- DL manuals

- Kanomax

- Measuring Instruments

- 3900

- Operation Manual

Kanomax 3900 Operation Manual

Summary of 3900

Page 1

Airborne particle counter model 3900 please read this operation manual carefully and understand the warnings described within before operating this instrument. Keep this manual handy for future reference. 03001 08.09 operation manual www.Actoolsupply.Com www.Actoolsupply.Com.

Page 2: Component List

Component list ■ standard item model qty main unit 3900 1 power cord (with nema plug) - 1 standard inlet 3900-06 1 isokinetic suction probe 3900-07 1 zero filter 3900-04 1 tygon tube (2m) - 1 printer paper (dust free paper) 3900-05 2 measurement software - 1 operation manual - 1 test certificate - 1...

Page 3: Important Safety Information

Important safety information i important safety information in this manual, warning types and classifications are defined as follows. [classification] warning: to prevent serious injury or death indicates a potentially hazardous situation which, if not avoided, may result in serious injury or death....

Page 4: Warning

Important safety information ii warning ¤ unplug the power cord when the instrument is not in use. …… failure to observe the above may result in electric shock, fire or damage to internal circuitry. ¤ when using the ac adapter, ensure there is no dust on the adapter. The ac outlet used must be withi...

Page 5: Table of Contents

Table of contents 1. Part names and functions ..................................................................................... 1 1.1 airborne particle counter.................................................................................................... 1 2. Getting started ..................

Page 6

5.1.6 standard............................................................................................................................... 51 6. Battery charge ...................................................................................................... 52 6.1 charging battery .............

Page 7: 1. Part Names and Functions

1. Part names and functions 1 1. Part names and functions 1.1 airborne particle counter front back/left inlet --- particles enter the unit here. Attach the provided standard inlet. To use the provided isokinetic suction probe, attach tygon tube on the end of the standard inlet. Lcd touch panel --- t...

Page 8: 2. Getting Started

2. Getting started 2 2. Getting started 2.1 power supply supply power to the main unit. There are two ways to supply power; using ac cord or battery. -- ac cord -- plug the ac cord into the connecting port located under the main power switch on the rear of the unit. Ac100v~240v power supply line sha...

Page 9: 2.2 Zero Check

2. Getting started 3 after pressing the power switch on the front of the instrument, you will hear a beep sound and the led will light up. If the power is supplied by the ac line, the led is green and if supplied by battery, the led is red. Several seconds later, the initial screen appears automatic...

Page 10: 3.1 Boot Screen

3. Display description and operation procedure 4 3. Display description and operation procedure 3.1 boot screen a few seconds after the instrument is turned on, the screen on the left will be displayed. The system is initializing. Please wait for a few moments. Www.Actoolsupply.Com www.Actoolsupply....

Page 11: 3.2 Initial Screen

3. Display description and operation procedure 5 3.2 initial screen 3.2.1 initial screen when the instrument is booted up, the initial screen on the left will be displayed. All operations can be started from this screen. (1) data display: displays numeric value and chart. (2) measurement condition: ...

Page 12

3. Display description and operation procedure 6 3.2.2 screen change – initial screen menu return config return mode monitor return start return return file return preset return www.Actoolsupply.Com www.Actoolsupply.Com.

Page 13: 3.3 Monitor

3. Display description and operation procedure 7 3.3 monitor tap [monitor] on the initial screen to start monitoring. Sampling will start 10 seconds after the pump starts operating. * note that if the pump is already operating, sampling will start immediately when you tap [monitor]. * note that the ...

Page 14: 3.4 Mode

3. Display description and operation procedure 8 3.4 mode tap [mode] to display the mode selection window. Choose a mode from the below selection and tap it: single, sequence, interval, repeat, stat or standard. Note that the instrument is capable of 180 hours of continuous operation in every measur...

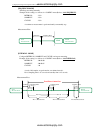

Page 15

3. Display description and operation procedure 9 [sequence mode] start/stop measuring manually. Example: if the setting is as follows in “config” menu (refer to 3.6.2 sequence ): interval : n/a sample t. : n/a cycles : n/a a continuous measurement is performed until you manually stop. Measurement fl...

Page 16

3. Display description and operation procedure 10 [repeat mode] configure sample t and cycles, and repeat measuring. Example: if the setting is as follows in “config” menu (refer to 3.6.4 repeat ): interval : n/a sample t. : 00:00:15 cycles : 20 20 measurement cycles lasting 15 seconds each are take...

