- DL manuals

- Karcher

- Pressure Washer

- 1.575-505.0

- Operator's Manual

Karcher 1.575-505.0 Operator's Manual

WARNING:

This product and accessories may contain a chemical

known

to the

State of California to cause cancer and birth defects or other

reproductive harm.

For more information about this regulation:

www.P65Warnings.ca.gov

9.800-078.0-R 10/10/17

HDS Series

Hot Water - Electric Powered - Diesel Heated

Operator’s Manual

Pressure Washer

MODELS: HDS 3.9/20 Ea Cage

1.575-505.0

HDS 3.5/30 Ea Cage

1.575-508.0

HDS 3.5/30 Eb Cage

1.575-509.0

HDS 3.5/30 Ec Cage

1.575-510.0

To locate your local Kärcher

Commercial Pressure Washer

Dealer nearest you, visit

www.karchercommercial.com

Summary of 1.575-505.0

Page 1

Warning: this product and accessories may contain a chemical known to the state of california to cause cancer and birth defects or other reproductive harm. For more information about this regulation: www.P65warnings.Ca.Gov 9.800-078.0-r 10/10/17 hds series hot water - electric powered - diesel heate...

Page 2

2 karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r machine data label.

Page 3

3 table of contents machine data label . . . . . . . . . . . . . . . . . . . . . . . . . . 2 table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 how to use this manual . . . . . . . . . . . . . . . . . . . . . 4 safety introduction & safety information . . . . . . . . . . . . ....

Page 4

4 how to use this manual this manual contains the following sections: • how to use this manual • safety • operations • maintenance • parts list the how to use this manual section will tell you how to find important information for ordering correct repair parts. Parts may be ordered from authorized d...

Page 5

5 safety introduction & safety information thank you for purchasing this pressure washer. We reserve the right to make changes at any time without incurring any obligation. Owner/user responsibility the owner and/or user must have an understanding of the manufacturer’s operating instructions and war...

Page 6

6 safety important safety information warning: to reduce the risk of injury, read operating instruc- tions carefully before using. Avertissement: pour réduire le risque de blessures, lire attentivement les instructions de fonctionnement avant l'utili- sation. 1.Read the owner's manual thor- oughly. ...

Page 7

7 safety warning: do not use gasoline crankcase draining or oil containing gasoline, solvents or alcohol. Doing so will result in fire and/or explosion. Avertissement : ne pas utiliser d'essence, de drainage du carter de moteur ou d'essence conte- nant de l'huile, de solvants ou de l'alcool. Ne pas ...

Page 8

8 safety 13. Be certain all quick coupler fittings are secured before using pressure washer. Warning: high pressure developed by these machines will cause personal injury or equipment damage. Keep clear of nozzle. Use caution when operating. Do not direct discharge stream at people or animals, or se...

Page 9

9 operations component identification caution hot water: m u s t u s e i n s u l a t e d spray gun and wand. High limit thermostat fuel tank wand holder downstream detergent injector pump fresh water faucet (not included) garden hose (not included) high pressure hose burner motor insulated spray gun...

Page 10

10 operations assembly instructions step 1: connect water supply hose. Step 4: engage the spray gun safety latch. Attach the high pressure hose to the spray gun using teflon tape on hose threads. Step 2: check fuel tank and pump oil levels. Step 5: connect the high pressure nozzle to the wand quick ...

Page 11

11 operations installation place machine in a convenient location providing ample support, draining and room for maintenance. This machine is intended for outdoor use. Machine must be stored indoors when not in use. Location the location should protect the machine from damaging environmental conditi...

Page 12

12 operations operating instructions step 1: turn water on. Step 4: before installing nozzle, turn on water supply and run machine, allowing water to flush through the system until clear. Turn switch to pump position. When a steady stream of water flows from the spray gun and wand the machine is rea...

Page 13

13 operations detergents & general operating techniques warning: some detergents may be harmful if inhaled or ingested, causing severe nausea, fainting or poisoning. The harmful elements may cause property damage or severe injury. Step 1: connect detergent injector to discharge nipple on machine, co...

