- DL manuals

- Karcher

- Pressure Washer

- 1.509-035

- Operating Instructions Manual

Karcher 1.509-035 Operating Instructions Manual

Summary of 1.509-035

Page 1

5.956-648 a 10369 (06/00) hd 4000 c 1.509-035 1.509-515 hd 6000 c 1.967-045 operating instructions.

Page 2

Operating instructions please read before operating the unit, and keep in a safe place for future reference. Proper disposal – for the sake of our environment packaging materials the packaging components used to ship the unit are composed of wood and cardboard, i.E., environment-friendly materials, ...

Page 3

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) 1 table of contents a. For your safety 1. System operating hazards 2. Safety information and instructions 3. Danger sources 4. Hazards posed by accessories 5. Noise protection 6. Workplaces 7. Authorised operators 8. Personal protective equipmen...

Page 4

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) a1 a. For your safety 1. System operating hazards this system is equipped with an overpressure protection feature which was subjected to a safety inspection. Improper operation or abuse of this feature constitutes an hazard to health and life of...

Page 5

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) a. For your safety ! Danger! N injury hazard. Hazard of chemical burns caused by cleaning detergents. Scalding hazard through hot water. Do not aim waterjet at persons or animals. Strictly observe safety instructions on detergent labels. N accid...

Page 6

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) ! Danger! N health hazard posed by toxic substances. Do not spray clean the following materials, because substances known to pose a risk to human health may be swirled up: – materials containing asbestos – materials that could possibly contain t...

Page 7

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) 10. Protective devices system operation is stopped by the emergency-stop master switch located at the instrument panel. N inadvertent contact with all hot system components is prevented by the protective housing. 11. Emergency drill disable the ...

Page 8

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) 1 2 3 4 1. Operating controls b. System operation b1 3 8 6 7 1 4 5 2 9 1 emergency-stop master switch q1 switches the system on and off; also serves as emergency-stop switch. 2 unlock button with operational indicator light starts the availabili...

Page 9

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) 2. Using emergency-stop turn the emergency-stop master switch to the 0 (off) position. N open the handgun until the water pressure has dissipated. N using the locking feature, secure the handgun against being opened inadvertently. 3. Starting th...

Page 10

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) ! Danger! N health hazard through cleaning detergents. Due to the possible adding of detergents to the system water, the water exiting from the system must not be used as drinking water. Switching the system on open the water tap for water suppl...

Page 11

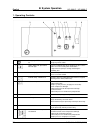

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) 1. Flow diagram c1 c. System function 1 high-pressure pumps 2 float valve 3 dirt trap 4 overflow 5 low-water sensor 6 pressure relief valve 7 filter 8 overflow valve 9 flow monitor 10 safety valve 11 solenoid valve (cooling water) 12 pressure co...

Page 12

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) 2. Description of functions water inlet the water is conveyed from the float reservoir to the intake side of the two pumps. The water level in the float reservoir is maintained by the float valve (2). The incoming water is cleaned in the dirt tr...

Page 13

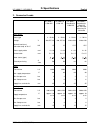

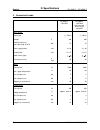

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) 1. Equipment features d. Specifications d1 hd 4000 c 1.509-035 hd 4000 ch 1.509-115 hd 4000 c scandinavia 1.509-515 hd 4000 c scandinavia 1.509-515 with hot-water accessory kit 2.638-689 supply volume l/h 3900 3900 3900 3900 operating pressure* ...

Page 14

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) 1. Equipment features d. Specifications d2 hd 6000 c 1.967-045 hd 6000 c 1.967-045 with hot-water accessory kit 2.638-697 supply volume l/h 5600 5600 operating pressure* bar 60 60 max. Operating pressure (safety valve) bar 90 90 dimensions: leng...

Page 15

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) 2. Connected loads d. Specifications d3 hd 4000 c 1.509-035 hd 4000 ch 1.509-115 hd 4000 c scandinavia 1.509-515 hd 4000 c scandinavia 1.509-515 with hot-water accessory kit 2.638-689 mains power: power type 3 ~ 50 hz 3 ~ 50 hz 3 ~ 50 hz 3 ~ 50 ...

