). Decrease backlash by moving ring gear closer to the pinion gear using the adjusters. Ring gear is too close to the pinion gear, drive side ...

Page 127

Pinion gear is set too high. Decrease pinion height by decreasing the pinion depth shim thickness (fig. 22). Side gear clearance when measuring side gear clearance, check each gear independently. If it necessary to replace a side gear, replace both gears as a matched set. (1) install axle shafts and...

Page 128

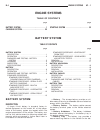

Specifications axle specifications description specification axle ratio 3.55, 3.73, 4.10 differential case flange runout 0.076 mm (0.003 in.) differential case clearance 0.12 mm (0.005 in.) ring gear diameter 209.5 mm (8.25 in.) ring gear backlash 0.12-0.20 mm (0.005-0.008 in.) ring gear runout 0.12...

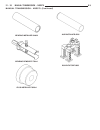

Page 129

Dial indicator c-3339 installer c-4076-b adjustment wrench c-4164 handle c-4171 installer c-4198 remover c-4307 installer c-4308 installer c-4340 remover c-4345 puller c-452 3 - 64 rear axle - 8 1/4 kj rear axle - 8 1/4 (continued).

Page 130

Handle c-4735 installer d-130 adapter plug sp-3289 remover 6310 installer 6448 holder 6719a pinion gauge set 6774 fixture 8138 pinion block 8540 arbor discs 8541 kj rear axle - 8 1/4 3 - 65 rear axle - 8 1/4 (continued).

Page 131: Cover-Differential

Cover-differential removal (1) with vehicle in neutral, position vehicle on hoist. (2) remove drain plug. (3) remove cover bolts. (4) remove cover and drain lubricant. Installation (1) apply a bead of orange mopar axle rtv seal- ant (1) or equivalent to the housing cover (2) (fig. 25). Caution: if c...

Page 132: Seal-Axle Shaft

Installation (1) lubricate bearing bore and seal lip with gear lubricant. (2) install axle shaft through seal, bearing and engage into side gear splines. (3) install c-lock in axle shaft end, then push axle shaft outward to seat c-lock in side gear. (4) install pinion mate shaft (1) into differentia...

Page 133: Bearing-Axle

Bearing-axle removal note: remove bearing with bearing remover 6310 and foot 6310-9. (1) remove axle shaft. (2) remove axle seal with seal pick. (3) position bearing (2) receiver (1) on axle tube (fig. 31). (4) insert bearing remover foot (3) through receiver (2) and bearing (1) (fig. 32). (5) tight...

Page 134: Seal-Pinion

(2) install axle shaft bearing with installer c-4198 (1) and handle c-4171 (2) (fig. 34). Drive bearing in until tool contacts the axle tube. Note: bearing is installed with the bearing part number against the installer. (3) coat new axle seal lip with axle lubricant. Install seal with installer c-4...

Page 135

Caution: do not exceed the minimum tightening torque when installing the companion flange retain- ing nut at this point. Failure to heed caution may result in damage. (8) hold companion flange with holder 6719 (2) and with a torque wrench (3) tighten pinion nut to 285 n·m (210 ft. Lbs.) (fig. 39). R...

Page 136: Differential

Caution: never loosen pinion nut to decrease pin- ion bearing rotating torque and never exceed spec- ified preload torque. Failure to follow these instructions will result in damage. (10) if rotating torque is low use holder 6719 to hold the companion flange and tighten pinion nut in 6.8 n·m (5 ft. ...

Page 137

(7) loosen differential bearing cap bolts (2) (fig. 43). (8) loosen differential bearing adjusters through the axle tubes (1) with wrench c-4164 (3) (fig. 44). (9) hold differential case while removing bearing caps and adjusters. (10) remove differential case and tag differential bearing cups and ad...

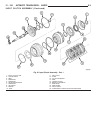

Page 138

Assembly note: if same gears and thrust washers are being used, install them into their original locations. (1) lubricate all differential components with axle lubricant. (2) install differential side gears (2) and thrust washers through differential window (1) (fig. 48). (3) install first pinion ge...

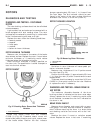

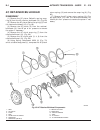

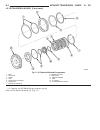

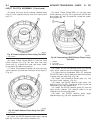

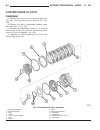

Page 139: Differential-Trac-Lok

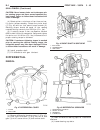

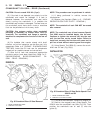

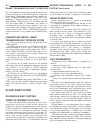

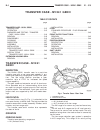

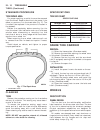

Differential-trac-lok operation this differentials clutches are engaged by two con- current forces. The first being the preload force exerted through belleville spring washers within the clutch packs (6). The second is the separating forces generated by the side gears (7) as torque is applied throug...

Page 140: Bearing-Differential

Bearing-differential case removal (1) remove differential case from axle. (2) remove differential bearings (3) from the case with puller/press c-293-pa (1) and adapters c-293-48 (2) and plug sp-3289 (5) (fig. 53). Installation caution: if equipped with vari-lok t , plenum must be seated against the ...

Page 141

(2) place differential case (1) in a vise with soft metal jaw. (3) remove bolts holding ring gear (2) to differen- tial case. (4) drive ring gear from differential case with a dead-blow hammer (3) (fig. 55). (5) hold flange yoke (1) with holder 6719a and remove flange nut and washer. (6) remove flan...