Page 14

14 operations shutting down and clean-up step 1: remove detergent suction tube from container and insert into 1 gallon of fresh water. Turn variable pressure wand handle for low pressure or connect the black detergent nozzle. Pull trigger on spray gun and siphon water for one minute. Step 4: turn ga...

Page 15

15 operations storage caution: always store your pressure washer in a location where the temperature will not fall below 32°f (0°c). The pump in this machine is susceptible to permanent damage if frozen. Freeze damage is not covered by warranty. Attention : toujours entreposer la laveuse à pression ...

Page 16

16 maintenance preventative maintenance 1. Use clean fuel — kerosene, no. 1 home heating fuel or diesel fuel. Clean or replace fuel filter every 100 hours of operation. Avoid water contaminated fuel as it will seize up the fuel pump. De-soot coils monthly. Use an additive if diesel is being used. 2....

Page 17

17 maintenance cleaning of coils in alkaline water areas, lime deposits can accumulate rapidly inside the coil pipes. This growth is increased by the extreme heat build up in the coil. The best preven- tion for liming conditions is to use high quality cleaning detergents. In areas where alkaline wat...

Page 18

18 maintenance electrode setting sr-series gage kna part number: 8.717-379.0 burner nozzle keep the tip free of surface deposits by wiping it with a clean, solvent-saturated cloth, being careful not to plug or enlarge the nozzle. For maximum efficiency, replace the nozzle each season. Fuel control s...

Page 19

19 maintenance oil burner burner air adjustment : the oil burner on this machine is preset for operation at altitudes below 500 feet. If operated at higher altitudes, it may be necessary to adjust the air band for a #1 or #2 smoke spot on the bacharach scale. To adjust, start machine and turn burner...

Page 20

20 maintenance maintenance charts this pressure washer was produced with the best available materials and quality craftsmanship. However, you as the owner have certain responsibili- ties for the correct care of the equipment. Attention to regular preventative maintenance procedures will assist in pr...

Page 21

21 maintenance troubleshooting problem possible cause solution low operating pressure faulty pressure gauge install new gauge. Insufficient water supply use larger garden hose; clean filter washer at water inlet. Old, worn or incorrect spray nozzle match nozzle number to machine and/or replace with ...

Page 22

22 maintenance troubleshooting problem possible cause solution low water temperature improper fuel or water in fuel drain fuel tank and replace with proper fuel. Low fuel pressure increase fuel pressure. Weak fuel pump check fuel pump temperature. Replace pump if needed. Fuel filter partially clogge...

Page 23

23 maintenance karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r.

Page 24

24 notes karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r.

Page 25: Parts

25 parts parts karcher hds hds 3.9/20 ea cage 1.575-505.0 hds 3.5/30 ea cage 1.575-508.0 hds 3.5/30 eb cage 1.575-509.0 hds 3.5/30 ec cage 1.575-510.0 karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r.

Page 26

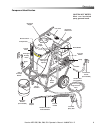

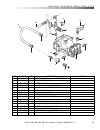

26 karcher hds 1.575-505.0, 508.0, 509.0, 510.0 karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r to fuel filter to ta nk 44 49 78 16 51 30 51 to fuel tank 32 for detail see control panel illus. 16 35 13 36 17 20 34 43 48 52 38 77 76 77 77 48 3 72 33 2 61 1 9 58 55 56 57 54 74 46 59 8...

Page 27

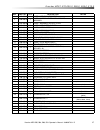

27 karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r karcher hds 1.575-505.0, 508.0, 509.0, 510.0 ref part no. Qty description notes 1 9.800-002.0 1 label, use only kerosene 2 9.800-006.0 1 label, "hot/caliente" with arrows warning 3 8.932-969.0 1 label, warning, service cord 4 9.800-...

