- DL manuals

- Kaisai

- Inverter

- SUPER DC INVERTER SERIES

- Service Manual

Kaisai SUPER DC INVERTER SERIES Service Manual

Summary of SUPER DC INVERTER SERIES

Page 1

Contents i new energy requirement super dc inverter series service manual 2012 lfis-b-1211.

Page 2

Ii general information.

Page 3

Contents lfis-b-1211 contents i part 1 general information .................................................................................................... 1 part 2 indoor units ................................................................................................................. 6 pa...

Page 5: Part 1

Lfis-b-1211 general information general information 1 part 1 general information 1. Model lists ................................................................................................ 2 2. External appearance ................................................................................ 3...

Page 6

Model lists lfis-b-1211 2 general information model lists 1.1 indoor units r410a (capacity multiplied by 1000btu/h) type function 18 24 36 super slim cassette cooling and heating ● ● ● duct cooling and heating ● ● ● ceiling-floor cooling and heating ● ● ● 1.2 outdoor units universal outdoor unit mod...

Page 7

Lfis-b-1211 external appearance general information 3 external appearance 1.2 indoor units super slim cassette duct ceiling-floor 2.2 outdoor units single fan outdoor unit.

Page 8

Nomenclature lfis-b-1211 4 general information nomenclature 3.1 indoor unit m u b t- 36 h r d n1- r power supply q 220~240v,1n, 50hz r 380~420v, 3n, 50hz n 220~230v, 1n, 60hz d 220v~, 3n, 60hz c 380~420v,3n,60hz refrigerant n1 r410a -- r22 d dc inverter -- on-off f full dc control mode w wired contr...

Page 9

Lfis-b-1211 features general information 5 features 4.1. To meet europe a level, actual eer/cop of new product with bldc motors of indoor & outdoor unit and dc compressor will be higher than 3.4. 4.2. Low ambient kit is standard for outdoor units 4.3. Network control function is standard for the ind...

Page 10: Part 2

Indoor units lfis-b-1211 6 indoor units part 2 indoor units super slim cassette type ............................................... 7 duct type ........................................................................ 20 ceiling & floor type ...................................................... 33.

Page 11: Super Slim Cassette Type

Lfis-b-1211 super slim cassette type indoor units 7 super slim cassette type 1. Features .............................................................................. 8 2. Dimensions ....................................................................... 12 3. Service space ...........................

Page 12

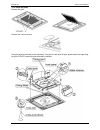

Features lfis-b-1211 8 indoor units 1. Features 1.1 overview compact design, super slim body size, less space requiring in installation each louver can be separately controlled, more comfort air blowing is possible. auto-lifting panel design, more convenient to clean and maintain the filter.(o...

Page 13

Lfis-b-1211 features indoor units 9 1.3 optional ionizer generator ionizer generator is optional to get refreshing air to your room. ionizer can be switched on or off by remote controller. When pressing the clean air button on the remote controller, ionizer will work and the indicator light on d...

Page 14

Features lfis-b-1211 10 indoor units 1.4 external air duct design reserve external air duct, more flexible for the air supply. 1.5 built-in draining pump due to the improvement of structure, more convenient to repair or replace the draining pump. built-in draining pump to make sure condensed w...

Page 15

Lfis-b-1211 features indoor units 11 1.6 terminals for alarm lamp and long-distance on-off controller connection are standard reserve terminals for the connection of alarm lamp and long-distance on-off controller, more human control. 1.7 standard touch screen wired controller touch screen wired ...

Page 16

Dimensions lfis-b-1211 12 indoor units 2. Dimensions model a h 18 205 >235 24 205 >235 36 245 >275.

Page 17

Lfis-b-1211 service space indoor units 13 3. Service space >1000mm >1000mm >1 00 0m m >10 00m m.

Page 18

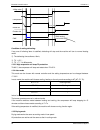

Wiring diagrams lfis-b-1211 14 indoor units 4. Wiring diagrams kcd-18hrfn1-qrc4 kcd-24hrfn1-qrc4 kcd-24hrfn1-qrc8 kcd-36hrfn1-qrc4.

Page 19

Lfis-b-1211 electric characteristics indoor units 15 5. Electric characteristics model indoor unit power supply hz voltage min max mfa kcd-18hrfn1-qrc4 50 220-240 198 254 15 kcd-24hrfn1-qrc4 50 220-240 198 254 15 kcd-24hrfn1-qrc8 50 220-240 198 254 15 kcd-36hrfn1-qrc4 50 220-240 198 254 15 notes: mf...

