- DL manuals

- Kalkhoff

- Bicycle

- Derby

- Instruction Manual

Kalkhoff Derby Instruction Manual

Belgium: Derby Cycle Werke GmbH, Siemensstr. 1-3, D-49661 Cloppenburg, Phone: +49-4471966101

France: Derby Cycle Werke GmbH, Siemensstr. 1-3, D-49661 Cloppenburg, Phone: +49-4471966101

Great Britain: 50Cycles Ltd., Unit M Littlemoor Lane, GB-Loughborough LE11 1SF, Phone: +44-1509 266656

Italy: Bike Evolution, Rigaste S. Zeno 39/B, I-37123 Verona, Phone: +39-045592410

Latvia: Laterns Ltd., Brivibas 353/16, LV-1000 Riga, Phone: +371-9848860

Lithuania: Meibalt, Svitrigailos 5, LT-2000 Vilnius, Phone: +370-52651259

Netherlands: Derby Cycle Werke GmbH, Siemensstr. 1-3, D-49661 Cloppenburg, Phone: +49-4471966101

Romania: S.c. SportBikeCenter. S.r.l, St. Penes Carcanul 3-5, RO-300124 Timisoara, Phone: +40-256220023

Slovakia: AGF Invest s.r.o., Hlinikova 365/39, SK-95201 Vrable, Phone: +421-262859549

Spain: Clean Laguna S.L., Urbanisation Sant Jordi da Alfama, E-43860 Ametlla de Mar, Phone: +34-977486160

Kalkhoff bikes

Derby Cycle Werke GmbH

Siemensstraße 1-3

49661 Cloppenburg

Tel. +49 (4471) 966-0

Fax +49 (4471) 966-44845

E-Mail: info@kalkhoff-bikes.de

www.kalkhoff-bikes.com

1973K0110002

Instruction manual

Guide d’utilisation

Instrucciones de uso

Handleiding

KALKHOFF - Ins

tr

uction manual - Guide d‘utilisation - Handleiding - Ins

tr

ucciones de uso

Summary of Derby

Page 1

Belgium: derby cycle werke gmbh, siemensstr. 1-3, d-49661 cloppenburg, phone: +49-4471966101 france: derby cycle werke gmbh, siemensstr. 1-3, d-49661 cloppenburg, phone: +49-4471966101 great britain: 50cycles ltd., unit m littlemoor lane, gb-loughborough le11 1sf, phone: +44-1509 266656 italy: bike ...

Page 2

Foreword your bicycle was delivered to you fully assembled. In case any bicycle parts are not assembled, please contact your bicycle dealer. These instructions help you in the ● appropriate, ● safe and ● advantageous use of your bicycle. We assume that users already have general knowledge regarding ...

Page 3

4 frame 32 forks 32 checking the wheels 34 checking the tyres and inner tubes 34 tyres 34 inner tubes 35 repairing a puncture 35 operating the lighting components 37 dynamo 37 failure of the lighting system 38 carrier 38 mudguards 38 bicycle stand 39 selecting accessories and equipment 39 handling c...

Page 4

Trekking bikes / atbs these bicycles may be used on public and made roads. They are also suitable for light off-road use. The manufacturer and dealer shall not be liable for any use of the bicycle which goes beyond the intended use. This particularly applies to non-compliance with safety advice and ...

Page 5

6 racing cycles / fitness bikes if racing cycles are to be used on public roads, the national regulations must be com- plied with. The manufacturer and dealer shall not be liable for any use of the bicycle which goes beyond the intended use. This particularly applies to non-compliance with safety ad...

Page 6

To open the quick release, proceed as follows: ➢ tilt the tensioning lever, so that the word open is readable. ➢ open the quick release as far as it will go. ➢ to loosen the quick release, turn the locking nut in an anticlockwise direction. To close the quick release, proceed as follows: ➢ adjust th...