Page 28

28 karcher hds 1.575-505.0, 508.0, 509.0, 510.0 ref part no. Qty description notes 35 9.802-171.0 1 nipple, 3/8" x 3/8" npt street male 36 9.149-003.0 1 manifold coil discharge 37 9.802-043.0 1 elbow, 1/2" jic x 1/2" female 38 8.918-423.0 1 hose, 3/8" x 22" 39 8.706-958.0 1 hose barb, 1/4" barb, 1/4...

Page 29

29 karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r karcher hds 1.575-505.0, 508.0, 509.0, 510.0 ref part no. Qty description notes 73 9.802-765.0 2 screw, 1/4-20 x 1/2" bh, soc 74 8.706-941.0 1 hose barb, 1/4" 75 9.802-779.0 11 nut, 3/8" esna 76 9.802-254.0 28" fuel line, 1/4" 77 8....

Page 30

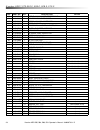

30 control panel - 1.575-505.0, 508.0, 509.0, 510.0 ref part no. Qty description notes 1 9.802-451.0 2 switch, rocker, carling w/green lens - - 1 - (time delay option) - 9.802-452.0 1 rocker switch, red lens (time delay option) 2 9.802-447.0 48" conduit, 1/4" split not shown 3 - - fuse see specifica...

Page 31

31 karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r control panel - 1.575-505.0, 508.0, 509.0, 510.0 ref part no. Qty description notes 10 8.712-357.0 1 nozzle, saqcmeg 0055, red (505.0) - 8.712-358.0 1 nozzle, saqcmeg 1505.5, yellow (505.0) - 8.712-359.0 1 nozzle, saqcmeg 2505.5, gr...

Page 32

32 float tank - 505.0, 508.0, 509.0, 510.0 karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r to float tank 18 19 6 3 5 2 1, 8 7 26 24 23 22 21 20 27 10 4 9 7 34 21 42 31 21 30 33 17 32 28 29 16 15 14 13 12 11 39 36 39 18 41 40 38 steam option auto start/stop option auto start/stop ste...

Page 33

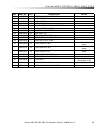

33 karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r float tank - 505.0, 508.0, 509.0, 510.0 ref part no. Qty description notes 1 8.706-645.0 1 tank, float 2 9.803-269.0 1 shelf, float tank, black 3 9.802-767.0 4 screw, 3/8" x 3/4" hh nc, whiz loc 4 9.802-039.0 1 elbow, 1/2" jic x 3/8...

Page 34

34 float tank - 505.0, 508.0, 509.0, 510.0 ref part no. Qty description notes 41 9.802-695.0 1 nut, 10/32" keps 42 8.706-858.0 1 tee, 1/4" street 43 8.706-797.0 1 nipple, 1/2" hex 44 9.802-119.0 1 cross, 1/2" female 45 8.706-915.0 1 bushing, 1/2" x 1/4" 46 9.802-128.0 1 nipple, 1/2" jic x 1/2" pipe ...

Page 35

35 karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r auto start / stop 505.0, 508.0, 509.0, 510.0 ref part no. Qty description notes 1 9.802-146.0 1 swivel, 1/2" mp x 3/4" ghf w/strainer 2 8.706-844.0 1 tee, 1/2" female pipe 3 8.706-797.0 1 nipple, 1/2" hex 4 9.802-127.0 1 nipple, 1/2...

Page 36

36 auto start / stop - steam options 505.0, 508.0, 509.0, 510.0 karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r o pen fo r st ea m 10-99011 5 8 9 10 11 12 1 13 2 4 7 6 15 14 16 17 18 19 20 21 22 23 3 6 22.

Page 37

37 karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r auto start / stop - steam options 505.0, 508.0, 509.0, 510.0 ref part no. Qty description notes 1 8.918-423.0 1 hose, 3/8" x 22" pressure loop 2 9.802-146.0 1 swivel, 1/2 x 3/4 ghf w/strainer 3 9.802-123.0 1 tee, 1/2" w/1/8" hole st...

