- DL manuals

- Karcher

- Floor Machine

- BD 120 RI

- Service Manual

Karcher BD 120 RI Service Manual

Summary of BD 120 RI

Page 1

Service manual 08.2007 5.906-252.0 br/bd 100/250 r / ri br/bd 120/250 r / ri 1.480- . . . Service manual.

Page 2

Br/bd 100/250 r bp / ri page 2 / 171 service manual 08.2007.

Page 3

Br/bd 100/250 r bp / ri foreword page 3 / 171 service manual 08.2007 foreword good servicing and maintenance requires comprehensive, practical training and clearly organised documents. This is why we offer all servicing engineers regular basic training and further qualification courses for the whole...

Page 4

Contents br/bd 100/250 r bp / ri page 4 / 171 service manual 08.2007 contents 1 equipment features ........................................................................................... 7-11 1.1 technical features (br/bd 100/250 r) ..................................................................

Page 5

Br/bd 100/250 r bp / ri contents page 5 / 171 service manual 08.2007 contents 5 basic settings and service procedures ....................................................... 78-116 5.1 test mode (head cpu from version 1.2) 5.1.1 access to the test mode (with program switch s9, position 1) .............

Page 6

Contents br/bd 100/250 r bp / ri page 6 / 171 service manual 08.2007 6 troubleshooting .......................................................................................... 117-146 6.1 troubleshooting without displays ........................................................... 117-120 6.1.1 uni...

Page 7

Br/bd 100/250 r bp / ri equipment features page 7 / 171 service manual 08.2007 battery – 36 volt block battery, 630 ah, low maintenance with filling system. – battery monitoring with deep-discharge pro- tection. Drive system – 3-wheel running gear with front wheel steering and front wheel hub motor ...

Page 8

Equipment features br/bd 100/250 r bp / ri page 8 / 171 service manual 08.2007 1.2 technical features (br/bd 100/250 ri) general information – the br/bd 100/250 ri has an additional pre- sweeping unit with suction function. – time savings through simultaneous sweeping and scrubbing. – side brushes, ...

Page 9

Br/bd 100/250 r bp / ri equipment features page 9 / 171 service manual 08.2007 1 fresh water filler opening 2 cover, dirty water tank 3 dirty water tank 4 fresh water tank, left 5 brush head, br version 6 suction beam, straight design 7 side sealing strip, with spring pressure 8 water filter 9 elect...

Page 10

Equipment features br/bd 100/250 r bp / ri page 10 / 171 service manual 08.2007 1 wing screw, steering column adjustment (max 2 cm) 2 steering column 3 deflection roller, both sides 4 brake pedal 5 drive pedal 6 side sealing strip, with spring pressure 7 brush head, bd version 8 fresh water tank, ri...

Page 11

Br/bd 100/250 r bp / ri equipment features page 11 / 171 service manual 08.2007 1 cover, dirty water tank 2 drain hose, dirty water tank 3 connection suction hose, suction beam 4 cleaning opening, dirty water tank 1.6 rear view 1 4 5 8 2 6 7 5 3 5 deflection roller, suction beam 6 support roller for...

Page 12

Technical features br/bd 100/250 r bp / ri page 12 / 171 service manual 08.2007 2.1 wheel hub motor (m1) 1 ram protector 2 front wheel, wheel hub motor (m1) 3 carbon brush cover 4 freewheeling lever, wheel hub motor (m1) 5 electromagnetic brake (y1) 1 3 4 5 note: the freewheeling lever (4) must be p...

Page 13

Br/bd 100/250 r bp / ri technical features page 13 / 171 service manual 08.2007 2.2 brush head 1 brush drive assembly cover plate 2 brush head support bracket (br version) 3 deflection roller 4 spring for mounting plate with sealing strip 5 mounting plate for sealing strip, with spring pressure 6 ad...

Page 14

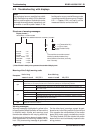

Technical features br/bd 100/250 r bp / ri page 14 / 171 service manual 08.2007 2.3 suction beam note: the front rubber strip is grooved as a standard and the rear is smooth. Both rubber strips can be turned in case of wear to increase the endurance. The springs (8, 9) protect and relieve the suspen...

Page 15

Br/bd 100/250 r bp / ri technical features page 15 / 171 service manual 08.2007 2.4 suction motor (m4) 1 mounting plate, right-hand fresh water tank 2 seat 3 suction motor (m4, ec longlife) 4 dirty water tank suction motor (m4) the suction motor (3) (ec = electronically con- trolled) generates a vac...

Page 16

Technical features br/bd 100/250 r bp / ri page 16 / 171 service manual 08.2007 water filter the water filter (2) is located on the front left- hand side under the fresh water tank. It filters the fresh water to protect the water pump. Water filter water pump (m5) and cleaning agent mete- ring pump ...

Page 17

Br/bd 100/250 r bp / ri technical features page 17 / 171 service manual 08.2007 1 connecting plug (x7) 2 level meter (b2) 3 probe, level meter (b2) 4 potentiometer, level meter (b2), not adjustable 5 servo motor 6 potentiometer 7 metering valve (y2) filling-level meter (b2) with probe filling-level ...

Page 18

Technical features br/bd 100/250 r bp / ri page 18 / 171 service manual 08.2007 2.5 water system 1 metering valve (y2) 2 connecting plug (x99) square, metering valve (y2) connecting plug (x99) square, metering valve (y2) connecting plug (x99) of the metering valve (y2) 1 2 pin 1 battery voltage 24 v...

Page 19

Br/bd 100/250 r bp / ri technical features page 19 / 171 service manual 08.2007 1 tank lid 2 seal, suction motor air intake 3 suction hose from suction beam 4 drain hose, dirty water tank 5 drain hose, fresh water tank 6 float switch (s11) 7 air intake, suction motor 8 flat pleated filter 9 seal, ta...

Page 20

Technical features br/bd 100/250 r bp / ri page 20 / 171 service manual 08.2007 2.7 control panel 1 wbd spray suction tool (optional) on/off 2 pre-sweeper (optional) on/off 3 service mode indicator light 4 chemical container empty indicator light 5 filter shaker control light (only ri version) on/of...

Page 21

Br/bd 100/250 r bp / ri technical features page 21 / 171 service manual 08.2007 2.8 program switch (s9) 1 driving (without cleaning functions) 2 wet scrubbing (with suction) 3 wet scrubbing (without suction) 4 suction (without scrubbing mode) 5 polishing (without suction) 6 polishing (with suction) ...

Page 22

Technical features br/bd 100/250 r bp / ri page 22 / 171 service manual 08.2007 2.9 seat sensor (s10) and distribution box (ext.X1) distribution box (ext. X1) the distribution box (3) is located on the rear left- hand side under the dirty water tank. The cables from the brush head lifting motor (m30...