Page 142

(11) remove rear bearing cup with remover c-4307 (1) and handle c-4171 (2) (fig. 59). (12) remove collapsible spacer (1) from pinion (3) (fig. 60). (13) remove rear pinion bearing with puller/press c-293-pa (1) and adapters c-293-47 (3) (fig. 61). (14) remove depth shims from the pinion shaft and re...

Page 143

Installation note: a pinion depth shim/oil baffle is placed between the rear pinion bearing cone and pinion gear. If ring and pinion gears are reused, the origi- nal pinion depth shim/oil baffle can be used. Refer to adjustments (pinion gear depth) to select the proper shim thickness if ring and pin...

Page 144

(7) install rear bearing (4) on pinion gear (3) and slinger if equipped, with installer 6448 (2) and a press (1) (fig. 65). (8) install a new collapsible spacer (1) on pinion shaft (3) and install pinion in housing (fig. 66). (9) install companion flange with installer c-3718 and holder 6719a. (10) ...

Page 145

(13) check pinion (1) rotating torque with an inch pound torque wrench (2) (fig. 68). The pinion gear rotating torque should be: • original bearings: 1 to 2 n·m (10 to 20 in. Lbs.). • new bearings: 1 to 5 n·m (10 to 30 in. Lbs.). (14) install ring gear (3) on differential case (4) and start two ring...

Page 146: Brakes

Brakes table of contents page page brakes - base . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 brakes - abs . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 brakes - base table of contents page page brakes - base description . . . . . . . . . . . . . . . . . . . . . . . . . . 2 war...

Page 147: Brakes - Base

Pedal description . . . . . . . . . . . . . . . . . . . . . . . . . 22 operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 installation . . . . . . . . . . . . . . . . . . . . . . . . . 23 power brake booster descrip...

Page 148

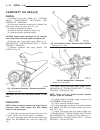

Warning warning: dust and dirt accumulating on brake parts during normal use may con- tain asbestos fibers from aftermarket linings. Breathing excessive concentra- tions of asbestos fibers can cause seri- ous bodily harm. Exercise care when servicing brake parts. Do not clean brake parts with compre...

Page 149

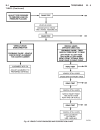

Road testing (1) if complaint involved low brake pedal, pump pedal and note if it comes back up to normal height. (2) check brake pedal response with transmission in neutral and engine running. Pedal should remain firm under constant foot pressure. (3) during road test, make normal and firm brake st...

Page 150

A common and frequently misdiagnosed pull condi- tion is where direction of pull changes after a few stops. The cause is a combination of brake drag fol- lowed by fade at one of the brake units. As the dragging brake overheats, efficiency is so reduced that fade occurs. Since the opposite brake unit...

Page 151

Bleed only one brake component at a time in the following sequence: • master cylinder • junction block • right rear wheel • left rear wheel • right front wheel • left front wheel follow the manufacturers instructions carefully when using pressure equipment. Do not exceed the tank manufacturers press...

Page 152

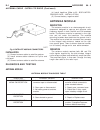

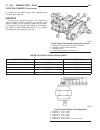

Specifications brake components specifications description specification disc brake rotor diameter front 288 x 28 mm (11.3 x 1.102 in) disc brake rotor diameter rear 285 x 12 mm (11 x 0.472 in) disc brake rotor ventilated front max. Runout 0.102 mm (0.004 in.) disc brake rotor solid rear max. Runout...

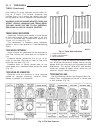

Page 153: Brake Lines

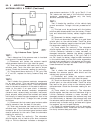

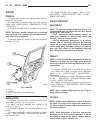

Special tools base brakes brake lines description flexible rubber hose is used at both front and rear brakes and at the rear axle junction block. Double walled steel tubing is used to connect the master cyl- inder to the major hydraulic braking components and then to the flexible rubber hoses. Doubl...

Page 154

(8) insert plug on gauge in the tube. Then swing compression disc over gauge and center tapered flar- ing screw in recess of compression disc (fig. 3). (9) tighten tool handle until plug gauge is squarely seated on jaws of flaring tool. This will start the inverted flare. (10) remove the plug gauge ...

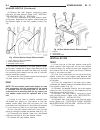

Page 155

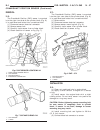

(2) remove the brake line (1) from the brake hose inside the engine compartment by the front control arm bolt (2) (fig. 5). (3) raise and support vehicle. (4) remove the brake hose banjo bolt at the cali- per. (5) remove the mounting bolt for the top of the brake hose (1) at the vehicle (fig. 6). (6...

Page 156: Brake Pads / Shoes

Installation - rear brake hose (1) install the hose. (2) install the mounting bolt for the brake hose at the axle (fig. 8). (3) install the two brake lines at the bottom of the hose located at the axle (fig. 8). (4) install the vent tube (fig. 8). (5) install the brake hose mounting bolt at the top ...

Page 157

Installation installation - front brake pads (1) install the inboard and outboard pads. (2) install the caliper (refer to 5 - brakes/hy- draulic/mechanical/disc brake calipers - installation). (3) install the tire and wheel assembly. (refer to 22 - tires/wheels/wheels - standard pro- cedure). Instal...

