- DL manuals

- Kaliburn

- Welding System

- FineLine 200PC

- User manual

Kaliburn FineLine 200PC User manual

Summary of FineLine 200PC

Page 1

Fineline 200pc user’s manual fineline 200pc high density plasma cutting system with automatic gas console revision h 7/12/07 manual part number 718059 455 fleming road charleston, sc 29412 usa (800) 252-2850 – toll free (843) 795-4286 – phone (843) 795-8931 – fax www.Kaliburn.Net.

Page 2

This page intentionally left blank.

Page 3: Limited Warranty

Fineline 200pc user’s manual limited warranty kaliburn expressly warrants that this product shall be free from defects in materials and workmanship, under proper and normal use for the intended function of such equipment, for a period of one (1) year for the fineline 200pc torch and leads and three ...

Page 4

Fineline 200pc user’s manual electromagnetic compatibility (emc) the 380v 50hz and 415v 50hz fineline 200pc plasma cutting systems are manufactured to comply with the european standards en 60974 (arc welding equipment – part 1: welding power sources) and en 50199 (electromagnetic compatibility (emc)...

Page 5: Table of Contents

Fineline 200pc user’s manual table of contents section 1 safety ..……………………………………..……………………………. 1-1 general precautions .…………………………………………………..……….…..……… 1-1 ultraviolet radiation protection ..…………………………………………………………. 1-1 noise protection .……………………………………………………..……………………. 1-1 toxic fume prevention ...……...

Page 6

Fineline 200pc user’s manual setting up a cut .........……………………………………………………………………… 4-5 making a cut .................……………………………………………………………………4-11 cut quality ................……………………………………………………………………… 4-11 consumable life .......……………………………………………………………………… 4-12 cutting charts ...........………………………...

Page 7: Section 8 Parts List

Fineline 200pc user’s manual chopper test procedure ........................................................................................................ 7-12 section 8 parts list ................................................................................................. 8-1 power supply .....

Page 8

Fineline 200pc user’s manual figure 2-3 torch dimensions ......................................................................................... 2-6 figure 3-1 system interconnection diagram .................................................................. 3-2 figure 3-2 primary power connections...

Page 9

Fineline 200pc user’s manual figure 8-5 remote high frequency console ................................................................. 8-8 figure 8-6 torch and torch valve assembly ................................................................ 8-9 figure 8-7 shielded torch leads ....................

Page 10

This page intentionally left blank.

Page 11: Section 1 Safety

Safety fineline 200pc user’s manual section 1 safety general precautions whereas plasma cutting has been used safely for years, it does require certain precautions to ensure the safety of the operator and other people around the equipment. It is management’s responsibility to see that the following ...

Page 12: Electric Shock Prevention

Safety fineline 200pc user’s manual galvanized metal can produce harmful gases during the cutting process. Ensure proper ventilation and use breathing equipment when cutting these materials. Certain metals coated with or containing lead, cadmium, zinc, beryllium, and mercury produce harmful toxins. ...

Page 13: Fire Prevention

Safety fineline 200pc user’s manual will give the capacitors inside the unit time to discharge. • never operate the fineline system without all of the covers in place. • preventive maintenance should be performed daily to avoid possible safety hazards. Fire prevention when using the fineline 200pc s...

Page 14: Health Support Equipment

Safety fineline 200pc user’s manual • clear the compressed gas cylinder connection point by opening the valve momentarily prior to installing a regulator. • never lubricate compressed gas cylinder valves or pressure regulators with any type of oil or grease. • never use a compressed gas cylinder or ...

Page 15

Safety fineline 200pc user’s manual 4. Aws standard f4.1, recommended safe practices for preparation for welding and cutting of containers and piping, obtainable from the american welding society, 550 nw lejeune road, miami, fl 33126. 5. Aws standard ulr, ultraviolet reflectance of paint, obtainable...

Page 16

Safety fineline 200pc user’s manual 16. Cga booklet p-14, accident prevention in oxygen-rich and oxygen- deficient atmospheres, obtainable from the compressed gas association, 1725 jefferson davis highway, suite 1004, arlington, va 22202. 17. Cga booklet tb-3, hose line flashback arrestors, obtainab...

Page 17: Section 2 Specifications

Specifications fineline 200pc user’s manual section 2 specifications system description the fineline 200pc is a microprocessor controlled, 200 amp, 100% duty cycle high current density plasma cutting and marking system. It utilizes a precision, dual gas torch that is capable of cutting mild steel up...

Page 18: System Components

Specifications fineline 200pc user’s manual system components the fineline 200pc consists of the following components: standard components • power supply • automatic gas console • remote high frequency (rhf) console • rhf console control cable • torch and handle assembly • torch lead set • torch sol...

Page 19

Specifications fineline 200pc user’s manual dimensions: width ................................................................... 30 in (762 mm) height (including agc) ...................................... 48 in (1219 mm) depth .................................................................... 43...

Page 20

Specifications fineline 200pc user’s manual automatic gas console specifications stock number ........................................................... 200865 height ........................................................................ 9 in (229 mm) width ..........................................

Page 21

Specifications fineline 200pc user’s manual remote high frequency console specifications stock number ........................................................... 205500 height ........................................................................ 5.35 in (136 mm) width ...............................

Page 22: Torch Specifications

Specifications fineline 200pc user’s manual torch specifications stock number: torch main body .................................................. 277000 torch handle assembly ........................................ 820134 diameter .......................................................................

Page 23: Airborne Noise Emissions

Specifications fineline 200pc user’s manual airborne noise emissions the fineline 200pc system generates high noise levels while cutting. Depending on the size of the cutting area, distance from the cutting torch, and arc current cutting level, acceptable noise levels may be exceeded. Proper ear pro...

