- DL manuals

- Jenn-Air

- Ranges

- JDS9860AAB

- Service

Jenn-Air JDS9860AAB Service

16026016

March 2005

©

2005 Maytag Services

This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

JDS8850AAB/Q/S/W

JDS8850ACS/W

JDS9860AAB/P/W

JDS9860ACB/P/W

Dual Fuel

Slide-In

Range

Summary of JDS9860AAB

Page 1

16026016 march 2005 © 2005 maytag services this base manual covers general information refer to individual technical sheet for information on specific models this manual includes, but is not limited to the following: service this manual is to be used by qualified appliance technicians only. Maytag d...

Page 2: Warning

2 16026016 ©2005 maytag services pride and workmanship go into every product to provide our customers with quality products. It is possible, however, that during its lifetime a product may require service. Products should be serviced only by a qualified service technician who is familiar with the sa...

Page 3: Table of Contents

©2005 maytag services 16026016 3 table of contents important information ................................................... 2 important safety information all appliances .......................................................... 4 surface cooking units ............................................. ...

Page 4: Important Safety Information

4 16026016 ©2005 maytag services important safety information warning ! To reduce the risk of the appliance tipping, it must be secured by a properly installed anti-tip bracket(s). To make sure bracket has been installed properly, remove the storage drawer and look under the range with a flashlight....

Page 5: Important Safety Information

©2005 maytag services 16026016 5 important safety information 5. User servicing—do not repair or replace any part of the appliance unless specifically recommended in the manual. All other servicing should be referred to a qualified technician. 6. Storage in or on appliance—flammable materials should...

Page 6: Important Safety Information

6 16026016 ©2005 maytag services important safety information connecting range to gas install manual shut-off valve in gas line for easy accessibility outside range. Be aware of the location of the shut-off valve. Extension cords do not use an extension cord with this product. Using the oven • do no...

Page 7

©2005 maytag services 16026016 7 ventilation hoods 1. Clean ventilation hoods frequently—grease should not be allowed to accumulate on hood or filter. 2. When flaming foods under hood, turn fan off. The fan, if operating, may spread the flame. Due to the nature of cooking, fires can occur as a resul...

Page 8: General Information

8 16026016 ©2005 maytag services this manual contains information needed by authorized service technicians to install and service dual fuel ranges. There may be, however, some parts which need further explanation. Refer to the installation instructions, use and care, technical sheets or the toll-fre...

Page 9: General Information

©2005 maytag services 16026016 9 specifications refer to individual technical sheet for specification information. Placement of the oven this freestanding range must be placed in the kitchen or comparable room. All safety guidelines must be followed (see chapter 2) and free air flow around the range...

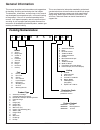

Page 10: Range Description

10 16026016 ©2005 maytag services range description bake element bottom access panel convection fan pressure regulator (back side of range) electronic control touchpad top surface burners and grates oven light model number rating label burner control valves burner control valves oven cavity broil el...

Page 11: Troubleshooting Procedures

Troubleshooting procedures ! Warning to avoid risk of electrical shock, personal injury, or death, disconnect power and gas to oven before servicing, unless testing requires power and/or gas. ©2005 maytag services 16026016 11 troubleshooting chart problem possible cause correction burners will not i...

Page 12: Troubleshooting Procedures

Troubleshooting procedures ! Warning to avoid risk of electrical shock, personal injury, or death, disconnect power and gas to oven before servicing, unless testing requires power and/or gas. 12 16026016 ©2005 maytag services problem possible cause correction no broil element operation open broil el...

Page 13: Troubleshooting Procedures

Troubleshooting procedures ! Warning to avoid risk of electrical shock, personal injury, or death, disconnect power and gas to oven before servicing, unless testing requires power and/or gas. ©2005 maytag services 16026016 13 problem possible cause correction oven door will not unlock. Oven is self-...

Page 14: Troubleshooting Procedures

Troubleshooting procedures ! Warning to avoid risk of electrical shock, personal injury, or death, disconnect power and gas to oven before servicing, unless testing requires power and/or gas. 14 16026016 ©2005 maytag services fault code description component to troubleshoot/replace f1-a lock/unlock ...