Page 17: 3.5 Start

3. Display description and operation procedure 11 3.5 start 3.5.1 single, sequence, interval, repeat tap [start] on the main screen to start a measurement in the setting configured in 3.4 mode and 3.6 config . Z if “start delay” is not checked in “config” setting: upon tapping [start], the pump will...

Page 18

3. Display description and operation procedure 12 after a measurement in repeat mode or interval mode is finished, the measurement result will be displayed. Www.Actoolsupply.Com www.Actoolsupply.Com.

Page 19

3. Display description and operation procedure 13 3.5.2 stat - when not using map (refer to 3.6 config for using a map.) tap [start] to display “confirm” window. A measurement will start based on the setting configured in “3.4 mode ” and “3.6 config”. Z if “start delay” is not checked in “config” se...

Page 20

3. Display description and operation procedure 14 when a measurement is finished at each measurement point, a measurement result window will be displayed each time. Tap [next] to display “confirm” window informing you the next measurement point, and wait for the next measurement. Tap [remeasure] to ...

Page 21

3. Display description and operation procedure 15 - when using map (refer to 3.6 config for using a map.) tap [start] to display map. Select a measurement point and tap [start]. Tap [stop] to stop a measurement. Tap [magnify] to enlarge a map. (this button will become [minify] button. Press [minify]...

Page 22

3. Display description and operation procedure 16 select a measurement point and tap [detail] to display the details of the selected measurement point. Tap [start] to start a measurement based on the setting configured in 3.4 mode and 3.6 config . Z if “start delay” is not checked in “config” settin...

Page 23

3. Display description and operation procedure 17 3.5.3 standard - when not using map (refer to 3.6 config for using a map.) tap [start] to display “confirm” window. Tap [start] to start a measurement based on the setting configured in 3.4 mode and 3.6 config . Z if “start delay” is not checked in “...

Page 24

3. Display description and operation procedure 18 after a measurement at each location is finished, a measurement result will be displayed. In [raw] tab, measurement data will be displayed. In [calc] tab, calculated data of minimum (min), maximum (max) and average (ave) will be displayed. Tap [next]...

Page 25

3. Display description and operation procedure 19 - when using map (refer to 3.6 config for using a map.) tap [start] to display map. Select a measurement point and tap [start]. Tap [stop] to stop a measurement. Tap [magnify] to enlarge a map. (this button will become [minify] button. Press [minify]...

Page 26

3. Display description and operation procedure 20 select a measurement point and tap [detail] to display the details of the selected measurement point. Tap [start] to start a measurement based on the setting configured in 3.4 mode and 3.6 config . Z if “start delay” is not checked in “config” settin...

Page 27

3. Display description and operation procedure 21 when a measurement is finished, the measurement point changes from green to red. When all measurements are finished, the measurement result will be displayed. Select [location] to display the result of the specific location. Tap [eval] to display an ...

Page 28

3. Display description and operation procedure 22 3.5.4 interlocking operations on the screen displaying data for 6 particle sizes while sampling, tap a particle size on the screen to display the data of the particular particle size. Then to display data for 6 particle sizes back again, tap the part...

Page 29: 3.6 Config

3. Display description and operation procedure 23 3.6 config in config setting screen you can configure measurement settings in each mode. You can set interval, sample t., cycles, manual stop, auto save, auto print and start delay. Please note that the setting item varies depending on the measuremen...

Page 30

3. Display description and operation procedure 24 3.6.2 sequence check “auto save” to store data automatically. Check “auto print” to print data automatically. Check “start delay” to use delay time prior to a measurement. Tap [ok] to save and activate the current settings. Tap [preset] to display a ...

Page 31

3. Display description and operation procedure 25 3.6.3 interval you can set interval, sample t., cycles and manual stop. To set interval and sample t, tap the entry field to display a numeric keypad. Enter “hour”, “minute” and “second”, and tap [ok]. Tap entry field for cycles to display a numeric ...

Page 32

3. Display description and operation procedure 26 3.6.4 repeat you can set sample t., cycles and manual stop. Tap the entry field of sample t. To display a numeric keypad. Enter “hour”, “minute” and “second” and tap [ok]. Tap the entry field of “cycles” to display a numeric keypad. Enter a value and...

Page 33

3. Display description and operation procedure 27 3.6.5 stat if there are any map files saved, select the file to load it. Tap the entry field for “sample t”. To display a numeric keypad. Enter “hour”, “minute” and “second” on the numeric keypad and tap [ok]. Tap the entry field of “cycles” to displ...

Page 34

3. Display description and operation procedure 28 when a map file is specified in “file”, tap [map] to display a map. ([start] and [stop] buttons are inactive.) you can change the location order. Tap the location to be changed. Use [up] and [down] buttons to change the order. Tap [ok]. Then a window...

