- DL manuals

- Kane

- Measuring Instruments

- KM9106

- Operator's Manual

Kane KM9106 Operator's Manual

Summary of KM9106

Page 1

Km9106 operators manual kane international limited kane house, swallowfield welwyn garden city hertfordshire al7 1jg tel: +44 (0) 1707 375550 fax: +44 (0) 1707 393277 e-mail: sales@kane.Co.Uk stock no 16958/8 february 2003 © kane international limited.

Page 2: Contents

Contents page no: 1. Analyser layout and features ................................................................................... 1 1.1 handset features ......................................................................................................... 1 1.2 analyser features.................

Page 3

7. Printing information ........................................................................................................ 30 7.1 changing printout parameters ................................................................................ 31 7.2 user defined printouts............................

Page 4

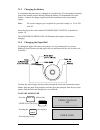

Km9106 operators manual 1 1. Analyser layout and features 1.1 handset features rubber boot remote lead socket (15 pin d type) also used for downloading data to pc 4 line display on/off key up key down key enter/setcal keys battery compartment (back) commonly used keys on/off up pages up through scre...

Page 5

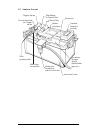

Km9106 operators manual 2 1.2 analyser layout connection lead for oxygen sensor oxygen sensor filter bridge or sulphur filter particle filter battery enclosure printer unit handset (stored in pocket) accessory storage space (leads/water trap etc.) dual pressure ports water trap connection water trap...

Page 6

Km9106 operators manual 3 1.3 standard probe configuration.

Page 7

Km9106 operators manual 4 1.4 analyser connections.

Page 8: 2. Safety

Km9106 operators manual 5 2. Safety warning this analyser extracts combustion gases that may be toxic in relatively low concentrations. These gases are exhausted from the bottom of the instrument. This instrument must only be used in well ventilated locations. It must only be used by trained and com...

Page 9

Km9106 operators manual 6 4. Normal start up sequence 4.1 every time you use the analyser before switch-on check that: the oxygen sensor is connected the particle filter is not dirty the sulphur filter is fitted for heavy oil or coal the water trap and probe line are empty of water all hose connecti...

Page 10

Km9106 operators manual 7 and show the countdown screen :- -- -- -- -- -- -- -- -- -- -- -- -- -- 9 calibrating 9 9 300 -- -- -- -- -- -- -- -- -- -- -- -- -- the display will countdown from 300 to zero in one second steps. If the analyser has been used recently it may complete automatic calibration...

Page 11

Km9106 operators manual 8 4.3 main displays the main display can be changed to show the following :- • page mode displays 4 lines of data in set format, each page is predefined. • line scroll mode allows you to customise the display with the data you require. To change between the different modes :-...

Page 12

Km9106 operators manual 9 4.3.2 line scroll mode line scroll mode allows you to customise the display. Use the key to change the bottom line of the display. Once the correct line is displayed press to confirm and move the line up. Select the next parameter and repeat until all lines display the desi...

Page 13

Km9106 operators manual 10 4.4 sampling the flue gas once the automatic calibration procedure has been completed and the specific fuel has been selected the probe can be inserted into the desired sampling point. It is recommended that the sampling point be located at least two flue diameters downstr...

Page 14

Km9106 operators manual 11 4.5 taking a pressure reading with the optional pressure module fitted a flue draught measurement can be made at any time. Connect the standard probe to the appropriate pressure sensor inlet and place the probe in the flue. The pressure reading will be displayed :- co/co2 ...

Page 15

Km9106 operators manual 12 4.7 normal shutdown sequence do this every time you use the analyser. Remove the probe from the flue - take care ! The probe will be hot - and allow it to cool naturally. Do not immerse the probe in water as this will be drawn into the analyser and damage the pump and sens...

Page 16: Using The Keypad

Km9106 operators manual 13 5. Using the keypad 5.1 basic operation basic operation of the keypad to change the display in page and line scroll mode is detailed section 4.3. These modes give you the facility to perform the following :- • page mode displays 4 lines of data in set format, each page is ...

Page 17

Km9106 operators manual 14 upper parameter keys always press upper function first then scale to display scaling setup parameters ambient to display ambient temperature plus sensor, flue and inlet so 2 to display sulphur dioxide reading plus nett, o 2 and co no 2 to display nitrogen dioxide reading p...

Page 18

Km9106 operators manual 15 5.4 display backlight and contrast the display contrast can be adjusted to suit different lighting conditions and the backlight can be switched on or off. To toggle the backlight on /off press upper function followed by to set the contrast press the followed by upper funct...

