Kane KANE451 Manual

Summary of KANE451

Page 1

Kane451 flue gas analyser with direct co 2 measurement stock no: 19116 july 2012 © kane international ltd.

Page 2

Page 2 contents page no: kane451 overview 4 analyser layout & features 5-6 1. Batteries 7 2. Before using the analyser every time 8-9 2.1 fresh air purge 8 2.2 status display 9 3. Using the four function buttons 10-12 4. Using the analyser 13-24 4.1 combustion tests ....................................

Page 3: 42-43

Page 3 11. En50379 regulated instructions 35-37 12. Cleaning 38 13. Analyser annual recalibration and service 38 14. Returning your analyser to kane 39 15. Service returns 40 appendix 1 – main parameters 42-43 addendum optional nitric oxide (no) sensor 44-47.

Page 4: Kane451 Overview

Page 4 kane451 overview the kane451 combustion analyser measures carbon dioxide (co 2 ) , carbon monoxide (co) to 10,000ppm, differential temperature and differential pressure. The direct measurement of co 2 is achieved using a kane designed infra-red sensing system. Co 2 is set to zero in fresh air...

Page 5: Analyser Layout & Features

Page 5 analyser layout & features rotary switch function buttons x 4 “battery charging” indicator water trap particle filter enter menu controls scroll up/down tasklight and infra-red emitter flue gas inlet temp and pressure connections battery compartment (behind rubber sleeve).

Page 6

Page 6.

Page 7: 1. Batteries

Page 7 1. Batteries battery type this analyser has been designed for use with disposable alkaline batteries or rechargeable nickel metal hydride (nimh) batteries. No other battery types are recommended. Warning the battery charger unit must only be used when nimh batteries are fitted. Replacing batt...

Page 8

Page 8 2. Before using the analyser every time: check the water trap is empty and the particle filter is not dirty: - to empty water trap, unscrew the red drain plug and re-plug once it is empty. - to change the particle filter, remove protective rubber sleeve, slide the water trap unit from the ana...

Page 9

Page 9 2.2 status display select “status” on the dial to view the following: bat 39 → replace alkaline batteries if less than 10. Recharge nimh batteries if less than 30. 14:56:29 → current time. Can be re-set via the “menu”. 11/03/06 → current date. Can be re-set via the “menu”. Cal 283 → shows num...

Page 10

Page 10 3. Using the four function buttons: switching on the analyser press / button to switch the unit on. This must be done in fresh air to ensure that the analyser auto calibrates its sensors properly. When switched on, the analyser beeps and briefly displays battery %, fuel and pressure units. I...

Page 11

Page 11 backlight & tasklight press / to switch the display's backlight and tasklight on and off. Note: use of the backlight/tasklight significantly increases the current drain on the batteries. Switching pump on / off the analyser normally operates with the pump on. Press / to switch the pump off a...

Page 12

Page 12 storing a set of readings press and hold / for approx. 2 seconds. The top line briefly displays the log number. Note: this store function is inhibited in normal operation if the pump is switched off. Using / / buttons the function buttons below the symbols / / are used to navigate through th...

Page 13: 4. Using The Analyser:

Page 13 4. Using the analyser: 4.1 combustion tests: insert the tip of the flue probe into the centre of the flue. The readings will stabilise within 60 seconds assuming the boiler conditions are stable. The rotary switch can be used to display the following information: ratio display nat gas → fuel...

Page 14

Page 14 press / to print a full combustion test, (or send to pc via optional bluetooth). Hold / for 2+ seconds to log a full combustion report. Aux display p 0.00 → the aux (auxillary) display can be customised via menu / screen / aux. R 0.0008 the parameters displayed on lines 1, 2, 3 and 4 can be ...

Page 15: Prs Display

Page 15 4.2 pressure test select “prs”. The pump stops automatically. Press / to auto-zero the pressure sensor. Using the black connectors and manometer hose, connect to p1 for single pressure or p1 and p2 for differential pressure. Prs display pressure → normal response or smoothed (damped) respons...

Page 16

Page 16 if using larger bore tubing when performing pressure tests: ; push ‘orange’ tube over the rim of the spigot to ensure a gas tight seal. : this may not produce a gas tight seal..

Page 17

Page 17 4.3 let-by & tightness testing select “tightness”. The pump stops automatically. Press / to auto- zero the pressure sensor. Connect from the test point to p1 using a black connector and manometer hose. The display shows “let by?”. Use , and to select yes or no. If yes is selected set the let...

