- DL manuals

- KAMA

- Engine

- KM376AG

- Operation Manual

KAMA KM376AG Operation Manual

Summary of KM376AG

Page 1

Three-cylinder water-cooled diesel km376 series.

Page 2

Preface thank you for purchasing kama km376 series three-cylinder water-cooled diesel engine. This manual describes safe information, operation instruction and maintenance of km376 series diesel engine. Be sure to read this manual carefully before operation, for keeping your engine at the best worki...

Page 4

Contents 1. Safety information 1.1 safety mark 1.2 safety caution 2. Product instructions 2.1 main specifications and data 2.2 specifications and data of key parts 2.3 main adjusting data table 2.4 tightening torque of main bolts and nuts 2.5 operation control device 3. Preparation before operation ...

Page 5

9. The engine fault and the elimination method 9.1 starting hard or can't start 9.2 the exhaust gas is excessive and its color is abnormal 9.3 fuel consumption is too large 9.4 the power is not enough 9.5 the running is not stable 9.6 stopping the engine suddenly 9.7 the engine can't stop when the s...

Page 6

1.1 safety marks be sure to read and follow the instructions on the manual and safety marks. Operating the engine without proper training or instruction is not allowed. Caution: many accidents are resulted from false operating. For your safety, please obey to the following instructions: 1. Safety in...

Page 7

Danger caution: to avoid fire resulted from improper operating. Use the recommended grade diesel oil. Other fuels such as gasoline and kerosene will cause engine rough running, fuel injection system fault even the fire or explosive. Be sure to use the recommended fuel described in this manual. Refue...

Page 8

Safety information about inspection and maintenance: danger caution: to avoid touching the battery electrolyte. The electrolyte contains diluted sulphuric acid, which can cause blindness and burn if eyes or skin contacted with it. If electrolyte splash into your eyes, flush thoroughly with water imm...

Page 9

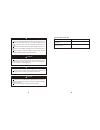

2. Product instruction 2.1 main specifications and data type combustion chamber type bore cycle(mm) cylinder no. Piston displacement (l) fire order (from the free end) compression ratio rated power (kw) rated speed(r/min) (15 minutes power) max torque/speed (n.M/r/min) max steady speed at zero-load(...

Page 10

2.2 specifications and data of key parts cooling water pump specifications and data ve distributor pump ve3/9f2500lnd 9mm mechanical full length s series; (p series) thread coupling dual function throttling pintle nozzle 13.5~14.5mpa 2500r/min 249kpa above 20l/min centrifugal 5000r/min 55l/min screw...

Page 11

2.3 main adjusting data table exhaust temperature non-compression space height inside the cylinder fuel delivery timing fuel spraying pressure (two bundle) 750 normal adjusting data value 0.7-1.0mm when the piston is at the upper dead point, the stroke of fuel pump plunger is: 0.97 0.03mm or 0.89 0....

Page 12

2.4 tightening torque of main bolts and nuts bolt qty. Thread specification tightening torque (nm) cylinder head bolt camshaft bearing bolt main bearing bolt*) oil sump bolt connecting rod bolt flywheel bolt thread of fuel injector body glow plug thread other bolts and nuts m12 1.25 m8 m10 1.25 m6 m...

Page 13

2.5 operation control device the operation control device connected to warm-up unit, electric starter and fuel pump solenoid valve respectively. The electric wiring of the control device is as below figure 2-1. The electric wiring of the starting motor is as below figure2-2. Recommended voltage is d...

Page 14

1. The solenoid of fuel injection pump 2. Warm-up indicating lamp 3. Voltmeter (10a) figure 2-1 the electric wiring diagram of control device figure 2-2 electric wiring diagram of starter motor 1. Housing ground 2.Terminal 50 3. Terminal 30 figure2-3 electric wiring of glow plug 1.To the solenoid of...

Page 15

3. Preparation before operation 3.1 prepare the fuel, lubricating oil and cooling water 3.1.1 fuel (1) to keep the engine in best working condition, be sure to use the recommend- ed fuel: light diesel oil jis k2204 (gb252-87) however, be sure to choose the appropriate brand for the light diesel oil ...

Page 16

[ ] operation note using the improper type lubricating oil will burn out the inner part of the engine, even cause the engine to wear rapidly. And the service life of the engine will be also shortened. 3.1.3 cooling water be sure to adopt tap water as cooling water. [ ] operation note be sure to add ...

Page 17

3.2 preparation before starting 3.2.1 add the lubricating oil (1) the amount of the lubricating oil added should flush with height of the lubricating oil level in the oil sump. Put the engine on a level surface at first, then check the oil level. (2) the lubricating oil level in the oil sump should ...

Page 18

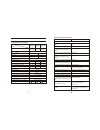

The fuel line of the engine fuel system is as shown in figure 3.2.2 followed: to eliminate the air in the low-pressure fuel line, loosen the connector of the intake pipe in the ve dispensing pump at first, then expel the air from the fuel. Inspect the connector of the ve pump return pipe. If there i...

Page 19

3.2.4 add the cooling water. (1) the water in the radiator water tank should be sufficient. Expel the air from the water line when adding the water. At the same time, check the water tank and connector of pipes for leakage, and remedy if in time. (2) after adding water, tighten the radiator water ta...

Page 20

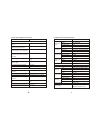

4. Operation instruction 4.1 starting 4.1.1 start the engine under no load. When starting the engine on the vehicle, let the vehicle to stop before. 4.1.2 set the throttle lever at the half-open position when you start the engine. 4.1.3 insert the key to the engine switch hole, then turn it to the o...

Page 21

[ ] operating notice when put the key at the on position, 12v dc voltage will open the solenoid valve in the ve pump. If the electrical bottle voltage is lower than 8v or the cable isn't connected as required, the solenoid valve won't be opened and the engine won't start, even sudden stop will happe...

Page 22

4.2.2 when the engine is running normally, inspect the engine oil pressure and temperature, cooling water temperature and the working condition of the charging indicator frequently be careful to observe the color of exhaust gas and listen to the working sound during the operation. 4.2.3 in the norma...

Page 23

4.3 check engine during the running make sure there is no abnormal case during the running referring to following items. 1. Whether the color of the exhaust gas is normal or not. If the engine exhausts black smoke continuously, stop to check it at once. If ignore this symptom, it leads to engine run...

Page 24

4.4 stop the engine 4.4.1 if the engine needs to be stopped, decrease the engine speed to the idle state gradually. Let the engine stop only when the temperature of the cooling water is below 70 c. 4.4.2 when you need to stop the engine, only turn the starter switch key to off position (refer to 4.1...

Page 25

5. Break-in period and trial run 5.3 after break-in and trial-run course, replace the engine oil in the oil sump. Clean the engine oil filter and fuel filter. Check the tightening torques of the cylinder head bolt and the others connecting bolts. These torques should meet the requirement as specifie...