Page 20

Sound levels lfis-b-1211 16 indoor units 6. Sound levels 1.0m microphone model noise power db(a) noise level db(a) h m l kcd-18hrfn1-qrc4 58 47 43 36 kcd-24hrfn1-qrc4 59 48 44 40 kcd-24hrfn1-qrc8 64 48 44 40 kcd-36hrfn1-qrc4 65 54 50 48.

Page 21

Lfis-b-1211 accessories indoor units 17 7. Accessories installation fittings name shape quantity installation paper board 1 bolt m5 4 tubing & fittings soundproof / insulation sheath 2 drainpipe fittings out-let pipe 1 out-let pipe sheath 1 out-let pipe clasp 1 remote controller & its frame remote c...

Page 22

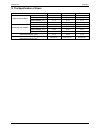

The specification of power lfis-b-1211 18 indoor units 8. The specification of power model 18000-24000btu/h 36000 36000 btu/h indoor unit power phase 1-phase 1-phase 1-phase frequency and voltage 220-240v, 50hz 220-240v, 50hz 220-240v, 50hz power wiring (mm 2 ) 3×1.0 3×1.0 3×1.0 circuit breaker (a) ...

Page 23

Lfis-b-1211 field wiring indoor units 19 9. Field wiring.

Page 24: Duct Type

Duct type lfis-b-1211 20 indoor units duct type 1. Features ............................................................................ 21 2. Dimensions ....................................................................... 24 3. Service space .........................................................

Page 25

Lfis-b-1211 duct type indoor units 21 1. Features 1.1 installation accessories: (optional) front board, canvas air passage, filter, panel, for easy installation 1.2 easy installation: two air inlet styles (bottom side or rear side) air inlet from rear is standard for all capacity; air inlet from...

Page 26

Duct type lfis-b-1211 22 indoor units replace the motor or centrifugal fan remove the ventilated panel firstly. Remove a half of blower housing and take out the motor with centrifugal fan. Directly remove two bolts, and then replace the motor or centrifugal fan easily. 1.5 reserved remote on-off a...

Page 27

Lfis-b-1211 duct type indoor units 23 1.7 built-in display board the standard indoor unit can be controlled by wired controller. there is a display board with a receiver in the e-box. Move out the display, and fix it in other place, even in the distance of 10m. The unit will realized remoter con...

Page 28

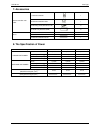

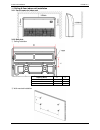

Duct type lfis-b-1211 24 indoor units 2. Dimensions h g e f a b d c l m capacity (kbtu) outline dimension(mm) air outlet opening size air return opening size size of outline dimension mounted plug a b c d e f g h i j k l m 18/24 920 270 635 570 65 713 35 179 815 260 20 960 350 30/36 1140 270 775 710...

Page 29

Lfis-b-1211 duct type indoor units 25 3. Service space ensure enough space required for installation and maintenance. All the indoor units reserve the hole to joint the fresh air pipe. The hole size as following:.

Page 30

Duct type lfis-b-1211 26 indoor units 4. Wiring diagrams ktb-18hwfn1-qrc4 ktb-24hwdn1-qrc4 ktb-36hwfn1-qrc4.

Page 31

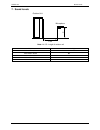

Lfis-b-1211 duct type indoor units 27 5. Static pressure 18,000btu/h 24,000btu/h super high speed 1400 1300 low speed 10 20 30 40 50 60 70 80 90 pa 800 900 1000 1100 air volume(m /h) 3 e xte rna l s tat ic p re ssu re ( pa) high speed mid speed 1200 1500 700 36,000btu/h 2400 2200 1600 1400 low speed...

Page 32

Duct type lfis-b-1211 28 indoor units 6. Electric characteristics model indoor unit power supply hz voltage min. Max. Mfa ktb-18hwfn1-qrc4 50 220-240 198 254 15 ktb-24hwdn1-qrc4 50 220-240 198 254 15 ktb-36hwfn1-qrc4 50 220-240 198 254 15 note: mfa: max. Fuse amps. (a).

Page 33

Lfis-b-1211 duct type indoor units 29 7. Sound levels suction discharge microphone 1.4m concealed duct type duct duct model sound power db(a) noise level db(a) h m l ktb-18hwfn1-qrc4 59 40 38 36 ktb-24hwdn1-qrc4 58 43 37 34 ktb-36hwfn1-qrc4 64 48 44 40

Page 34

Duct type lfis-b-1211 30 indoor units 8. Accessories tubing & fittings name shape quantity soundproof / insulation sheath 2 binding tape 1 seal sponge 1 drainpipe fittings (for cooling & heating) drain joint 1 seal ring 1 wired controller & its frame wired controller 1 others owner , s manual 1 inst...