Page 24

This page intentionally left blank.

Page 25: Section 3 Installation

Installation fineline 200pc user’s manual section 3 installation initial inspection all systems undergo full testing before being shipped from kaliburn. In the unlikely event that one of your components is defective or missing, please contact kaliburn so a replacement item can be sent to you. Also, ...

Page 26

Installation fineline 200pc user’s manual in n er lo g ic , in c. Pr ec is io n a r c v o lt a g e c o n t r o l figure 3-1 system interconnection diagram 3-2.

Page 27: Power Supply Installation

Installation fineline 200pc user’s manual power supply installation the fineline power supply should be lifted by a forklift or pallet jack. In order to prevent damaging the power supply, the forks should be of adequate length to protrude on the far side of the power supply. The proper location of t...

Page 28

Installation fineline 200pc user’s manual 3 phase input voltage (vac) input current at maximum output (amps) recommended time-delay fuse size (amps) 208v 60hz 115 170 230v 60hz 104 150 380v 50hz 63 90 415v 50hz 58 80 460v 60hz 52 75 575v 60hz 42 60 use a type so power cable to connect the primary po...

Page 29

Installation fineline 200pc user’s manual power supply output connections perform the following steps to connect the output of the power supply to the rhf console and the work table. See figure 3-3 for additional information. Power supply electrode lead 1. Route one end of the #1/0awg power supply e...

Page 30

Installation fineline 200pc user’s manual power supply coolant return hose 1. Connect one end of the power supply coolant return hose to the coolant return fitting on the rear of the power supply. Note that the coolant return fitting has left hand threads. 6 2. Connect the other end of the power sup...

Page 31

Installation fineline 200pc user’s manual figure 3-3 power supply output connections 3-7.

Page 32

Installation fineline 200pc user’s manual torch leads to rhf console connections perform the following steps to connect the torch leads to the rhf console. See figure 3-4 for additional information. Note: when making hose connections, only tighten the brass fittings enough to make water or gas seals...

Page 33

Installation fineline 200pc user’s manual figure 3-4 torch leads to rhf console connections 3-9.

Page 34: Torch Connections

Installation fineline 200pc user’s manual torch connections perform the following steps to connect the torch leads and gas hoses to the torch and torch solenoid assembly. See figure 3-5 for additional information. Note: when making hose connections, only tighten the brass fittings enough to make wat...

Page 35

Installation fineline 200pc user’s manual torch to torch handle installation 1. Thread the torch handle onto the torch body. 2. Attach the solenoid valve assembly to the torch handle. The top of the aluminum solenoid bracket should be flush with the top of the torch handle. Torch plasma gas hose 16 ...

Page 36

Installation fineline 200pc user’s manual figure 3-5 torch connections 3-12.

Page 37

Installation fineline 200pc user’s manual automatic gas console input connections perform the following steps to connect the gas supply lines to the automatic gas console. See section 2 for gas supply requirements. Mating hose barbs and connectors are supplied with the system and are sized for 1/4 i...

Page 38

Installation fineline 200pc user’s manual automatic gas console output connections perform the following steps to connect the automatic gas console outputs to the torch gas hoses. Note: when making hose connections, only tighten the brass fittings enough to make gas seals. The fittings are subject t...

Page 39: Torch Coolant Requirements

Installation fineline 200pc user’s manual cnc machine interface connections perform the following steps to properly interface the fineline 200pc system with a cnc cutting machine. See the system schematic for additional information. Plasma start signal • the fineline 200pc requires a contact closure...

Page 40

Installation fineline 200pc user’s manual this solution provides freezing protection down to -13º c (9º f). For operating temperatures below -13º c, the concentration of propylene glycol in the coolant solution must be increased. See figure 3-8 to determine the percentage of propylene glycol require...

Page 41

Installation fineline 200pc user’s manual filling the torch coolant reservoir note: never turn on the power supply before filling the torch coolant reservoir with the proper coolant solution. 1. Remove the coolant reservoir cap and fill the reservoir with 2 gallons of coolant solution. 2. Apply main...

Page 42

This page intentionally left blank.

Page 43: Section 4 Operation

Operation fineline 200pc user’s manual 4-1 section 4 operation power supply front panel controls all of the fineline controls and status indicator lights are located on the front panel of the system. This section describes the function of each control and indicator. See figure 4-1 for front panel co...

Page 44

Operation fineline 200pc user’s manual 4-2 • coolant temperature indicator illuminates when the torch coolant temperature is satisfactory. Remains extinguished when the coolant temperature is too hot. If the torch coolant indicator goes out, leave the unit energized until it illuminates. Automatic g...

Page 45: Automatic Gas Console Keypad

Operation fineline 200pc user’s manual 4-3 automatic gas console keypad all cutting information is entered on the keypad of the automatic gas console as shown in figure 4-2. This section provides a description of each key and its function. Figure 4-2 automatic gas console keypad menu key the menu ke...

Page 46

Operation fineline 200pc user’s manual 4-4 arrow keys the arrow keys are used to scroll up and down in order to edit or select a particular item. Function keys the function keys are used for various purposes in the editing and maintenance modes. The help prompt instructs the user on the use of the f...

Page 47: Setting Up A Cut

Operation fineline 200pc user’s manual 4-5 automatic gas console status screen when the automatic gas console is in the status mode, the status screen is displayed as shown in figure 4-4. The status screen displays all of the primary cutting parameters. To edit a parameter on the status screen, the ...

Page 48

Operation fineline 200pc user’s manual 4-6 selecting material type from the status mode, press the down arrow once to scroll down to substance, or press menu, then material. The substance area should be highlighted as shown in figure 4-5 and the substance type should be blinking. To change the subst...