Page 158: Disc Brake Calipers

(10) apply brakes several times to seat caliper pis- tons and brake shoes and obtain firm pedal. (11) top off master cylinder fluid level. Disc brake calipers description the calipers are a single piston type. The calipers are free to slide laterally, this allows continuous com- pensation for lining...

Page 159

Removal front (1) install prop rod on the brake pedal to keep pressure on the brake system. (2) raise and support vehicle. (3) remove front wheel and tire assembly. (4) remove the brake hose banjo bolt (4) if replac- ing caliper (fig. 16). (5) remove the caliper mounting slide pin bolts (2) (fig. 16...

Page 160

Warning: never attempt to catch the pis- ton as it leaves the bore. This may result in personal injury. (5) remove caliper piston dust boot with suitable pry tool (fig. 20). (6) remove caliper piston seal with wood or plastic tool (fig. 21). Do not use metal tools as they will scratch piston bore. (...

Page 161

Caution: if the caliper piston is replaced, install the same type of piston in the caliper. Never inter- change phenolic resin and steel caliper pistons. The pistons, seals, seal grooves, caliper bore and piston tolerances are different. The bore can be lightly polished with a brake hone to remove v...

Page 162

Installation front (1) install caliper (1) to the caliper adapter. (2) coat the caliper mounting slide pin bolts (2) with silicone grease. Begin with the bolt closet to the bleeder screws (top), then install and tighten the bolts to 15 n·m (11 ft. Lbs.). (3) install the brake hose banjo bolt (4) if ...

Page 163: Disc Brake Caliper

Rear (1) install the brake pads if removed. (2) lubricate ant-rattle clips (2) for the disc brake pads (fig. 30). (3) install caliper to the caliper adapter. (4) coat the caliper mounting slide pin bolts (1) with silicone grease. Then install and tighten the bolts to 15 n·m (11 ft. Lbs.). (5) instal...

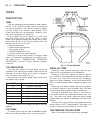

Page 164: Rotors

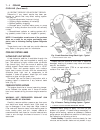

Rotors diagnosis and testing diagnosis and testing - disc brake rotor the rotor braking surfaces should not be refinished unless necessary. Light surface rust and scale can be removed with a lathe equipped with dual sanding discs. The rotor surfaces can be restored by machining in a disc brake lathe...

Page 165

Causes the drum in hat rotor to exceed the maximum allowable diameter. Standard procedure standard procedure - disc brake rotor the disc brake rotor can be machined if scored or worn. The lathe must machine both sides of the rotor simultaneously with dual cutter heads. The rotor mounting surface mus...

Page 166: Brake Junction Block

Installation front (1) install the disc brake rotor (1) to the hub. (2) install the caliper mounting adapter (2) (fig. 36). (refer to 5 - brakes/hydraulic/mechani- cal/disc brake caliper adapter - instal- lation). (3) install the tire and wheel assembly. (refer to 22 - tires/wheels/wheels - standard...

Page 167: Pedal

Removal (1) install prop rod on the brake pedal to keep pressure on the brake system. (2) remove the brake lines from the junction block (2). (3) remove mounting nuts (3) and remove the junction block (3) (fig. 38). Installation (1) install the junction block (2) on the mounting studs. (2) install m...

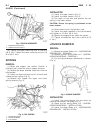

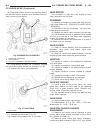

Page 168: Power Brake Booster

Operation the brake pedal(4) is attached to the booster push rod (5). When the pedal is depressed, the primary booster push rod (5) is depressed which move the booster secondary rod. The booster secondary rod depress the master cylinder piston (1) (fig. 41). Removal (1) remove the knee blocker under...

Page 169

Two push rods are used in the booster. The pri- mary push rod connects the booster to the brake pedal. The secondary push rod connects the booster to the master cylinder to stroke the cylinder pistons. The booster assembly is of the tie-bar design. This means the structural support of the assembly i...

Page 170

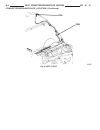

(3) observe the vacuum supply. If vacuum supply is not adequate, repair vacuum supply. (4) clamp hose shut between vacuum source and check valve. (5) stop engine and observe vacuum gauge. (6) if vacuum drops more than one inch hg (33 millibars) within 15 seconds, booster diaphragm or check valve is ...

Page 171

Right hand drive (rhd) (1) remove the air box (refer to 9 - engine/air intake system/air cleaner element - removal). (2) relocate the cruise control servo to gain access to the booster for removal. (3) remove the brake lines from the master cylin- der. (4) remove the master cylinder (refer to 5 - br...

Page 172

(2) install booster mounting nuts. Tighten nuts just enough to hold booster in place (fig. 51). (3) slide booster push rod (2) onto the brake pedal (1). Then secure push rod to pedal pin with retaining clip (fig. 52). Note: lubricate the pedal pin with mopar multi- mileage grease before installation...

Page 173: Master Cylinder

(6) install the knee blocker, (refer to 23 - body/ instrument panel/knee blocker - instal- lation). (7) if original master cylinder is being installed, check condition of seal at rear of master cylinder. Replace seal if cut, or torn. (8) clean cylinder mounting surface of brake booster. Use shop tow...

Page 174

(2) attach bleed tubes to cylinder outlet ports. Then position each tube end into reservoir (fig. 57). (3) fill reservoir with fresh brake fluid. (4) press cylinder pistons inward with wood dowel. Then release pistons and allow them to return under spring pressure. Continue bleeding operations until...

