- DL manuals

- Jenn-Air

- Ranges

- JGS8750ADB

- Service Manual

Jenn-Air JGS8750ADB Service Manual

16022089

March 2005

©

2005 Maytag Services

This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

JGS8750ADB/S/W

JGS8850ADB/Q/S/W

Gas

Slide-In

Range

Summary of JGS8750ADB

Page 1

16022089 march 2005 © 2005 maytag services this base manual covers general information refer to individual technical sheet for information on specific models this manual includes, but is not limited to the following: service this manual is to be used by qualified appliance technicians only. Maytag d...

Page 2: Warning

2 16022089 ©2005 maytag services pride and workmanship go into every product to provide our customers with quality products. It is possible, however, that during its lifetime a product may require service. Products should be serviced only by a qualified service technician who is familiar with the sa...

Page 3: Table of Contents

©2005 maytag services 16022089 3 table of contents important information ................................................... 2 important safety information safety practices for servicer .................................... 4 servicing ....................................................................

Page 4: W A R N In G

4 16022089 ©2005 maytag services w a r n in g ! Due to the nature of cooking, fires can occur as a result of overcooking or excessive grease. Although a fire is unlikely, if one occurs proceed as follows: oven fires 1. Do not open the oven door. 2. Turn all controls to the off position. 3. As an add...

Page 5: Caution

©2005 maytag services 16022089 5 4. Using lights—use a hand flashlight when servicing ranges or checking for gas leaks. Electric switches should not be operated where leaks are suspected. This will avoid creating arcing or sparks which could ignite the gas. If electric lights are already turned on, ...

Page 6: Important Safety Information

6 16022089 ©2005 maytag services baking, broiling, and roasting • do not use oven area for storage. • stand back from range when opening door of a hot oven. Hot air or steam can cause burns to hands, face, and eyes. • do not use aluminum foil anywhere in the oven. This could result in a fire hazard ...

Page 7: General Information

©2005 maytag services 16022089 7 this manual contains information needed by authorized service technicians to install and service gas ranges. There may be, however, some parts which need further explanation. Refer to the installation instructions, use and care, technical sheets or the toll-free tech...

Page 8: General Information

8 16022089 ©2005 maytag services specifications refer to individual technical sheet for specification information. Placement of the oven this freestanding range must be placed in the kitchen or comparable room. All safety guidelines must be followed and free air flow around the range is essential (s...

Page 9: General Information

©2005 maytag services 16022089 9 general information grounding note: this appliance must be properly grounded, for personal safety. Power cord on this appliance is equipped with a three- prong grounding plug. This matches standard three-prong grounding wall receptacle to prevent possibility of elect...

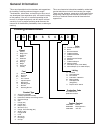

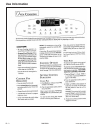

Page 10: Range Description

10 16022089 ©2005 maytag services range description broil burner bake burner bottom access panel convection fan shut-off valve/ pressure regulator (backside of range) electronic control touchpad top surface burners and grates oven light model number rating label burner control valves burner control ...

Page 11: Troubleshooting Procedures

Troubleshooting procedures ! Warning to avoid risk of electrical shock, personal injury, or death, disconnect power and gas to oven before servicing, unless testing requires power and/or gas. ©2005 maytag services 16022089 11 troubleshooting chart problem possible cause correction burners will not i...

Page 12: Troubleshooting Procedures

Troubleshooting procedures ! Warning to avoid risk of electrical shock, personal injury, or death, disconnect power and gas to oven before servicing, unless testing requires power and/or gas. 12 16022089 ©2005 maytag services problem possible cause correction no gas flows to burner. Ignitor glows re...

Page 13: Troubleshooting Procedures

Troubleshooting procedures ! Warning to avoid risk of electrical shock, personal injury, or death, disconnect power and gas to oven before servicing, unless testing requires power and/or gas. ©2005 maytag services 16022089 13 problem possible cause correction clock and timer not working. Power outag...

Page 14: Troubleshooting Procedures

Troubleshooting procedures ! Warning to avoid risk of electrical shock, personal injury, or death, disconnect power and gas to oven before servicing, unless testing requires power and/or gas. 14 16022089 ©2005 maytag services fault code description component to troubleshoot/replace f1-a lock/unlock ...

Page 15: Component Testing Procedures

Component testing procedures ! Warning to avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing, unless testing requires power and/or gas. ©2005 maytag services 16022089 15 component testing procedures illustration component test procedure result...

Page 16: Testing Procedures

Testing procedures ! Warning to avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing, unless testing requires power and/or gas. 16 16022089 ©2005 maytag services illustration component test procedure results bake burner verify gas is supplied. O...

Page 17: Testing Procedures

Testing procedures ! Warning to avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing, unless testing requires power and/or gas. ©2005 maytag services 16022089 17 oven control testing procedures changing factory set default options: 1. Press setu...

Page 18: Testing Procedures

Testing procedures ! Warning to avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing, unless testing requires power and/or gas. 18 16022089 ©2005 maytag services component test procedure results control panel assembly closed circuitry resistance...

Page 19: Testing Procedures

Testing procedures ! Warning to avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing, unless testing requires power and/or gas. ©2005 maytag services 16022089 19 relay logic note: subsequent changes implemented after the release of this technica...

Page 20: Testing Procedures

Testing procedures ! Warning to avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing, unless testing requires power and/or gas. 20 16022089 ©2005 maytag services " quick test" mode for electronic oven control (eoc) ii follow the procedure below ...