Page 15: Troubleshooting Procedures

Troubleshooting procedures ! Warning to avoid risk of electrical shock, personal injury, or death, disconnect power and gas to oven before servicing, unless testing requires power and/or gas. ©2005 maytag services 16026016 15 oven sensor and meat probe charts oven sensor sensor type: rtd 1000 Ω plat...

Page 16: Testing Procedures

Testing procedures ! Warning to avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless testing requires power. 16 16026016 ©2005 maytag services component testing procedures illustration component test procedure results oven light housing all mode...

Page 17: Testing Procedures

Testing procedures ! Warning to avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing, unless testing requires power and/or gas. ©2005 maytag services 16026016 17 illustration component test procedure results top surface burner 6.5 k btu, 9.1 k b...

Page 18: Testing Procedures

Testing procedures ! Warning to avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing, unless testing requires power and/or gas. 18 16026016 ©2005 maytag services illustration component test procedure results venturi, rear (long) model jds9860a**...

Page 19: Testing Procedures

Testing procedures ! Warning to avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing, unless testing requires power and/or gas. ©2005 maytag services 16026016 19 ! Warning to avoid risk of electrical shock, personal injury or equipment failure, ...

Page 20: Testing Procedures

Testing procedures ! Warning to avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing, unless testing requires power and/or gas. 20 16026016 ©2005 maytag services component test procedure results control panel assembly closed circuitry resistance...

Page 21: Testing Procedures

Testing procedures ! Warning to avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing, unless testing requires power and/or gas. ©2005 maytag services 16026016 21 relay logic note: subsequent changes implemented after the release of this technica...

Page 22: Testing Procedures

Testing procedures ! Warning to avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing, unless testing requires power and/or gas. 22 16026016 ©2005 maytag services " quick test " mode for electronic oven control (eoc) ii follow the procedure below...

Page 23: Testing Procedures

Testing procedures ! Warning to avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing, unless testing requires power and/or gas. ©2005 maytag services 16026016 23 description of fault codes each fault code consists of an " f " followed by a numbe...

Page 24: Disassembly Procedures

24 16026016 ©2005 maytag services disassembly procedures to avoid risk of electrical shock, personal injury or death; disconnect power to unit before servicing. Top burner lower assembly 1. Remove maintop, see "maintop removal" procedure. (perform steps 1 – 7.) 2. Disconnect tubing from lower assemb...

Page 25: Disassembly Procedures

©2005 maytag services 16026016 25 to avoid risk of electrical shock, personal injury or death; disconnect power to unit before servicing. Disassembly procedures control panel electronic control bottom access panel 1. Grasp top of bottom access panel and gently pull down and out. 2. Reverse procedure...

Page 26: Disassembly Procedures

26 16026016 ©2005 maytag services disassembly procedures to avoid risk of electrical shock, personal injury or death; disconnect power to unit before servicing. Meat probe receptacle (select models) 1. Turn power off. 2. Remove range from installation position, see “removing and replacing range” pro...

Page 27: Disassembly Procedures

©2005 maytag services 16026016 27 to avoid risk of electrical shock, personal injury or death; disconnect power to unit before servicing. Disassembly procedures 1. Remove power from unit. 2. Open oven door and locate oven light. 3. Grasp lens cover and pull outward on one side to gain access to bulb...

Page 28: Disassembly Procedures

28 16026016 ©2005 maytag services disassembly procedures to avoid risk of electrical shock, personal injury or death; disconnect power to unit before servicing. Access panel glass retainer door trim door trim door gasket door lining glass frame inner glass inner glass oven door insulation glass supp...

Page 29: Appendix A

©2005 maytag services 16026016 a – 1 appendix a.

Page 30

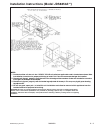

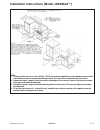

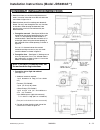

A – 2 16026016 ©2005 maytag services installation instructions (model jds8850a**) installation drawings important please keep for the use of the local electrical inspector. Figure 1 note: figure may not be representative of actual unit. The 30 inches (76.2 cm) minimum clearance between the top of th...