Page 35

Lfis-b-1211 duct type indoor units 31 9. The specification of power model 18000-24000btu/h 36000 36000 btu/h indoor unit power phase 1-phase 1-phase 1-phase frequency and voltage 220-240v, 50hz 220-240v, 50hz 220-240v, 50hz power wiring (mm 2 ) 3×1.0 3×1.0 3×1.0 circuit breaker (a) 15 15 15 outdoor ...

Page 36

Duct type lfis-b-1211 32 indoor units 10. Field wiring.

Page 37: Ceiling & Floor Type

Lfis-b-1211 duct type indoor units 33 ceiling & floor type 1. Features ...................................................................... 34 2. Dimensions ................................................................. 35 3. Service space ..........................................................

Page 38

Duct type lfis-b-1211 34 indoor units 1. Features 1.1. New design, more modern and elegant appearance. 1.2. 1.2. Convenient installation --the ceiling type can be easily installed into a corner of the ceiling even if the ceiling is very narrow --it is especially useful when installation of an air co...

Page 39

Lfis-b-1211 duct type indoor units 35 2. Dimensions capacity (btu/h) a b c d e 18k, 24k 1068 675 235 983 220 36k 1285 675 235 1200 220

Page 40

Duct type lfis-b-1211 36 indoor units 3. Service space.

Page 41

Lfis-b-1211 duct type indoor units 37 4. Wiring diagrams kue-18hrdn1-qrc4 kue-24hrdn1-qrc4 kue-24hrfn1-qrc8 kue-36hrfn1-qrc4.

Page 42

Duct type lfis-b-1211 38 indoor units 5. Electric characteristics model indoor units power supply hz voltage min. Max. Mca mfa kue-18hrdn1-qrc4 50 220-240v 197v 254v 1.25 20 kue-24hrdn1-qrc4 50 220-240v 197v 254v 1.25 20 kue-24hrfn1-qrc8 50 220-240v 197v 254v 1.25 20 kue-36hrfn1-qrc4 50 220-240v 197...

Page 43

Lfis-b-1211 duct type indoor units 39 7. Accessories remote controller & its holder 1. Remote controller 1 2. Remote controller holder 1 3. Mounting screw (st2.9×10-c-h) 2 4. Alkaline dry batteries (am4) 2 others 5. Owner's manual 1 6. Installation manual 1 7. Remote controller manual 1 8. The speci...

Page 44

Field wiring lfis-b-1211 40 part 3 9. Field wiring.

Page 45: Part 3

Lfis-b-1211 part 3 part 3 41 part 3 outdoor units 1. Dimensions ................................................................................................. 42 2. Service space ............................................................................................. 43 3. Piping diagrams .....

Page 46

Dimensions lfis-b-1211 42 part 3 1. Dimensions model unit:mm a b c d e f h kou-18hfn1-qrc4 845 560 335 360 313 324 700 kou-24hfn1-qrc4 895 590 333 355 302 313 862 kou-24hfn1-qrc8 895 590 333 355 302 313 862 kou-36hfn1-qrc4 990 624 366 396 340 354 966 kou-36hfn1-rrc4 990 624 366 396 340 354 966.

Page 47

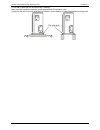

Lfis-b-1211 service space part 3 43 2. Service space more than 60cm more than 30cm more than 60cm more than 200cm air inlet air inlet more than 30cm air outlet (wall or obstacle) maintain channel.

Page 48

Piping diagrams lfis-b-1211 44 part 3 3. Piping diagrams kou-18hfn1-qrc8 kou-24hfn1-qrc4 kou-24hfn1-qrc8 low pressure switch high pressure switch liquid side gas side heat exchange (evaporator) heat exchange (condenser) compressor 2-way valve 3-way valve 4-way valve cooling heating t2 evaporator tem...

Page 49

Lfis-b-1211 wiring diagrams part 3 45 4. Wiring diagrams kou-18hfn1-qrc4 kou-24hfn1-qrc4 kou-24hfn1-qrc4 kou-36hfn1-qrc4.

Page 50

Wiring diagrams lfis-b-1211 46 part 3 kou-36hfn1-rrc4.

Page 51

Lfis-b-1211 electric characteristics part 3 47 5. Electric characteristics model outdoor unit hz voltage min. Max. Kou-18hfn1-qrc4 50 220-240v 198v 254v kou-24hfn1-qrc4 50 220-240v 198v 254v kou-24hfn1-qrc8 50 220-240v 198v 254v kou-36hfn1-qrc4 50 220-240v 198v 254v kou-36hfn1-rrc4 50 380-415v 342v ...