Page 7

8 determining the correct saddle height ➢ sit on the bicycle saddle. ➢ try to reach the pedal at its lowest position with your heel. Your knee should be almost completely straight at this point. ➢ place the ball of your foot in the centre of the pedal. If your knee is now slightly bent, the saddle h...

Page 8

In the case of a saddle with a collar clamp, the locking screw is located at the side. If necessary, adjust the saddle tilt by proceeding as follows: ➢ to loosen the locking screw, turn it in an anticlockwise direction. It may be necessary to hold the nut located on the other side using a second spa...

Page 9

Adjustment of the a-head system handlebar height stems such as the one illustrated here are called a-head stems. If this system is fitted, it is compulsory to have the handlebar height adjusted by a dealer. Aligning the handlebar to the front wheel to align the handlebar to the front wheel, proceed ...

Page 10

The crank arms must be seated tightly, otherwise the crank assembly may become damaged. ➢ since the crank arms can become loose, check the tightness of the bottom bracket regularly. ➢ to check that the crank arms are seated tightly on the axles, shake them regularly. ➢ if any play is found in the cr...

Page 11

Actuating the chain guide lever ● lever a: shifting to a larger ● lever b: shifting to a smaller rear rear sprocket. Lever a latches sprocket. By pressing lever b once, in positions 1, 2 and 3. Gear is shifted to the next smaller rear sprocket. 12 actuating the derailleur lever (standard) lever ‘b’ ...

Page 12

Trimming (noise minimisation) depending on the chain position after completion of shifting, the chain may rub against the outer or inner chain guide plate and cause noises. In this case, press lever ‘a’ or lever ‘b’ lightly in order to move the derailleur slightly so that it no longer contacts the c...

Page 13

Standard shift lever both levers (a) and (b) return to their initial positions after actuation. The crank must always be turned when actuating a lever. Actuating the derailleur shift lever shifting from a small to a larger chain sprocket by pressing lever (a) once, the chain is shifted from a small ...

Page 14

If the chain falls on the crank arm side: if shifting from the middle to the large chain sprocket is difficult: if shifting from the middle to the small chain sprocket is difficult: if the chain rubs against the inner chain guide when set to the largest chain sprocket: if the chain rubs against the ...

Page 15

Chain guide have the chain gear shifter maintained, adjusted or replaced by a cycle dealer! Fine adjustment of the chain guide actuate the lever to shift the chain from the smallest rear sprocket to the second rear sprocket. Then take up the slack and turn the crank arm. If the chain jumps to the th...

Page 16

2 3 starting off/riding on sand or over uneven ground/riding uphill/ carrying heavy luggage/ riding against the wind/ riding with lights switched on riding on level roads riding at high speed … …….......…… ……….......… press the button to shift gear. Increasing pedal force 3 indicator against indicat...

Page 17

Shimano 7/8-speed shift lever turn the twistgrip to shift to all 8 (7) gears. Increasing pedal force ➢ indicator against 8 (7) increasing pedal force ➢ indicator against 8 (7) decreasing pedal force ➢ indicator against 1 decreasing pedal force ➢ indicator against 1 dismounting and mounting the rear ...

Page 18

7r cj-8s20 japan lock shifter arm slot in the dropout safety washer (right side) safety washer (left side) chainstay 7r markierung ➢ tension the chain and fix the wheel to the frame with the cap nuts, tightening torque 30 – 45 nm. Illustration of 7/8-speed shifter: illustration of 3-speed shifter: c...

Page 19

Adjusting the angle lever – fine adjustment ➢ set the revo twistgrip to (2). Turn the cable adjustment screw so that the red line on the rod is aligned to the end of the hub axle. The red line on the rod and the end of the hub axle must be aligned to one another. If the red line is not visible, the ...

Page 20

➢ turn the cable 60° to the right and fix it to the hook. ➢ attach the cable to the shifter wheel as shown in the illustration. ➢ pull the cable through the slot in the shifter unit holder and push the end of the cable sheath firmly into the cable sheath holder. ➢ if it is easier, first insert the c...