Page 19

Km9106 operators manual 16 6. User selectable setting the following features are under your control at any time and can be changed as detailed later in this section. Time and date day/ month order is selectable and the real time clock and calendar are fully adjustable . Fuel type standard pre-progra...

Page 20

Km9106 operators manual 17 they drift. This may happen if the sensor is taken to very high concentrations for long periods of time or over-ranged. 6.1 time and date (setting numbers) this section gives details on setting the time and date and also the general principle of setting a number from 0-9 u...

Page 21

Km9106 operators manual 18 to set the time: time 16-01-12 set as with the date each number in the time is to be set. Parameter controls options time: select each number using or key and 0 - 9 once the last number has been set the screen will show the main display last shown before entering the set t...

Page 22

Km9106 operators manual 19 to set a standard fuel: there are over 70 standard fuels programmed into quintox. The fuels are arranged into tables for each country and the table should be selected for the origin of the fuel used in your boiler. Each table contains different fuel types, choose the fuel ...

Page 23

Km9106 operators manual 20 to set a user fuel: if one of the standard fuels does not approximate to the one you are using in your boiler then it is possible to set the quintox up for a user fuel. The information required to be able to set this are the chemical breakdown of the fuel and the gross and...

Page 24

Km9106 operators manual 21 to set gross or nett efficiency press the -- -- -- -- -- -- -- -- -- -- -- -- -- set -- -- -- -- -- -- -- -- -- -- -- -- -- pressing the key displays set efficiency gross parameter controls options eff select using or key and gross net 6.4 scale options the scale option ro...

Page 25

Km9106 operators manual 22 parameter controls options select language select using or key and english spanish netherlands french italian german swedish finnish set line rejection 50 hz parameter controls options line rejection select using or key and 50 hz - uk 60 hz - usa ppm(n) or mg/m 3 (n) param...

Page 26

Km9106 operators manual 23 parameter controls options compensation select using or key and off on set temperature celsius parameter controls options temperature select using or key and celsius fahrenheit set pressure ppm parameter controls options pressure select using or key and mbar inwg note: mba...

Page 27

Km9106 operators manual 24 selecting yes allows you to set an oxygen reference value different to that shown in the fuel constants. For example 3% is set in the natural gas constants, to reference the toxic gas values to a different value select using the screen below (use the number setting sequenc...

Page 28

Km9106 operators manual 25 parameter controls options ref nox select using or key and nox = sum nox = no nox = no2 there are three ways of displaying the value of nox when the values are converted to mg/m3. Local authorities may require a certain calculation. The options are as follows: • nox = sum ...

Page 29

Km9106 operators manual 26 6.5 inlet temperature the quintox uses as default the internal ambient sensor when calculating the net temperature. If an optional inlet probe is fitted then inlet is used in the calculation. As an alternative to both of the above, the inlet air entering the boiler can be ...

Page 30

Km9106 operators manual 27 6.6 oxygen calibration if used over long periods the oxygen sensor may drift slightly and for maximum accuracy may require resetting. To reset oxygen sensor with the flue probe sampling fresh air and the flue temperature reading less than 50 °c/122°f, or the temperature pl...

Page 31

Km9106 operators manual 28 calibrate sensor select using or key and yes no select yes set zero ? No parameter controls options set zero select using or key and yes no select yes select sensor co -------- . . -17 parameter controls options select sensor select using or key and list of fitted sensors ...

Page 32

Km9106 operators manual 29 6.8 co alarm it is possible to set a point in the range of the sensor so that it alarms and warns the user of a dangerous level of carbon monoxide. The default level is set at 400 ppm. This should be used when there is a local limit on the level of co that should not be em...

Page 33: 7. Printing

Km9106 operators manual 30 7. Printing information while in any of the main displays a manual print can be obtained by pressing the display will show the printout as it is printing :- 7 77 printing 777 -- -- -- -- -- -- -- -- -- -- -- -- -- 77 kane-may 77 -- -- -- -- -- -- -- -- -- -- -- -- -- stand...

Page 34

Km9106 operators manual 31 the remainder of this section explains the following :- setting auto-timed printing or logging allows information to be printed or logged automatically at set time intervals (from 10 seconds to 90 minutes). Care must be taken in setting the interval time; a standard quinto...

Page 35

Km9106 operators manual 32 the next screen enables or disables the integral printer. Default is on. Printer ? On use or key to select on or off and press to edit the printout header select yes. Set header ? No use or keys to select yes or no and press the cursor _ will be positioned under the first ...

Page 36

Km9106 operators manual 33 7.2 user defined printouts general principle: a user defined printout can have a maximum of 40 lines. The contents of each line can be defined by the user from the master list of parameters detailed later in this section. The standard printout with line numbers and paramet...