Page 52

Operation limits lfis-b-1211 48 part 3 6. Operation limits temperature mode cooling operation heating operation room temperature ≥17℃ ≤30℃ outdoor temperature -15℃~50℃ -15℃~24℃ caution: 1. If the air conditioner is used beyond the above conditions, certain safety protection features may come into op...

Page 53

Lfis-b-1211 sound levels part 3 49 7. Sound levels h 1.0m outdoor unit microphone note: h= 0.5 × height of outdoor unit model sound power db(a) kou-18hfn1-qrc4 65 kou-24hfn1-qrc4 69 kou-24hfn1-qrc8 69 kou-36hfn1-qrc4 69 kou-36hfn1-rrc4 70

Page 54: Part 4

Installation lfis-b-1211 50 installation part 4 installation 1. Installation procedure .................................................... 51 2. Location selection .......................................................... 52 3. Indoor unit installation ................................................

Page 55

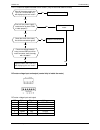

Lfis-b-1211 installation procedure installation 51 1. Installation procedure vacuum drying and leakage checking additional refrigerant charge insulation the joint part of refrigerant pipe wiring connection and electric safety checking test operation refrigerant pipe installation and insulation drain...

Page 56

Location selection lfis-b-1211 52 installation 2. Location selection 2.1 indoor unit location selection the place shall easily support the indoor unit’s weight. the place can ensure the indoor unit installation and inspection. the place can ensure the indoor unit horizontally installed. the ...

Page 57

Lfis-b-1211 indoor unit installation installation 53 3. Indoor unit installation 3.1 supper slim cassette indoor unit installation 3.1.1 service space for indoor unit model a h remark 24-30 205 >235 r410a and r22 cooling / cooling & heating 36-48 245 >275 r410a and r22 cooling / cooling & heating 3....

Page 58

Indoor unit installation lfis-b-1211 54 installation drill four holes of Ø12mm, 45~50mm deep at the selected positions on the ceiling. Then embed the expansible hooks (fittings). 3.1.4 install the main body make the 4 suspender through the 4 hanger of the main body to suspend it. Adjust the hexangul...

Page 59

Lfis-b-1211 indoor unit installation installation 55 3.1.5 install the panel remove the grille remove the 4 corner covers. Hang the panel to the hooks on the mainbody. If the panel is with auto-lift grille, please watch the ropes lifing the grille, do not make the ropes enwinded or blocked..

Page 60

Indoor unit installation lfis-b-1211 56 installation tighten the screws under the panel hooks till the panel closely stick on the ceiling to avoid condensate water. Hang the air-in grill to the panel, then connect the lead terminator of the swing motor and that of the control box with corresponding ...

Page 61

Lfis-b-1211 indoor unit installation installation 57 3.2 a5 duct indoor unit installation 3.2.1 service space for indoor unit 3.2.2 bolt pitch capacity(kbtu) size of outline dimension mounted plug l m 24 960 350 30/36 1180 490 48/60 1240 500 3.2.3 install the pendant bolt select the position of inst...

Page 62

Indoor unit installation lfis-b-1211 58 installation 3.2.4 install the main body make the 4 suspender through the 4 hanger of the main body to suspend it. Adjust the hexangular nuts on the four installation hooks evenly, to ensure the balance of the body. Use a leveling instrument to make sure the l...

Page 63

Lfis-b-1211 indoor unit installation installation 59 3.3.7 change the air inlet direction ① take off ventilation panel and flange, cut off the staples at side rail. ② stick the attached seal sponge as per the indicating place in the following fig, and then change the mounting positions of air return...

Page 64

Indoor unit installation lfis-b-1211 60 installation 3.3 ceiling & floor indoor unit installation 3.3.1 service space for indoor unit 3.3.2 bolt pitch ① ceiling installation capacity (btu/h) d e 18k, 24k 983 220 36k 1200 220 48k, 60k 1565 220 ② wall-mounted installation.

Page 65

Lfis-b-1211 indoor unit installation installation 61 3.3.3 install the pendant bolt ① ceiling installation select the position of installation hooks according to the hook holes positions showed in upper picture. Drill four holes of Ø12mm, 45~50mm deep at the selected positions on the ceiling. Then e...

Page 66

Indoor unit installation lfis-b-1211 62 installation put the side panels and grilles back. ② wall-mounted installation hang the indoor unit by insert the tapping screws into the hanging arms on the main unit. (the bottom of body can touch with floor or suspended, but the body must install vertically...