Page 49

Operation fineline 200pc user’s manual 4-7 setting material thickness to set the material thickness, use the down arrow to scroll down to thickness. The material thickness should be highlighted as shown in figure 4-6 and the editing cursor should be blinking. Use the numerical keypad to enter the ma...

Page 50

Operation fineline 200pc user’s manual 4-8 selecting process to set the operating process, use the down arrow to scroll down to process. The process area should be highlighted as shown in figure 4-7 and the process should be blinking. To change the process, press f3 as indicated by the help prompt. ...

Page 51

Operation fineline 200pc user’s manual 4-9 viewing the torch parts required to make the cut once the material substance, thickness, and process have been chosen, the default cutting parameters are selected and adjusted accordingly. To display a pictorial view of the torch parts required to make the ...

Page 52

Operation fineline 200pc user’s manual 4-10 cap and clean as necessary. 5. Install a small amount of o-ring lubricant to the three o-rings on the torch body. 6. Apply a small amount of o-ring lubricant to the retaining cap o-ring and install the retaining cap onto the torch body. Tighten the cap fir...

Page 53: Making A Cut

Operation fineline 200pc user’s manual 4-11 making a cut once the material type, thickness, and process have been entered, the correct torch parts are installed, and the x/y machine and height control systems have been properly configured, perform the following steps to cut with the system: 1. Depre...

Page 54: Consumable Life

Operation fineline 200pc user’s manual 4-12 the cutting speed is too slow. 3. Top dross usually occurs when the torch standoff distance is too high. 4. Bottom dross usually occurs when the cutting speed is either too slow (slow- speed dross) or too fast (high-speed dross). Low-speed dross is easily ...

Page 55: Cutting Charts

Operation fineline 200pc user’s manual 4-13 cutting charts the cutting charts shown on the following pages are intended to give the operator the best starting point to use when making a cut on a particular material type and thickness. Small adjustments may have to be made to achieve the best cut. Al...

Page 56

Operation fineline 200pc user’s manual 4-14 mild steel - cutting 30 amps – oxygen plasma / oxygen shield shield cap nozzle electrode 277145 277120 277130 outer cap retaining cap swirl ring torch main body 277154 277153 277140 277000 imperial material thickness preflow (air) plasma (oxygen) shield (o...

Page 57

Operation fineline 200pc user’s manual 4-15 mild steel - cutting 50 amps – oxygen plasma / oxygen or air shield shield cap nozzle electrode 277115 277122 277131 outer cap retaining cap swirl ring torch main body 277154 277153 277140 / 277142 277000 imperial cold-rolled steel – oxygen shield – swirl ...

Page 58

Operation fineline 200pc user’s manual 4-16 mild steel - cutting 70 amps – oxygen plasma / air shield shield cap nozzle electrode 277150 277125 277131 outer cap retaining cap swirl ring torch main body 277154 277153 277142 277000 imperial material thickness preflow (air) plasma (oxygen) shield (air)...

Page 59

Operation fineline 200pc user’s manual 4-17 mild steel - cutting 100 amps – oxygen plasma / air shield shield cap nozzle electrode 277286 277284 277282 outer cap retaining cap swirl ring torch main body 277154 277151 277283 277000 imperial material thickness preflow (air) plasma (oxygen) shield (air...

Page 60

Operation fineline 200pc user’s manual 4-18 mild steel - cutting 150 amps – oxygen plasma / air shield shield cap nozzle electrode 277117 277293 277292 outer cap retaining cap swirl ring torch main body 277154 277151 / 277152 277139 277000 imperial retaining cap 277151 material thickness preflow (ai...

Page 61

Operation fineline 200pc user’s manual 4-19 mild steel - cutting 200 amps – oxygen plasma / air shield shield cap nozzle electrode 277274 277289 277291 outer cap retaining cap swirl ring torch main body 277154 277266 277143 277000 imperial material thickness preflow (air) plasma (oxygen) shield (air...

Page 62

Operation fineline 200pc user’s manual 4-20 stainless steel - cutting 30 amps – air plasma / air shield shield cap nozzle electrode 277144 277121 277137 outer cap retaining cap swirl ring torch main body 277154 277110 277138 277000 imperial material thickness preflow (air) plasma (air) shield (air) ...

Page 63

Operation fineline 200pc user’s manual 4-21 stainless steel - cutting 50 amps – air plasma / nitrogen shield shield cap nozzle electrode 277149 277123 277137 outer cap retaining cap swirl ring torch main body 277154 277110 277142 277000 imperial material thickness preflow (air) plasma (air) shield (...

Page 64

Operation fineline 200pc user’s manual 4-22 stainless steel - cutting 70 amps – h17 plasma / nitrogen shield this gas combination gives the best cut quality and minimum dross levels shield cap nozzle electrode 277150 277124 277132 outer cap retaining cap swirl ring torch main body 277154 277113 2771...

Page 65

Operation fineline 200pc user’s manual 4-23 stainless steel - cutting 70 amps – air plasma / nitrogen shield this gas combination gives medium cut quality and minimum dross levels shield cap nozzle electrode 277150 277125 277131 outer cap retaining cap swirl ring torch main body 277154 277153 277142...

Page 66

Operation fineline 200pc user’s manual 4-24 stainless steel - cutting 100 amps – h17 plasma / nitrogen shield this gas combination gives the best cut quality and minimum dross levels shield cap nozzle electrode 277146 277126 277133 outer cap retaining cap swirl ring torch main body 277154 277113 277...

