- DL manuals

- Kaba

- Door locks

- Peaks Classic

- Technical Manual

Kaba Peaks Classic Technical Manual

Summary of Peaks Classic

Page 1

Technical manual preferred/classic.

Page 2

Table of contents section 1 introduction section 2 product information section 3 key cutting & pinning section 4 key control & record keeping section 5 cylinder installation guide a publication of kaba access control 2941 indiana ave. Winston-salem, nc 27105 no part of this book may be reproduced or...

Page 3: Peaks

Peaks ® preferred/classic notes.

Page 4

Technical manual section 1: introduction preferred/classic.

Page 5

Section 1 - 1 in tr o d u c tio n pa t # 7 1 8 1 9 4 1 • blanks and cut keys protected by strong, uncontested utility patents • patented key control without added expense of ul437 • retrofits a wide variety of lock brands • combines conventional mortise, rim and key-in-knob cylinders, with best, arr...

Page 6

Section 1 - 2 in tr o d u c ti o n peaks preferred is the most cost effective, application flexible, patented end-user key control system available. Two projections near the key bow, called “peaks” are part of the utility patents safeguarding the key blanks. The “peak” operates the patent pin stack....

Page 7

Section 1 - 3 in tr o d u c tio n 150 spacing is used for peaks small format interchangeable cores only! There are no conventional cylinders or other large format interchangeable cores in 150 spacing. 150 small format interchangeable cores cannot be interkeyed with the 140 family. The pin-to-pin spa...

Page 8

Section 1 - 4 in tr o d u c ti o n increment systems a2 system: ten depths, numbered 0 to 9, shallow to deep, respectively. The increment of .0125" requires two step progression. Choose a specific parity pattern by using either the odd or even bittings in any given posi- tion. The preferred factory ...

Page 9

Section 1 - 5 in tr o d u c tio n kaba recommends the following resources: 1. Door and hardware institute publications, available from dhi, 14170 newbrook drive, chantilly, va, 22021. Tel: 703-222-2010 –abbreviations and symbols as used in architectural door and hardware schedules and specifications...

Page 10

Section 1 - 6 in tr o d u c ti o n patents competitive patents brand patent type expires medeco keymark x4 utility 2027 peaks preferred utility 2024 schlage primus xp utility 2024 kaba’s peaks global utility 2023 assa cliq utility 2021 medeco m3 utility 2021 kaba l10 utility 2017 corbin pyramid util...

Page 11

All peaks key blanks are marked with a unique identification number. The kaba key control contract and this manual specify certain key control procedures. Breach of contract or failure to abide by factory key records policies can result in loss of the product line. Contracts specify that: 1. The bla...

Page 12

Technical manual section 2: product information preferred/classic.

Page 13: 6-Pin 140

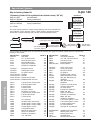

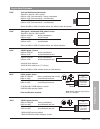

Section 2 - 1 p ro d u c t in fo rm a tio n 3418-00-3000 3418-00-3001 3418-00-3002 3418-00-3003 corbin russwin adams rite standard best and dl4000 corbin russwin length: 1.080" cloverleaf 3418-00-3004 3418-00-3008 3418-00-3009 3418-00-3010 sargent and yale ar 4070 schlage l falcon length: 1.010" 6-p...

Page 14: 6-Pin 140

Section 2 - 2 p ro d u c t in fo rm a ti o n 6-pin 140 8402-xx-1010 3402-xx-1010 standard screw hole locations 8402-xx-1012 3402-xx-1012 screw holes “high and outside” for sargent exit devices plug & shell assembly break-off screws 2 required backplate 3500-xx-2003 collar finish to match cylinder ea...

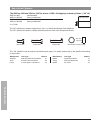

Page 15: 6-Pin 140

Universal cylinder kit for cylindrical and tubular locks (“99” kit) 8400-xx-1099 uncombinated 8400-xx-1299-99 factory combinated 3400-xx-1099 uncombinated 3400-xx-1299-99 factory combinated xx = finish section 2 - 3 p ro d u c t in fo rm a tio n key-in-knob cylinders 6-pin 140 the screw cap plug ret...