Page 67

Lfis-b-1211 outdoor unit installation (side discharge unit) installation 63 4. Outdoor unit installation (side discharge unit) 4.1 service space for outdoor unit 4.2 bolt pitch model b c d 18k 560 335 360 24k 590 333 355 36k 624 366 396 4.3 install the unit since the gravity center of the unit is no...

Page 68

Outdoor unit installation (side discharge unit) lfis-b-1211 64 installation do not lean it more than 45, and do not lay it sidelong. Make concrete foundation according to the specifications of the outdoor units. Fasten the feet of this unit with bolts firmly to prevent it from collapsing in case of ...

Page 69

Lfis-b-1211 refrigerant pipe installation installation 65 5. Refrigerant pipe installation 5.1 maximum pipe length and height drop considering the allowable pipe length and height drop to decide the installation position. Make sure the distance and height drop between indoor and outdoor unit not exc...

Page 70

Refrigerant pipe installation lfis-b-1211 66 installation 5.2.12 locate the pipe and fix it by supporter for horizontal refrigerant pipe, the distance between supporters should not be exceed 1m. for vertical refrigerant pipe, the distance between supporters should not be exceed 1.5m. 5.2.13 conn...

Page 71

Lfis-b-1211 refrigerant pipe installation installation 67 5.3.2 size of joint pipes for indoor unit (r410a) 5.3.3 size of joint pipes for outdoor unit (r410a) 5.3.4 the branching pipe must be installed horizontally, error angle of it should not large than 10°. Otherwise, malfunction will be caused..

Page 72

Drainage pipe installation lfis-b-1211 68 installation 6. Drainage pipe installation install the drainage pipe as shown below and take measures against condensation. Improperly installation could lead to leakage and eventually wet furniture and belongings. 6.1 installation principle ensure at leas...

Page 73

Lfis-b-1211 drainage pipe installation installation 69 6.2.3 individual design of drainage pipe system the drainage pipe of air conditioner shall be installed separately with other sewage pipe, rainwater pipe and drainage pipe in building. the drainage pipe of the indoor unit with water pump sho...

Page 74

Drainage pipe installation lfis-b-1211 70 installation indoor unit more than 50mm more than 25mm plug water storage pipe 6.2.7 lifting pipe setting of indoor unit with water pump the length of lifting pipe should not exceed the pump head of indoor unit water pump. Pump head of big four way cassett...

Page 75

Lfis-b-1211 drainage pipe installation installation 71 6.3 drainage test 6.3.1 water leakage test after finishing the construction of drainage pipe system, fill the pipe with water and keep it for 24 hours to check whether there is leakage at joint section. 6.3.2 water discharge test 1. Natural drai...

Page 76

Vacuum drying and leakage checking lfis-b-1211 72 installation 7. Vacuum drying and leakage checking 7.1 purpose of vacuum drying eliminating moisture in system to prevent the phenomena of ice-blockage and copper oxidation. Ice-blockage shall cause abnormal operation of system, while copper oxide ...

Page 77

Lfis-b-1211 additional refrigerant charge installation 73 8. Additional refrigerant charge after the vacuum drying process is carried out, the additional refrigerant charge process need to be performed. the outdoor unit is factory charged with refrigerant. The additional refrigerant charge volum...

Page 78

Engineering of insulation lfis-b-1211 74 installation 9. Engineering of insulation 9.1 insulation of refrigerant pipe 9.1.1 operational procedure of refrigerant pipe insulation cut the suitable pipe → insulation (except joint section) → flare the pipe → piping layout and connection→ vacuum drying → ...

Page 79

Lfis-b-1211 engineering of insulation installation 75 cause leakage to damage the house decoration..

Page 80

Engineering of electrical wiring lfis-b-1211 76 installation 9.2.3 insulation material selection for drainage pipe the insulation material should be flame retardant material, the flame retardancy of the material should be selected according to the local law. thickness of insulation layer is usua...

Page 81

Lfis-b-1211 test operation installation 77 11. Test operation 11.1 the test operation must be carried out after the entire installation has been completed. 11.2 please confirm the following points before the test operation. the indoor unit and outdoor unit are installed properly. tubing and wiri...

Page 82: Part 5

Electrical control system lfis-b-1211 78 electrical control system part 5 electrical control system 1. Electrical control function ...................................... 79 2. Troubleshooting ........................................................ 88 3. Controller .....................................