Page 23: –

Br/bd 100/250 r bp / ri technical features page 23 / 171 service manual 08.2007 1 connection cable, seat sensor (s10) 2 connection cable with battery (–) 3 connector, filling hose 4 filling hose 5 level indicator, filling valve 6 filling valve (18x) 7 battery (g1) (6.654-136), low maintenance 8 conn...

Page 24

Technical features br/bd 100/250 r bp / ri page 24 / 171 service manual 08.2007 2.11 battery charger 1 connecting plug (x1) with the battery charger 2 battery charger mains cable 3 battery charger (6.654-155) 1 3 2 operating instructions: 1. Connect charging cable with the battery. Note battery pola...

Page 25

Br/bd 100/250 r bp / ri technical features page 25 / 171 service manual 08.2007 2.12 side brush (optional) 1 headlight (optional) 2 side brush (optional) 3 side brush suspension (optional) 4 bowden cable deflection pully (optional) 5 bowden cable side brush suspension (optional) side brush suspensio...

Page 26

Technical features br/bd 100/250 r bp / ri page 26 / 171 service manual 08.2007 2.13 pre-sweeper unit (br/bd 100/250 ri only) 1 pre-sweeper unit 2 side brush, lh 3 side brush motor, rh 4 side brush, rh 5 transport roller (2x) 6 debris container (lh/rh) 1 2 3 5 6 4.

Page 27

Br/bd 100/250 r bp / ri technical features page 27 / 171 service manual 08.2007 2.13 pre-sweeper unit, view from the front / side brush 1 6 5 2 3 5 6 4 4 1 pre-sweeper unit 2 side brush, lh 3 side brush motor (m41), lh 4 bracket, side brush motor suspension 5 side brush motor (m42), rh 6 side brush,...

Page 28

Technical features br/bd 100/250 r bp / ri page 28 / 171 service manual 08.2007 2.13 pre-sweeper unit, side view 1 front wheel, wheel hub motor (m1) 2 cover, main brush 3 sealing lip, side 4 transport roller 5 side brush, rh 6 bracket, side brush motor suspension 7 side brush, lh 1 3 4 7 6 5 2.

Page 29

Br/bd 100/250 r bp / ri technical features page 29 / 171 service manual 08.2007 2.13 pre-sweeper unit, side view 1 filter case cover 2 handwheel, filter locking system 3 filter case housing 1 3 2.

Page 30

Technical features br/bd 100/250 r bp / ri page 30 / 171 service manual 08.2007 2 3 2.13 pre-sweeper unit, parallelogram (adjustment) 1 locking nut (above) 2 adjusting rod (above) 3 adjusting rod (below) 4 locking nut (below) adjust parallelism the hexagonal rods (2, 3) are used to align and adjust ...

Page 31

Br/bd 100/250 r bp / ri technical features page 31 / 171 service manual 08.2007 2.13 pre-sweeper unit, parallelogram (adjustment) 1 br 100/250 basic unit 2 br 100/250 pre-sweeping unit adjust parallelism if the adjusting rods of the parallelogram have been adjusted to a length of 200 mm (7.88 in), t...

Page 32

Technical features br/bd 100/250 r bp / ri page 32 / 171 service manual 08.2007 2.13 pre-sweeper unit, control panel 1 key switch (s0) 2 filter shaker indicator lamp on/off 3 display, warning- and information module (a0) 4 indicator lamp, pre-sweeper on/off 5 information button, rotary and keying fu...

Page 33

Br/bd 100/250 r bp / ri technical features page 33 / 171 service manual 08.2007 2.13 pre-sweeper unit, housing cover open 1 impeller fan housing 2 drive belt, fan 3 fan motor (m13) 4 bowden cables raise/lower main brush 5 bowden cables raise/lower side brush 6 lifting motor, main brush and side brus...

Page 34

Technical features br/bd 100/250 r bp / ri page 34 / 171 service manual 08.2007 2.13 pre-sweeper unit, debris container 1 debris container, rh 1 the pre-sweeper unit is equipped with two de- bris containers. The debris containers are atta- ched on the lh and rh side of the pre-sweeper unit..

Page 35

Br/bd 100/250 r bp / ri technical features page 35 / 171 service manual 08.2007 2.13 pre-sweeper unit, housing cover open 1 housing cover, pre-sweeper unit 2 electrical box 3 filter case 4 round filter 5 handwheel, filter locking system 6 impeller fan housing 7 fan motor 2 7 1 3 4 5 6.

Page 36

Technical features br/bd 100/250 r bp / ri page 36 / 171 service manual 08.2007 2.13 pre-sweeper unit, round filter with retainer 1 filter case 2 round filter 3 retaining screws (2x), retainer plate 4 ball bearing 5 rubber grommet, dust guard 6 retainer plate 7 handwheel, filter locking system 8 rub...

Page 37

Br/bd 100/250 r bp / ri technical features page 37 / 171 service manual 08.2007 2.13 pre-sweeper unit, motor, filter shaker 1 filter case 2 filter shaker motor (m14) 2 1.

Page 38

Technical features br/bd 100/250 r bp / ri page 38 / 171 service manual 08.2007 2.13 pre-sweeper unit, impeller fan system 1 impeller fan housing 2 drive belt, fan 3 fan motor (m13) 1 3 2 1 2 3.

Page 39

Br/bd 100/250 r bp / ri technical features page 39 / 171 service manual 08.2007 2.13 pre-sweeper unit, lifting motor/ main brush / side brush 1 lifting motor (m40), main brush and side brush 2 bowden cables raise/lower side brush 3 bowden cables raise/lower main brush 1 3 2 3.

Page 40

Technical features br/bd 100/250 r bp / ri page 40 / 171 service manual 08.2007 2.13 pre-sweeper unit, motor main brush 1 motor (m12), main brush 2 drive shaft, motor 3 tension roller 4 drive belt 5 pulley 6 tension spring, tension roller 2 3 5 1 4 6.

Page 41

Br/bd 100/250 r bp / ri technical features page 41 / 171 service manual 08.2007 2.13 pre-sweeper unit, retainer lh / main brush 1 adjust-/locknut, bowden cabel 2 adjust-/locknut, bowden cabel 3 bowden cables, raise/lower main brush 4 drive belt, main brush 5 pulley, main brush 6 rocker arm, main bru...

Page 42

Technical features br/bd 100/250 r bp / ri page 42 / 171 service manual 08.2007 2.13 pre-sweeper unit, retainer lh / main brush 1 rocker arm, main brush retainer 2 tension spring 3 tension roller 4 hollow screw with internal spring 5 main brush rocker arm vibration damper 6 pulley, main brush 6 1 2 ...

Page 43

Br/bd 100/250 r bp / ri technical features page 43 / 171 service manual 08.2007 2.13 pre-sweeper unit, retainer rh / main brush 1 rocker arm, main brush retainer 2 retainer centering arbor 3 centering arbor 4 main brush 5 bowden cable raise/lower main brush 1 5 4 3 2.