Page 35

3. Display description and operation procedure 29 3.6.6 standard standard measurement setting based on the standard setting configured in 3.9.2 option , the setting items for class and items in extention tab varies. In the basic tab; configure the setting of class, schedule, room, location, cycles a...

Page 36

3. Display description and operation procedure 30 check “auto save” to store data automatically. Check “auto print” to print data automatically. Check “start delay” to use delay time prior to a measurement. Tap [ok] to store and activate the settings. Tap [preset] to display a window asking you to i...

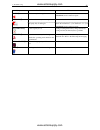

Page 37: 3.7 File

3. Display description and operation procedure 31 3.7 file select [file] on the initial screen. Then a screen shown on the left will be displayed. The file name consists of abbreviation of the measurement mode + date + time. The measurement mode abbreviations are; you can display, print or delete da...

Page 38: 3.8 Preset

3. Display description and operation procedure 32 3.8 preset select “preset” on the initial screen to display call preset screen. The selected preset file will be reflected in the mode and config setting. The first two letters in the file name indicates the mode type. Sg: single measurement sq: sequ...

Page 39: 3.9 Menu

3. Display description and operation procedure 33 3.9 menu select “menu” on the initial screen to display the control panel window. 3.9.1 chart configure the axis of the chart and range setting. For x axis select either “10”, “20”, “50”, “100”, “150” or “300”. For y axis in particle tab select eithe...

Page 40

3. Display description and operation procedure 34 3.9.2 option in the option window you can configure “alarm”, “standard”, “password”, “message”, “print” and “start delay” settings. In alarm setting set threshold for particle alarm and option sensor alarm. In the particle tab, configure the unit and...

Page 41

3. Display description and operation procedure 35 in the select standard window, select a measurement standard to be applied in the standard mode. There are 7 types of standard as follows: ・ iso14644-1 ・ iso14644-1 sequential sampling ・ federal standard (m) ・ federal standard (ft) ・ british standard...

Page 42

3. Display description and operation procedure 36 in the password lock window, you can select the functions to be restricted by password. The below functions can be restricted by checking the lock items box; * access control panel - the following settings in the control panel will be restricted: - c...

Page 43

3. Display description and operation procedure 37 when the items are unlocked, tap [change password] to change the password. You will be asked to enter the old password and new password and reenter the new password. If the entry is properly done, the password will be changed. In the message setting ...

Page 44

3. Display description and operation procedure 38 in the print setting window set the output items for printing. In raw data tab, configure the following settings: - raw data printing on/off - particle size to be printed - option sensor data printing on/off check “raw data include” to print raw data...

Page 45

3. Display description and operation procedure 39 in start delay window set a measurement delay time. Tap the entry field to display a keyboard. Enter “hour”, “minute” and “second” and tap [ok]. Tap [ok] in order to activate the setting. · start delay www.Actoolsupply.Com www.Actoolsupply.Com.

Page 46

3. Display description and operation procedure 40 3.9.3 hardware in hardware setting, you can configure the following settings; - option sensor - pump - remote mode in the option sensor setting window you can confirm if the option sensor is connected or not, and set to use or not use the sensor. You...

Page 47

3. Display description and operation procedure 41 in the pump setting, set to turn the pump on all the time or not. To turn the pump on all the time, check the check box “pump always on”. If you check this box, you can eliminate the preparation time before sampling. In the remote mode setting, check...

Page 48

3. Display description and operation procedure 42 3.9.4 system in the system setting, configure the following settings: - date/time - lcd - sound - communication - stylus - about date/time setting; to adjust date, tap [ ▼ ] to display a calendar and set the date. To change the time, tap “hour”, “min...

Page 49

3. Display description and operation procedure 43 in sound setting, configure the following settings; - volume - alarm sound on volume tab, adjust the tap volume using sound volume slider or “soft” and “loud” buttons. To mute tap sound, uncheck “operations” and “screen taps”. “operations” indicates ...

Page 50

3. Display description and operation procedure 44 in stylus setting you can correct tap accuracy. Tap [recalibrate] button. After using the instrument for a prolonged time, tap accuracy may degrade. Use this menu to correct the tap location. Tap the center of the cross by stylus. There are 5 setting...

Page 51

3. Display description and operation procedure 45 tap [about]. The firmware version of the instrument and remaining capacity of the memory card will be displayed. 3.9.5 remote change to remote mode. 3.9.6 shutdown tap [shutdown]. A window will be displayed asking “do you want to shut down the power?...