Page 175: Fluid

(7) if master cylinder reservoir requires service, (refer to 5 - brakes/hydraulic/mechanical/ fluid reservoir - removal). (fig. 58) installation note: if master cylinder is replaced, bleed cylinder before installation. (1) clean cylinder mounting surface of brake booster (2). (2) install master cyli...

Page 176: Fluid Reservoir

Caution: never use any type of a petroleum-based fluid in the brake hydraulic system. Use of such type fluids will result in seal damage of the vehicle brake hydraulic system causing a failure of the vehicle brake system. Petroleum based fluids would be items such as engine oil, transmission fluid, ...

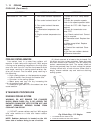

Page 177: Parking Brake

Installation (1) install support plate on axle flange. Tighten attaching bolts to 115 n·m (85 ft. Lbs.). (2) install the park brake shoes (2) (fig. 62), (refer to 5 - brakes/parking brake/shoes - installation). (3) install parking brake cable in the brake lever. (4) install axle shaft (3), (fig. 63)...

Page 178: Cables

A parking brake switch is mounted on the parking brake lever and is actuated by movement of the lever. The switch, which is in circuit with the red warning light in the dash, will illuminate the warn- ing light whenever the parking brakes are applied. Parking brake is self-adjusting when the lever i...

Page 179

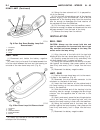

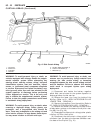

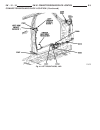

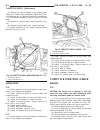

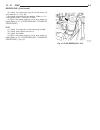

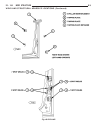

(2) remove the rear seat (refer to 23 - body/ seats/seat - removal). (3) pull the carpet forward far enough in the rear to gain access to the two parking brake cables thru the floor (fig. 66). (4) disconnect the two cables (1) from the front mount (fig. 67). (5) push the cables (2) thru the floor wi...

Page 180: Lever

(5) lay the carpet (2) back down in the rear (fig. 71). (6) install the rear seat (refer to 23 - body/ seats/seat - installation). (7) remove the lock out device (2) on the lever (1) (fig. 72). (8) adjust the park brake shoes (refer to 5 - brakes/parking brake/shoes - adjust- ments). (9) test the pa...

Page 181: Shoes

(5) remove the parking brake lever assembly (1) mounting bolts (fig. 75). (6) remove the lever assembly (1). Installation (1) install the parking brake lever assembly (2). (2) install the parking brake lever assembly (2) to the mounting bolts. Tighten (fig. 75). (3) engage the front cables (3) to th...

Page 182

(4) remove the disc brake rotor, (fig. 77), (refer to 5 - brakes/hydraulic/mechanical/rotors - removal). (5) disassemble the rear park brake shoes (2) (fig. 78). Cleaning - rear drum in hat brake clean the individual brake components, including the support plate exterior, with a water dampened cloth...

Page 183

Installation note: on a new vehicle or after parking brake lin- ing replacement, it is recommended that the park- ing brake system be conditioned prior to use. This is done by making one stop from 25 mph on dry pavement or concrete using light to moderate force on the parking brake lever. (1) reasse...

Page 184

Adjustment - rear drum in hat park brake (rotor removed) under normal circumstances, the only time adjust- ment is required is when the shoes are replaced, removed for access to other parts, or when one or both rotors are replaced. Adjustment can be made with a standard brake gauge or with adjusting...

Page 185

(7) reduce the inside diameter measurement of the brake drum that was taken using special tool c-3919 (2) by 1/64 of an inch. Reset gauge, brake shoe, special tool c-3919 (2) or the equivalent used, so that the outside measurement jaws are set to the reduced measurement (fig. 85). (8) place gauge, b...

Page 186: Brakes - Abs

Brakes - abs table of contents page page brakes - abs description . . . . . . . . . . . . . . . . . . . . . . . . . 41 operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 diagnosis and testing - antilock braking system . . . . . . . . . . . . . . . . . . . . 42 standard procedure - ab...

Page 187

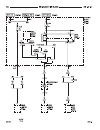

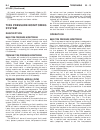

Electronic brake distribution upon entry into ebd the inlet valve for the rear brake circuit is switched on so that the fluid supply from the master cylinder is shut off. In order to decrease the rear brake pressure the outlet valve for the rear brake circuit is pulsed. This allows fluid to enter th...

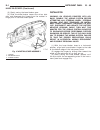

Page 188: Electrical

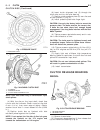

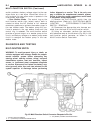

Electrical description three wheel speed sensors are used. The front sen- sors are mounted to the steering knuckles. The rear sensor is mounted at the top of the rear axle differ- ential carrier. Tone wheels are mounted to the out- board ends of the front axle shafts. The gear type tone wheel serves...

Page 189: Rear Wheel Speed Sensor

(6) install the disc brake rotor (3) (refer to 5 - brakes/hydraulic/mechanical/rotors - installation) (fig. 2). (7) install the disc brake caliper adapter. (refer to 5 - brakes/hydraulic/mechanical/disc brake caliper adapter - installation). (8) install the tire and wheel assembly (refer to 22 - tir...