Page 16

Section 2 - 4 p ro d u c t in fo rm a ti o n 3450-00-2002 long double cylinder lost motion tailpiece 3450-00-2001 short double cylinder lost motion tailpiece 3450-00-2000 single cylinder lost motion tailpiece 3450-80-2004 timing washer 3450-80-2003 spacing washer 1590-80-2000 sd/3a 4700-80-2001 sa/3...

Page 17

The 8800-xx-1006 and 3400-xx-1006 for arrow—lsda—schlage key-in-knob cylinders (“06” kit) 8400-xx-1006 uncombinated 8400-xx-1206-06 factory combinated 3400-xx1006 uncombinated 3400-xx-1206-06 factory combinated xx = finish the “06” cylinder also accepts original arrow, ilco, lori, marks and sargent ...

Page 18

Section 2 - 6 p ro d u c t in fo rm a ti o n 3800-00-4050 peaks multi-gage checks .140" and .150" spacing and depth for the a2 and a4 system. 6440-00-4001 staking tool 6840-00-3540 staking fixture 3800-00-3548 ejector tool 3840-00-3540 140 capping block (6 holes) 3400-00-4000 staking fixture for con...

Page 19: Peaks

Section 2 - 7 p ro d u c t in fo rm a tio n peaks ® preferred/classic notes.

Page 20: 6-Pin 140

Arrow single cylinder deadlocks 8400-xx-1299-90 factory combinated 8400-xx-1099 uncombinated and use* 3400-xx-1299-90 factory combinated 3400-xx-1099 uncombinated and use* *3450-00-2000 lost motion tailpiece *3450-80-2004 timing washer section 2 - 8 p ro d u c t in fo rm a ti o n key-in-knob cylinde...

Page 21

Arrow double cylinder deadlocks 8400-xx-1299-92 factory combinated 8400-xx-1099 uncombinated and use* 3400-xx-1299-92 factory combinated 3400-xx-1099 uncombinated and use* *3450-00-2002 long double cylinder lost motion tailpiece standard for 1 3 / 4 " doors *3450-80-2004 timing washer *3450-00-2001 ...

Page 22

Section 2 - 10 p ro d u c t in fo rm a ti o n corbin cl3300 grade 1 levers russwin 8400-xx-1299-20 factory combinated 8400-xx-1099 uncombinated and use* 3400-xx-1299-20 factory combinated 3400-xx-1099 uncombinated and use* *4700-80-2001 sa/3b tailpiece, vertical *3450-80-2003 spacing washer or, the ...

Page 23

Section 2 - 1 p ro d u c t in fo rm a tio n falcon ly grade 1 levers (same as early model imported pdq lever) 8400-xx-1299-23 factory combinated 8400-xx-1099 uncombinated and use* 3400-xx-1299-23 factory combinated 3400-xx-1099 uncombinated and use* *4700-80-2001 sa/3b tailpiece, vertical *3450-80-2...

Page 24

Falcon x series grade 1, hana knobs 8400-xx-1206-33 factory combinated 8400-xx-1006 uncombinated* 3400-xx-1206-33 factory combinated 3400-xx-1006 uncombinated* *4700-80-2006 fh tailpiece, horizontal *3450-80-2003 spacing washer or, use falcon tp-2, tp-4 or tp-6 with retainer tpr-1 falcon parts are n...

Page 25

Section 2 - 1 p ro d u c t in fo rm a tio n section 2 - 13 falcon older x series grade 1 knobs and unit locks with one-piece (capless) knobs and knob hole bushings 8400-xx-1295-21 factory combinated 8400-xx-1095 uncombinated and use* 3400-xx-1295-21 factory combinated 3400-xx-1095 uncombinated and u...

Page 26

Section 2 - 14 p ro d u c t in fo rm a ti o n lsda lx1000 grade 1 levers (prior to 1994) field modification required. 8400-xx-1299-18 factory combinated 8400-xx-1099 uncombinated and use* 3400-xx-1299-18 factory combinated 3400-xx-1099 uncombinated and use* *3450-80-2003 spacing washer *1590-80-2000...