Page 67

Operation fineline 200pc user’s manual 4-25 stainless steel - cutting 100 amps – air plasma / nitrogen shield this gas combination gives medium cut quality and minimum dross levels shield cap nozzle electrode 277286 277284 277282 outer cap retaining cap swirl ring torch main body 277154 277151 27728...

Page 68

Operation fineline 200pc user’s manual 4-26 stainless steel - cutting 150 amps – h17 plasma / nitrogen shield this gas combination gives the best cut quality and minimum dross levels shield cap nozzle electrode 277298 277297 277135 outer cap retaining cap swirl ring torch main body 277154 277266 277...

Page 69

Operation fineline 200pc user’s manual 4-27 stainless steel - cutting 150 amps – air plasma / nitrogen shield this gas combination gives medium cut quality and minimum dross levels shield cap nozzle electrode 277117 277293 277292 outer cap retaining cap swirl ring torch main body 277154 277152 27713...

Page 70

Operation fineline 200pc user’s manual 4-28 stainless steel - cutting 200 amps – h17 plasma / nitrogen shield this gas combination gives the good cut quality and minimum dross levels shield cap nozzle electrode 277274 277287 277135 outer cap retaining cap swirl ring torch main body 277154 277266 277...

Page 71

Operation fineline 200pc user’s manual 4-29 stainless steel - cutting 200 amps – air plasma / nitrogen shield this gas combination gives medium cut quality and minimum dross levels shield cap nozzle electrode 277274 277289 277291 outer cap retaining cap swirl ring torch main body 277154 277266 27714...

Page 72

Operation fineline 200pc user’s manual 4-30 aluminum - cutting 30 amps – air plasma / nitrogen shield shield cap nozzle electrode 277145 277120 277130 outer cap retaining cap swirl ring torch main body 277154 277153 277140 277000 imperial material thickness preflow (air) plasma (air) shield (nitroge...

Page 73

Operation fineline 200pc user’s manual 4-31 aluminum - cutting 50 amps – air plasma / nitrogen shield shield cap nozzle electrode 277150 277122 277131 outer cap retaining cap swirl ring torch main body 277154 277153 277142 277000 imperial material thickness preflow (air) plasma (air) shield (nitroge...

Page 74

Operation fineline 200pc user’s manual 4-32 aluminum - cutting 70 amps – air plasma / nitrogen shield shield cap nozzle electrode 277150 277125 277131 outer cap retaining cap swirl ring torch main body 277154 277153 277142 277000 imperial material thickness preflow (air) plasma (air) shield (nitroge...

Page 75

Operation fineline 200pc user’s manual 4-33 aluminum - cutting 100 amps – air plasma / nitrogen shield shield cap nozzle electrode 277286 277284 277282 outer cap retaining cap swirl ring torch main body 277154 277151 277283 277000 imperial material thickness preflow (air) plasma (air) shield (nitrog...

Page 76

Operation fineline 200pc user’s manual 4-34 aluminum - cutting 150 amps – air plasma / nitrogen shield shield cap nozzle electrode 277117 277293 277292 outer cap retaining cap swirl ring torch main body 277154 277152 277139 277000 imperial material thickness preflow (air) plasma (air) shield (nitrog...

Page 77

Operation fineline 200pc user’s manual 4-35 aluminum - cutting 200 amps – air plasma / nitrogen shield shield cap nozzle electrode 277274 277289 277291 outer cap retaining cap swirl ring torch main body 277154 277266 277143 277000 imperial material thickness preflow (air) plasma (air) shield (nitrog...

Page 78

Operation fineline 200pc user’s manual 4-36 mild steel - marking 10 amps – nitrogen plasma / nitrogen shield shield cap nozzle electrode 277145 277120 277190 outer cap retaining cap swirl ring torch main body 277154 277152 277140 277000 imperial material thickness preflow (air) plasma (nitrogen) shi...

Page 79

Operation fineline 200pc user’s manual 4-37 stainless steel - marking 8 amps – nitrogen plasma / nitrogen shield shield cap nozzle electrode 277145 277120 277190 outer cap retaining cap swirl ring torch main body 277154 277152 277140 277000 imperial material thickness preflow (air) plasma (nitrogen)...

Page 80

Operation fineline 200pc user’s manual 4-38 aluminum - marking 10 amps – nitrogen plasma / nitrogen shield shield cap nozzle electrode 277145 277120 277190 outer cap retaining cap swirl ring torch main body 277154 277152 277140 277000 imperial material thickness preflow (air) plasma (nitrogen) shiel...

Page 81: Functions

Automatic gas console advanced functions fineline 200pc user’s manual section 5 automatic gas console advanced functions this section describes how to operate the fineline unit when non-standard cutting conditions are desired. Instructions are also given on how to access the various maintenance mode...

Page 82

Automatic gas console advanced functions fineline 200pc user’s manual setting the pierce delay time after the fineline cutting arc transfers to the workpiece, a motion signal (ok to move signal) is sent to the x/y controller or torch height control. The time delay between arc transfer and the motion...

Page 83: Altering Gas Types

Automatic gas console advanced functions fineline 200pc user’s manual altering gas types although the gas types should not normally be changed, the procedure is given here anyway. Note that the preflow gas cannot be changed. To alter the gas types used for a particular cut, use the arrows to scroll ...

Page 84: Altering Gas Pressures

Automatic gas console advanced functions fineline 200pc user’s manual altering gas pressures normally, the preflow gas and plasma gas pressures should not be changed. The shield gas is normally adjusted in small increments to fine-tune a cut. To alter the gas pressures, use the arrow keys to scroll ...