Page 190

Pressure decrease the outlet valve is opened and the inlet valve is closed during the pressure decrease cycle. A pressure decrease cycle is initiated when speed sen- sor signals indicate high wheel slip at one or more wheels. At this point, the abm closes the inlet then opens the outlet valve, which...

Page 191

(2) separate the abm module (1) from the hcu (2) (fig. 8). Assembly (1) clean any debris off the mating surfaces of the hcu and abm module. Caution: when installing new o-rings or solenoid valve stem seals, do not use any type of lubricant. (2) if the seals on the components are not new, they must b...

Page 192

(5) install the four screws attaching the abm mod- ule to the hcu (fig. 12). Tighten the mounting screws to 2 n·m (17 in. Lbs.) torque. (6) if the mounting bracket needs to be installed, install the mounting pins in the hcu as necessary and tighten to 11 n·m (97 in. Lbs.) torque. Insert the mounting...

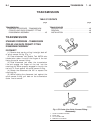

Page 194: Clutch

Clutch table of contents page page clutch warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 diagnosis and testing clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 specifications . . . . . . . . . . . . . . . . . . . . . . . . 5 clutch disc removal . . . . . . . . ...

Page 195

Road splash contamination is dirt/water entering the clutch housing due to loose bolts, housing cracks. Driving through deep water puddles can force water/ road splash into the housing through such openings. Improper release or clutch engagement clutch release or engagement problems are caused by we...

Page 196

Diagnosis chart condition possible causes correction disc facing worn out 1. Normal wear. 1. Replace cover and disc. 2. Driver frequently rides (slips) the clutch. Results in rapid overheating and wear. 2. Replace cover and disc. 3. Insufficient clutch cover diaphragm spring tension. 3. Replace cove...

Page 197

Condition possible causes correction clutch disc binds on input shaft splines. 1. Clutch disc hub splines damaged during installation. 1. Clean, smooth, and lubricate hub splines if possible. Replace disc if necessary. 2. Input shaft splines rough, damaged, or corroded. 2. Clean, smooth, and lubrica...

Page 198: Clutch Disc

Condition possible causes correction contact surface of release bearing damaged. 1. Clutch cover incorrect or release fingers bent or distorted. 1. Replace clutch cover and release bearing. 2. Release bearing defective or damaged. 2. Replace the release bearing. 3. Release bearing misaligned. 3. Che...

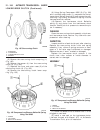

Page 199: Clutch Release Bearing

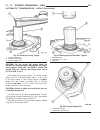

Note: disc must slide freely on transmission input shaft splines. (4) with the disc on the input shaft, check face runout with dial indicator. Check runout at disc hub 6 mm (1/4 in.) from outer edge of facing. Obtain another clutch disc if runout exceed 0.5 mm (0.020 in.). (5) position clutch disc o...

Page 200: Flywheel

(3) inspect bearing slide surface of transmission front bearing retainer. Replace retainer if slide sur- face is scored, worn, or cracked. (4) inspect release fork and fork pivot. Be sure pivot is secure and in good condition. Be sure fork is not distorted or worn. Replace release fork retainer spri...

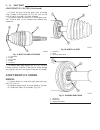

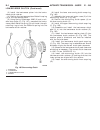

Page 201: Pilot Bearing

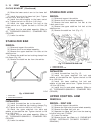

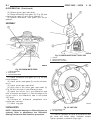

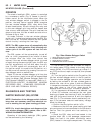

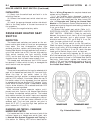

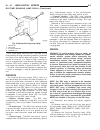

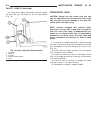

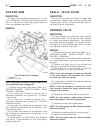

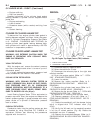

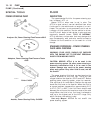

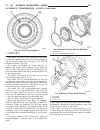

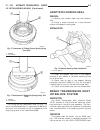

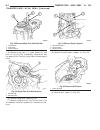

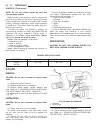

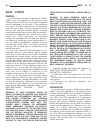

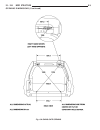

The dual mass flywheel (fig. 6) is used on the 2.4l engine and 2.8l diesel. The flywheel incorpo- rates the ring gear (5) around the outer circumfer- ence to mesh with the starter to permit engine cranking. The primary flywheel (6) side is bolted to the crankshaft. The secondary flywheel (3) side se...

Page 202: Linkage

Linkage removal note: the clutch master cylinder, slave cylinder and connecting line are serviced as an assembly only. The linkage components cannot be over- hauled or serviced separately. The cylinders and connecting line are sealed units. (1) with vehicle in neutral, position vehicle on hoist. (2)...

Page 203: Master Cylinder

(1) tighten master cylinder reservoir cap to avoid spills. (2) position clutch linkage components in vehicle. Work connecting line and slave cylinder downward past engine and adjacent to clutch housing. (3) position clutch master cylinder (1) on dash panel. (4) attach clutch master cylinder actuator...

Page 204: Clutch Switch Override

Installation (1) place clutch pedal and bracket over studs on dash panel and cowl support. (2) install pedal and bracket to dash panel nuts and tighten to 39 n·m (29 ft. Lbs.). (3) engage captured bushing (4) and actuator on brake pedal pivot (3) (fig. 12). (4) connect clutch pedal position switch w...