Page 27

Section 2 - 15 p ro d u c t in fo rm a tio n marks 170, 190, 195 series levers, 210 series knobs 8400-xx-1299-01 factory combinated and use* 8400-xx-1099 uncombinated and use* 3400-xx-1299-01 factory combinated and use* 3400-xx-1099 uncombinated and use* *mark's tailpieces all functions except da, d...

Page 28

Section 2 - 16 p ro d u c t in fo rm a ti o n omnilock lever, key by-pass 8400-xx-1299-18 factory combinated 8400-xx-1099 uncombinated and use* 3400-xx-1299-18 factory combinated 3400-xx-1099 uncombinated and use* *1590-80-2000 sd/3a tailpiece, vertical *3450-80-2003 spacing washer sd/3a “99” plug &...

Page 29

Large diameter plug requires j or k series bottom pins section 2 - 17 p ro d u c t in fo rm a tio n sargent 10 + line levers, 2000 exit device trim 8400-xx-1295-10 factory combinated 8400-xx-1095 uncombinated and use* 3400-xx-1295-10 factory combinated 3400-xx-1095 uncombinated and use* *4700-00-400...

Page 30

Section 2 - 18 p ro d u c t in fo rm a ti o n sargent 464, 484 double cylinder deadlocks 8400-xx-1299-92 factory combinated 8400-xx-1099 uncombinated and use* 3400-xx-1299-92 factory combinated 3400-xx-1099 uncombinated and use* *3450-00-2002 long double cylinder lost motion tailpiece standard for 1...

Page 31

Section 2 - 19 p ro d u c t in fo rm a tio n schlage b100, b400, e, eb, fi60 and md double cylinder deadlocks 8400-xx-1299-92 factory combinated 8400-xx-1099 uncombinated and use* 3400-xx-1299-92 factory combinated 3400-xx-1099 uncombinated and use* *3450-80-2004 timing washer *3450-00-2002 long dou...

Page 32

Section 2 - 20 p ro d u c t in fo rm a ti o n schlage c & d series, and vandlgard grade 1 levers 8400-xx-1299-18 factory combinated 8400-xx-1099 uncombinated and use* 3400-xx-1299-18 factory combinated 3400-xx-1099 uncombinated and use* *1590-80-2000 sd/3a tailpiece, vertical *3450-80-2003 spacing w...

Page 33

Section 2 - 21 p ro d u c t in fo rm a tio n ultra 7000 ball knob 8400-xx-1299-18 factory combinated 8400-xx-1099 uncombinated and use* 3400-xx-1299-18 factory combinated 3400-xx-1099 uncombinated and use* *1590-80-2000 sd/3a tailpiece, vertical *3450-80-2003 spacing washer trilogy 2500 bypass, leve...

Page 34

Section 2 - 22 p ro d u c t in fo rm a ti o n yale 5300l grade 2 levers 8400-xx-1295-95 factory combinated then modify 8400-xx-1095 uncombinated and use* 3400-xx-1295-95 factory combinated then modify 3400-xx-1095 uncombinated and use* *4700-80-2001 sa/3b tailpiece, vertical *3450-80-2003 spacing wa...

Page 35: 6-Pin 140

1. “l” adapter 2. Shorten adapter* 3. Notch for key tip and retainer ring *dealers have reported that shortening isn’t always necessary. American padlocks use 8400-xx-1006 or 3400-xx-1006 cylinder. Shorten medeco adapter .050" lori adapter may also be modified. Section 2 - 23 p ro d u c t in fo rm a...

Page 36: 6-Pin 140

Section 2 - 24 p ro d u c t in fo rm a ti o n • 8800/8900 or 3800/6800 small format interchangeable cores can be installed in most cabinet locks, mailbox locks and switch locks prepped for small format interchangeable core. • olympus cabinet lock with corbin russwin large format interchangeable core...