Page 21: Testing Procedures

Testing procedures ! Warning to avoid risk of electrical shock, personal injury or death; disconnect power and gas to oven before servicing, unless testing requires power and/or gas. ©2005 maytag services 16022089 21 description of fault codes each fault code consists of an "f" followed by a number,...

Page 22: Disassembly Procedures

22 16022089 ©2005 maytag services disassembly procedures to avoid risk of electrical shock, personal injury or death; disconnect power and gas before servicing. Top burner lower assembly 1. Remove maintop, see "maintop removal" procedure. (perform steps 1 – 6.) 2. Disconnect tubing from lower assemb...

Page 23: Disassembly Procedures

©2005 maytag services 16022089 23 to avoid risk of electrical shock, personal injury or death; disconnect power and gas before servicing. Disassembly procedures 2. Remove screws securing broil element to top and rear of oven cavity. 3. Pull broil element forward to allow disconnection of terminals o...

Page 24: Disassembly Procedures

24 16022089 ©2005 maytag services disassembly procedures to avoid risk of electrical shock, personal injury or death; disconnect power and gas before servicing. Electronic control 1. Remove control panel, see “control panel” procedure, steps 1 through 4. 2. Remove screws securing electronic control ...

Page 25: Disassembly Procedures

©2005 maytag services 16022089 25 to avoid risk of electrical shock, personal injury or death; disconnect power and gas before servicing. Disassembly procedures front side trim 1. Remove power from unit. 2. Slide unit out far enough to access side trim. 3. Remove screws securing front side trim piec...

Page 26: Disassembly Procedures

26 16022089 ©2005 maytag services disassembly procedures to avoid risk of electrical shock, personal injury or death; disconnect power and gas before servicing. Access panel glass retainer door trim door trim door gasket door lining glass frame inner glass inner glass oven door insulation glass supp...

Page 27: Appendix A

©2005 maytag services 16022089 a – 1 appendix a.

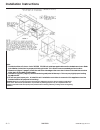

Page 28: Installation Instructions

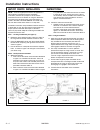

A – 2 16022089 ©2005 maytag services installation instructions notes: 1. Provide for either a 3-wire or 4-wire 120/208, 120/240 volt outlet per applicable cord in shaded area shown. Refer to installation instructions for proper positioning of outlet. This is also the recommended gas line location. 2...

Page 29: Installation Instructions

©2005 maytag services 16022089 a – 3 installation instructions figure 4 dimension “a” is to be a minimum of 3-inches (7.5 cm). Check the range model number plate to see if the range is approved for installation in mobile homes and/or recreational vehicles. If approved the following items are applica...

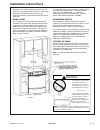

Page 30: Installation Instructions

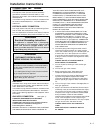

A – 4 16022089 ©2005 maytag services installation instructions anti-tip device installation instructions note: a risk of range tip over exists if the appliance is not installed in accordance with the installation instructions provided. The proper use of this device minimizes the risk of tip-over. In...

Page 31: Installation Instructions

©2005 maytag services 16022089 a – 5 installation instructions connecting the range electric supply the appliance, when installed, must be electrically grounded in accordance with local codes or, in the absence of local codes, with the national electrical code, ansi/nfpa 70. In canada the range must...

Page 32: Installation Instructions

A – 6 16022089 ©2005 maytag services installation instructions connecting the range electric supply the appliance, when installed, must be electrically grounded in accordance with local codes or, in the absence of local codes, with the national electrical code, ansi/nfpa 70. In canada the range must...

Page 33: Appendix B

©2005 maytag services 16022089 b – 1 appendix b.

Page 34: Use Information

B – 2 16022089 ©2005 maytag services use information.

Page 35: Use Information

©2005 maytag services 16022089 b – 3 use information.

Page 36: Use Information

B – 4 16022089 ©2005 maytag services use information.

Page 37: Use Information

©2005 maytag services 16022089 b – 5 use information.

Page 38: Care Information

B – 6 16022089 ©2005 maytag services care information.

Page 39: Care Information

©2005 maytag services 16022089 b – 7 care information.

Page 40: Care Information

B – 8 16022089 ©2005 maytag services care information.

Page 41: Appendix C

©2005 maytag services 16022089 c – 1 appendix c.

Page 42: Lp Conversion Instructions

C – 2 16022089 ©2005 maytag services lp conversion instructions gas conversion general all ranges and cooktops are equipped with double coaxial (universal) orifices and with a convertible appliance pressure regulator. The unit model number plate states which gas it was adjusted for at the factory. T...

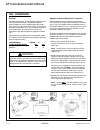

Page 43: Lp Conversion Instructions

©2005 maytag services 16022089 c – 3 lp conversion instructions figure 13a natural gas setting figure 13b lp gas setting for all top burner and oven safety valve conversion (except eaton valve) for eaton oven safety valve conversion figure 13c natural gas setting figure 13d lp gas setting orifice co...

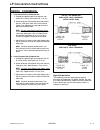

Page 44: Lp Conversion Instructions

C – 4 16022089 ©2005 maytag services lp conversion instructions burner head burner base surface burner heads and burner bases s the surface burner heads are removable. The cap portion of the head is porcelain and the port area is aluminum. Wash the burner heads in the sink with mild detergent and a ...