Page 205: Clutch Pedal Position

Clutch pedal position switch description the clutch pedal position switch (2) is located under the instrument panel, attached to the clutch master cylinder (1) push rod (fig. 14). The wiring harness connection for the switch is in the engine compartment (fig. 14). The clutch pedal position switch ov...

Page 206: Cooling

Cooling table of contents page page cooling description 2.4l engine . . . . . . . . . . . . . . . . . . . . . . . . . . 1 3.7l engine . . . . . . . . . . . . . . . . . . . . . . . . . . 1 description - cooling system routing 3.7l engine . . . . . . . . . . . . . . . . . . 1 description - hose clamps...

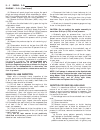

Page 207

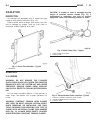

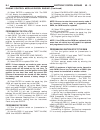

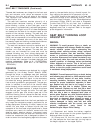

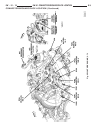

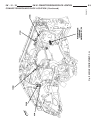

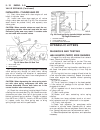

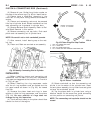

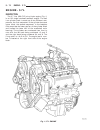

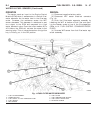

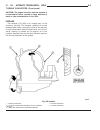

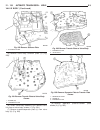

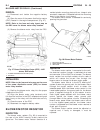

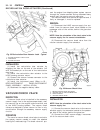

Fig. 1 engine cooling system 3.7l engine 1 - lh cyl. Head 2 - air bleed 3 - thermostat location 4 - rh cyl. Head 5 - rh bank cyl. Block 6 - lh bank cyl. Block 7 - coolant temp. Sensor 7 - 2 cooling kj cooling (continued).

Page 208

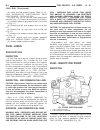

Description - hose clamps the cooling system utilizes spring type hose clamps. If a spring type clamp replacement is neces- sary, replace with the original mopar t equipment spring type clamp. Warning: constant tension hose clamps are used on most cooling system hoses. When removing or installing, u...

Page 209

(2) recent service or accident repair: determine if any recent service has been per- formed on vehicle that may effect cooling system. This may be: • engine adjustments (incorrect timing) • slipping engine accessory drive belt(s) • brakes (possibly dragging) • changed parts. Incorrect water pump, or...

Page 210

Tem. However, there could be an internal leak that does not appear with normal system test pressure. If it is certain that coolant is being lost and leaks can- not be detected, inspect for interior leakage or per- form internal leakage test. Drops slowly: indicates a small leak or seepage is occurri...

Page 211

Cooling system diagnosis chart - gas engine cooling system diagnosis chart condition possible causes correction temperature gauge reads low 1. Has a diagnostic trouble code (dtc) been set indicating a stuck open thermostat? 1. Refer to (refer to 25 - emis- sions control - descrip- tion) for on-board...

Page 212

Condition possible causes correction temperature gauge reads high or the coolant warn- ing lamp illuminates. Cool- ant may or may not be lost or leaking from the cool- ing system. 1. Trailer is being towed, a steep hill is being climbed, vehicle is operated in slow moving traffic, or engine is being...

Page 213

Condition possible causes correction 8. Incorrect coolant concentration 8. Check coolant. (refer to 7 - cooling/engine/coolant - description) for correct coolant/ water mixture ratio. 9. Fan installed backwards on vis- cous drive. 9. Mount fan on drive correctly. 10. Radiator or a/c condenser fins a...

Page 214

Condition possible causes correction temperature gauge read- ing is inconsistent (fluctu- ates, cycles or is erratic) 1. During cold weather operation, with the heater blower in the high position, the gauge reading may drop slightly. 1. A normal condition. No correc- tion is necessary. 2. Temperatur...

Page 215

Condition possible causes correction coolant loss to the ground without pressure cap blowoff. Gauge read- ing high or hot 1. Coolant leaks in radiator, cool- ing system hoses, water pump or engine. 1. Pressure test and repair as nec- essary. (refer to 7 - cooling - diagnosis and testing). Detonation...

Page 216

Condition possible causes correction inadequate heater perfor- mance. Thermostat failed in open position 1. Has a diagnostic trouble code (dtc) been set? 1. (refer to 25 - emissions control - description) for correct procedures and replace thermostat if necessary 2. Coolant level low 2. (refer to 7 ...

Page 217

Condition possible causes correction fan runs all the time 1. Fan control sensors inoperative. 1. Check for dtc’s. Verify sensor readings. 2. Fan control solenoid stuck 9 on 9 . 2. Check fan operation speeds. Refer to fan speed operation table. 3. Fan control solenoid harness damaged. 3. Check for d...

Page 218

Refilling cooling system (1) tighten the radiator draincock and the cylinder block drain plug(s) (if removed). Caution: failure to purge air from the cooling sys- tem can result in an overheating condition and severe engine damage. (2) fill cooling system with the antifreeze mixture (refer to lubric...

Page 219

Install the thermostat and housing with a replace- ment gasket (refer to 7 - cooling/engine/en- gine coolant thermostat - installation). Connect the radiator hoses. Refill the cooling system with the correct antifreeze/water mixture (refer to 7 - cooling - standard pro- cedure). Inspection after per...

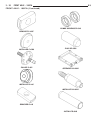

Page 220

Special tools cooling pliers 6094 release tool 8875a adapter pins 8346 spanner wrench 6958 with 8346 adapter pins pressure tester 7700–a coolant refractometer 8286 kj cooling 7 - 15 cooling (continued).