Page 37: 6-Pin 140

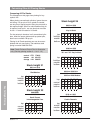

Section 2 - 25 p ro d u c t in fo rm a tio n uncombinated: combinated: 8840-xx-1006 8840-xx-1206 140, 6-pin 8850-xx-1006 8850-xx-1206 150, 6-pin 8850-xx-1007 8850-xx-1207 150, 7-pin 3840-xx-1006 3840-xx-1206 140, 6-pin 3850-xx-1006 3850-xx-1206 150, 6-pin 3850-xx-1007 3850-xx-1207 150, 7-pin 6-pin 1...

Page 38: 6-Pin 140

Section 2 - 26 p ro d u c t in fo rm a ti o n note: yale cores are not interchangeable across yale’s product line. It must be determined if you are replacing a yale 1210, 6-pin core, or a yale 1220, 7-pin core. Uncombinated: combinated: 8244-xx-1006 8244-xx-1206 for yale 1210 140, 6-pin 6240-xx-1006...

Page 39: 6-Pin 140

Section 2 - 27 p ro d u c t in fo rm a tio n 6-pin 140 • brass plug • alloy shell and control sleeve with patented plating and coating • spring cover retains pins and springs • 6840-00-3540 staking fixture and 6440-00-4001 staking tool required • no forbidden or mandatory control combinations • face...

Page 40

Section 2 - 28 p ro d u c t in fo rm a ti o n for specification purposes, 6-pin peaks products have seven active pin stacks and 7-pin peaks products have eight active pin stacks. Texts of product specifications are available upon request. Mechanical testing testing of 8900/6800 series cores has prov...

Page 41: Peaks

Section 2 - 30 p ro d u c t in fo rm a tio n peaks ® preferred/classic notes.

Page 42: Peaks

Section 2 - 31 p ro d u c t in fo rm a ti o n peaks ® preferred/classic notes.

Page 43: Peaks

Section 2 - 32 p ro d u c t in fo rm a tio n peaks ® preferred/classic notes.

Page 44

Technical manual section 3: key cutting and pinning preferred/classic.

Page 45

Pat # 7181941 pat # 7181941 section 3 - 1 k e y c u tti n g & p in n in g cylinder stamping, marking, lubrication & tailpiece installation stamping and marking kaba access control recommends marking cylinders with an indelible marker. If stamping or engraving of cast cylinders is unavoidable the sta...

Page 46

Section 3 - 2 k e y c u tt in g & p in n in g stops peaks keys have two stops, a bow stop and a tip stop. The bow stop gauges keys in all current products. The tip stop gauges only in non-domed face small format interchangeable cores made prior to march, 1996. Either stop may be used when code cutti...

Page 47

Section 3 - 3 k e y c u tti n g & p in n in g duplication peaks tolerances are tighter than most other brands. Both depth and spacing must be held within +/- 0.002" for proper key operation. Key machines should be periodically gauged to maintain tolerances. Framon #2 contact framon at 517-354-5623 r...

Page 48

Section 3 - 4 k e y c u tt in g & p in n in g peaks products may be pinned to the a2 or a4 system. The patent pin stack is built into the face of all small format interchangeable cores. In large format interchangeable cores and conventional cylinders, the patent pins are installed when combinating. ...

Page 49

Section 3 - 5 k e y c u tti n g & p in n in g peaks preferred spring covers spring covers are curved. Install them by flattening with the 3400-00-4001 staking tool. 6800-00-2006 6-pin 6800 small format interchangeable cores 6800-00-2007 7-pin 6800 small format interchangeable cores, 5340 medeco larg...

Page 50

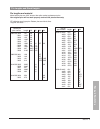

Section 3 - 6 k e y c u tt in g & p in n in g pin lengths and stack heights pin lengths and material kaba bottom pins are .003" shorter than after market replacement pins. Non-original pins will not work properly and void the product warranty. “s” indicates spool type pins. Bottom pins are nickel si...

Page 51

Section 3 - 7 k e y c u tti n g & p in n in g pin lengths and stack heights (continued) 8400 k-i-k 8400-xx-1099 8401/8402 8800 8144 corbin 8244 8444 8544 except 8400-xx-1095 conventional and russwin r/c yale schlage sargent 8400-xx-1099 with large mortise 8900 with large r/c r/c 8400-xx-1095 diamete...