Page 85

Automatic gas console advanced functions fineline 200pc user’s manual altering arc voltage control and x/y machine parameters if the pierce height, cutting height, arc voltage, or x/y machine speed must be altered to achieve the desired cut quality, switch to the voltage screen, use the arrow keys t...

Page 86: Gas Purge

Automatic gas console advanced functions fineline 200pc user’s manual saving a user created cutting condition if one of the default cutting parameters must be altered to achieve good cut quality, the new cutting condition can be saved for later use. To save a user created cutting condition, use the ...

Page 87: Maintenance Screen

Automatic gas console advanced functions fineline 200pc user’s manual maintenance screen to display the maintenance screen, press the menu key then the maint key. The maintenance screen will be displayed as shown in figure 5-7. From the maintenance screen, use the arrow keys to scroll up or down to ...

Page 88: Viewing Messages

Automatic gas console advanced functions fineline 200pc user’s manual viewing messages to view status messages from the fineline power supply and automatic gas console, scroll down to the view messages selection on the maintenance screen and press ent. The message screen will be displayed as shown i...

Page 89: Viewing Cut Errors

Automatic gas console advanced functions fineline 200pc user’s manual viewing cut errors the fineline has an error tracking system that keeps a record of certain cutting faults that occur during operation. These faults affect the consumable parts life and measures should be taken to prevent them fro...

Page 90

Automatic gas console advanced functions fineline 200pc user’s manual selecting an error set to view when the cut errors screen is being displayed, press f3 to view the actual cut errors. When f3 is pressed the error selection screen is displayed as shown in figure 5-10. Use the arrow keys to scroll...

Page 91

Automatic gas console advanced functions fineline 200pc user’s manual viewing actual errors once the error set is selected and the ent key is pressed on the error selection screen, the actual cut errors will be displayed as shown in figure 5-11. Figure 5-11 actual cut errors screen when any of the e...

Page 92

Automatic gas console advanced functions fineline 200pc user’s manual • transferred arc lost during downslope - this error occurs when the arc is lost after a stop signal is received but before the current downslope completes. It substantially shortens the electrode life and is typically due to an i...

Page 93: Pressure Diagnostics

Automatic gas console advanced functions fineline 200pc user’s manual pressure diagnostics to enter the pressure diagnostics mode, scroll down to the pressure diagnostics selection on the maintenance screen and press ent. The pressure diagnostics screen will be displayed as shown in figure 5-12. Pre...

Page 94

Automatic gas console advanced functions fineline 200pc user’s manual setting the default delay parameter as previously mentioned, the pierce delay time is usually adjusted such that the cutting arc fully penetrates the workpiece before the motion output signal is generated. If the pierce delay time...

Page 95

Automatic gas console advanced functions fineline 200pc user’s manual restoring factory default cutting conditions to restore a factory default cutting condition, scroll down to the restore factory defaults selection on the maintenance screen and press ent. The restore screen will be displayed as sh...

Page 96: Measurement System

Automatic gas console advanced functions fineline 200pc user’s manual measurement system the fineline system will operate using imperial units or metric units. To change the units of operation, scroll down to the measurement system selection on the maintenance screen and press ent. The measurement s...

Page 97: Communication Node

Automatic gas console advanced functions fineline 200pc user’s manual communication node when multiple fineline systems are being used together on an rs-422 serial communication link, each system must have a unique identification number (node number) to identify itself to the network. To set the com...

Page 98: Inova Parameter Transmit

Automatic gas console advanced functions fineline 200pc user’s manual inova parameter transmit if an inova arc voltage control system is not being used with the fineline system, the inova parameter transmit feature must be disabled. With the inova parameter transmit feature enabled, pressing f3 whil...

Page 99

Automatic gas console advanced functions fineline 200pc user’s manual viewing serial communications to view the serial communication between the fineline and an external device, scroll down to the view serial communication selection on the maintenance screen and press enter. The serial communication...

Page 100

Automatic gas console advanced functions fineline 200pc user’s manual configuring the optional hydrogen manifold when a hydrogen manifold is installed on the system, the hydrogen mixture will automatically be selected as the plasma gas for certain material types and thicknesses. To prevent the use o...

Page 101: Setting An Arc Off Delay

Automatic gas console advanced functions fineline 200pc user’s manual setting an arc off delay in some instances, such as when cutting thicker stainless steel materials, it may be desirable to delay the extinction of the cutting arc after a stop signal is received. To program an arc off delay, scrol...

Page 102: Software Updates

Automatic gas console advanced functions fineline 200pc user’s manual software updates the automatic gas console has a floppy disk drive that is used to update the software as new revisions are released. To access the floppy disk drive, remove the floppy disk drive cover on the rear panel of the con...

Page 103: Fineline System

Serial communication fineline 200pc user’s manual section 6 serial communication initializing the fineline system the fineline system uses an rs-422 serial communication port located on the rear of the automatic gas console to receive and respond to commands that are transmitted from an x/y controll...

Page 104: Communication Error Checking

Serial communication fineline 200pc user’s manual to send a parameter, the parameter value needs to be sent as part of the command. For example, to send a desired pierce delay time of 1000 milliseconds to the system, look up the set pierce delay command in the command table. You will see the followi...

Page 105

Serial communication fineline 200pc user’s manual troubleshooting serial communication when troubleshooting serial communication with the fineline system, switch to the view serial communication screen to view incoming and outgoing data. See section 5 for information on the serial communication scre...

Page 106: Rs-422 Serial Commands

Serial communication fineline 200pc user’s manual rs-422 serial commands note: in the following commands, “nn” represents the net node of the power supply that is to receive the command. To send a global command to all power supplies in a network configuration, “nn” should be set to c8 hex (200 deci...