Page 221: Accessory Drive

Accessory drive table of contents page page accessory drive diagnosis and testing - serpentine drive belt diagnosis . . . . . . . . . . . . . . . . 16 belt tensioners description . . . . . . . . . . . . . . . . . . . . . . . . . 18 operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 r...

Page 222

Serpentine drive belt diagnosis chart condition possible causes correction rib chunking (one or more ribs has separated from belt body) 1. Foreign objects imbedded in pul- ley grooves. 1. Remove foreign objects from pulley grooves. Replace belt. 2. Installation damage. 2. Replace belt. Rib or belt w...

Page 223: Belt Tensioners

Condition possible causes correction belt broken (note: iden- tify and correct problem before new belt is installed) 1. Excessive tension. 1. Replace belt and automatic belt tensioner. 2. Incorrect belt. 2. Replace belt. 3. Tensile member damaged during belt installation. 3. Replace belt. 4. Severe ...

Page 224: Drive Belts

Warning: because of high spring tension, do not attempt to disassemble automatic tensioner. Unit is serviced as an assembly (except for pulley on tensioner). (3) remove pulley bolt. Remove pulley from ten- sioner. 3.7l engine (1) remove accessory drive belt (refer to 7 - cooling/accessory drive/driv...

Page 225

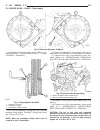

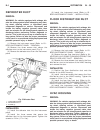

3.7l engine note: the belt routing schematics are published from the latest information available at the time of publication. If anything differs between these sche- matics and the belt routing label, use the sche- matics on belt routing label. This label is located in the engine compartment. Cautio...

Page 226

(3) with the drive belt installed, inspect the belt wear indicator. On 2.4l engines the gap between the tang and the housing stop ( measurement a ) must not exceed 24 mm (.94 inches). 3.7l engine note: the belt routing schematics are published from the latest information available at the time of pub...

Page 227: Engine

Engine table of contents page page coolant description hoat coolant . . . . . . . . . . . . . . . . . . . . . . 23 engine coolant . . . . . . . . . . . . . . . . . . . . 24 operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 coolant recovery container description coolant recovery pres...

Page 228: Coolant

Description - water pump bypass - 3.7l . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41 operation 2.4l/3.7l engines . . . . . . . . . . . . . . . . . . . . 41 removal 2.4l engine . . . . . . . . . . . . . . . . . . . . . . . . . 41 3.7l . . . . . . . . . . . . . . . . . . . . . . ....

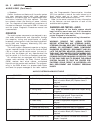

Page 229: Coolant Recovery

Year/100,000 mile formula (glycol base coolant with corrosion inhibitors called hoat, for hybrid organic additive technology) is recommended. This coolant offers the best engine cooling without corrosion when mixed with 50% distilled water to obtain to obtain a freeze point of -37°c (-35°f). If it l...

Page 230

Ated pressure. The bottle acts as a reserve coolant source to keep air out of the system but must have a specified minimum amount of coolant in the bottle at all times. The expansion and contraction of the cool- ant in the pressurized closed coolant loop allows the reserve bottle to accept and give ...

Page 231: Engine Block Heater

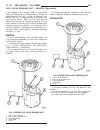

Removal pressure system - 3.7l/2.8l diesel (1) remove pressure cap from bottle (fig. 1). (2) siphon coolant from pressure bottle into a con- taminant free container. (3) disconnect coolant bottle to radiator hose at coolant bottle. (4) disconnect lower hose at coolant bottle. (5) remove mounting nut...

Page 232

Operation the block heater element is submerged in the cool- ing system’s coolant. When electrical power (110 volt a.C.) is applied to the element, it creates heat. This heat is transferred to the engine coolant. This pro- vides easier engine starting and faster warm-up when vehicle is operated in a...

Page 233: Engine Coolant

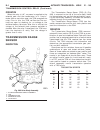

Engine coolant temperature sensor description the engine coolant temperature (ect) sensor is used to sense engine coolant temperature. The sensor protrudes into an engine water jacket. The ect sensor is a two-wire negative thermal coefficient (ntc) sensor. Meaning, as engine coolant temperature incr...

Page 234: Engine Coolant

3.7l engine the engine coolant temperature (ect) sensor is installed into a water jacket at front of intake mani- fold near rear of generator (fig. 6). Warning: hot, pressurized coolant can cause injury by scalding. Cooling system must be partially drained before remov- ing the coolant temperature s...

Page 235

The same thermostat is used for winter and sum- mer seasons. An engine should not be operated with- out a thermostat, except for servicing or testing. Operating without a thermostat causes other prob- lems. These are: longer engine warmup time, unreli- able warmup performance, increased exhaust emis...

Page 236: Hose Clamps

(6) remove thermostat housing mounting bolts, thermostat housing and thermostat (fig. 10). Installation 2.4l engine (1) clean all gasket sealing surfaces. (2) place a new gasket (dipped in clean water) on the coolant outlet connector surface. Position thermo- stat with air bleed at 12 o’clock positi...