Page 52

Section 3 - 8 k e y c u tt in g & p in n in g 8401 mortise specify cam 3425-00-2006 8800-00-3004 3425-00-3002 3800-00-4010 4701-98-4118 mortise/rim/rc stainless cam screws spring cover 3418-00-2000 cam cover 8402 rim 3410-00-2001 3425-00-2006 8800-00-3004 3425-00-3002 3800-00-4010 retainer mortise/r...

Page 53

3401 mortise specify cam 3425-00-2006 3800-00-3004 3425-00-3002 3800-00-4010 4701-98-4118 mortise/rim/rc stainless cam screws spring cover 3418-00-2000 cam cover 3402 rim 3410-00-2001 3425-00-2006 3800-00-3004 3425-00-3002 3800-00-4010 retainer mortise/rim/rc stainless spring cover 3400 key-in-knob ...

Page 54

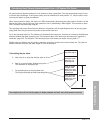

Section 3 - 10 k e y c u tt in g & p in n in g peaks conventional cylinders are designed to be top loaded. Install the peaks patent bottom and top pins in the patent chamber immediately next to the plug face. Peaks classic patent bottom pins are installed small end down, whereas peaks preferred pate...

Page 55

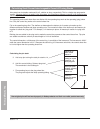

Section 3 - 11 k e y c u tti n g & p in n in g rekeying conventional cylinders pry off and discard the spring cover. Rekey and apply a new spring cover. Since all peaks products are designed to be top loaded, use of a follower for rekeying is optional. Mortise/rim cylinder screws have a loctite ® co...

Page 56

Section 3 - 12 k e y c u tt in g & p in n in g staking technique capping blocks and fixtures are designed to support cores at their waist to prevent sleeves and shells from becoming out-of-round. Working without proper equipment and technique can cause deformation resulting in poor operation, and ca...

Page 57

Section 3 - 13 k e y c u tti n g & p in n in g 8244/6240 large format interchangeable core for yale the 8244/6240 large format interchangeable core have an a2 system pin stack total of 26. Use 8244-xx-1006 or 6240-xx-1006 to retrofit yale 1210. 8244 cores use the following components: a2 system: a s...

Page 58

Section 3 - 14 k e y c u tt in g & p in n in g 8444/6440 schlage removable core the 8444/6440 large format removable core has an a2 system pin stack total of 26. 8444 cores use the large diameter plug and require the following components: a2 system: x series bottom pins and w series top pins a4 syst...

Page 59

Section 3 - 15 k e y c u tti n g & p in n in g rekeying pry off and discard the spring cover. Rekey, lubricate the cylinder with poxylube ® , and apply a new spring cover. Since all peaks products are designed to be top loaded, use of a follower for rekeying is optional. Mortise/rim cylinder screws ...

Page 60

Section 3 - 16 k e y c u tt in g & p in n in g calculating small format interchangeable core – a2 system pin stacks a2 system has ten depths numbered 0 to 9, shallow to deep, respectively. Two step progression must be used to prevent key interchange. In a2 system, parity must be maintained in each p...

Page 61

Section 3 - 17 k e y c u tti n g & p in n in g comparing a2 pin stacks the examples on this page show pinning for key symbol 1aa. When pinning conventional cylinders, ignore the con- trol bitting. If a top pin of 20 or greater is needed, use two pins of equal length to bring the pin stack to the req...

Page 62

#4 top pin makes stack total 23. #12 buildup pin makes stack height 19 for control. #2 master pin makes #7 cut of change key work. #5 bottom pin for #5 cut of tmk change key cut is 7 section 3 - 18 k e y c u tt in g & p in n in g 4 12 2 5 a small format interchangeable core pinning chart is an expan...

Page 63

Section 3 - 19 k e y c u tti n g & p in n in g calculating small format interchangeable cores a4 pinning stacks plug total add top pin to make a stack total of 14 buildup pin equals control cut + 6 minus plug total master pin equals the deep operating cut minus the shallow cut bottom pin equals the ...