Page 107

Serial communication fineline 200pc user’s manual command # hex string additional information torch height control pierce height 12 aa nn fa 0c -- -- 0d if requested in command #30, the agc will transmit the recommended pierce height in mils (inches x 1000). Range: 0 to 999 torch height control cutt...

Page 108

Serial communication fineline 200pc user’s manual command # hex string additional information torch shield cap part number (msw) 26 aa nn fa 1a -- -- 0d if requested in command #30, the agc will transmit the most significant word of the shield cap part number. Torch shield cap part number (lsw) 27 a...

Page 109

Serial communication fineline 200pc user’s manual command # hex string additional information set process 32 aa nn fa 20 00 -- 0d 00 = cutting 01 = marking software version 33 aa nn fa 21 00 -- 0d if requested in command #30, the agc will transmit the software version x 10. Cutting chart version 34 ...

Page 110

Serial communication fineline 200pc user’s manual command # hex string additional information set pierce height 44 aa nn fa 2c -- -- 0d pierce height in mils (inches / 1000) valid range: 0 to 999. Also updates the inova height control, if used. Set travel speed 45 aa nn fa 2d -- -- 0d sets travel sp...

Page 111: Routine Maintenance

Maintenance and troubleshooting fineline 200pc user’s manual section 7 maintenance and troubleshooting warning: only qualified maintenance personnel should perform maintenance on the fineline system. The system utilizes potentially fatal a.C. And d.C. Voltages. All maintenance should be performed wi...

Page 112

Maintenance and troubleshooting fineline 200pc user’s manual torch, torch leads, and gas hoses 1. Verify that all torch lead and gas hose connections are tight and that there are no gas or water leaks. Only tighten the fittings enough to make a water or gas seal. The fittings are subject to damage i...

Page 113: Replacing The Torch Coolant

Maintenance and troubleshooting fineline 200pc user’s manual replacing the torch coolant the torch coolant should be flushed out of the system every six months and replaced with new coolant. The following procedure should be used to prevent damage to the cooling system. 1. Remove primary power to th...

Page 114

Maintenance and troubleshooting fineline 200pc user’s manual 230/460v 60 hz transformer configurations 230v 60 hz and 460v 60 hz power supplies are shipped with a dual voltage main transformer tr1. The primary taps on tr1 are labeled with their corresponding voltages. To change the operating voltage...

Page 115

Maintenance and troubleshooting fineline 200pc user’s manual figure 7-1 230v 60 hz transformer configuration figure 7-2 460v 60 hz transformer configuration 7-5.

Page 116

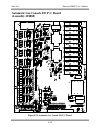

Maintenance and troubleshooting fineline 200pc user’s manual microprocessor status led’s the microprocessor p.C. Board controls all of the functions of the fineline system. It has 31 led’s which aid in troubleshooting the system. The led’s illuminate when a particular event occurs. Illuminated led’s...

Page 117

Maintenance and troubleshooting fineline 200pc user’s manual microprocessor sequence of operation the following led’s should illuminate after primary power is applied: • led 16 5v up pwr • led 17 12v up pwr • led 18 ilk pwr • led 19 analog pwr • led 20 gas pwr • led 28 comm pwr • led 29 –15v the fol...

Page 118

Maintenance and troubleshooting fineline 200pc user’s manual troubleshooting using the control panel status led’s if the fineline system develops a problem, first check the control panel status led’s. If one or more of the led’s does not illuminate after the on button is depressed, use the status le...

Page 119: Messages Screen

Maintenance and troubleshooting fineline 200pc user’s manual troubleshooting using the automatic gas console messages screen if all of the status led’s are illuminated but the fineline system still has a problem, switch to the messages screen on the automatic gas console (see section 5 for specific ...

Page 120: General Troubleshooting

Maintenance and troubleshooting fineline 200pc user’s manual general troubleshooting the following chart lists general troubleshooting guidelines for the fineline system when the status led’s or the automatic gas console messages screen do not give any insight to the particular problem being experie...

Page 121

Maintenance and troubleshooting fineline 200pc user’s manual pat is not closing properly. Check the relay for proper operation. Also, check the par and pat led’s on the microprocessor p.C. Board and pat drive p.C. Board. 7. Damaged or loose torch lead connections. 8. Shorted torch or torch leads. Ch...

Page 122: Chopper Test Procedure

Maintenance and troubleshooting fineline 200pc user’s manual low pressure error 1. Supply gas pressure(s) less than 150 psi. 2. Faulty pressure switch or associated wiring inside gas console. Pressure error during cut 1. Supply gas pressure(s) fluctuating during cut. Chopper test procedure warning: ...

Page 123

Maintenance and troubleshooting fineline 200pc user’s manual 7. With a start signal applied, check for 300 vdc at the fineline output terminal block between electrode and work. If 300 v is present, the chopper is working properly. 8. If 300 vdc is not present at the output terminal block, check the ...

Page 124

Maintenance and troubleshooting fineline 200pc user’s manual figure 7-3 chopper diagnostics - part 1 7-14.

Page 125

Maintenance and troubleshooting fineline 200pc user’s manual figure 7-4 chopper diagnostics - part 2 7-15.

Page 126

This page intentionally left blank.

Page 127: Section 8 Parts List

Parts list fineline 200pc user’s manual section 8 parts list power supply note: see figures 8-1 to 8-4. Item number part number quantity description 1 708088 1 off switch, red 2 708111 1 off actuator, red 3 708090 1 on switch, green 4 708089 1 on actuator, green / illuminated 5 501163 2 light housin...

Page 128

Parts list fineline 200pc user’s manual 8-2 item number part number quantity description 37 500511 1 coolant pump, 70 gph 38 708061 1 solenoid valve, 220/240vac 39 715084 1 check valve, coolant return 40 708068 1 con3 coolant pump relay 41 708059 1 fs1 coolant flow switch 42 500516 2 fan, heat excha...

