- DL manuals

- Jen-Ken Kilns

- Recording Equipment

- AF3P

- Operating Manual

Jen-Ken Kilns AF3P Operating Manual

1

Jen-Ken Kilns

-SP-

Small Piece Glass

Fuse

Tack

Slump

Polish

+ 4 Extra

Jen-Ken Kilns

3615 Ventura Dr. W. – Lakeland, FL 33811

863-648-0585

www.jenkenkilns.com

Jen-Ken Kilns and Orton have produced the most user friendly and powerful, kiln controller for artists. If the Jen-

Ken Kiln can perform all the above tasks then all of the above settings will been turned on. The Chilipepper is a

low firing annealing kiln and will only have the –BEAD- setting turned on. The AF3P Bead Annealer with flip

door will have all of the above turned on except the Cone feature because the kiln cannot fire that hot.

AF3P Pre-programmed

“One Smart Controller”

Operating

Manual

-CONE-

Ceramic

Cones 022 to 6

+4 Extra

Set for Limits of kiln

-BEAD-

Small Moretti

Large Moretti

Batch Anealing

Borosilicate

+4 Extra

-USER-

6 User Defined

Programs that can

be used for

anything

-LP-

Large Piece Glass

Fuse

Tack

Slump

Polish

+ 4 Extra

-CLA-

PMC

Fast Fire PMC+

Slow Fire PMC+

Slow Fire PMC3

Firing PMC Standard

Firing PMC Gold

+4 Extra

Summary of AF3P

Page 1

1 jen-ken kilns -sp- small piece glass fuse tack slump polish + 4 extra jen-ken kilns 3615 ventura dr. W. – lakeland, fl 33811 863-648-0585 www.Jenkenkilns.Com jen-ken kilns and orton have produced the most user friendly and powerful, kiln controller for artists. If the jen- ken kiln can perform all...

Page 2

2 this manual contains instructions on the operation of our jen-ken kilns with the af3p pre-programmed controller, that was made for us by orton, as well as a discussion of general fusing procedures. It is not intended to replace a fusing class or comprehensive fusing instructional media. The produc...

Page 3

3 table of contents safety first.......................................................................................................... 4 about your kiln ................................................................................................... 5 kiln accessories ...........................

Page 4

4 read and understand all operating instructions before operating your kiln. Safety precautions: kilns are as safe as any other electrical appliance when used under normal and proper operating conditions. All safety precautions throughout this manual should be observed. O use common sense while inst...

Page 5

5 introduction the af3p preprogrammed controller is an outstanding unit that we have developed for a range of jen-ken kilns. The controller has been designed and programmed to jen-ken kilns specifications by orton ceramics. Elements elements are the coils of wire that produce heat inside the kiln. T...

Page 6

6 kiln brick all jen-ken kilns are made of hand selected 2300°f refractory brick. The brick is strong as a whole and has a very long life. The brick can chip easily and care should be taken to avoid bumps while loading and unloading shelves. Frequently vacuum, using a soft vacuum brush, the brick li...

Page 7

7 recommended kiln accessories glass kiln wash is a mixture of very fine minerals that will not fuse or melt together at high temperatures and act as a barrier between the kiln shelf or mold and glass. It is used to help prevent glass from sticking to the tops of the kiln shelves and the firebrick b...

Page 8

8 kiln specifications to operate the kiln safely and efficiently, your kiln needs the proper electrical outlet with the correct electrical capacity and voltage. The chart below will assist you in the selection of the proper wire and breaker size for your jen-ken kiln. A licensed electrician or the l...

Page 9

9 jen-ken ceramic kilns models voltage amperage draw wire size required fuse required receptacle 11/9 120 17 12 20 5-20r 15/9 120 17 12 20 5-20r 1811 240 20 10 30 6-30r 1822 240 26 8 30 6-30r 1829 240 39 6 50 6-50r 2122 240 30 8 40 6-50r 2422 240 36 6 50 6-50r 2431 240 45 6 50 6-50r 2829* 240 45 or ...

Page 10

10 choosing a location for your kiln the proper location is as important as choosing the right kiln. Below are some safety guidelines. O please review the safety considerations listed on page 5 when selecting a location for your kiln. O your kiln should be located in a covered, dry, fireproof and we...

Page 11

11 brush kiln wash on the floor. Vacuum any loose debris setting up your kiln o assemble the kiln stand and place it on the floor in your work space. The round top carriage bolts are on top and the 8 hex head bolts are used on the side of the stand. Tighten all bolts and make sure the stand is sturd...