Page 18

Page 18 when complete readjust the gas pressure if necessary then press to start the tightness test: tightn’s p1 20.01 → pressure at start of tightness test. P2 20.01 → real time pressure reading. Time 119 → tightness default time is 2 minutes. Can be changed via “menu”. When complete the display wi...

Page 19

Page 19 4.4 differential temperature select “diff temp” to measure flow, return and differential temperatures diff temp display temp → pump stops automatically when dial is moved to diff temp. T1c 60.4 → use the t1 connection for the flow temperature sensor. T2c 55.2 → use the t2 connection for the ...

Page 20

Page 20 4.5 room co testing select “room co” to measure and record co readings. Up to 30 co tests can be stored in each log. I) interval and start screen interval 5 min? → the test interval can be set to 1, 5 or 10 minutes + - → ↓ ↓ use the and buttons to select the required test interval then press...

Page 21

Page 21 iii) pause / stop screen pause? → press to pause recording stop? → press to stop recording p s ↓ ↓ if pause is selected the display will change to ‘paused screen’. In paused mode the ‘live’ co readings are displayed but not recorded. If stop is selected the co test series is ended. The displ...

Page 22

Page 22 v) restart / stop screen restart? → press to restart recording stop? → press to stop recording r s ↓ ↓ if restart is selected the display recerts to the ‘measure and record screen’. Co readings are displayed and recorded at the interval originally selected. If stop is selected the co test se...

Page 23

Page 23 press / to print the test, (or send to pc via optional bluetooth). Note: the analyser’s memory can store up to 30 room co logs. Room co tests are logged automatically, therefore the room co section of the memory will be full after the 30 th room co log is complete. Before the 31 st room co l...

Page 24

Page 24 4.6 kane451 printouts kane451 v 1.04b kane451 v 1.04b kane451 v 1.04b your company name & phone number here your company name & phone number here your company name & phone number here serial no. 123456789 serial no. 123456789 serial no. 123456789 date 31/01/11 pressure diff temp time 12:00:0...

Page 25: 5. Using The Menu

Page 25 5. Using the menu select “menu” on the rotary switch and navigate using the function buttons: u = scroll up v = scroll down = enter main menu sub menu options / comments setup set fuel nat gas, l oil, propane, butane, lpg, pellets (wood) n Å c Æ g ef(c) = condensing boiler nett efficiency ef...

Page 26

Page 26 main menu sub menu options / comments report comb’n stored combustion tests: view, del all, exit pressure stored pressure tests: view, del all, exit tightn’s stored tightness tests: view, del all, exit temp stored differential temperature tests: view, del all, exit room co stored room co tes...

Page 27: Pressure Meter

Page 27 6. Using the kane451 as a thermometer or pressure meter with the kane451 switched off, press and hold down the / button and then press and release / . Release / after mano_mod is displayed on top line. The kane451 will now operate as a fixed display thermometer/pressure meter with the pump o...

Page 28

Page 28 if using larger bore tubing when performing pressure tests: ; push ‘orange’ tube over the rim of the spigot to ensure a gas tight seal. : this may not produce a gas tight seal..

Page 29: 7. Measuring Flue Gases

Page 29 7. Measuring flue gases after the countdown is finished and the analyser is correctly set up, put its flue probe into the appliance’s sampling point. The tip of the probe should be at the centre of the flue. Use the flue probe’s depth stop cone to set the position. With balanced flues, make ...

Page 30

Page 30 8. Analyser problem solving if any problems are not solved with these solutions, contact us or an authorized repair center. Fault symptom causes / solutions • oxygen too high • co 2 too low • air leaking into probe, tubing, water trap, connectors or internal to analyser. • co reading (- - - ...

Page 31

Page 31 fault symptom causes / solutions • analyser just continually beeps • turn dial back to menu and press enter • turn dial back to tightness and press enter • bat only shows 65 with fully charged nimh batteries fitted • this is not a problem and is to be expected. Nimh batteries only deliver 1....

Page 32: 9. Analyser Specification

Page 32 9. Analyser specification (note: may be subject to change) parameter range resolution accuracy temp measurement flue temperature inlet temperature (internal sensor) inlet temperature (external sensor) 0-600 o c 0-50 o c 0-600 o c 0.1 o c 0.1 o c 0.1 o c +2.0 o c +0.3% reading +1.0 o c +0.3% ...