Page 129

Parts list fineline 200pc user’s manual front panel fans not shown (item numbers 42 and 82) figure 8-1 power supply front view 8-3.

Page 130

Parts list fineline 200pc user’s manual figure 8-2 power supply rear view 8-4.

Page 131

Parts list fineline 200pc user’s manual figure 8-3 power supply left side view 8-5.

Page 132

Parts list fineline 200pc user’s manual figure 8-4 power supply right side view 8-6.

Page 133

Parts list fineline 200pc user’s manual remote high frequency console note: see figure 8-5. Item number part number quantity description 1 715051 2 coolant return fitting (left hand) 2 715050 1 coolant supply fitting (right hand) 3 709227 1 strain relief 4 710147 1 lock nut 5 709001 1 4 pin receptac...

Page 134

Parts list fineline 200pc user’s manual figure 8-5 remote high frequency console 8-8.

Page 135

Parts list fineline 200pc user’s manual torch and torch valve assembly item number part number quantity description 1 277475 1 torch valve assembly (includes bracket) 2 500549 1 torch valve bracket 3 820134 1 torch handle 4 277000 1 torch main body 5 500740 1 torch solenoid plasma hose 6 820209 1 o-...

Page 136: Shielded Torch Leads

Parts list fineline 200pc user’s manual shielded torch leads part number length 200304-10 10 ft. (3.0 m) 200304-15 15 ft. (4.6 m) 200304-20 20 ft. (6.1 m) 200304-25 25 ft. (7.6 m) 200304-30 30 ft. (9.1 m) 200304-35 35 ft. (10.7 m) 200304-40 40 ft. (12.2 m) 200304-45 45 ft. (13.7 m) 200304-50 50 ft. ...

Page 137: Gas Hose Package

Parts list fineline 200pc user’s manual gas hose package part number length 200317-20 20 ft. (6.1 m) 200317-25 25 ft. (7.6 m) 200317-30 30 ft. (9.1 m) 200317-35 35 ft. (10.7 m) 200317-40 40 ft. (12.2 m) 200317-45 45 ft. (13.7 m) 200317-50 50 ft. (15.2 m) 200317-55 55 ft. (16.8 m) 200317-60 60 ft. (1...

Page 138: Coolant and Power Leads

Parts list fineline 200pc user’s manual coolant and power leads part number length 200306-5 5 ft. (1.5 m) 200306-10 10 ft. (3.0 m) 200306-15 15 ft. (4.6 m) 200306-20 20 ft. (6.1 m) 200306-25 25 ft. (7.6 m) 200306-30 30 ft. (9.1 m) 200306-35 35 ft. (10.7 m) 200306-40 40 ft. (12.2 m) 200306-45 45 ft. ...

Page 139: Work Ground Cable

Parts list fineline 200pc user’s manual work ground cable part number length 200318-10 10 ft. (3.0 m) 200318-15 15 ft. (4.6 m) 200318-20 20 ft. (6.1 m) 200318-25 25 ft. (7.6 m) 200318-30 30 ft. (9.1 m) 200318-35 35 ft. (10.7 m) 200318-40 40 ft. (12.2 m) 200318-45 45 ft. (13.7 m) 200318-50 50 ft. (15...

Page 140

Parts list fineline 200pc user’s manual torch consumables - mild steel cutting outer cap shield cap retaining cap nozzle swirl ring electrode torch body 277154 277145 277153 277120 277140 277130 277000 30a 277154 277115 277153 277122 277140/ 277142 277131 277000 50a 277154 277150 277153 277125 27714...

Page 141: (Air Plasma)

Parts list fineline 200pc user’s manual torch consumables - stainless steel cutting (air plasma) outer cap shield cap retaining cap nozzle swirl ring electrode torch body 277154 277144 277110 277121 277138 277137 277000 30a 277154 277149 277110 277123 277142 277137 277000 50a 277154 277150 277153 27...

Page 142: (H17 Plasma)

Parts list fineline 200pc user’s manual torch consumables - stainless steel cutting (h17 plasma) outer cap shield cap retaining cap nozzle swirl ring electrode torch body 277154 277150 277113 277124 277140 277132 277000 70a 277154 277146 277113 277126 277141 277133 277000 100a 277154 277298 277266 2...

Page 143

Parts list fineline 200pc user’s manual torch consumables - aluminum cutting outer cap shield cap retaining cap nozzle swirl ring electrode torch body 277154 277145 277153 277120 277140 277130 277000 30a 277154 277150 277153 277122 277142 277131 277000 50a 277154 277150 277153 277125 277142 277131 2...

Page 144: Torch Consumables - Marking

Parts list fineline 200pc user’s manual torch consumables - marking outer cap shield cap retaining cap nozzle swirl ring electrode torch body 277154 277145 277152 277120 277140 277190 277000 figure 8-15 torch consumables - marking 8-18.

Page 145: Automatic Gas Console

Parts list fineline 200pc user’s manual automatic gas console (assembly 200865) note: see figures 8-16 and 8-17. Item number part number quantity description 1 500032 1 agc decal / membrane switch 2 501146 1 agc aluminum display panel 3 500860 1 agc display window 4 710199 4 aluminum standoff 5 5008...

Page 146

Parts list fineline 200pc user’s manual quick data figure 8-16 gas console - exterior 8-20

Page 147

Parts list fineline 200pc user’s manual figure 8-17 gas console – interior 8-21.