Page 37

Km9106 operators manual 34 the above example will send the time and oxygen reading to the printout every two minutes. To stop the quintox auto printing or logging, select auto print off above and return to the main displays. 7.2.1 standard printout - parameter options used: line number parameter use...

Page 38

Km9106 operators manual 35 7.2.2 master list of printed parameters the following list is a master list of printed parameters. Details of the measured and calculated variables are given in the appendix. Print description 1 *** kane-may *** company identification 2 ** km quintox** analyser identificat...

Page 39

Km9106 operators manual 36 8. Quintox logging and pc download 8.1 overview 8.1.1 description data is sent to the handset through the connection lead and can be stored if required. All information logged can be displayed on the hand-set, down-loaded to a computer or output directly to a printer. The ...

Page 40

Km9106 operators manual 37 8.1.3 logging data data logging is done with the handset operating in 2. Quintox control and by either pressing the key or requesting an auto print, information will be captured by the logger and stored. The display will show the following screen to confirm information has...

Page 41

Km9106 operators manual 38 8.3 logger control this facility allows access to all of the information stored in the handset; data can be cleared, viewed on the display or output to a printer or pc. The logger records each page of quintox information and gives it a unique log number; as additional logs...

Page 42

Km9106 operators manual 39 log data ? No enter yes to tell the logger to store data in memory and no to disable the logging function. Download memory no download memory allows you to output the stored information to a pc, output is in our own format and requires a special program to extract the data...

Page 43

Km9106 operators manual 40 enter the desired location to display the memory from. Entering numbers is detailed in section 6. Log no. Date time battery % 0100 23/10/96 10:32:36 54 to scroll through data, use and , note the log starts with the log number followed by quintox data. Note also that once a...

Page 44

Km9106 operators manual 41 8.4.1 setting up your pc a standard communications package will be able to collect the data from the quintox. Windows terminal software is a suitable package. The communications protocol should be set to :-.

Page 45

Km9106 operators manual 42 8.4.2 capturing data from quintox to capture data direct from the quintox into a pc the rs232 port on the quintox has to be connected to the serial port on your pc. Using the standard rs232 lead, and ibm/at lead if you serial port is a 9 pin d type, connect the quintox to ...

Page 46: 9. Continuous

Km9106 operators manual 43 9. Continuous monitoring the quintox is designed primarily as a portable emissions monitoring analyser. It can however be used for longer periods if the gas is treated correctly before being supplied to the analyser. The main problem with continuous monitoring is the build...

Page 47: 10. Main Purge

Km9106 operators manual 44 10. Main purge the main purge facility for quintox is used where longer sampling of flue gas is required. It should be used with the km9008 gas conditioning unit or in conjunction with any other water removal system. If dry gas is supplied to the quintox for a long period ...

Page 48

Km9106 operators manual 45 to access timed purge enter the following :- enter the code 0000 at the following display :- enter service code -- -- -- -- > 0 0 0 0 the following screens will be displayed, enter no to both :- calibrate sensor no print memory ? No the purge sequence now begins, by using ...

Page 49

Km9106 operators manual 46 set yes or no depending on whether auto zero is required or not. Auto zero ? No note: during both manual and timed purge operation the following screen will be displayed for approximately one second every 3 seconds. -------------------------------------- purge on ---------...

Page 50: 11. Maintenance

Km9106 operators manual 47 11. Maintenance 11.1 emptying and cleaning the in-line water trap the water trap should be checked and emptied on a regular basis. Water vapour will condense and gather in the probe line this may move suddenly to the trap when the probe is moved. Care should be taken at al...

Page 51

Km9106 operators manual 48 11.3 charging the battery it is important that the battery is charged on a regular basis. The instrument constantly powers the internal sensors and may flatten the battery if left unattended for some months. Connect the charger supplied with the instrument to the correct m...

Page 52

Km9106 operators manual 49 11.5 changing the printer ribbon the printer ribbon cartridge will last for approximately two rolls of paper. Remove the printer cover as detailed above. Marked on one end of the cartridge is push. Gently press down on this end and the ribbon cartridge will pop up at the o...

Page 53: 12. Problem Solving

Km9106 operators manual 50 12. Problem solving the following is a list of problems that may occur on the instrument through its operating life. If the cause of the fault is not easy to identify then we advise you to contact the kane international service department or an international distributor fo...

Page 54: 13. Annual Re-Calibration

Km9106 operators manual 51 13. Annual re-calibration whilst the sensors have an expected life of more than two years in normal use it is recommended that the analyser is re-calibrated at least annually. This is so that long term drift on the sensors and electronics can be eliminated. Local regulatio...

