- DL manuals

- Kanomax

- Measuring Instruments

- 2211

- Operation Manual

Kanomax 2211 Operation Manual

IAQ MONITOR

MODEL 2211

Operation Manual

Please use this instrument properly by reading

this user’s manual and following the warning instructions.

Keep this manual in a place where it can be accessed quickly.

02001

04.11

netzerotools.com

netzerotools.com

netzerotools.com

kanomax-2211-handheld-iaq-monitor

Summary of 2211

Page 1

Iaq monitor model 2211 operation manual please use this instrument properly by reading this user’s manual and following the warning instructions. Keep this manual in a place where it can be accessed quickly. 02001 04.11 netzerotools.Com netzerotools.Com netzerotools.Com kanomax-2211-handheld-iaq-mon...

Page 2: Please Use This

Thank you for purchasing kanomax product. Please use this instrument properly by reading this operation manual and following the warning instructions. Netzerotools.Com netzerotools.Com.

Page 3: List of Components

List of components ■ standard items model qty. Functions main body 2211-00 1 - probe 2211-01 1 co, co 2 , temperature, humidity sensor carrying case 2211-02 1 hard case probe stand 2211-03 1 probe fixture gas calibration cap 2211-04 1 gas calibration tubing - 1 connecting to gas tank operation manua...

Page 4: Table of Contents

Table of contents 1. Iaq monitor anatomy.................................................................... 1 1.1 main body .................................................................................................................................. 1 1.2 operation panel .........................

Page 5

7. Other setting ................................................................................ 33 7.1 date .............................................................................................................................................33 7.2 units and baud rate .........................

Page 6: 1.1 Main Body

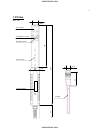

1 1. Iaq monitor anatomy 1.1 main body unit : mm app rox. 51 approx.. 88 probe terminal operation panel display approx. 66 rs232c terminal dc input ternimal power switch i : ON O: OFF analog output terminal (optional) a pp ro x. 18 8 battery box iaq monitor netzerotools.Com netzerotools.Com.

Page 7: 1.2 Operation Panel

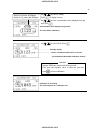

2 1.2 operation panel menu key press once to access the main menu.. ※ if you press this key while measuring or setting, this key will work as cancel and bring you back to the main menu. Menu start hold set mode iaq monitor set key press the key to execute the selected item. Mode key you can select t...

Page 8: 1.3 Probe

3 1.3 probe unit : mm φ15 43 320 169 53 φ25 CO 2 sensor humidity sensor temperature sensor CO sensor probe number φ32 l=2000 netzerotools.Com netzerotools.Com.

Page 9: 2. Getting Started

4 2. Getting started 2.1 installing batteries place iaq monitor facedown. ④insert the battery observing the polarity. This instrument requires 6 aa size batteries. Use only aa size manganese (r6), alkaline (lr6) or ni-cd batteries for replacement. Do not mix new batteries with used ones, for it may ...

Page 10: 2.2 Connecting Probe

5 ① 2.2 connecting probe ※ make sure that the power is off when connecting or disconnecting probe/probe cable. ① main body connector and probe connector only fit one way. ② push-in the connector until you hear click. ※ do not force to connect probe, it may cause a serious damage to the instrument. 2...

Page 11

6 2.4 powering iaq monitor on/off you can turn on and off the iaq monitor by flicking the switch on the side. When you turn on the power after connecting probe , manufacturer’s logo, model name and its software version appear on the display for a few seconds. ◆ battery level indicator the indicator ...

Page 12: 2.5 How to Make Measurement

7 2.5 how to make measurement 2.5.1 measuring co and co 2 and attentions the diffusion state of the air(state of flow) affects response time of co and co 2 sensor. In order to obtain an exact measurement result, please measure in the place which has the flow of air as much as possible. Mechanism of ...

Page 13

8 when atmospheric pressure of the place to measure is different from normal atmospheric pressure (such as high altitude), please follow below steps for atmospheric pressure setting (initial value: 1013hpa). Since the change of weather does not significantly affect the atmospheric pressure as long a...

Page 14

9 2.5.3 measuring humidity and attensions high humidity or rapid temperature change in atmosphere may cause humidity reading value to be exceedingly high because of the condensation occurred on this sensor. Incase of the condensation, leave a probe under atmosphere of less than 40%rh for 24 hours to...