Page 38

38 pump - 1.575-505.0, 508.0, 509.0, 510.0 ref part no. Qty description notes 1 8.707-256.0 1 pump protector, 1/2" 2 9.802-458.0 1 pressure switch, 1/4" 3 9.802-039.0 1 elbow, 1/2" jic x 3/8", 90° 4 9.802-146.0 1 swivel, 1/2" ghf 5 - - unloader see specifications pages 6 - - pump see specifications ...

Page 39

39 karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r steam options - 1.575-505.0, 508.0, 509.0, 510.0 ref part no. Qty description notes 1 8.706-958.0 2 hose barb, 1/4" barb x 1/4" npt, 90° 2 6.390-126.0 2 clamp, hose, .46-, .54 st 3 9.802-187.0 1 valve, flow control w/metering 4 8.70...

Page 40

40 hose & spray gun karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r 7 2 1 4 3 8 6 9 10 5 pressure nozzle.

Page 41

41 karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r hose & spray gun ref part no. Qty description notes 1 9.802-165.0 1 coupler, 1/4" male - 9.802-096.0 1 quick coupler o-ring, small not shown 2 9.802-286.0 1 nozzle only, 1/8" soap not shown 3 9.802-222.0 1 wand, zinc, vp, w/coupler ...

Page 42

42 uu1 unloader valve karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r 9.175-018.0, 3500 psi universal unloader 21 2 3 20 16 18 5 15 19 6 7 25 4 8 9 15 12 17 11 27 28 23 26 13 24 25 27 1 14 10 26 22 27.

Page 43

43 karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r uu1 unloader valve ref part no. Qty description notes 1 - 1 piston housing kit a 2 - 1 piston kit c 3 8.749-795.0 1 piston o-ring back up 4 8.749-796.0 1 main block 5 9.152-372.0 1 piston ring 6 - 1 ball seat kit c 7 - 1 o-ring, 10....

Page 44

44 km.3 series pump ref part no. Qty description notes 1 8.751-216.0 1 crankcase 2 - 3 plunger oil seal see kits table 3 - 3 o-ring Ø1.78 x 31.47 see kits table 4 - 3 pressure ring see kits table 5 - 3 u-seal see kits table 6 - 3 intermediate ring see kits table 7 - 3 u-seal see kits table 8 9.803-1...

Page 45

45 karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r km.3 series pump ref part no. Qty description notes 24 8.717-210.0 1 closed bearing housing 25 9.803-192.0 2 o-ring Ø1.78 x 60.05 26 8.933-011.0 2 tapered roller bearing 27 8.751-222.0 1 crankshaft (5030,3540) - 8.751-223.0 1 cranks...

Page 46

46 wayne burner karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r.

Page 47

47 wayne burner ref part no. Qty description notes 1 8.756-293.0 1 motor, burner, 1/5 120v 50-60hz 120v - 8.756-294.0 1 motor, burner, 1/5 230v 50-60hz 230v 2 13121 1 motor cord cover 3 8.700-730.0 1 blower wheel, 5-.25' x 3-7/16(307000) 4 8.700-735.0 1 burner housing ehasr 5 8.700-802.0 1 ignitor, ...

Page 48

48 specifications pump motor model pump model # pump parts unloader replacement unloader production pully pully part # 1.575-505.0 km-4035 9.175-189.0 9.175-018.0 9.175-016.0 2ak74h 9.802-374.0 1.575-508.0 km-4035 9.175-189.0 9.175-018.0 9.175-016.0 2bk80h 9.802-389.0 1.575-509.0 km-4035 9.175-189.0...

Page 49

49 karcher hds 505, 508, 509, 510 operator’s manual 9.800-078.0 - r specifications controls wayne ehasr burner burner replacement parts model overload stepdown transformer primary fuse part # second fuse part # 1.575-505.0 n/a 9.802-551.0 9.802-460.0 9.802-463.0 1.575-508.0 8.724-306.0 9.802-551.0 8...

Page 50

9 . 8 00-07 8 .0 • printed in u.S.A..