Page 31

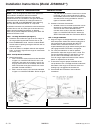

©2005 maytag services 16026016 a – 3 installation instructions (model jds8850a**) notes: 1. Provide for either a 3-wire or 4-wire 120/208, 120/240 volt outlet per applicable cord in shaded area shown. Refer to installation instructions for proper positioning of outlet. This is also the recommended g...

Page 32

A – 4 16026016 ©2005 maytag services installation instructions (model jds8850a**) figure 5 anti-tip device installation instructions warning: a risk of range tip-over exists if the appliance is not installed in accordance with the provided installation instructions. The proper use of this device min...

Page 33

©2005 maytag services 16026016 a – 5 installation instructions (model jds8850a**) step 2 - anti-tip bracket installation options a. Wood construction: 1. Floor: locate the center of the two holes identified in figure 5 as “holes for floor.” drill a 1/8 (3 mm) pilot hole in the center of each hole (a...

Page 34

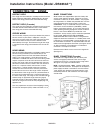

A – 6 16026016 ©2005 maytag services installation instructions (model jds8850a**) figure 7 connecting the range to electric supply electric supply the range must be installed in accordance with local and national electric code (nec) ansi/nfpa no. 70-latest edition. See rating plate for total connect...

Page 35

©2005 maytag services 16026016 a – 7 installation instructions (model jds8850a**) figure 8 normal - 3 wire plug figure 8 3-wire service cord or conduit installation 1. Insure that the copper ground strap is connected between the middle post of the main terminal connection block and the range chassis...

Page 36

A – 8 16026016 ©2005 maytag services connecting the range to gas supply gas supply installation of this range must conform with local codes or, in the absence of local codes, with the national fuel gas code, ansi z223.1-latest edition. In canada the range must be installed in accordance with the cur...

Page 37

©2005 maytag services 16026016 a – 9 installation instructions (model jds9860a**) notes: 1. Provide for either a 3-wire or 4-wire 120/208, 120/240 volt outlet per applicable cord in shaded area shown. Refer to installation instructions for proper positioning of outlet. This is also the recommended g...

Page 38

A – 10 16026016 ©2005 maytag services anti-tip device installation instructions note: a risk of range tip over exists if the appliance is not installed in accordance with the installation instructions provided. The proper use of this device minimizes the risk of tip-over. In using this device the co...

Page 39

©2005 maytag services 16026016 a – 11 figure 7 connecting the range electric supply the range must be installed in accordance with local and national electric code (nec) ansi/nfpa no. 70-latest edition. See rating plate for total connected kw rating. Electric supply (canada) the range must be instal...

Page 40

A – 12 16026016 ©2005 maytag services installation instructions (model jds9860a**) 3-wire service cord or conduit installation 1. Insure that the copper ground strap is connected between the middle post of the main terminal connection block and the range chassis. 2. The middle wire of the service co...

Page 41

©2005 maytag services 16026016 a – 13 installation instructions (model jds9860a**) s determine where you will be locating the electrical outlet. It must be in the floor or on the wall within the area shown in figure 2 or 3. S determine how you will be venting your downdraft blower. You may vent thro...

Page 42

A – 14 16026016 ©2005 maytag services installation instructions (model jds9860a**) note: the mounting br ackets shown in figure 16 are as assembled at the factory for floor or rear wall venting. A. Right side venting (figure 17). 1. Remove nuts from studs 1, 2 and 3 on the motor side. 2. Remove brac...

Page 43

©2005 maytag services 16026016 a – 15 installation instructions (model jds9860a**) range installation connecting the downdraft blower to electrical (figure 18) s connect the blower power cord to the blower motor housing. Installing the flex duct to blower s use one of the duct clamps provided. Using...

Page 44

A – 16 16026016 ©2005 maytag services a qualified serviceman or gas appliance installer must make the gas supply connection. Leak testing of the appliance shall be conducted by the installer according to the instructions given. Install gas shutoff valve install a manual shutoff valve in an accessibl...

Page 45: Appendix B

©2005 maytag services 16026016 b – 1 appendix b.

Page 46

B – 2 16026016 ©2005 maytag services use information (model jds8850a**) 6 o ven c ooking c ontrol p ad o peration c ontrol o ptions s c f etting ontrol unctions c lock p ad t imer p ads.