Page 15: 3. Normal Measurement

10 3. Normal measurement this is the mode that you will be in, when you first turn on the instrument. In this mode you cannot save any data. The display will be updated every 1 second. 3.1 selecting the measuring parameters display procedure ① press , and display mode moves in order, as shown below....

Page 16: 3.2 Display Hold

11 ⑤ ⑥ 3.2 display hold display procedure while measuring, press (also available on humidity measuring.) “ hold ” indicator appears on the display to indicate that the reading shown is held. Press again to release. Maximum hold ・・・ how to hold the maximum value display procedure while measuring, pre...

Page 17

12 4. Measuring maximum, minimum & mean calculation mode will automatically calculate the maximum, minimum and mean of measured data. Display procedure press . Use to select “ 2. Calculation ” press . Trial(1) trial(2) trial(n) measuring time ・・・ sampling time × N( number of trial ) sampling time ● ...

Page 18

13 display procedure < to set calculation mode > use and select “ 1. Mode ” press . Use and select average or instant press . < to set sampling time > use and select “ 2. Sampling time ” press . Use and select sampling time (1 to 999sec ) . Press . < to set no. Trial (n) > use and select “ 3. No. Tr...

Page 19

14 < ready > press to start. Display procedure < while measuring > press to stop. If you have selected “ yes ” for “ 4. Data storage ? ” , the measured data will be stored. Press can also stop the measurement but this would not store any data. < result > after all the trials are finished, the calcul...

Page 20: 5. %oa Mode

15 5. %oa mode % oa mode is to provide calculation of ventilation ratio with temperature or co 2 . Calculation is based on below formula: %oa = (r_a - s_a) / (r_a – o_a) × 100 * %oa : ventilation ratio r_a : temperature and co 2 in respiratory air s_a : temperature and co 2 in supplied air o_a : tem...

Page 21

16 display procedure press press and select [3.Oa%] . Use to select [1.Mode] P ress . Use to select [temp.] or [co2] P ress . Press and select [2.Sampling time] press . Use to set an appropriate number (1-999), press . Press and select [3.No.Trial], press . Press to select no. Trial (1-999), press ....

Page 22

17 display procedure press to select [4.Data storage], press . Use and select [yes] or [no], press . Use and select [5.Set to start], press . ※ if you press before saving the settings it will return you back to main menu. Press to start. Press to stop. Press again to resume. ※ press can also stop th...

Page 23

18 display steps after all the trials are finishied, the calculated result will appear in display. Press to display average values in order of : r_a, s_a, and o_a. Press to return to main menu. If you have selected [yes] for [data storage], the result will be stored. Related functions: ■ if printer ...

Page 24: 6. Data Output

19 6. Data output 6.1 what can be stored ? Measuring display stored parameters calculation mode all co 2 , co, temperature, humidity ( including the items of humidity ) temp. %oa; r_a, s_a, and o_a temperature %oa mode co 2 %oa; r_a, s_a, and o_a co 2 concentration 6.2 to recall stored data display ...

Page 25

20 display procedure calculation recalled data will be displayed. Use for scroll. If you measured in calculation mode, you can select temperature or humidity to be displayed by pressing . % oa ( 温度の場合 ) you can select the range of calculation. ( if you are not going to change the data range, press t...

Page 26: 6.3 Print Out

21 6.3 print out you can connect iaq monitor to a printer using an rc232c cable for data printout. 6.3.1 preparation - printer (optional)……….. Dpu-h245 (seiko instruments) - recommended - printer cable ( optional ) you need to coordinate the baud rate and data transmission conditions on both main bo...

Page 27

22 examples of print out 6.3.3 calculation mode print out display procedure press after the measurement and calculation to print out the result. 2004/05/12 15:40:45 co2 523 ppm co 1.7 ppm temperature 24.4 ゚ c humidity 52.7 %rh ………… co 2 ………… co ………… temperature ………… humidity netzerotools.Com netzero...

Page 28

23 6.3.4 %oa mode print out display procedure press after %oa measurement and calculation to print out the result. Examples of print out page set page :004 mode :calculation(i) date :2004/06/19 time :17:24:33 atm. :1013hpa data :005 sampling time:001 start:001 end:005 max 612 ppm co2 avg 598 ppm co2...

Page 29

24 6.3.5 stored data print out display procedure press . Use to select [4.Data output], press . Use to select [2.Printer], press . Use to select page that you want to print out, press . The data you have selected will be displayed. Press to scroll. If you measured in calculation mode, you can select...