Page 12

12 enough of this reading stuff – i want to fire something! For those of you who can’t wait, here is a brief guide to get you up and running. It is strongly recommended that you do take time to look over the controller instructions as soon a possible. Quick start guide: plug the kiln in to an approp...

Page 13: Af3P Controllers

13 af3p controllers (auto fire 3 button programmable controller) ` af3p controller af3p chilipepper controller this button is for selecting a firing program and advancing through the programming steps. After programming is complete, use this button to start and stop the firing. This button is used t...

Page 14

14 the controller is equipped with a small buzzer that will sound during button presses and at the successful completion of a firing for 30 seconds. The alarm will also sound to notify you of diagnostic alarms that may occur during a firing. To silence an active buzzer, press any button. Temperature...

Page 15

15 ramp rate each step of a firing program must have a programmed rate of temperature increase or decrease. These rate values are selected as degrees per hour. During the programming the display prompt for rate settings are ra followed by the step number like ra1 , ra2 , ra3 , etc… this may be eithe...

Page 16

16 -lp- for larger glass projects for the kiln (full shelf size and/or 3 or more layers) -sp- for smaller glass projects (small pieces on the same shelf and/or 2 layers) bead for bead annealing projects cone for cone firing of ceramics (only if kiln is rated for over 1800ºf and is not top firing) cl...

Page 17

17 -lp- large piece program mode for pieces that are large in size for the shelf of the kiln (over 2/3 the shelf area and/or 3 or more layers thick). This is a good place to start for that large project knowing that you can speed up the rates (ra) later if the piece turns out well. The l arge p iece...

Page 18

18 100.0f(55.5c)/hour * 700.0f(371.1c) * 00.00 * pr01 user pr02 user pr03 user pr04 user the preset large piece programs can be edited. Each program segment can be changed by the operator. To restore the factory values, enter a zero value for the first ra1 segment of each program and press the progr...

Page 19: Beads

19 fire polish displayed as pol this program heats at 300ºf/hour to 1000ºf and holds this temperature for 0 minutes. Then heats at 500ºf/hour to 1200ºf and holds this temperature for 15 minutes. Then heats at full power (fast as it can) to 950ºf and holds this temperature for 30 minutes. . -sp- prog...

Page 20

20 ramp and holding working programs are useful while beading and lampworking. When the program is started the kiln heats fast and then holds at an annealing temperature for the longest amount of time that is planned to work. In this case 4 hours and if the time to work suddenly becomes less, then u...

Page 21

21 full* 100.0f(55.5c)/hour * 940.0f(504.4c) * 500.0f(260.0c) * 00.30 * 00.00 * pr01 user pr02 user pr03 user pr04 user the preset bead programs can be edited. Each program segment can be changed by the operator. To restore the factory values, enter a zero value for the first ra1 segment of each pro...

Page 22

22 std pmc standard full * 1650.2°f(899 .0°c) * 02.00 * gold pmc 22c. Gold full * 1290.0°f(698.8°c) * 01.30 * pr01 user pr02 user pr03 user pr04 user the preset metal clay programs can be edited. Each program segment can be changed by the operator. To restore the factory values, enter a zero value f...

Page 23

23 each step of a firing program must have a programmed heating or cooling temperature. The controller must have at least one heating step to accept the firing program as valid (an invalid program results in a badp display alarm). A heating step is simply any step with a temperature setting that is ...

Page 24

24 if no buttons are pressed for 1 full minute during programming, the controller will automatically exit the program mode and return to the idle display. During a firing, if the options menu is activated for programming, the controller will return to the active display if no buttons are pressed for...

Page 25

25 prompt. The review can be used to bypass making any changes to the current firing schedule. Program recall program review can be used to quickly select any firing schedule that is already programmed into the controller memory. To select a saved program, the controller should first be at the idle ...

Page 26

26 threshold alarm during the firing, it is possible to set an audible alarm and display alarm for when the actual temperature reaches a specified value. The buzzer will sound (for 30 seconds) and the display will show the alarm code alar. To set the alarm, press increase button during the active fi...

Page 27

27 3. When power is restored, the temperature drop during the power interruption must be less than 72ºf (40ºc). If not, the display will show the alarm code pf 3 and terminate the firing. Status display codes below is a list of normal display codes which indicate the controller mode of operation. Id...