Page 64

Section 3 - 20 k e y c u tt in g & p in n in g comparing a4 pin stacks the examples on this page show pinning for key symbol 1aa. When pinning conventional cylinders, ignore the control bitting. If a top pin of 12 or greater is need- ed, use two pins of equal length to bring the pin stack to the req...

Page 65

Section 3 - 21 k e y c u tti n g & p in n in g a4 system small format interchangeable core pinning chart #7 top pin makes stack total 14 #4 buildup pin makes stack height 7 for control. #1 master pin makes #3 cut of change key work. #2 bottom pin for #2 cut of tmk change key cut is 3 control 1 5 3 0...

Page 66: Peaks

Section 3 - 22 k e y c u tt in g & p in n in g peaks ® preferred/classic notes.

Page 67: Peaks

Section 3 - 23 k e y c u tti n g & p in n in g peaks ® preferred/classic notes.

Page 68

Preferred/classic technical manual section 4: key control & record keeping.

Page 69

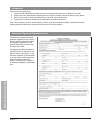

Section 4 - 1 k e y c o n tr o l & r e c o rd k e e p in g the kaba key system authorized signature registration form records the key system’s physical location and signature specimens of the persons authorized to order locks and keys from kaba. A completed authorized signature registration form is ...

Page 70

Section 4 - 2 k e y c o n tr o l & r e c o rd k e e p in g adding/deleting names on the authorized signature registration form 1. Current signatories only a person currently on the authorized signature registration form can add or delete others. 2. No current signatories a. Declaration of authority ...

Page 71

Section 4 - 3 k e y c o n tr o l & r e c o rd k e e p in g dealer written key systems dealers should follow the same authorization procedures as kaba for adding and deleting names on the authorized signature registration form. The initial order for a new key system factory systems: initial orders fo...

Page 72

Section 4 - 4 k e y c o n tr o l & r e c o rd k e e p in g cross keying cross keying kaba key systems discourages cross keying of any sort. If kaba key systems creates a key system, it is our intent to avoid cross keying totally if possible. If asked to generate a system with cross keying, we will g...

Page 73

Section 4 - 5 k e y c o n tr o l & r e c o rd k e e p in g expansion information is essential for accurately planning a key sys- tem. Expansion should include the installed portion of the key system and planned future growth. The key system expansion should be furnished in clear terms. For example, ...

Page 74

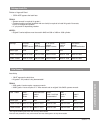

Ggm a b aa ab ba bb aa1 aa2 aa3 ab1 ab2 ab3 ba1 ba2 ba3 bb1 bb2 skd1 a aa ab aa1 aa2 aa3 a1 ab1 ab2 ab3 skd1 skd2 aa 1aa 2aa 3aa 4aa 5aa skd1 skd1 skd2 skd3 skd4 skd5 skd6 section 4 - 6 k e y c o n tr o l & r e c o rd k e e p in g the following key symbols are the lock industry standard, used by man...

Page 75

Section 4 - 7 k e y c o n tr o l & r e c o rd k e e p in g special symbols ggm ctr a b aa ba aa1 aa2 aa3 a1 ba1 ba2 ba3 b1 ggm1 skd1 change keys directly under higher level master keys take the name of their associated master key and add numbers after the letter(s). Skd’s, if used, are considered pa...

Page 76

Section 4 - 8 k e y c o n tr o l & r e c o rd k e e p in g skd’s used in a master key system the symbol skd is used to indicate combinations in a master key system that are never operated by a master key. Typical uses are for securing personnel records, pharmacies, evidence rooms in police stations,...

Page 77

Section 4 - 9 k e y c o n tr o l & r e c o rd k e e p in g the standards given below are used by the factory in designing and generating bitting lists. They apply to the top master key (tmk) in a system as well as the control key (ctr). Design standards 1. Tmk’s should have at least one of the shall...

Page 78

Section 4 - 10 k e y c o n tr o l & r e c o rd k e e p in g the tmk register logs all top master keys and control keys by system register number to prevent duplication of systems.This type of register is kept by all manufacturers. Kaba maintains their logs by keyway, parity pattern and system locati...