Page 44

Technical features br/bd 100/250 r bp / ri page 44 / 171 service manual 08.2007 2.13 pre-sweeper unit, sealing strip 1 mounting plate, small, sealing strip 2 sealing strip, side 3 mounting plate, large, sealing strip 1-3 mm (0.039 in - 0.118 in) 2 3 1 the sealing strip (2) is mounted and its height ...

Page 45

Br/bd 100/250 r bp / ri technical features page 45 / 171 service manual 08.2007 2.13 pre-sweeper unit, coarse dirt flap 1 side brush, lh 2 coarse-dirt flap 3 sealing lip, front 4 side brush, rh 5 return spring, coarse dirt flap 2 3 4 1 3 2 5.

Page 46

Technical features br/bd 100/250 r bp / ri page 46 / 171 service manual 08.2007 2.13 pre-sweeper unit, pedal arrangement 1 drive pedal 2 brake pedal 3 steering column 4 coarse-dirt flap pedal 4 2 1 3.

Page 47

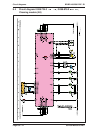

Br/bd 100/250 r bp / ri unit functions page 47 / 171 service manual 08.2007 3.1 functional diagram 1 cover, dirty water tank 2 cleaning agent tank with level switch (full/empty), (optional) 3 fresh water tank 4 water filter, fresh water 5 water pump (m5) 6 cleaning agent metering pump (m6) 7 meterin...

Page 48

Unit functions br/bd 100/250 r bp / ri page 48 / 171 service manual 08.2007 3.1.1 brush head mounting parts 1 rear suspension, brush head 2 lifting motor - brush head (m20) 3 springs (4x), brush head 4 brush head (br version) 5 guide, brush head left 6 adjusting screws 7 brush head retainer 8 guide,...

Page 49

Br/bd 100/250 r bp / ri unit functions page 49 / 171 service manual 08.2007 3.1.2 brush system - contact pressure adjustment contact pressure adjustment the brush contact pressure is adjusted by the lifting motor (m20). If the required contact pres- sure is set at the display (adjustable using the o...

Page 50

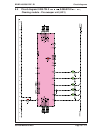

Unit functions br/bd 100/250 r bp / ri page 50 / 171 service manual 08.2007 3.1.3 pre-sweeper unit functional diagram (br/bd 100/250 ri only) 11 1 4 8 7 9 6 5 2 3 10 1 fan motor 2 filter impeller fan and housing 3 main brush (over-throw principle) 4 lifting module (a4/1) 5 side brush motor, lh 6 sid...

Page 51

Br/bd 100/250 r bp / ri unit functions page 51 / 171 service manual 08.2007 1 3 4 5 6 8 10 2 3.1.3 pre-sweeper unit functional diagram (br/bd 100/250 ri only) 1 fan motor 2 filter impeller fan and housing 3 lifting module (a4/1) 4 side brush motor, rh 5 side brush, rh 6 transport roller (1x) 7 main ...

Page 52

Unit functions br/bd 100/250 r bp / ri page 52 / 171 service manual 08.2007 3.2 operator and service program overview operator functions: the overview describes the operator functions with the corresponding processes and access to the information menu. The manufacture set- tings for the operator fun...

Page 53

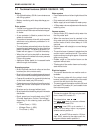

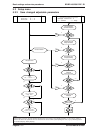

Br/bd 100/250 r bp / ri unit functions page 53 / 171 service manual 08.2007 3.3 operator functions note: apart from the test mode and setup menu, the service diagnosis will be introduced at a later date. For operator for service technician bedienerfunktionen 1. Drive (without cleaning functions) 2. ...

Page 54

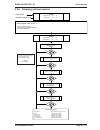

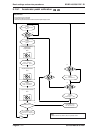

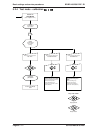

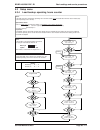

Unit functions br/bd 100/250 r bp / ri page 54 / 171 service manual 08.2007 3.3.1.1 initial operation and information menu switch program switch (s8) to position „1“ main relay (k1) switched off error display? Display shutdown soon display error display switch off key switch (s0) display battery: e....

Page 55

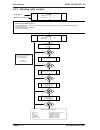

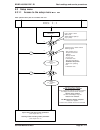

Br/bd 100/250 r bp / ri unit functions page 55 / 171 service manual 08.2007 3.3.1.2 initial operation and information menu display self-diagnosis display exit user menu ? Switch program switch to pos.8 switch on key switch (so) self-test o.K.? Main relay (k1) is switched on switch off key switch (so...

Page 56

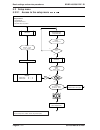

Unit functions br/bd 100/250 r bp / ri page 56 / 171 service manual 08.2007 3.3.2.1 driving (without cleaning functions) display battery: e....F water/c: e....F initial operation shutdown procedure switch program switch to pos 1 (no cleaning components active) drive motor (m1) ready driver`s seat oc...

Page 57

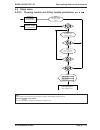

Br/bd 100/250 r bp / ri unit functions page 57 / 171 service manual 08.2007 3.3.2.2 driving (without cleaning functions) display battery: e....F water/c: e....F initial startup shutdown procedure drive motor (m1) ready driver`s seat occupied? (seat sensor s10) drive pedal pressed? (magnetic sensor b...

Page 58

Unit functions br/bd 100/250 r bp / ri page 58 / 171 service manual 08.2007 3.3.3 wet scrubbing (with suction) display battery: e....F water/c: e....F initial startup shutdown procedure switch program switch to pos. 2 - suction motor (m4) „on“, lifting motor suction beam (m30) lowers suction beam if...

Page 59

Br/bd 100/250 r bp / ri unit functions page 59 / 171 service manual 08.2007 3.3.4 wet scrubbing (without suction) display battery: e....F water/c: e....F initial startup shutdown procedure drive motor (m1) active magnetic brake (y1) released display battery: e....F water/c: e....F display (flashing)...

Page 60

Unit functions br/bd 100/250 r bp / ri page 60 / 171 service manual 08.2007 3.3.5 suction (without scrubbing mode) display battery: e....F water/c: e....F initial startup shutdown procedure display battery: e....F water/c: e....F yes no switch program switch to pos. 4 - suction motor (m4) „on“ - lif...

Page 61

Br/bd 100/250 r bp / ri unit functions page 61 / 171 service manual 08.2007 3.3.6 polishing (without suction) display battery: e....F water/c: e....F drive motor (m1) active magnetic brake (y1) released display battery: e....F water/c: e....F display (flashing) brush pressure:iiiiii display (flashin...

Page 62

Unit functions br/bd 100/250 r bp / ri page 62 / 171 service manual 08.2007 3.3.7 polishing (with suction) display battery: e....F water/c: e....F drive motor (m1) active magnetic brake (y1) released display battery: e....F water/c: e....F display (flashing) brush pressure:iiiiii display (flashing) ...