Page 28

28 1. The heating or cooling rate is slower than 27°f (15°c) per hour 2. The current program step has lasted 2 hours longer than anticipated. In most cases, the ftl alarm occurs during heating if the heating rate is set to a fast speed that cannot be maintained by the kiln. If the heating rate is wi...

Page 29

29 wiring diagram special note about cold conditions controller is not designed to be started in temperatures under 32ºf, it will not hurt the kiln to be stored around this temperature. If your kiln is set up in an unheated area and the room temperature has dropped to below 32ºf the kiln will not st...

Page 30

30 fused glass projects working with tested compatible glasses to ensure success when fusing glass, use glass that has been pre-tested by the manufacturer how to prepare your glass project select glass that is “tested compatible” and has the same coe (coefficient of expansion) for the entire project...

Page 31

31 between 1250°f and 1350°f (577°c - 732°c), the glass is becoming even softer, and at the top end of this range will be fully slumped. It’s not recommended to exceed 1350 f if you are slumping because at higher temperatures, there is a loss of control of the glass and it may slide down too far or ...

Page 32

32 soaked only long enough to achieve the desired look. It’s important not to hold the project at these temperatures for a long period of time, or you run the risk of devitrification (a visible clouding of the glass surface due to crystallization). Fast cooling (1500 ° f to 1100 ° f range): after th...

Page 33

33 another possible scenario is that the edges of the glass have melted more quickly, trapping a large amount of air in the center of the piece which expands into large bubbles within the glass, thus distorting the design. Both scenarios could have been avoided simply by slowing down the firing prog...

Page 34

34 firing metal clay drying time allow your pieces to be completely dried before firing them in the kiln to ensure that they don’t warp. Loading the kiln if you fire both glass and metal clay in your kiln, it is recommended that you invest in a second shelf so that you can fire only glass on the gla...

Page 35

35 cla metal clay press (program) button to select this configuration. Once completed the led display will return to the idle mode. Select firing program to select the correct firing program, press (program) button to display the current firing program press (increase) button to scroll to the correc...

Page 36

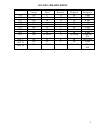

36 kiln firing log pro 1 pro 2 pro 3 pro 4 pro 5 pro 6 seg 1 ra1 ºf/hr ºf/hr ºf/hr ºf/hr ºf/hr ºf/hr ºf1 ºf ºf ºf ºf ºf ºf hld1 min. Min. Min. Min. Min. Min. Seg 2 ra2 ºf/hr ºf/hr ºf/hr ºf/hr ºf/hr ºf/hr ºf2 ºf ºf ºf ºf ºf ºf hld2 min. Min. Min. Min. Min. Min. Seg 3 ra3 ºf/hr ºf/hr ºf/hr ºf/hr ºf/hr...

Page 37: Cone Firings

37 cone firings ceramic and ceram-a-glass kilns only this is not for glass fusing kilns. Kilns that have top and side heating elements only fire to 1700 degrees f max. And will not fire ceramics, glazes, or pottery. Please do not attempt it will harm the kiln. Ceramics projects and pottery firing no...

Page 38

38 3. Cone number alternates with the firing temperature. Use or to change the cone number . Press to continue. 4. Firing speed is displayed. Use or to change the speed to [fast] = 20% faster, [ ed] = medium or [slo] =20% slower – press to continue. 5. [hld] alternates with the programmed hold time....

Page 39

39 cone # ramp 1 setpoint 1 ramp 2 setpoint 2 low fire degrees f 022 396 979 108 1087 021 396 1004 108 1112 020 396 1051 108 1159 019 396 1144 108 1252 018 396 1211 108 1319 017 396 1252 108 1360 016 396 1314 108 1422 015 396 1348 108 1456 014 396 1377 108 1485 013 396 1431 108 1539 012 396 1474 108...

Page 40

40 orton controller limited warranty this limited warranty is given only to the immediate purchaser (“buyer”) of the autofire ® express kiln controller. This limited warranty is not transferable. The edward orton jr. Ceramic foundation (“orton”) warrants the controller motherboard installed on the a...

Page 41

41 jen-ken kiln warranty jen-ken kilns are warranted to the original purchaser to be free from defects in materials and workmanship when used under normal and proper conditions for the periods specified below. The warranty period begins at the date of original purchase from jen-ken kilns , a jen -ke...