Page 148: (Assembly 200450)

Parts list fineline 200pc user’s manual power supply microprocessor p.C. Board (assembly 200450) figure 8-18 power supply microprocessor p.C. Board 8-22.

Page 149: A.C. Detect P.C. Board

Parts list fineline 200pc user’s manual a.C. Detect p.C. Board (assembly 500810) figure 8-19 a.C. Detect p.C. Board 8-23.

Page 150: Relay P.C. Board

Parts list fineline 200pc user’s manual relay p.C. Board (assembly 500348) figure 8-20 relay p.C. Board 8-24.

Page 151: Power Supply I/o P.C. Board

Parts list fineline 200pc user’s manual power supply i/o p.C. Board (assembly 277452) figure 8-21 power supply i/o p.C. Board 8-25.

Page 152: (Assembly 201080)

Parts list fineline 200pc user’s manual automatic gas console i/o p.C. Board (assembly 201080) figure 8-22 automatic gas console i/o p.C. Board 8-26.

Page 153: (Assembly 505600)

Parts list fineline 200pc user’s manual automatic gas console interface p.C. Board (assembly 505600) figure 8-23 automatic gas console interface p.C. Board 8-27.

Page 154: Consumable Spare Parts Kit

Parts list fineline 200pc user’s manual consumable spare parts kit (part number 282267) part number quantity description 277130 3 electrode 30a mild steel - 30a aluminum 277137 2 electrode 30/50a stainless (air) 277131 6 electrode 50/70a mild steel - 70a stainless (air) - 50/70a aluminum 277132 2 el...

Page 155

Parts list fineline 200pc user’s manual part number quantity description 277287 3 nozzle 200a stainless (h17) 277145 3 shield cap 30a mild steel - 30a aluminum 277144 3 shield cap 30a stainless (air) 277149 3 shield cap 50a stainless (air) 277115 3 shield cap 50a mild steel 277150 3 shield cap 70a m...

Page 156

Parts list fineline 200pc user’s manual part number quantity description 277151 1 inner retaining cap 100a mild steel - 100a stainless (air) - 100a aluminum 150a mild steel – 1/2” and below 277152 1 inner retaining cap 150a mild steel – 5/8” and above – 150a stainless (air) 150a aluminum 277113 1 in...

Page 157

Propylene glycol msds fineline 200pc user’s manual appendix a propylene glycol msds a-1.

Page 158

Propylene glycol msds fineline 200pc user’s manual a-2.

Page 159

Propylene glycol msds fineline 200pc user’s manual a-3.

Page 160

Propylene glycol msds fineline 200pc user’s manual a-4.

Page 161

Propylene glycol msds fineline 200pc user’s manual a-5.

Page 162

Propylene glycol msds fineline 200pc user’s manual a-6.

Page 163

Propylene glycol msds fineline 200pc user’s manual a-7.

Page 164

Propylene glycol msds fineline 200pc user’s manual a-8.

Page 165: (Emc)

Electromagnetic compatibility (emc) fl-200pc user’s manual appendix b electromagnetic compatibility (emc) background the 380v 50hz and 415v 50hz fineline 200pc plasma cutting systems are manufactured to comply with the european standard en 50199 (electromagnetic compatibility (emc) – product standar...

Page 166: Assessment of Area

Electromagnetic compatibility (emc) fl-200pc user’s manual assessment of area before installing plasma cutting equipment, the user shall make an assessment of potential electromagnetic problems in the surrounding area. The following shall be taken into account: a) other supply cables, control cables...

Page 167

Electromagnetic compatibility (emc) fl-200pc user’s manual plasma cutting cables the plasma cutting cables should be kept as short as possible and should be positioned close together, running at or close to the floor level. Equipotential bonding bonding of all metallic components in the plasma cutti...

Page 168

This page intentionally left blank.

Page 169: Description

Hydrogen manifold (optional) fineline 200pc user’s manual appendix c hydrogen manifold (optional) description the hydrogen manifold can be used when cutting stainless steel at least 3/16” (4.75 mm) thick and a smooth, shiny cut surface finish is desired. When using the manifold, h17 (17.5% hydrogen ...

Page 170: Installation

Hydrogen manifold (optional) fineline 200pc user’s manual gas supply requirements inlet gas type ........................................................ H17* inlet gas flow rate (maximum) ............................. 57 scfh (1614 liters/hour) inlet gas pressure ......................................

Page 171

Hydrogen manifold (optional) fineline 200pc user’s manual figure c-2 hydrogen manifold mounting location c-3.

Page 172: Operation

Hydrogen manifold (optional) fineline 200pc user’s manual operation the hydrogen manifold is fully integrated with the operating software of the fineline automatic gas console. When an appropriate thickness stainless steel is selected, h17 will be selected for the plasma gas and nitrogen will be sel...

Page 173: Parts List

Hydrogen manifold (optional) fineline 200pc user’s manual parts list item number part number quantity description 1 709003 2 receptacle, 9 position 2 709207 1 receptacle, 7 position 3 706041 1 transformer, 12v 4 704009 3 led, panel mount 5 707006 1 input power module 6 709033 1 fuse, 1a 7 708076 1 p...

Page 174: (Assembly 200285)

Hydrogen manifold (optional) fineline 200pc user’s manual hydrogen manifold microprocessor p.C. Board (assembly 200285) figure c-3 hydrogen manifold microprocessor p.C. Board c-6.

Page 175: Dip Switch Settings

Hydrogen manifold (optional) fineline 200pc user’s manual dip switch settings dip switch 1 (sw1): rs-422 node termination sw1-1 and sw1-2 should be switched on if the manifold is the last on a string of nodes. Sw1-1 and sw1-2 should be switched off in all other manifolds on the network. Dip switch 3...