Page 237

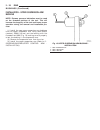

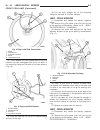

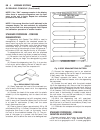

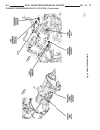

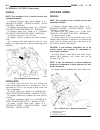

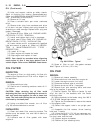

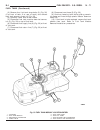

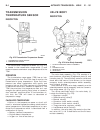

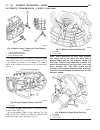

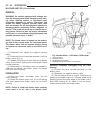

Fig. 10 thermostat and thermostat housing 1 - thermostat housing 2 - thermostat location 3 - thermostat and gasket 4 - timing chain cover fig. 11 thermostat position 1 - locator notch 2 - air bleed fig. 12 spring clamp size location 1 - spring clamp size location 7 - 32 engine kj hose clamps (contin...

Page 238: Radiator

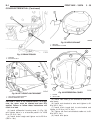

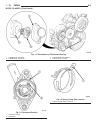

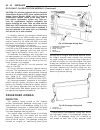

Radiator description all vehicles are equipped with a cross flow type radiator with plastic side tanks (fig. 13). Plastic tanks, while stronger than brass, are sub- ject to damage by impact, such as from tools or wrenches. Handle radiator with care. Removal 2.4l engine warning: do not remove the cyl...

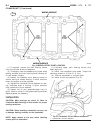

Page 239

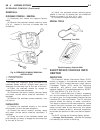

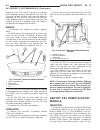

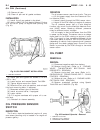

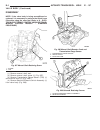

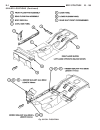

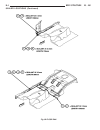

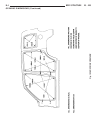

Caution: when removing the radiator or a/c con- denser for any reason, note the location of all radi- ator-to-body and radiator-to-a/c condenser rubber air seals (fig. 16). These are used at the top, bot- tom and sides of the radiator and a/c condenser. To prevent overheating, these seals must be in...

Page 240: Radiator Pressure Cap

Installation 2.4l engine caution: before installing the radiator or a/c con- denser, be sure the radiator-to-body and radiator-to- a/c condenser rubber air seals are properly fastened to their original positions. These are used at the top, bottom and sides of the radiator and a/c condenser. To preve...

Page 241: Radiator Fan - Electric

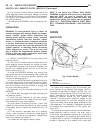

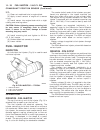

Cleaning clean the radiator pressure cap using a mild soap and water only. Inspection visually inspect the pressure valve gasket on the cap. Replace cap if the gasket is swollen, torn or worn. Inspect the area around radiator filler neck for white deposits that indicate a leaking cap. Radiator fan -...

Page 242

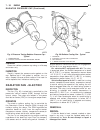

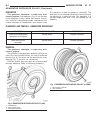

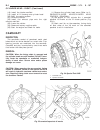

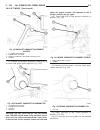

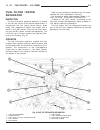

Note: for 3.7l heavy duty/max cool/trailer tow cooling package, the viscous fan cannot be removed separate from the shroud. Both fan and shroud must be removed together. (1) disconnect battery negative cable. (2) using special tool 6958 spanner wrench and 8346 adapters, remove the viscous fan from t...

Page 243: Radiator - Fan - Viscous

Installation installation note: for 3.7l heavy duty/max cool/trailer tow cooling package, the viscous fan cannot be installed separate from the shroud. Both fan and shroud must be installed together. (1) gently lay viscous fan into shroud. (2) install fan shroud assembly into the vehicle. Tighten fa...

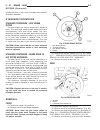

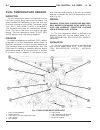

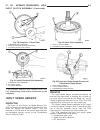

Page 244

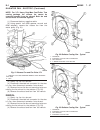

(2) obtain a dial thermometer with an 8 inch stem (or equivalent). It should have a range of -18° to 105°c (0° to 220° f). Insert thermometer through the hole in the shroud. Be sure that there is adequate clearance from the fan blades. (3) connect a tachometer and an engine ignition timing light (ti...

Page 245: Thermostat Housing

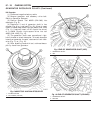

Caution: if fan blade assembly is replaced because of mechanical damage, water pump and viscous fan drive should also be inspected. These components could have been damaged due to excessive vibration. (1) remove fan blade assembly from viscous fan drive unit (four bolts). (2) lay fan on a flat surfa...

Page 246

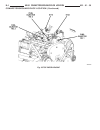

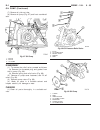

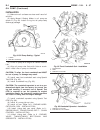

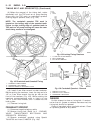

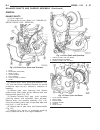

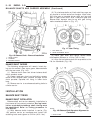

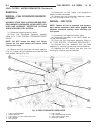

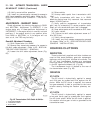

Cated by the antifreeze in the coolant mixture. No additional lubrication is necessary. Both heater hoses are connected to fittings on the timing chain front cover. The water pump is also mounted directly to the timing chain cover and is equipped with a non serviceable integral pulley (fig. 27). 2.4...

Page 247

(10) remove the timing belt (refer to 9 - engine/ valve timing/timing belt and sprocket(s) - removal). (11) remove timing belt idler pulley. (12) hold camshaft sprocket with special tool c-4687 and adaptor c-4687-1 while removing bolt. Remove both cam sprockets. (13) remove the timing belt rear cove...

Page 248