Page 79: Peaks

Section 4 - 11 k e y c o n tr o l & r e c o rd k e e p in g peaks ® preferred/classic notes.

Page 80

Preferred/classic technical manual section 5: cylinder installation guide.

Page 81

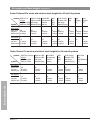

Section 5 - 1 c y lin d e r in s ta lla tio n g u id e this is an aid to selecting peaks key-in-knob cylinders for grade 1 and 2 cylindrical locksets. It should be used in conjunction with section 2 of the peaks technical manual and your own library of competitors' cata- logs and technical literatur...

Page 82

Section 5 - 2 c y li n d e r in s ta ll a ti o n g u id e identifying the manufacturer logo brand on face notes arrow yes “amerock” and other oem names have been used. Corbin yes prior to the brand merger in 1993, the individual brand names “corbin” or russwin “russwin” were used. The emhart logo, a...

Page 83

C y lin d e r i n s ta lla tio n g u id e key demountable handle (kdh): remove cylinder by turning any operating key, de press ing a retainer in the shank of the handle, and pulling on the handle. Most contemporary cylindrical locks have key demountable handles. Non-key demountable handle (non-kdh):...

Page 84

Division of yale security assa abloy • depending on the vintage, “corbin”, “corbin russwin”, “emhart”, and “russwin” will all be seen on latch faces. • corbin russwin’s proprietary profile core can be retrofit with peaks 8144/6140 rcore. Section 5 - 4 c y li n d e r in s ta ll a ti o n g u id e corb...

Page 85

Section 5 - 5 c y lin d e r i n s ta lla tio n g u id e retrofitting corbin russwin ck4200 grade 1 knobs current model, 1976 to date 1. Loosen inside rose with spanner wrench; depress knob retainer. 2. Remove inside trim; remove lock from door. Older locks do not have this plate. 3. Depress outside ...

Page 86

Section 5 - 6 c y li n d e r in s ta ll a ti o n g u id e retrofitting corbin russwin ck4200 grade 1 knobs models prior to 1976 locksets made prior to 1976 were made with the outside knob retainer rigid. To remove the outside knob on pre-1976 locksets, remove one of the chassis screws completely, an...

Page 87

Section 5 - 7 c y lin d e r i n s ta lla tio n g u id e division of ingersoll rand • “falcon” appears on the latch face. . Tools: • spanner wrench is required for grade 1. • 1 / 16 " pin punch for depressing retainer. Hole in edge of rose rose amityville, new york • “marks” appears on the latch face...

Page 88

Div. Of assa abloy “sargent” appears on the latch face. Latch face bears a number indicating product line (6, 7, 8, 9, 10, etc.). Sargent 10 line is identical to arrow lever, except for small plug face diameter. Tools: 7, 8 and 9 line grade 1 knobs require a 3 / 32 " hand held punch and mallet. 10 l...

Page 89

Section 5 - 9 c y lin d e r i n s ta lla tio n g u id e retrofitting sargent 7, 8 and 9 line grade 1 knobs rose unscrewed 1. With spanner wrench, loosen inside rose and unscrew outside rose com plete ly. 5. Pry up nylon ring and remove knob collar. 6. Drive roll pin com plete ly into knob with 3 / 3...

Page 90

Assa abloy • “yale” appears the latch face. • all grade 1 & 2 product is key demountable.* tools: • 3400 grade 1 knobs require a spanner wrench. • 3400l grade 1 levers require an 1 / 8 " allen wrench and an original yale 5400l spanner wrench. Section 5 - 10 c y li n d e r in s ta ll a ti o n g u id ...

Page 91: Peaks

Section 5 - 11 c y lin d e r i n s ta lla tio n g u id e peaks ® preferred/classic notes.

Page 92

Kaa1149 1209 kaba access control 2941 indiana avenue winston-salem, nc 27105 usa tel: (800) 849-8324 (336) 725-1331 fax: (800) 346-9640 (336) 725-3269 www.Kabaaccess.Com.