Page 63

Br/bd 100/250 r bp / ri unit functions page 63 / 171 service manual 08.2007 3.3.8 hand cleaning with wall-ceiling-floor tool (optional) display battery: e....F water/c: e....F initial startup shutdown procedure switch program switch to pos. 7 (empty field) - suction motor „on“ - led manual vacuuming...

Page 64

Unit functions br/bd 100/250 r bp / ri page 64 / 171 service manual 08.2007 3.3.9 operator functions - manufacture settings process switch menu, br 100/250 r manufacture settings - dated 12/04 processing / setting program switch (s9) adjustable process parameters bar display, manufacture setting bar...

Page 65

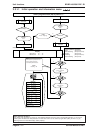

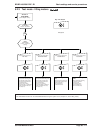

Br/bd 100/250 r bp / ri modular electronic control circuits page 65 / 171 service manual 08.2007 4.0 modular electronic control circuits module networking module cross-linking with all options and service module a3 cleaning- module a2 traction module a4 lift module a7 charging module a5 accessory mo...

Page 66

Modular electronic control circuits br/bd 100/250 r bp / ri page 66 / 171 service manual 08.2007 4.1 modular system br/bd 100/250 r basic unit accessories kärcher bus cable 1:1, (6-pin, with integrated rs 485 bus system) kärcher bus with rs 485 communication core a1 a2 a3 a4 a5 kopf-cpu master-modul...

Page 67

Br/bd 100/250 r bp / ri modular electronic control circuits page 67 / 171 service manual 08.2007 4.2 modular system br/bd 100/250 r with side brush (optional) basic unit accessories kärcher bus cable 1:1, (6-pin, with integrated rs 485 bus system) kärcher bus with rs 485 communication core a1 a2 a3 ...

Page 68

Modular electronic control circuits br/bd 100/250 r bp / ri page 68 / 171 service manual 08.2007 4.3 modular system br/bd 100/250 ri basic unit accessories kärcher bus cable 1:1, (6-pin, with integrated rs 485 bus system) kärcher bus with rs 485 communication core a1 a2 a3 a4 a5 kopf-cpu master-modu...

Page 69

Br/bd 100/250 r bp / ri modular electronic control circuits page 69 / 171 service manual 08.2007 4.4 emergency operation (driving) using the example of the br/bd 100/250 r basic unit accessories kärcher bus cable 1:1, (6-pin, with integrated rs 485 bus system) note: if modules are defective (e.G. A3...

Page 70

Modular electronic control circuits br/bd 100/250 r bp / ri page 70 / 171 service manual 08.2007 4.5 control panel (view from below) with warning and information module (a0) and head cpu module (a1) 1 warning and information module (a0) 2 ribbon cable (w201, 34-pin) 3 emergency-stop push button (s1)...

Page 71

Br/bd 100/250 r bp / ri modular electronic control circuits page 71 / 171 service manual 08.2007 4.6 lifting module (a4) and accessories module (a5) 1 2 6 1 1 8 10 14 1 3 7 12 11 4 5 6 8 15 lifting module (a4) accessories module (a5) (optional) 13 4 3 5 9 11 12 7 1 1 terminal strips (not available /...

Page 72

Modular electronic control circuits br/bd 100/250 r bp / ri page 72 / 171 service manual 08.2007 4.7 driving module (a2) and cleaning module (a3) 30 1 2 3 4 5 6 7 8 9 10 11 25 12 13 14 15 16 17 26 18 20 19 21 22 23 24 31 27 29 28.

Page 73

Br/bd 100/250 r bp / ri modular electronic control circuits page 73 / 171 service manual 08.2007 4.7 driving module (a2) and cleaning module (a3) 1 terminal strip (x5/a2) 2 terminal strip (x4/a2) 3 terminal strip (x3/a2) 4 terminal strip (x7/a3) 5 terminal strip (x2/a3) 6 terminal strip (x1/a3) 7 te...

Page 74

Modular electronic control circuits br/bd 100/250 r bp / ri page 74 / 171 service manual 08.2007 4.8 lifting module (a4/1) (optional) and cleaning module (a3/1) (optional) 1 2 8 9 10 11 12 17 16 15 3 5 18 6 7 14 4 13 19.

Page 75

Br/bd 100/250 r bp / ri modular electronic control circuits page 75 / 171 service manual 08.2007 4.8 lifting module (a4/1) (optional) and cleaning module (a3/1) (optional) 1 terminal strip (x7/a3/1) 2 terminal strip (x2/a3/1) 3 terminal strip (x1/a3/1) 4 programming plug (x3/a3/1) 5 terminal strip (...

Page 76

Modular electronic control circuits br/bd 100/250 r bp / ri page 76 / 171 service manual 08.2007 4.9 service module (a9) service module (a9) service module (a9), view from the left service module (a9), view from the right connection cable 3 4 5 2 6 7 8 1 9 10 11 12 13 1 service module (a9) 2 power o...

Page 77

Br/bd 100/250 r bp / ri modular electronic control circuits page 77 / 171 service manual 08.2007 – the service module (3) can be integrated any- where in the bus using the connection cable (5). – the service module (3) can be used to con- nect a service pc or a laptop (1) for diagnosis purposes and ...

Page 78

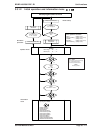

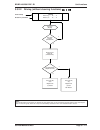

Basic settings and service procedures br/bd 100/250 r bp / ri page 78 / 171 service manual 08.2007 5.1.1 access to the test mode (with program switch s9, position 1) main relay (k1) switches off requirements - unit switched off - program switch (s9) in pos 1 (drive) - key switch (so) in „o“ position...

Page 79

Br/bd 100/250 r bp / ri basic settings and service procedures page 79 / 171 service manual 08.2007 5.1.2 access to the test mode (with program switch s9, position 2) brush/roller on/off main relay (k1) switches off requirements - unit switched off - program switch (s9) in pos 2 (wet scrubbing with v...

Page 80

Basic settings and service procedures br/bd 100/250 r bp / ri page 80 / 171 service manual 08.2007 5.1.2.1 current measurement with switching on/off function requirements - unit is ready for service in test mode - program switch (s9) in pos 2 wet scrub with vacuuming (orpos 1 drive) - above the rota...

Page 81

Br/bd 100/250 r bp / ri basic settings and service procedures page 81 / 171 service manual 08.2007 5.1.3 access to the test mode (with program switch s9, position 3) function notes: the i-button inch function (press continuously) is used to activate the unit; while it is active the led service (yell...

Page 82

Basic settings and service procedures br/bd 100/250 r bp / ri page 82 / 171 service manual 08.2007 5.1.4 access to the test mode (with program switch s9, position 4) this access is only possible in the following unit versions. - br-100/250 r with pre-sweeper and side brush - br-100/250 r with side b...