Page 52

4. Connecting optional extras 46 4. Connecting optional extras 4.1 connecting optional extras 3 types of sensors are available as optional extras for this instrument. By connecting sensors to 4 different connectors on the rear of the unit, you can perform 3 kinds of measurement and one contact outpu...

Page 53: 5. Printing Example

5. Printing example 47 5. Printing example 5.1 printing example for each measurement mode 5.1.1 single 5.1.2 sequence sg20080525120000.Csv sample t.=10 cycles=1 time 0.3u 0.5u 1.0u 12:00:00 8000 5000 3000 time 3.0u 5.0u 10.0u 12:00:00 1000 500 100 time t[c] h[%] v[m/s] p[pa] 12:00:00 25.2 68.5 0.1 1...

Page 54

5. Printing example 48 5.1.3 interval in20080525120000.Csv sample t.=5 cycles=5 0.3u ave=162.8 min=137 max=185 0.5u ave=16.8 min=13 max=25 1.0u ave=3.8 min=2 max=6 3.0u ave=0.0 min=0 max=0 5.0u ave=0.0 min=0 max=0 10.0u ave=0.0 min=0 max=0 temperature ave=25.6 min=23.5 max=27.5 humidity ave=63.0 min...

Page 55

5. Printing example 49 5.1.4 repeat rp20080525120000.Csv sample t.=5 cycles=5 0.3u ave=162.8 min=137 max=185 0.5u ave=16.8 min=13 max=25 1.0u ave=3.8 min=2 max=6 3.0u ave=0.0 min=0 max=0 5.0u ave=0.0 min=0 max=0 10.0u ave=0.0 min=0 max=0 temperature ave=25.6 min=23.5 max=27.5 humidity ave=63.0 min=5...

Page 56

5. Printing example 50 5.1.5 stat st20080525120000.Csv sample t.=5 cycles=5 location 1 0.3u ave=162.8 min=137 max=185 0.5u ave=16.8 min=13 max=25 1.0u ave=3.8 min=2 max=6 3.0u ave=0.0 min=0 max=0 5.0u ave=0.0 min=0 max=0 10.0u ave=0.0 min=0 max=0 temperature ave=25.6 min=23.5 max=27.5 humidity ave=6...

Page 57

5. Printing example 51 5.1.6 standard 1 0.3u ave=162.8 min=137 max=185 0.5u ave=16.8 min=13 max=25 1.0u ave=3.8 min=2 max=6 3.0u ave=0.0 min=0 max=0 5.0u ave=0.0 min=0 max=0 10.0u ave=0.0 min=0 max=0 temperature ave=25.6 min=23.5 max=27.5 humidity ave=63.0 min=58.9 max=68.5 velocity ave=0.20 min=0.1...

Page 58: 6. Battery Charge

6. Battery charge 52 6. Battery charge 6.1 charging battery you cannot charge the battery when it is installed in the instrument. Open the battery compartment cover on the rear of the instrument. To open the cover turn the knob around 90 degrees. (use a coin or something similar to turn it easily.) ...

Page 59: 7. Main Specifications

7. Main specifications 53 7. Main specifications product name airborne particle counter model model 3900 optical source laser diode (two-year warranty) particle size distribution 0.3 / 0.5 / 1.0 / 3.0 / 5.0 / 10.0 μ m (6 channels) rated flow 28.3l/min. Counting efficiency 50±20% (compliant with iso ...

Page 60: 8. Troubleshooting

8. Troubleshooting 54 8. Troubleshooting symptom possible cause maintenance 1) inside the optical system may be dirty. Attach the zero filter and perform aging for a prolonged time. After performing a measurement in the highly concentrated environment, attach the zero filter and perform aging. 2) th...

Page 61

8. Troubleshooting 55 symptom possible cause maintenance 【 ld err 】 the laser may be damaged. Return the instrument to your distributor or to your kanomax service center for repair. The flow channel may be interrupted. Make sure that the inlet or outlet is not blocked. 【 flow err 】 the pump may be d...

Page 62: Kanomax Limited Warranty

9. Warranty and after-sales service 56 9. Warranty and after-sales service kanomax limited warranty the limited warranty set below is given by kanomax with respect to the kanomax brand airborne particle counter, its attachment parts including probe and other accessories (hereafter referred to as “pr...

Page 63: After-Sales Service

9. Warranty and after-sales service 57 after-sales service if the product is malfunctioning, please check with “troubleshooting” to find possible cause first. Repair parts are retained for a minimum period of five (5) years after production cessation of the product. This storage period of repair par...