Page 55

Km9106 operators manual 52 14. How to get expert help there will be occasions when despite having read the manual there will be problems that you cannot resolve and so you need external help. Before calling kane international or one of its international distributors please first check the following:...

Page 56: 15. Product Specification

Km9106 operators manual 53 15. Product specification instrument parameter resolution accuracy range temp measurement flue temperature inlet temperature 0.1 o (c/f) 0.1 o (c/f) 1.O o c +/-0.3% of reading 1.O o c +/-0.3% of reading 0 - 1100°c, 32 - 2140°f * use high temperature probe for gases > 600°c...

Page 57

Km9106 operators manual 54 handset dimensions 220 mm long 120 mm high 50 mm wide keypad 16 tactile keys with sounder display 4 line lcd with backlight and contrast control extension cable specification: 8 pin din to 15 pin ‘d’ screened cable cable lengths: 5m standard 10-20m-optional probe choose fr...

Page 58

Km9106 operators manual 55 ambient operating range 0 - 40°c (+32°f to 104°f) 20 - 80% rh non condensing storage: 0-50°c maximum gas temperature at sensors: continuous +40°c intermittent +55°c.

Page 59: Appendices

Km9106 operators manual 56 appendices a - parameter meanings the parameters and their meanings are detailed as follows : - date : analyser date. See section 6.1 to change. Time : analyser time. Use section 6.1 to change. Instability : this is an indication of how stable the signals are from all the ...

Page 60

Km9106 operators manual 57 nett : nett temperature calculated by deducting the internal ambient temperature from the measured flue temperature. Displays in either centigrade c or fahrenheit f and will display not fitted if flue probe not connected. If an external inlet probe is used then inlet is de...

Page 61

Km9106 operators manual 58 co/co2 r : the co/co2 ratio, is the ratio of measured co divided by co2. It gives an indication of the following :- • how good a gas sample the instrument is reading. • how clean the boiler is running. For example : a new or clean domestic boiler will display a ratio of le...

Page 62

Km9106 operators manual 59 cxhy : unburnt hydrocarbon reading in % of lel of methane, the sensor is calibrated with methane. Displayed when a hydrocarbon sensor fitted. Lel is the lower explosive limit of a gas when mixed with air, for methane this has the ratio of 19:1 air:methane. Below the lel th...

Page 63: B. Nox

Km9106 operators manual 60 b. Nox calculations only an no sensor fitted. Working in ppm: nox referenced to no the user can select the assumed no 2 percentage and the o 2 normalised level then: nox in ppm = no in ppm multiplied by (1 + assumed no 2 percentage) in this setup nox can only be displayed ...

Page 64

Km9106 operators manual 61 nox referenced to no 2 nox in mg/m 3 = no in ppm multiplied by 2.05 multiplied by (1 + assumed no 2 percentage) or nox in mg/m 3 = no in mg/m 3 divided by 1.34, multiplied by 2.05 and multiplied by (1 + assumed no 2 percentage) normalising readings normalised reading = ini...

Page 65

Km9106 operators manual 62 only an no 2 sensor fitted when there is only an no 2 sensor fitted the nox function is disabled no 2 in mg/m 3 = no 2 in ppm multiplied by 2.05 normalising readings ppmn = initial reading in ppm multiplied by (21 minus the o 2norm setting) and then divided by (21 minus th...

Page 66

Km9106 operators manual 63 c. Combustion efficiency calculation the efficiency calculation is based upon british standard bs845. This identifies three sources of loss associated with fuel burning: losses due to flue gasses: dry flue gas loss, moisture and hydrogen sensible heat of water vapour unbur...

Page 67

Km9106 operators manual 64 calculated data: tnet = net temperature % co2 content in flue gas % dry flue gas losses % wet losses % unburned carbon loss % efficiency %co2 = (20.9 - %o2m) x k2 / 20.9 tnet = flue temperature - inlet temperature dry flue gas loss = 20.9 x k1n x (tnet) / k2 x (20.9 - %o2m...

Page 68

Km9106 operators manual 65 d. Calculation of fuel data for any fuel not specified by kane international the net calorific value, gross calorific value and composition should be obtained from the fuel supplier. The following fuel data has been calculated with reference to the efficiency calculation. ...

Page 69: Statement

Km9106 operators manual 66 e. Electromagnetic compatability (ce) statement this product has been tested for compliance with the following generic standards: en 50081-1 en 50082-1 and is certified to be compliant specification ec/emc/ki/km9106 details the specific test configuration, performance and ...