Page 83

Br/bd 100/250 r bp / ri basic settings and service procedures page 83 / 171 service manual 08.2007 5.1.5 access to the test mode (with program switch s9, position 5) requirements - unit switched off - program switch (s9) in pos 5 (polish) - key switch (so) in „o“ position main relay (k1) switches of...

Page 84

Basic settings and service procedures br/bd 100/250 r bp / ri page 84 / 171 service manual 08.2007 5.1.5.1 accelerator pedal calibration requirements – unit is ready for service in test mode – program switch (s9) in pos 5 polish – above the rotary function i-button the calibrate accelerator pedal? D...

Page 85

Br/bd 100/250 r bp / ri basic settings and service procedures page 85 / 171 service manual 08.2007 5.1.5.2 illuminated symbol test requirements – unit is ready for service in test mode – program switch (s9) in pos 5 polish – above the rotary function i-button, the illuminated symbo l test display is...

Page 86

Basic settings and service procedures br/bd 100/250 r bp / ri page 86 / 171 service manual 08.2007 5.1.5.3 service-operator menu requirements – unit is ready for service in test mode – program switch (s9) in pos 5 polish – above the rotary function i-button the call up service/operator menu? Display...

Page 87

Br/bd 100/250 r bp / ri basic settings and service procedures page 87 / 171 service manual 08.2007 5.2.1 access to the test mode requirements - unit switched off - program switch in pos 1 (drive) - key switch (so) in „o“ position display shutdown takes a few seconds display battery: e....F water/c: ...

Page 88

Basic settings and service procedures br/bd 100/250 r bp / ri page 88 / 171 service manual 08.2007 5.2.2 test mode - drive units >3s display tester-mode drives access to test-mode (see chapter 5.2.1) display tester-mode drives flashing program switch s9 position no. 1 drive 2 scrub - vacuum 3 wet sc...

Page 89

Br/bd 100/250 r bp / ri basic settings and service procedures page 89 / 171 service manual 08.2007 5.2.3 test mode - lifting motors display tester-mode linear actuators switch program switch (s9) to pos 1 drive >3s display tester-mode linear actuators (flashing) key: info button inching mode switch ...

Page 90

Basic settings and service procedures br/bd 100/250 r bp / ri page 90 / 171 service manual 08.2007 5.2.4 test mode - calibration display tester-mode adjustment switch program switch (s9) to pos 1 drive >3sec display tester-mode adjustment (flashing) key: info button keying function switch program sw...

Page 91

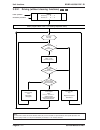

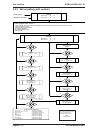

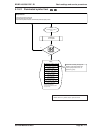

Br/bd 100/250 r bp / ri basic settings and service procedures page 91 / 171 service manual 08.2007 5.3 setup menu 5.3.1.1 access to the setup menu display battery: e....F water/c: e....F display parameter setup menu? Yes no switch program selection switch to pos. 1 yes no yes no 10s 10s display quit...

Page 92

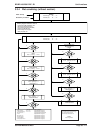

Basic settings and service procedures br/bd 100/250 r bp / ri page 92 / 171 service manual 08.2007 5.3 setup menu 5.3.1.2 system menu and driving module parameters access to the setup menu (see chapter 5.3.1.1) cleaning modul parameters and lifting modul parameters (see chapter 5.3.1.3) yes no displ...

Page 93

Br/bd 100/250 r bp / ri basic settings and service procedures page 93 / 171 service manual 08.2007 5.3 setup menu 5.3.1.3 cleaning module and lifting module parameters note: if the i-button is not pressed within 30 seconds the program automatically switches to battery: e.......F water/c: e.......F t...

Page 94

Basic settings and service procedures br/bd 100/250 r bp / ri page 94 / 171 service manual 08.2007 5.3 setup menu 5.3.2.1 access to the setup menu requirements - unit switched off - program switch in pos. 8 - key switch (so) in „o“ position display battery: e....F water/c: e....F yes no -keep i-butt...

Page 95

Br/bd 100/250 r bp / ri basic settings and service procedures page 95 / 171 service manual 08.2007 5.3 setup menu 5.3.2.1 access to the setup menu setup menu (continuation) >3s display activate module parameter setup? Display activate module parameter setup (flashing) system parameters and driving m...

Page 96

Basic settings and service procedures br/bd 100/250 r bp / ri page 96 / 171 service manual 08.2007 5.3 setup menu 5.3.2.2 system menu and driving module parameters display activate module parameter setup (flashing) lifting module (see chapter 5.3.2.3) display parameter menu traction module? Yes no y...

Page 97

Br/bd 100/250 r bp / ri basic settings and service procedures page 97 / 171 service manual 08.2007 5.3 setup menu 5.3.2.3 cleaning module and lifting module parameters access to setup menu (see chapter 5.2.1) display activate module parameter setup (flashing) system parameters and drive module (see ...

Page 98

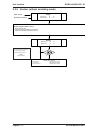

Basic settings and service procedures br/bd 100/250 r bp / ri page 98 / 171 service manual 08.2007 5.3 setup menu 5.3.3 save changed adjustable parameters display battery: e....F water/c: e....F 30s yes no display save yes: ? Display (from chapter 5.2.2/chapter 5.2.3), for example lanuage selection:...

Page 99

Br/bd 100/250 r bp / ri basic settings and service procedures page 99 / 171 service manual 08.2007 5.3 setup menu 5.3.4 load backup operating hours counter note: if the cpu has been changed the operating hours counter reading must be loaded back from the clean module (a3) (saved operating hours coun...

Page 100

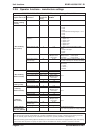

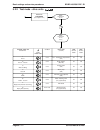

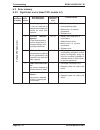

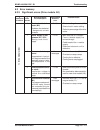

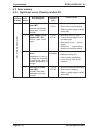

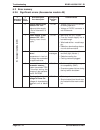

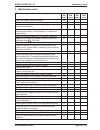

Basic settings and service procedures br/bd 100/250 r bp / ri page 100 / 171 service manual 08.2007 5.3 setup menu 5.3.5 module parameter manufacture settings parameter-setup, sequence and factory settings br 100/250r(i) - state 2005/05/20 module parameter presentation in display factory setting min...

Page 101

Br/bd 100/250 r bp / ri basic settings and service procedures page 101 / 171 service manual 08.2007 5.3 setup menu 5.3.5 module parameter manufacture settings standard parameter setup menu adjustments must be made by service department for accessory kits or upgrades! Available for pre-sweeper option...

Page 102

Basic settings and service procedures br/bd 100/250 r bp / ri page 102 / 171 service manual 08.2007 5.3 setup menu 5.3.5 module parameter - manufacture settings subsequent installation of options - note 1. Chemical metering if the chemical metering is attached the "chemi- cal metering" option must b...