Page 83

Lfis-b-1211 electrical control function electrical control system 79 1. Electrical control function 1.1 definition t1: indoor room temperature t2: coil temperature of indoor heat exchanger middle. T2b: coil temperature of indoor heat exchanger outlet. T3: coil temperature of condenser t4: outdoor am...

Page 84

Electrical control function lfis-b-1211 80 electrical control system 1.3 operation modes and functions 1.3.1 fan mode ( 1) outdoor fan and compressor stop. (2) temperature setting function is disabled, and no setting temperature is displayed. (3) indoor fan can be set to high/(med)/low/auto. (4) the...

Page 85

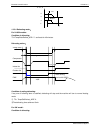

Lfis-b-1211 electrical control function electrical control system 81 5.0 4.0 high low 2.0 medium 3.0 1.3.2.4 evaporator low temperature t2 protection. When t2 1.3.2.5 condenser high temperature t3 protection when t3≥65℃ for 3 seconds, the compressor will shut off. When t3<52,the compressor will rest...

Page 86

Electrical control function lfis-b-1211 82 electrical control system -2 t1-ts- ¦ ¤ t -3 high low -5 medium -4 1.3.3.4 defrosting mode: for 24-36k models: condition of defrosting: t3≤tempenterdefrost_add ℃ and lasts for 40 minutes. Defrosting action: 4-way valve indoor fan outdoor fan 480p pmv pmv ru...

Page 87

Lfis-b-1211 electrical control function electrical control system 83 t4 3℃ time1 time2 time conditions: time1 time conditions(meet the following conditions) 1.Running in heating mode 2. T4 ≥3℃ 3. Compressor is on 4. T3 ≤tempenterdefrost_add ℃ cleared conditions (meet any one of the following conditi...

Page 88

Electrical control function lfis-b-1211 84 electrical control system 4-way valve indoor fan outdoor fan 480p pmv pmv running 8 mins with 300p compressor 10s 30s timea 10s no longer than 10min condition of ending defrosting: if any one of following items is satisfied, defrosting will stop and the mac...

Page 89

Lfis-b-1211 electrical control function electrical control system 85 1.3.6 timer function 1.3.6.1 timing range is 24 hours. 1.3.6.2 timer on. The machine will turn on automatically when reaching the setting time. 1.3.6.3 timer off. The machine will turn off automatically when reaching the setting ti...

Page 90

Electrical control function lfis-b-1211 86 electrical control system 1.3.10 point check function there is a check switch in outdoor pcb. Press the switch sw1 to check the states of unit when the unit is running. Press the switch n times it will display the content corresponding to no. N. After getti...

Page 91

Lfis-b-1211 electrical control function electrical control system 87 show single digit and tens digit. (for example, the digital display tube show “0.5”,it means the igbt radiator temp. Is 105 degree. The digital display tube show “1.6”,it means the igbt radiator temp. Is 116 degree) 18 indoor unit ...

Page 92

Troubleshooting lfis-b-1211 88 electrical control system 2. Troubleshooting 2.1 display board 2.1.1 icon explanation on indoor display board (super slim cassette). 2.1.2 icon explanation on indoor display board (a5 duct) operation timer def./fan alarm temporary button operation lamp timer indicator ...

Page 93

Lfis-b-1211 troubleshooting electrical control system 89 2.2 indoor unit malfunction no. Malfunction running lamp timer lamp defrosting lamp alarm lamp display(digital tube) 1 communication malfunction between indoor and outdoor units. X ☆ x x e1 2 open or short circuit of t1 temperature sensor ☆ x ...

Page 94

Troubleshooting lfis-b-1211 90 electrical control system 2.4 solving steps for typical malfunction 2.4.1 for the indoor unit 2.4.1.1 open or short circuit of temperature sensor check the connections between temperature sensor and pcb. Are the connections good? Correct the connections. No yes yes rep...

Page 95

Lfis-b-1211 troubleshooting electrical control system 91 2.4.1.2. Outdoor unit malfunction whether the outdoor main board has error display refer to corresponding solving steps yes no no check whether the power is on replace outdoor main board yes whether the outdoor unit is power on check whether t...

Page 96

Troubleshooting lfis-b-1211 92 electrical control system 2.4.1.3. Indoor eeprom malfunction if the eeprom chip is welded on pcb, replace the pcb directly. Otherwise, check whether the eeprom chip plugged in pcb well? Yes no yes insert the eeprom well replace the indoor pcb. Shut off the power supply...

Page 97

Lfis-b-1211 troubleshooting electrical control system 93 2.4.1.5. Indoor fan speed has been out of control. (only for the units used dc motor) shut off the power supply and turn it on 1 minute later. Is it still displaying the error code? Shut off the power supply, rotate the fan by hand. Does it ro...