Page 21

Sram hub gear shifter shifting ● continue to pedal without force when shifting gear. ● if the desired gear does not engage immediately, stop pedalling briefly. ● change down in good time before uphill sections. Brakes ● be sure to use the second brake (front wheel brake) alternately on long, steep d...

Page 22

Shifter adjustment ➢ place the shifter lever in gear position ‘3’. Move the pedal arm to ensure that the gear is engaged. ➢ push the clamping bush (2, fig. 2) onto the pulling chain (3) until the pulling cable is taut. Do not pull the pulling chain out of the pulley (4) during this operation. Checki...

Page 23

If the clip nut loosens itself from the brake arm or the clip screw or brake arm clip are damaged, the brake arm can rotate on the chainstay. This can cause the handlebar to move suddenly or the wheel to lock, which can lead to a fall with serious injuries. Shifter adjustment to adjust the shifter, ...

Page 24

There are several different kinds of brakes, depending on where they are used: ● hub brakes, ● disc brakes and ● wheel rim brakes. The brakes may be actuated mechanically or hydraulically. Normally, in the case of hub gear shifters, the brake lever for the front brake is at the right-hand side of th...

Page 25

Adjusting the brakes your bicycle’s brakes have been correctly adjusted in the factory or by your dealer. The gap between the brake block and the wheel rim is approx. 1 – 1.5 mm. However, the brake blocks are subject to wear, so that the gap becomes ever larger and the brake lever travel becomes lon...

Page 26

The brake saddle and the disc may be hot after braking, therefore do not touch them during or immediately after riding, as you could burn yourself. Before adjusting the brakes, check that the parts have cooled down sufficiently. Your bicycle may be fitted with a disc brake only when appropriate fixi...

Page 27

Carry out a braking test after each adjustment by pushing the bicycle strongly whilst pulling the brake lever. Only use your bicycle when it can be safely braked. Check the tubes and connections for leaks each time before riding. Leaking tubes and connections can result in brake fluid leaking out of...

Page 28

The brake arm of the drum brake is fixed to the frame by means of a suitable pipe clip (1). Mount the brake arm between the two tabs of the pipe clip! The pipe clip must sit on the frame with absolutely no play! Use a self-locking nut! Tightening torque: 2 – 3 nm. Mounting / dismounting the drum bra...

Page 29

Shimano drum brake (inter-m) if any of the following signs occur when braking, you must not ride any further: 1) abnormal braking noises, or 2) unusually high braking power or 3) unusually weak braking power. In these cases, consult a specialist workshop. The brake drum can get very hot after prolon...

Page 30

Adjusting the brake cable ➢ check whether the wheel shows resistance to rotation when the brake cable is taut. Pull the brake lever strongly about ten times towards the grip in order to stretch the cable. Adjust the brake lever play to about 15 mm using the cable adjustment screw on the brake unit o...

Page 31

32 the rivet must be located in the middle of part a of the cam plate. ➢ pull the brake lever and check the brake function. If the brake does not function properly, the brake cable must be adjusted. Adjusting the brake cable ➢ check whether the wheel shows resistance to rotation when the brake cable...

Page 32

To adjust an oil-air fork, proceed as follows: ➢ adjust the suspension hardness via the air pressure in the fork. ➢ check the air pressure regularly with a pump. To adjust an elastomer fork, proceed as follows: ➢ to increase the spring tension, turn the adjustment knob on the top of the fork head cl...

Page 33

34 tighten all screws to the specified torque, otherwise the screws could break off and parts may become loose. (see chapter ‘tightening torques of screws, nuts and bolts’, page 45). Checking the wheels the wheels form the interface between bicycle and road. Unevenness of the road surface and the we...