Page 103

Br/bd 100/250 r bp / ri basic settings and service procedures page 103 / 171 service manual 08.2007 5.4.1 steering steering column the steering column pipe (4) with internal stee- ring rod (16) is fixed to the base frame (8) with four retaining screws (9). The steering movement of the steering wheel...

Page 104

Basic settings and service procedures br/bd 100/250 r bp / ri page 104 / 171 service manual 08.2007 5.4.2 lifting motor - suction beam (m30) adjust microswitch (s30, s31) if the suction beam does not reach its upper or lower limit positions or if there is no lifting move- ment, the microswitch (s30,...

Page 105

Br/bd 100/250 r bp / ri basic settings and service procedures page 105 / 171 service manual 08.2007 5.4.3 lifting motor - brush head (m20) microswitches and cams, lifting motor (m20) piston, lifting motor (m20) adjust lifting motor - brush head (m20) 1 microswitch (s20) cam 2 shaft, lifting motor 3 ...

Page 106

Grundeinstellungen und servicearbeiten br/bd 100/250 r bp / ri seite 106 / 170 service-handbuch 08.2007 5.4.3 hubmotor bürstenkopf (m20) a bürstenwalzen oben b umschaltpunkt regelgeschwindigkeit v1>v2 c bürstenwalzen unten bürstenkopfabsenkung - funktionsprinzip obere endstellung (s21 ge- schaltet) ...

Page 107

Br/bd 100/250 r bp / ri basic settings and service procedures page 107 / 171 service manual 08.2007 5.4.4 brush head - maintenance work replace brush roller (br version) – remove the wing nuts (1) and (5) and pull off the mouting plate (4). – pull out the brush (2) and check for wear, re- place if n...

Page 108

Basic settings and service procedures br/bd 100/250 r bp / ri page 108 / 171 service manual 08.2007 5.4.4 brush head - maintenance work check brush rollers for foreign matter and remove if the foreign matter is stick on the brush roller, this can impair the cleaning result. – remove foreign matter f...

Page 109

Br/bd 100/250 r bp / ri basic settings and service procedures page 109 / 171 service manual 08.2007 5.4.4 brush head - maintenance work 5 4 1 2 3 brush head faste- ning with electrical connection brush head fastening (br version) 9 5 4 11 remove brush head – secure the machine against rolling away. ...

Page 110

Basic settings and service procedures br/bd 100/250 r bp / ri page 110 / 171 service manual 08.2007 5.4.5 drive sensor (b1) 1 floor panel 2 retaining screws (2x), drive sensor 3 drive sensor (b1) 4 drive sensor cable adjust drive sensor (b1) – remove the retaining screws of the floor panel (1) and r...

Page 111

Br/bd 100/250 r bp / ri basic settings and service procedures page 111 / 171 service manual 08.2007 5.4.6 wheel hub motor tyres (m1) check/replace carbon brushes – remove carbon brush cover (2). – remove the retaining screw (6) from the carbon brush (5). – pull out the carbon brush (5). – check the ...

Page 112

Basic settings and service procedures br/bd 100/250 r bp / ri page 112 / 171 service manual 08.2007 5.4.6 wheel hub motor tyres (m1) 1 circlip 2 tyres 3 wheel hub motor (m1) replace the tyres – secure the machine against rolling away. – remove ram protector. 4 1 2 circlip pull off the tyre recess on...

Page 113

Br/bd 100/250 r bp / ri basic settings and service procedures page 113 / 171 service manual 08.2007 5.4.7 magnet brake (y1) electromagnetic brake (y1) set freewheeling lever (4) remove and check the electromagnetic brake (y1) the electromagnetic brake (1) is correctly adju- sted in the factory. Depe...

Page 114

Basic settings and service procedures br/bd 100/250 r bp / ri page 114 / 171 service manual 08.2007 5.4.7 magnet brake (y1) 1 mounting plate 2 allen wrench 3 magnet coil, magnet brake (y1) 4 rubber sealing washer 5 feeler gauge 6 wrench 7 brake air gap 8 sleeve screw 9 brake disk, magnet brake (y1) ...

Page 115

Br/bd 100/250 r bp / ri basic settings and service procedures page 115 / 171 service manual 08.2007 5.4.8 rear wheel brake rear wheel brake bowden cable of the left rear wheel brake bowden cable of the rear wheel brake at the brake pedal 1 brake cable 2 brake lever (drum brake) 3 rear wheel brake (d...

Page 116

Basic settings and service procedures br/bd 100/250 r bp / ri page 116 / 171 service manual 08.2007 5.5 replacement intervals component battery with crane or fork lift floor tool brush roller bearing brush rollers brush drive belt brush motor carbon brushes brush motor transmission (brush drive asse...

Page 117

Br/bd 100/250 r bp / ri troubleshooting page 117 / 171 service manual 08.2007 6.1 troubleshooting without displays note: the troubleshooting test mode function is described in chapter 5.1. Faults not shown on the display behebung unit won't start – insert/check/replace central battery plug (x1) (see...

Page 118

Troubleshooting br/bd 100/250 r bp / ri page 118 / 171 service manual 08.2007 6.1 troubleshooting without displays faults not shown on the display solution no or too little cleaning agent supplied – check hose to brush head/remove blockage/kink. – check/replace fuse (f3). – test chemical tank float ...

Page 119

Br/bd 100/250 r bp / ri troubleshooting page 119 / 171 service manual 08.2007 6.1 troubleshooting without displays faults not shown on the display suction beam cannot be raised/lowered – check/replace fuse (f4). – lifting mechanism blocked. – test microswitch (s30, s31) using test mode/replace. – te...

Page 120

Troubleshooting br/bd 100/250 r bp / ri page 120 / 171 service manual 08.2007 6.1 troubleshooting without displays faults not shown on the display solution device raises dust/does not vacuum (only for ri version with pre-sweeping unit) – check/replace side brush and main brush. – check direction of ...

Page 121

Br/bd 100/250 r bp / ri troubleshooting page 121 / 171 service manual 08.2007 6.1.1 unit won’t start insert/check/replace the central plug (x1) check central plug (2), replace defective plug. Check/replace key switch (s0). – pull off top section of the central plug (2). – turn key switch (4) to „0“ ...

Page 122

Troubleshooting br/bd 100/250 r bp / ri page 122 / 171 service manual 08.2007 6.1.2 water volume too low metering valve (y2) fill fresh water tank – open the cover of the fresh water tank and fill with fresh water and cleaning agent. Check/clean/replace water filter – remove the water filter housing...

Page 123

Br/bd 100/250 r bp / ri troubleshooting page 123 / 171 service manual 08.2007 6.1.2 water volume too low fresh water distribution pipe, view from below fresh water distribution pipe check/clean/replace fresh water distributi- on pipe the fresh water distribution pipe (1) is located in front of the f...

