Warning: this product and accessories may contain a chemical known to the state of california to cause cancer and birth defects or other reproductive harm. For more information about this regulation: www.P65warnings.Ca.Gov 9.800-967.0-c 06/21/17 hds cabinet series hot water - electric powered - elec...

2 karcher hds series operator’s manual 9.800-967.0 - c machine data label.

3 table of contents machine data label . . . . . . . . . . . . . . . . . . . . . . . . . . 2 table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 how to use this manual . . . . . . . . . . . . . . . . . . . . . 4 safety introduction & safety information . . . . . . . . . . . . ....

4 how to use this manual this manual contains the following sections: • how to use this manual • safety • operations • maintenance the how to use this manual section will tell you how to find important information for ordering correct repair parts. Parts may be ordered from authorized dealers. When ...

5 safety introduction & safety information thank you for purchasing a kärcher commercial pressure washer. This manual covers the operation and maintenance of the hds 4.0/20 and hds 4.0/30 washers. All informa- tion in this manual is based on the latest product infor- mation available at the time of ...

6 safety warning: risk of fire. Do not install or operate near any flammable liquids. Avertissement: risque d'incendie. Ne pas installer ou utiliser à proximité de liquides inflammables. Warning: before obtaining access to electric terminals, all supply circuits must be disconnected. Avertissement: ...

7 operations 19. Do not overreach or stand on unstable support. Keep good footing and balance at all times. 20. When making repairs disconnect from electrical source. 21. Do not operate this product when fatigued or under the influence of alcohol or drugs. Keep operating area clear of all persons. W...

8 operations time r — 7 d ay con tr olad or de ti em po d e s iete die as minu te rie de 7 j our s po w er co rr ie nte cou rant he at er ca le ntad or ch auff e-e au pu ll ou t pi ns to set desi red “on” time s ex tr aig a las cl av ija s p ar a e sta ble cer el tiem po de se ad o. Tir er le s p oi...

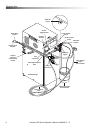

9 operations component identification pump — delivers a specific gpm to the high pressure nozzle which develops pressure. Spray gun — controls the application of water and detergent onto cleaning surface with trigger device. Includes safety latch. Detergent injector — allows you to siphon and mix de...

10 operations assembly instructions step 1: place machine in a conve- nient location providing ample support, drainage and room for maintenance. Remove pallet bolts and remove pallet, then re-install bolts to level machine by adjusting (machine must be level). Step 2: place the pump package on top o...

11 operations step 5: attach variable pressure control wand to spray gun using teflon tape on threads to prevent leakage. Position safety latch to prevent trigger from being pulled. Step 6: pull the spring-loaded collar of the wand coupler collar back to insert your choice of pressure nozzle. Cautio...

12 operations operating instructions step 1: connect the high pressure hose quick coupler to the discharge nipple by sliding the quick coupler collar back and inserting the quick coupler onto the discharge nipple and pushing the quick coupler collar forward to secure it. Secure desired pressure nozz...

13 operations detergents & general cleaning techniques warning: some detergents may be harmful if inhaled or ingested, causing severe nausea, fainting or poisoning. The harmful elements may cause property damage or severe injury. Avertissement: certains détergents peuvent être dangereux s'ils sont i...

14 operations shutdown procedures step 1: rinse all lines (and injector) with clean water, to remove any soap residue then turn toggle switch off. Step 2: turn off water supply. Step 3: open spray gun to relieve remaining pressure and remove water supply hose. In freezing conditions, disconnect wate...

15 maintenance maintenance daily: to ensure a problem free system, simple visual checks can be performed. Check for leaks in inlet supply, pumping system, pump to heater hose, heater, spray gun(s) and high pressure hose. Check for normal operating functions and pump oil level/condition. Check nozzle...

16 maintenance preventative maintenance this pressure washer was produced with the best available materials and quality craftsmanship. However, you as the owner have certain responsibilities for the correct care of the equipment. Attention to regular preventative main- tenance procedures will assist...

17 maintenance troubleshooting problem possible cause solution low operating pressure faulty pressure gauge install new gauge. Insufficient water supply use larger garden hose; clean filter washer at water inlet. Old, worn or incorrect spray nozzle match nozzle number to machine and/or replace with ...

18 maintenance problem possible cause solution oil squirts out of oil cap on pump pump overfilled with oil maintain oil level at red dot on sight glass at rear of pump or at top of notch on dipstick (where applicable). Water dripping from under pump piston packing worn check and replace if necessary...

19 maintenance problem possible cause solution water escaping from fill pipe on heat exchanger cold water added to heat exchanger will stop once at operating temperature. Ruptured coil or leaking check, repair or replace fittings. Unloader does not go into bypass or will cycle itself spray gun or ho...

9.800-967.0 • printed in u.S.A..