Page 98

Troubleshooting lfis-b-1211 94 electrical control system control chip is in main pcb no. 1 2 3 4 5 color orange grey white pink black signal hu hv hw vcc gnd color red blue yellow signal w v u 1) release the uvw connector. Measure the resistance of u-v, u-w, v-w. If the resistance is not equal to ea...

Page 99

Lfis-b-1211 troubleshooting electrical control system 95 2.4.2 for the super-slim cassette with up-down panel 2.4.2.1communication error between indoor unit and up-down panel 2.4.2.2 up-down panel is defective.

Page 100

Troubleshooting lfis-b-1211 96 electrical control system 2.4.2.3 up-down panel is not closed.

Page 101

Lfis-b-1211 troubleshooting electrical control system 97 2.4.3 for the unit with twins function 2.4.3.1 communication failure between master unit and indoor unit.

Page 102

Troubleshooting lfis-b-1211 98 electrical control system 2.4.4 for the outdoor unit 2.4.4.2. E0 malfunction if the eeprom chip is welded on pcb, replace the pcb directly. Otherwise, check whether the eeprom chip plugged in pcb well? Yes no yes insert the eeprom well replace the outdoor main board ou...

Page 103

Lfis-b-1211 troubleshooting electrical control system 99 2.4.4.3. E2 malfunction (only for 12k) yes yes measure vs, is it moving alternately between positive value and negative value? (vs is the voltage between s and n of outdoor unit.) yes power off, then turn on the unit 5 seconds later(reconnect ...

Page 104

Troubleshooting lfis-b-1211 100 electrical control system 2.4.4.4. E2 malfunction (for 18-60k) no power off, then turn on the unit 5 seconds later(reconnect the power wire).Is the error still displaying after several minutes? Check whether the signal wire is shield cable or whether the shield cable ...

Page 105

Lfis-b-1211 troubleshooting electrical control system 101 2.4.4.5. E3 malfunction communication malfunction between ipm board and outdoor main board is there at least one led in the ipm board light? Check the signal wire between the ipm module and the main board, is it connected good? Reconnect and ...

Page 106

Troubleshooting lfis-b-1211 102 electrical control system 2.4.4.6. E4 malfunction judge 1: outdoor condenser temp. Sensor (t3) is malfunction e4 display no no replace condenser temp. Sensor(t3) check whether the wiring of the condenser temp. Sensor(t3) is broken off check whether the resistance of c...

Page 107

Lfis-b-1211 troubleshooting electrical control system 103 2.4.4.7. E5 malfunction (for single phase units) voltage protection check the voltage of outdoor unit power supply, whether the voltage between l(1) and n is about 220~240vac check the power supply check whether the voltage of ipm board p and...

Page 108

Troubleshooting lfis-b-1211 104 electrical control system 2.4.4.8. E5 malfunction (for three phases units) voltage protection check the voltage of outdoor unit power supply, whether the voltage between l(1) ,l(2),l(3)and n is about 220vac and between l(1) ,l(2),l(3) is about 380vac check the power s...

Page 109

Lfis-b-1211 troubleshooting electrical control system 105 2.4.4.9. E6 malfunction (only for 36k, 48k with 1 phase) e6 display pfc module protection check whether the connecting line between main board and the pfc module is connected tightly yes check whether the voltage range of p-n on ipm module is...

Page 110

Troubleshooting lfis-b-1211 106 electrical control system 2.4.4.10. P0 malfunction p0 display temperature protection of compressor top whether compressor operates? Whether refrigerant circulation volume is normal? Whether abnormality is the same after gas charging? Yes no no reconnect and retest. No...

Page 111

Lfis-b-1211 troubleshooting electrical control system 107 2.4.4.11. P1 malfunction (only for 30k~60k) p1 display high pressure protection judge 1: whether the wiring between the high pressure switch and main control board is connected well or correctly method: short connect the high pressure protect...

Page 112

Troubleshooting lfis-b-1211 108 electrical control system 2.4.4.12. P2 malfunction (only for 30k~60k) p2 display low pressure protection judge 1: whether the wiring between the low pressure protector and main control board is connected well or correctly method: short connect the low pressure protect...

Page 113

Lfis-b-1211 troubleshooting electrical control system 109 2.4.4.13. P3 malfunction p3 display current protection of compressor judge 1: check whether the input current of the power supply wire is more than 20a (for 36k & 48k with 1 phase, it is 30a) yes replace the electric control box check whether...