Page 33

Page 33 ambient operating range 0 o c to +40 o c 10% to 90% rh non-condensing battery type / life 4 aa cells >8 hours using alkaline aa cells chargers (optional) 220v charger, for nimh batteries only 12v in vehicle charger, for nimh batteries only dimensions weight: handset: probe: 0.8kg handset wit...

Page 34

Page 34 10. Electromagnetic compatibility european council directive 89/336/eec requires electronic equipment not to generate electromagnetic disturbances exceeding defined levels and have adequate immunity levels for normal operation. Specific standards applicable to this analyser are stated below....

Page 35

Page 35 11. En 50379 regulated instructions en 50379 section 4.3.2 “instructions” defines a number of specific points that must be included in the relevant instruction manuals. The paragraph numbering below relates to that section of en 50379. A) the kane451 is designed to be compliant with en 50379...

Page 36

Page 36 h) some commonly occurring materials, vapour or gases may affect the operation of the kane451 in the long or the short term though in normal use kane international ltd is not aware of any specific issues that have affected the product. The following list is included to satisfy the stated req...

Page 37

Page 37 the particle filter should be checked at least on a daily basis when using ‘clean’ fuels and more often when using liquid or solid fuels. Detailed instructions regarding the changing of the filter and the emptying of the water trap are given in section 2 of this manual. M) warning! When usin...

Page 38: 12. Cleaning

Page 38 12. Cleaning this product can be cleaned using a damp lint free cloth and a small amount of non- abrasive detergent. Take care to avoid moisture entering the sensor’s grill and after cleaning leave the product in a warm dry place to allow any surface dampness to evaporate. Under no circumsta...

Page 39: Packing Your Analyser

Page 39 14. Returning your analyser to kane when returning your kane451, please always ensure that you enclose: 9 your full contact details 9 a daytime telephone number 9 details of faults you might have experienced 9 any relevant accessories (eg. Probe, printer, adaptor and leak detectors). Any acc...

Page 40: Service Returns

Page 40 service returns (simply cut out and attach to your package) northern service department kane international ltd gibfield park avenue atherton manchester m46 0sy northern service department kane international ltd gibfield park avenue atherton manchester m46 0sy northern service department kane...

Page 41

Page 41.

Page 42: Appendix 1 - Main Parameter:

Page 42 appendix 1 - main parameter: here are the legends used and what they mean: o 2 : oxygen (calculated) reading in percentage (%) co : carbon monoxide (measured) reading displayed in ppm (parts per million). If ‘- - - -’is displayed there is a fault with the co sensor or the instrument has not ...

Page 43

Page 43 bat : displays the battery power available. Replace alkaline batteries if reading is less than 10 recharge nimh batteries if reading is less than 20 readings may be affected if used with low power batteries. Date : date shown as day, month and year, dd/mm/yy. Date is recorded when each combu...

Page 44

Page 44.

Page 45: Addendum

Page 45 addendum instructions for kane451 analysers fitted with optional nitric oxide (no) sensors.

Page 46: Displaying The No Reading

Page 46 displaying the no reading select “menu” on the rotary switch and navigate using the function buttons: u = scroll up v = scroll down = enter the menu main structure is as follows: main menu sub menu options / comments setup pressure report screen contrast aux enables users to customise the pa...

Page 47

Page 47 use or to navigate to the main menu option screen. Press . Use or to navigate to the sub menu option aux. Press . The display will show aux line 1 press and a third line will appear. Use or to navigate to the desired parameter to be displayed on line 1. Press to select the parameter for line...

Page 48

Page 48 nitric oxide sensor specification gas measurement nitric oxide (no) (low range) nitric oxide (no) (high range) resolution 1 ppm 1ppm accuracy + 2ppm *1 +5 ppm > 30ppm +5ppm *1 +5% reading >100ppm range 0 to 100 ppm 0 to 1000 ppm *1 using dry gases at stp.

Page 49

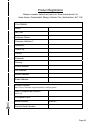

Page 49 product registration please complete, detach and return to: kane international ltd, kane house, swallowfield, welwyn garden city, hertfordshire, al7 1jg your details name: job title: company name: company address 1: address 2: town/city: county: postcode: country: phone number: fax number: m...

Page 50

Page 50 why did you buy a kane product? Dealer recommendation other recommendation value for money our fixed price servicing programme kane previous owner not your decision other: what brand was your previous analyser? How did you hear about kane? Magazine advert trade counter literature personal re...

Page 51

Page 51.

Page 52: Www.Kane.Co.Uk

Page 52 thank you for buying this analyser. Before use, please register on our website www.Kane.Co.Uk or complete, detach and return the product registration page..