Page 30

25 you can select the range of calculation. ( if you are not going to change the data range, press to calculate the entire data. ) press . Cursor will appear on “ start ” use to select starting point. Press . Cursor will move to “ end ” use to select l. Press . Press to calculate. You cannot set mor...

Page 31

26 Example of Print Out page set page :002 mode :%oa(tmp.) date :2004/06/19 time :13:35:23 atm. :1013hpa data :010 sampling time:001 start:001 end:010 max 25.5 ゚ c r̲a avg 25.4 ゚ c r̲a min 25.4 ゚ c r̲a max 24.3 ゚ c s̲a avg 24.2 ゚ c s̲a min 24.1 ゚ c s̲a max 23.2 ゚ c o̲a avg 23.0 ゚ c o̲a min 22.8 ゚ c ...

Page 32: 6.4 Digital Output

27 6.4 digital output 6.4.1 preparation you can download the data stored in iaq monitor to your pc, by connecting iaq monitor and your pc with the rc232c cable. - computer - rs-232c cable (provided) - data processing software ( software for windows dc-rom is provided ) you need to coordinate the dat...

Page 33: 6.5 to Access From Your Pc

28 6.5 to access from your pc to connect iaq monitor to your pc, please refer to p.27. ――― icons and its meaning ――― : space : return or press enter * : a number ※ please input all commands with a capital letter. 6.5.1 transmission of on-time data display procedure example: measuring model and typed...

Page 34

29 display procedure press [u ] after “au”, the data will be displayed. Output co unit; co 2 unit; temperature unit; humidity unit ; dt unit; wb unit; ah unit; hr unit; oa% unit 6.5.2 transmission of stored memory display procedure press [f ] , after [af] , humidity related data (such as dt, wb, ah,...

Page 35: 6.6 Analog Output (Optional)

30 display procedure press “ m **** ” ( ※ must type in 4 digits) type in the desired page number after “ am ” . Contents ① measuring mode 000: calculation mode 001: %oa mode ② sampling time ③ number of data ④ calculation setting calculation -- avg: average, ins: instant %oa -- tmp: temperature co2; ...

Page 36

31 of the output range, the low end will be set at 0v and the high end will be set at 1v . Data output interval is always 1 second. Way to take in measured data ( analog output ) explanation take the data at every 1 second, output the value every 1 second. Display procedure press use to select [6.Ut...

Page 37

32 use to select [3.Save info]. Press ※ if you press before you save, you will return to main menu and setting will not be saved. Netzerotools.Com netzerotools.Com.

Page 38: 7. Other Setting

33 7. Other setting 7.1 date display procedure press . Use to select “ 7. Utility ” . Press . Use to select “ 1. Time adjust ” . Press . Use to select "1.Style" or "2.Date". Press . 1.Style: select jp,us or eu japanese style(jp) yyyy/mm/dd us style(us) mm/dd/yyyy eu style(eu) dd/mm/yyyy 2.Date: date...

Page 39: 7.2

34 7.2 units and baud rate display procedure press . Use to select “ 6. Utility ” . Press . Use to select “ 2. Unit select ” . Press . Use to select the desired item ( 1 thru 5 ) . Press . Use to change the setting. Press . Use to select “ 5. Save info ” . Press . ※ if you press before you save, you...

Page 40: 7.3

35 7.3 to delete data 7 .3.1 to delete a page of data display procedure press . Use to select “ 6. Data clear ” . Press . Use to select “ 1. Clear ” . Press . Use to select the starting page. Press . Use to select the ending page. Press . Use to select “ yes ” for partial delete. Press . ……starting ...

Page 41

36 selected page will be deleted and the remaining data will shift up. (see diagram below) 7 .3.2 to delete all data display procedure press . Use to select “ 5. Data clear ” . Press . Use to select “ 2. All clear ” . Press . Use to select “ yes ” to delete. Press . All the data will be deleted and ...

Page 42: 7.4 Contrast Adjustment

37 7.4 contrast adjustment in case you find the lcd display of main body too dark or too light, there is an adjusting volume at the back, bottom of main body, inside the battery cover. You can adjust by using a precision driver (-) ( 0.9 ~ 1.5mm ) . Turn it clockwise to darken and vice versa. Contra...