Page 47

©2005 maytag services 16026016 b – 3 7 c b p / onvect ake ad c onvect r oast p ad select models ( ) c ancel p ad a uto s et p ad b ake p ad notes: o ven c ooking , . Cont use information (model jds8850a**).

Page 48

B – 4 16026016 ©2005 maytag services 8 b roil p ad c ook t ime top /s t ime ads p (c lock c ontrolled ven o c ooking ) q uick p reheat p ad ( select models ) notes: use information (model jds8850a**).

Page 49

©2005 maytag services 16026016 b – 5 9 b read p roofing p ad select models ( ) k eep w arm p ad ( select models ) meat p robe p ad ( select models ) notes: o ven c ooking , . Cont use information (model jds8850a**).

Page 50

B – 6 16026016 ©2005 maytag services 12 o ptions a vailable : e - -t nd of imer s ignal imer (t 1 & t imer 2) c ontrol l ock (1) 12 h our o ff abbath ode /s m (2) s l (3) ound evel 12/24 h our c lock (4) s croll s peed (5) e - -c nd of ook t ime ignal s (6) t emp c/f (7) l anguage (8) d efault (9) d...

Page 51

©2005 maytag services 16026016 b – 7 use information (model jds9860a**) o ven c ooking c ontrol p ad o peration c ontrol o ptions s c f etting ontrol unctions c lock p ad t imer p ads.

Page 52

B – 8 16026016 ©2005 maytag services use information (model jds9860a**) o ven c ooking , . Cont c b p / onvect ake ad c onvect r oast p ad c ancel p ad a uto s et p ad b ake p ad b roil p ad notes:.

Page 53

©2005 maytag services 16026016 b – 9 use information (model jds9860a**) c ook t ime top /s t ime ads p (c lock c ontrolled ven o c ooking ) q p p uick reheat ad notes:.

Page 54

B – 10 16026016 ©2005 maytag services use information (model jds9860a**) o ven c ooking , . Cont b read p roofing p ad k eep w arm p ad meat p robe p ad notes:.

Page 55

©2005 maytag services 16026016 b – 11 use information (model jds9860a**) o ptions a vailable end-of-timer s ignal imer (t 1 and t imer 2) c ontrol l ock (1) 12 h our o ff abbath ode /s m (2) s l (3) ound evel 12/24 h our c lock (4) s croll s peed (5) e - -c nd of ook t ime ignal s (6) t emp c/f (7) ...

Page 56: Care Information

B – 12 16026016 ©2005 maytag services care information c lean p ad c are & c leaning notes:.

Page 57: Care Information

©2005 maytag services 16026016 b – 13 care information c are & c leaning , . Cont c lock and c ontrol ad p a rea c ontrol p anel c ontrol k nobs & s ealed g as urner b c artridge - p orcelain e namel d oor h andle – p lastic f inishes w indow & d oor – g lass o ven i nteriors o ven r acks c leaning ...

Page 58: Care Information

B – 14 16026016 ©2005 maytag services care information s ealed g as b urner a ssembly s tainless s teel select models ( ) g rill a ssembly – b asin – p orcelain – c ast aluminum coated with non stick - finish g rill b urner g rease c up.

Page 59: Appendix C

©2005 maytag services 16026016 c – 1 appendix c.

Page 60: Lp Conversion Instructions

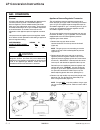

C – 2 16026016 ©2005 maytag services lp conversion instructions gas conversion general all ranges and cooktops are equipped with double coaxial (universal) orifices and with a convertible appliance pressure regulator. The unit model number plate states which gas it was adjusted for at the factory. T...

Page 61: Lp Conversion Instructions

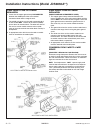

©2005 maytag services 16026016 c – 3 lp conversion instructions figure 13a natural gas setting figure 13b lp gas setting for all top burner and oven safety valve conversion (except eaton valve) for eaton oven safety valve conversion figure 13c natural gas setting figure 13d lp gas setting orifice co...

Page 62: Lp Conversion Instructions

C – 4 16026016 ©2005 maytag services lp conversion instructions burner head burner base surface burner heads and burner bases s the surface burner heads are removable. The cap portion of the head is porcelain and the port area is aluminum. Wash the burner heads in the sink with mild detergent and a ...