Page 114

Troubleshooting lfis-b-1211 110 electrical control system 2.4.4.14. P4 malfunction whencompressor discharge temperature is higher than 115°c, the unit will stop, and unit runs again when compressor discharge temperature is lower than 90°c. P4 display temperature protection of compressor discharge ch...

Page 115

Lfis-b-1211 troubleshooting electrical control system 111 2.4.4.15. P5 malfunction when condenser high temp. Is more than 65°c, the unit will stop, and unit runs again when outdoor pipe temp. Less than 52°c. P5 display high temperature protection of condenser check whether the condenser temperature ...

Page 116

Troubleshooting lfis-b-1211 112 electrical control system 2.4.4.16. P6 malfunction (for single phase units) at first test the resistance between every two ports of u, v, w of ipm and p, n. If any result of them is 0 or close to 0, the ipm is defective. Otherwise, please follow the procedure below: p...

Page 117

Lfis-b-1211 troubleshooting electrical control system 113 2.4.4.17. P6 malfunction (for three phases units) at first test the resistance between every two ports of u, v, w of ipm and p, n. If any result of them is 0 or close to 0, the ipm is defective. Otherwise, please follow the procedure below: p...

Page 118

Troubleshooting lfis-b-1211 114 electrical control system 2.4.4.18. P7 malfunction p7 display high temperature protection of evaporator whether compressor operates? Yes check whether the heat exchanger is dirty, the air- outlet is blocked and the indoor fan is running normal? No check refrigerant sy...

Page 119

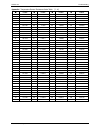

Lfis-b-1211 troubleshooting electrical control system 115 appendix 1 temperature sensor resistance value table (℃--k) ℃ k ohm ℃ k ohm ℃ k ohm ℃ k ohm -20 115.266 20 12.6431 60 2.35774 100 0.62973 -19 108.146 21 12.0561 61 2.27249 101 0.61148 -18 101.517 22 11.5000 62 2.19073 102 0.59386 -17 96.3423 ...

Page 120

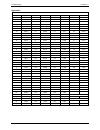

Troubleshooting lfis-b-1211 116 electrical control system appendix 2 unit: ℃---k discharge temp. Sensor table -20 542.7 20 68.66 60 13.59 100 3.702 -19 511.9 21 65.62 61 13.11 101 3.595 -18 483 22 62.73 62 12.65 102 3.492 -17 455.9 23 59.98 63 12.21 103 3.392 -16 430.5 24 57.37 64 11.79 104 3.296 -1...

Page 121

Lfis-b-1211 controller electrical control system 117 3. Controller 3.1wireless remote controller 3.1.1rg51q1/bge general function for wireless remote controller: model rg51q1/bge rated voltage 3.0v(2pieces of lr03 7# batteries) min voltage for sending signal of cpu 2.4v effective receiving distance ...

Page 122

Controller lfis-b-1211 118 electrical control system buttons and functions 1. Adjust : decrease the set temp. Keeping pressing will decrease the temp with 1℃ per 0.5s. 2. Adjust : increase the set temp. Keeping pressing will increase the temp with 1℃ per 0.5s. 3. Mode: once pressing, running mode wi...

Page 123

Lfis-b-1211 controller electrical control system 119 3.1.2 r51/e remote controller specifications model r51/e rated voltage 3.0v lowest voltage of cpu emitting signal 2.0v reaching distance 8m (when using 3.0 voltage, it can get 11m) environment temperature range -5℃~60℃ introduction of function but...

Page 124

Controller lfis-b-1211 120 electrical control system 10. Fan speed button: this button is used for setting fan speed in the sequence that goes from auto, low, med to high, and then back to auto. 11. Temp up button: push this button to increase the indoor temperature setting or to adjust the timer in...

Page 125

Lfis-b-1211 controller electrical control system 121 3.2 wired remote controller 3.2.1 kjr-10b name and functions of buttons on the wire controller 1 mode selection button: it is used to select mode, push the button one time, then the operation modes will change in turn as follows: auto cool dry hea...

Page 126

Controller lfis-b-1211 122 electrical control system name and function of lcd on the wire controller 1 mode select button (mode): press mode button to select “cool”, “dry” , "heat", or "fan only" mode.(heat is invalid for cool only wire controller.) auto cool dry heat fan 2 fan speed button (fan spe...

Page 127

Lfis-b-1211 controller electrical control system 123 installation installation notice: when the air conditioner needs the constant frequency wire controller, be sure adding a wire joint with 5 terminal named a, b, c, d, e in indoor unit, and fixing a infrared emitter whose anode and cathode connecti...