Page 43: 8. Calibrating Co/co

38 8. Calibrating co/co 2 sensor 8.1 preparation please turn on the main unit to fully warm up (about 10 minutes) before calibration. In general, calibrate in order of zero gas prior to span gas (the calibration of only either zero gas or span gas is possible). Valve close open turn to turn to the b...

Page 44

39 8.2 calibration procedure – zero calibration display procedure connect zero gas tank and iaq monitor. Press use to select [7.Calibration] press . Use to select sensor (1.Co2 or 2.Co). Press . (co2 is selected in the example.) use to select [zero]. Press . Use to select [1.Zero], press . …… curren...

Page 45

40 ‘‘‘‘ use to select [yes]. Press to start calibration. Fully open the regulator valve to pour the gas flow, press to start calibration. When the calibration result is ok calibration is completed. If [end] is displayed, the valve of regulator will be closed and gas will be stopped. Press to save al...

Page 46

41 calibration result is ng if [end] is displayed, the valve of regulator will be closed and gas will be stopped. ※ if [2.Save info] will not be able to be selected, the result is ng. Select [yes] to retry the calibration. Press to open menu screen. ※ if [--err--] is displayed, please check, return ...

Page 47

42 use to select [1.Span]. Press to display a cursor. Use to enter a concentration value displayed on a gas tank, press . Use to select [yes]. Press replace zero gas cylinder with span gas tank: fully open the regulator valve to pass the gas flow, press to start a calibration. ……………… concentration v...

Page 48

43 calibration result is ok calibration is completed. If [end] is displayed, the valve of regulator will be closed and gas will be stopped. Use to select [2.Save info]. Press to save all datas, return to menu . If you press before you save, you will return to main menu and the setting will not be sa...

Page 49: 9. Specification

44 9. Specification product iaq monitor model 2211 object clean air flow method electrochemical range 0.0-50.0 ppm ( 0.0~500 ppm* ) resolution 0.0-99.9ppm:0.1ppm,100-500ppm:1ppm accuracy ± 3% of displayed value or ± 3ppm; whichever that is larger ( @20 ℃) compensation: temp ± 0.125 %fs/ ℃ ( within ‐...

Page 50: 10.1 What Is Dt

45 10. Calculation result: dt, wb, ah, and hr 10.1 what is dt dt -- dew point temperature air with higher temperature contains more water vapor, and the air reaches a saturation point as temperature lowered ( relative humidity: 100 %) . Then continuously lowered temperature causes water vapor to sta...

Page 51: 10.2 What Is Wb

46 10.2 what is wb wet bulb temperature -- wb wet-bulb temperature is measured with a wet-bulb thermometer, which is a regular thermometer with a wet muslin wick cover. To calculate wet-bulb temperature without using a wet-bulb thermometer, existing dry-bulb temperature and relative temperature are ...

Page 52: 10.4 What Is Hr

47 10.4 what is hr humidity mixture ratio -- -hr humidity ratio (mixture ratio) is the proportion of masses between water vapor and dry air. Temperature and relative humidity are used on below formula. Society of heating, air-conditioning and sanitary engineers of japan r=ε× e/(p-e) × 1000 ε : molar...

Page 53: 11. Troubleshooting

48 11. Troubleshooting 11.1 battery check problem possible cause(s) / solution(s) refer to (page no.) iaq monitor will not turn on the battery is defective. → turn off the power and replace the batteries. 4,6 nothing appears on the display contrast is not set properly. → adjust the contrast volume s...

Page 54

49 11.4 printer check problem possible cause(s) / solution(s) refer to (page no.) printer is not connected properly. → check the connection. Re-connect if necessary. 21 the baud rate is not set properly. → check both, climomaster and printer, settings. 21 printer may not be compatible (dpu-h245 and ...

Page 55

50 11.7 calibration check problem possible cause(s) / solution(s) refer to (page no.) [-err] appears during the co span calibration. Output level of co sensor may be abnormal or the sensor is damaged. Contact a distributor near you. (although span calibration is not available, you can use existing c...

Page 56: Warranty and After Service

51 1 2 . warranty and after service kanomax limited warranty the limited warranty set below is given by kanomax japan, inc. (hereafter referred to as “ kji ” ) with respect to the kanomax brand iaq monitor, its attachment parts including probe and other accessories (hereafter referred to as “ produc...

Page 57: After Service

52 after service whenever the product is malfunctioning, please check with “ troubleshooting ” to find possible cause first. Repair parts are retained for a minimum period of five (5) years after production cessation of the product. This storage period of repair parts is considered as the period dur...