Page 16

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) 2. Connected loads d. Specifications d4 hd 6000 c 1.967-045 hd 6000 c 1.967-045 with hot-water accessory kit 2.638-697 mains power: power type 3 ~ 50 hz 3 ~ 50 hz voltage v 400 400 nominal load (max.) with water temp. Of 20°c kw 15 15 power supp...

Page 17

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) 3. Dimension diagram d. Specifications d5.

Page 18

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) 1. Maintenance contract only a properly maintained system is really safe. It is in your best interest to ensure that regular system maintenance procedures are carried out according to the maintenance schedule outlined below. You may wish to ente...

Page 19

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) e. Maintenance e2 a safety valve b pump side c pressure controller d solenoid valve (cooling water) e drip pan f pressure relief valve g cooling coil h float reservoir with float valve j overflow valve, pressure switch k flow monitor l oil level...

Page 20

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) e. Maintenance e3 interval procedure subject assembly activity by whom daily check handgun all handguns check whether handgun closes properly. Check function of safeguard against inadvertent operation. Replace defective handguns. Operator check ...

Page 21

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) e. Maintenance e4 interval procedure subject assembly activity by whom monthly, or after 200 operating hrs. Check overflow valve overflow valve dependent on the number of high-pressure handguns used, the pressure reading fluctuates between the p...

Page 22

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) e. Maintenance e5 interval procedure subject assembly activity by whom semi- annually, or after 1000 operating hours oil change all high-pressure pumps caution! Hot oil scalding hazard. Prior to oil change, allow pump to cool for 15 minutes. Dra...

Page 23

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) 3. Removing the cover certain repair or service procedures may require the removal of the cover. Proceed as follows: n remove cover, “a”. N remove both cover retaining screws, “b”. N slide off cover horizontally, as indicated by the arrow. 4. De...

Page 24

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) f1 f. Trouble shooting problem possible cause remedy by whom high-pressure pump fails to come up to pressure leaking suction-side tubing system check fastener and hose connections operator water starvation correct the cause operator defective va...

Page 25

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) f. Trouble shooting f2 problem possible cause remedy by whom general fault and “water supply fault” led light up on printed circuit board insufficient water in float tank check site water supply operator temperature of the water inlet too high r...

Page 26

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) f. Trouble shooting f3 motor fault lights up motor protection switch q1 or q2 has triggered owing to overcurrent or drop-out of one phase of power supply system check voltage of the three phases customer service/ electrician motor protection swi...

Page 27

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) f4 system runs for about 15 sec after pressing the unlock button and then switches off. General fault and “admission pressure of hot-water pump too low” led light up admission pressure of hot water too low check pump rotation direction, check wa...

Page 28

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) g. System installation g1 1. Placement the system must be installed in dry indoor surroundings free from explosion hazard. The components shall be placed on firm and level ground, and the system must be easily accessible for the purpose of maint...

Page 29

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) 4. Hard-water treatment excessive water hardness (>15° dh) can lead to deposits and result in malfunctions. Contact the manufacturer in the event of unusually high degrees of water hardness. 5. Preparations for commissioning n thoroughly rinse e...

Page 30

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) g. System installation authorised professional personnel only g3 6. Space assignment plan authorised professional personnel only a : pressure outlet m30x1.5 b : water inlet g 1¼" hd 4000 c g 1 ¾" hd 6000 c c : overflow o.D. 41 d : cooling water ...

Page 31

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) handguns with different spray lances dependent on the cleaning application, different spray lance extensions are required, ranging from 250 mm for one- hand operation to 2040 mm for cleaning high objects. Spray lance with bypass valve featuring ...

Page 32

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) h2 h. Accessories area of application contamination type application method cleaning agent approx. Ph value 1 %-solution automotive, petrol stations, motor carriers, vehicle fleets dust, road grime, mineral oils (on painted surfaces) rm 55/1000-...

Page 33

Hd 4000 c / hd 6000 c english 5.956-648 a10369 (06/98) j. Customer service j1 system type: works no. Commissioned: (date) inspected: (date)...................................................................................................... Results/comments: ...................................... S...