Page 124

Troubleshooting br/bd 100/250 r bp / ri page 124 / 171 service manual 08.2007 6.1.3 suction performance too low / dirty water tank overflows clean/replace rubber strips on suction beam clean the rubber strips (10) on the suction beam and check for damage/wear. Turn over/replace if necessary. – remov...

Page 125

Br/bd 100/250 r bp / ri troubleshooting page 125 / 171 service manual 08.2007 suction performance too low check/clean/replace the seal on the cover of the dirty water tank check the seal (1) at the dirty water tank for damage and dirt, clean/replace if necessary. Clean the flat pleated filter in the...

Page 126

Troubleshooting br/bd 100/250 r bp / ri page 126 / 171 service manual 08.2007 6.2 troubleshooting with displays meaning of the 3-digit warning code warning messages: warning messages (highlighted in yellow in the following tables) affect operation of the machine in different ways. Alarms and warning...

Page 127

Br/bd 100/250 r bp / ri troubleshooting page 127 / 171 service manual 08.2007 6.2 troubleshooting with displays structure of error messages meaning of the 3-digit error code group error: a single fault can often cause error messages in several modules (group error). Example: short circuit at main re...

Page 128

Troubleshooting br/bd 100/250 r bp / ri page 128 / 171 service manual 08.2007 6.2 troubleshooting with displays module clones (br/bd 100/250 r/i) – clones and their order are detected during the self-test. – if several clones of a module are available (e.G. A3 and a3/1), the clone order according to...

Page 129

Br/bd 100/250 r bp / ri troubleshooting page 129 / 171 service manual 08.2007 6.2 troubleshooting with displays procedure: – when a fault display appears, a key switch reset should first be performed. Before the key switch is switched on again, wait for a time of approx. 10 seconds to empty the ener...

Page 130

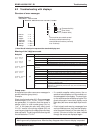

Troubleshooting br/bd 100/250 r bp / ri page 130 / 171 service manual 08.2007 6.2.1 drive module (a2) error messages module involved: a2 module clone: only a drive module is currently generally used display code: f1/xxx for faults/warnings of drive module module fault classification display code act...

Page 131

Br/bd 100/250 r bp / ri troubleshooting page 131 / 171 service manual 08.2007 6.2.1 drive module (a2) error messages module fault classification display code action drive module f error when storing setup parameters in the drive module (a2) f1/101 1. Change menu in parameter setup. 2. Change the set...

Page 132

Troubleshooting br/bd 100/250 r bp / ri page 132 / 171 service manual 08.2007 6.2.1 drive module (a2) error messages module fault classification display code action drive module f motor protection is activated driving motor is hot! Cool off! 1. Switch off key switch (s0). 2. Cool drive motor (m1) fo...

Page 133

Br/bd 100/250 r bp / ri troubleshooting page 133 / 171 service manual 08.2007 6.2.1 drive module (a2) error messages module fault classification display code action drive module f drive module (a2) registers external relay drop (k1) is protection open? Emer- gency shutoff button? 1. Perform key swit...

Page 134

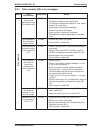

Troubleshooting br/bd 100/250 r bp / ri page 134 / 171 service manual 08.2007 6.2.2 accessories module (a5) error messages module involved: a5 module clone: 1 accessory module is currently generally only used display code: z1/xxx for faults/warnings of accessories module module fault classification ...

Page 135

Br/bd 100/250 r bp / ri troubleshooting page 135 / 171 service manual 08.2007 6.2.2 accessories module (a5) error messages module fault classification display code action accessories module z cable break or short circuit at a5/x6, or x10 z1/511 1. Check supply lines to the connected consumers a5/x6,...

Page 136

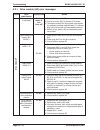

Troubleshooting br/bd 100/250 r bp / ri page 136 / 171 service manual 08.2007 6.2.3 lifting module (a4) and cleaning module (a3) error messages module involved: a3, a4 module clone: currently up to 2 lift modules and up to 2 cleaning modules are optionally possible. Display code: hy/xxx for errors/w...

Page 137

Br/bd 100/250 r bp / ri troubleshooting page 137 / 171 service manual 08.2007 6.2.3 lifting module (a4) and cleaning module (a3) error messages module fault classification display code action h error when storing setup parameters in the lift module hy/101 1. Change menu in parameter setup. 2. Change...

Page 138

Troubleshooting br/bd 100/250 r bp / ri page 138 / 171 service manual 08.2007 6.2.3 lifting module (a4) and cleaning module (a3) error messages module fault classification display code action h short circuit or overload on a4/ x5-2/6 and/ or a4/x4-2/6 hy/131 1. Disconnect lifting motor a4/x5-2,6. 2....

Page 139

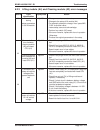

Br/bd 100/250 r bp / ri troubleshooting page 139 / 171 service manual 08.2007 6.2.3 lifting module (a4) and cleaning module (a3) error messages module fault classification display code action h cable break lifting motor - suction beam (m30) h1/142 equipment version: br/bd 100/250 r 1. Disconnect lif...

Page 140

Troubleshooting br/bd 100/250 r bp / ri page 140 / 171 service manual 08.2007 6.2.3 lifting module (a4) and cleaning module (a3) error messages module fault classification display code action c power electronic unit for lifting module (a3) is too hot controls are too hot! Cool off! 1. Switch off key...

Page 141

Br/bd 100/250 r bp / ri troubleshooting page 141 / 171 service manual 08.2007 6.2.4 head cpu (a1) error messages module involved: head cpu (a1) module clone: there is only this bus master display code: f1/xxx for faults/warnings of head cpu module fault classification display code action head cpu ac...

Page 142

Troubleshooting br/bd 100/250 r bp / ri page 142 / 171 service manual 08.2007 6.2.4 head cpu (a1) error messages module fault classification display code action head cpu no drive module (a2) found for emergency operation k1/113 1. Couple drive module (a2) directly with the head cpu (a1). 2. If fault...

Page 143

Br/bd 100/250 r bp / ri troubleshooting page 143 / 171 service manual 08.2007 6.2.4 head cpu (a1) error messages module fault classification display code action head cpu forward and reverse operation are present at the same time k1/163 1. Check function of travel direction switch (s2) (*) and contac...

Page 144

Troubleshooting br/bd 100/250 r bp / ri page 144 / 171 service manual 08.2007 6.3 error memory 6.3.1 module error codes – display pattern sitzschalter unterbrochen! Displays german displays englisch seat switch open! Gaspedal loslassen! Release gaspedal! Batterie leer -> laden! Battery empty -> char...

Page 145

Br/bd 100/250 r bp / ri troubleshooting page 145 / 171 service manual 08.2007 6.3 error memory 6.3.1 module error codes – display pattern display pattern of significant errors module description :*) head cpu module (a1) = 0 drive module (a2) = 1 cleaning module (a3), clone 1 = 2 cleaning module (a3)...