Page 34

To pump up an inner tube with a dunlop or lightning valve and schrader or automatic valve, proceed as follows: ➢ screw off the valve cap in an anticlockwise direction. ➢ pump up the inner tube using a suitable pump. ➢ screw the valve cap onto the valve in a clockwise direction. Repairing a puncture ...

Page 35

Removing a side-pull brake ➢ loosen the screws fastening the brake blocks to the brake arms. The tyre slips through between the brake pads. Removing a hub gear shifter, roller, drum or coaster brakes ➢ loosen the screw or the quick release on the brake arm. Removing the wheel ➢ if your bicycle has a...

Page 36

Operating the lighting components only lighting elements which are stipulated by and approved according to national regulations may be attached to bicycles. If in doubt, consult your dealer. Lighting regulations ● the light cone from the front headlamp may only be half as high at a distance of 5 met...

Page 37

Chainstay carrier mount child seats on chainstay carriers only if appropriate fixings are present. Do not exceed the maximum allowable weight class. This type of carrier is supported by the chainstays of the bicycle. Due to the weight of the uncushioned mass, the reaction of the chainstay carrier su...

Page 38

Never ride if the braces are loose. Refasten them. If it is not possible to refasten the braces, have them replaced by a dealer. Latching the sks asr safety device ➢ push the front wheel mudguard (profile and brace) onto the asr plug until it latches. ➢ adjust the mudguard so that the tyre and the f...

Page 39

A child may only be carried in a child seat up to the age of 7 years. The rider must be at least 16 years old. It is not permitted to attach a child seat to a carbon frame, as this could damage the frame. Bicycle trailer use only bicycle trailers which conform to the national bicycle regulations. Tr...

Page 40

Recutting the thread and the bearing shells or rubbing out the seat tube are not allowed. It is not permitted to mount a child seat on a carbon frame – there is a risk that the frame could break. ● carbon handlebar transitional area around the handlebar stem, grips, clamping areas of other attached ...

Page 41

Splinters carbon fibres are very thin and hard. Therefore, handle damaged carbon parts very carefully. Individual fibres may become loose and protrude. If they come into contact with your skin, small splinters may penetrate the skin. Small repairs in an assembly stand if you wish to fix your carbon ...

Page 42

Chain sprockets, rear sprockets, bottom bracket and gear shift rollers in the case of bicycles with chain gear shifter, the chain sprockets, rear sprockets, bottom bracket and gear shift rollers are subject to wear. The level of wear is dependant on the care, maintenance and usage of the bicycle (mi...

Page 43

When ? After each use of the bicycle after every 300 to 500 km after 1000 km maintenance / check ➢ check ➛ spokes, ➛ wheel rims for wear and roundness, ➛ tyres for foreign bodies, ➛ quick releases, ➛ gear shifter and suspension function, ➛ brakes, ➛ lights and ➛ bell. ➢ have the following checked: ➛...

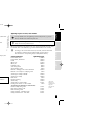

Page 44

Technical data total permissible weight of the bicycle the total permissible weight of the bicycle comprises the weight of the bicycle, the weight of the rider and the weight of the luggage. Bicycle type total permissible weight 20“ trailer 50 kg 20“ child’s bicycle 60 kg 24“ child’s bicycle 80 kg m...

Page 45

Racing cycle brake (br) fixing screw (welded socket) 5 nm inner cable fixing screw 6 nm brake pad fixing bolt 8 nm cantilever brake (br) fixing screw (welded socket) 5 nm inner cable fixing screw 6 nm brake pad fixing bolt 8 nm brake lever (bl) clip fixing screw 6 nm brake lever on carbon handlebar ...

Page 46

Lighting system type power supply headlamp, neon bulb 6 volt 2,4 watt headlamp, halogen 6 volt 2,4 watt hs3 rear light with parking light 6 volt 0,6 watt rear light 6 volt 0,6 watt rear light, d-toplight plus diode carrier rear light with leds (no bulb) dynamo, right/left-hand 6 volt 3 watt hub dyna...