Page 146

Troubleshooting br/bd 100/250 r bp / ri page 146 / 171 service manual 08.2007 6.3 error memory 6.3.2 significant errors (head cpu module a1) x description of module y error number brief description/ error description potential causes 0 = head cpu module (a1) 0 no status query / a1 has not received a...

Page 147

Br/bd 100/250 r bp / ri troubleshooting page 147 / 171 service manual 08.2007 6.3 error memory 6.3.3 significant errors (drive module a2) x description of module y error number brief description/ error description potential causes 1 = drive module (a2) 0 short circuit drive motor (m1) hardware has d...

Page 148

Troubleshooting br/bd 100/250 r bp / ri page 148 / 171 service manual 08.2007 6.3 error memory 6.3.4 significant errors (cleaning module a3) x description of module y error number brief description/ error description potential causes 2,3 = cleaning module (a3) 0 short circuit, brush motor (m2) hardw...

Page 149

Br/bd 100/250 r bp / ri troubleshooting page 149 / 171 service manual 08.2007 6.3 error memory 6.3.5 significant errors (lifting module a4) x description of module y error number brief description/ error description potential causes 4,5 = lifting module (a4) 0 short circuit lifting motor (m20, m30, ...

Page 150

Troubleshooting br/bd 100/250 r bp / ri page 150 / 171 service manual 08.2007 x description of module y error number brief description/ error description potential causes 6 = accessories module (a5) 0 module supply is not between 12v..14v / logic and driver supply is out of tolerance/ is missing. – ...

Page 151

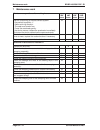

Br/bd 100/250 r bp / ri maintenance work page 151 / 171 service manual 08.2007 7 maintenance work maintenance operations after working hours every 200 hours every 400 hours every 600 hours every 1000 hours check the battery poles for oxidation. O check the secure attachment of the battery connection...

Page 152

Maintenance work br/bd 100/250 r bp / ri page 152 / 171 service manual 08.2007 7 maintenance work maintenance operations after working hours every 200 hours every 400 hours every 600 hours every 1000 hours test the functioning of the seat contact system: – key switch to position „1“ – select a drivi...

Page 153

Br/bd 100/250 r bp / ri circuit diagrams page 153 / 171 service manual 08.2007 8.1 circuit diagram 0.088-734.0 , head cpu (a1).

Page 154

Circuit diagrams br/bd 100/250 r bp / ri page 154 / 171 service manual 08.2007 8.2 circuit diagram 0.088-876.0 , head cpu (a1).

Page 155

Br/bd 100/250 r bp / ri circuit diagrams page 155 / 171 service manual 08.2007 8.3 circuit diagram 0.088-734.0 , 0.088-876.0 , driving module (a2).

Page 156

Circuit diagrams br/bd 100/250 r bp / ri page 156 / 171 service manual 08.2007 8.4 circuit diagram 0.088-734.0 , 0.088-876.0 , cleaning module (a3).

Page 157

Br/bd 100/250 r bp / ri circuit diagrams page 157 / 171 service manual 08.2007 8.5 circuit diagram 0.088-734.0 , 0.088-876.0 , cleaning module - pre-sweeper unit (a3/1).

Page 158

Circuit diagrams br/bd 100/250 r bp / ri page 158 / 171 service manual 08.2007 8.6 circuit diagram 0.088-734.0 , 0.088-876.0 , lifting module (a4).

Page 159

Br/bd 100/250 r bp / ri circuit diagrams page 159 / 171 service manual 08.2007 8.7 circuit diagram 0.088-734.0 , 0.088-876.0 , lifting module - side brush (a4/1).

Page 160

Circuit diagrams br/bd 100/250 r bp / ri page 160 / 171 service manual 08.2007 8.8 circuit diagram 0.088-734.0 , 0.088-876.0 , lifting module - pre-sweeper unit (a4/2).

Page 161

Br/bd 100/250 r bp / ri circuit diagrams page 161 / 171 service manual 08.2007 8.9 circuit diagram 0.088-734.0 , 0.088-876.0 , accessory module (a5).

Page 162

Circuit diagrams br/bd 100/250 r bp / ri page 162 / 171 service manual 08.2007 8.10 circuit diagram 0.088-734.0 , 0.088-876.0 , listing a0 warning-info module (only 0.088-734.0) a1 head cpu a2 driving module a3 cleaning module a3/1cleaning module - pre-sweeper unit (option) a4 lifting module a4/1lif...

Page 163

Br/bd 100/250 r bp / ri technical features page 163 / 171 service manual 08.2007 the technical data sheets and the circuit diagrams will be included in the next issue of the spare parts cd-rom (disis) and are available in kaercher-inside (https://kaercher-inside.Com). If required, the operating inst...

Page 164

Technical features br/bd 100/250 r bp / ri page 164 / 171 service manual 08.2007 10 special tools steering wheel extraction tool 2.860-166.0 cable set for tests on the modular controls 4.822-417.0 mounting plate for brake adjustment 5.116-199.0 multimeter 6.803-022.0 torque wrench 2 - 25 nm 6.815-09...

Page 165

Br/bd 100/250 r bp / ri index page 165 / 171 service manual 08.2007 12 index a access to the setup menu ................... 94, 95 access to the setup menu .......................... 91 access to the test mode ............................ 87 access to the test mode (with program switch s9) ............

Page 166

Index br/bd 100/250 r bp / ri page 166 / 171 service manual 08.2007 12 index check/replace emergency off switch (s1) .............. 121 check/replace float switch (s11) ............. 125 check/replace fuse (f1) .......................... 121 check/replace key switch (s0) ................ 121 check/r...

Page 167

Br/bd 100/250 r bp / ri index page 167 / 171 service manual 08.2007 12 index dirty water tank overflows ....................... 125 dirty water tank with recycling function (optional) ....................... 19 discharge lug ............................................. 22 discharge lug against stat...

Page 168

Index br/bd 100/250 r bp / ri page 168 / 171 service manual 08.2007 12 index info-mode switch, rotary and pusch button function ................................. 20 information button, rotary and keying function ........................................... 32 initial operation and information menu .....

Page 169

Br/bd 100/250 r bp / ri index page 169 / 171 service manual 08.2007 12 index cleaning module ......................................... 33 printed circuit board (a4/1), lifting module .. 33 printed circuit board - cleaning module (a3/1), (optional) .......................................................

Page 170

Index br/bd 100/250 r bp / ri page 170 / 171 service manual 08.2007 12 index spring, brush head ..................................... 13 spring for mounting plate with sealing strip 13 spring, lifting motor (m30) .................. 14, 104 springs, suction beam ................................ 14 sp...

Page 171

Br/bd 100/250 r bp / ri index page 171 / 171 service manual 08.2007 w warning and information module (a0) ........ 70 warning code ........................................... 126 warning messages .................................. 126 water connection ..................................... 109 water ...